Page 3 of 10

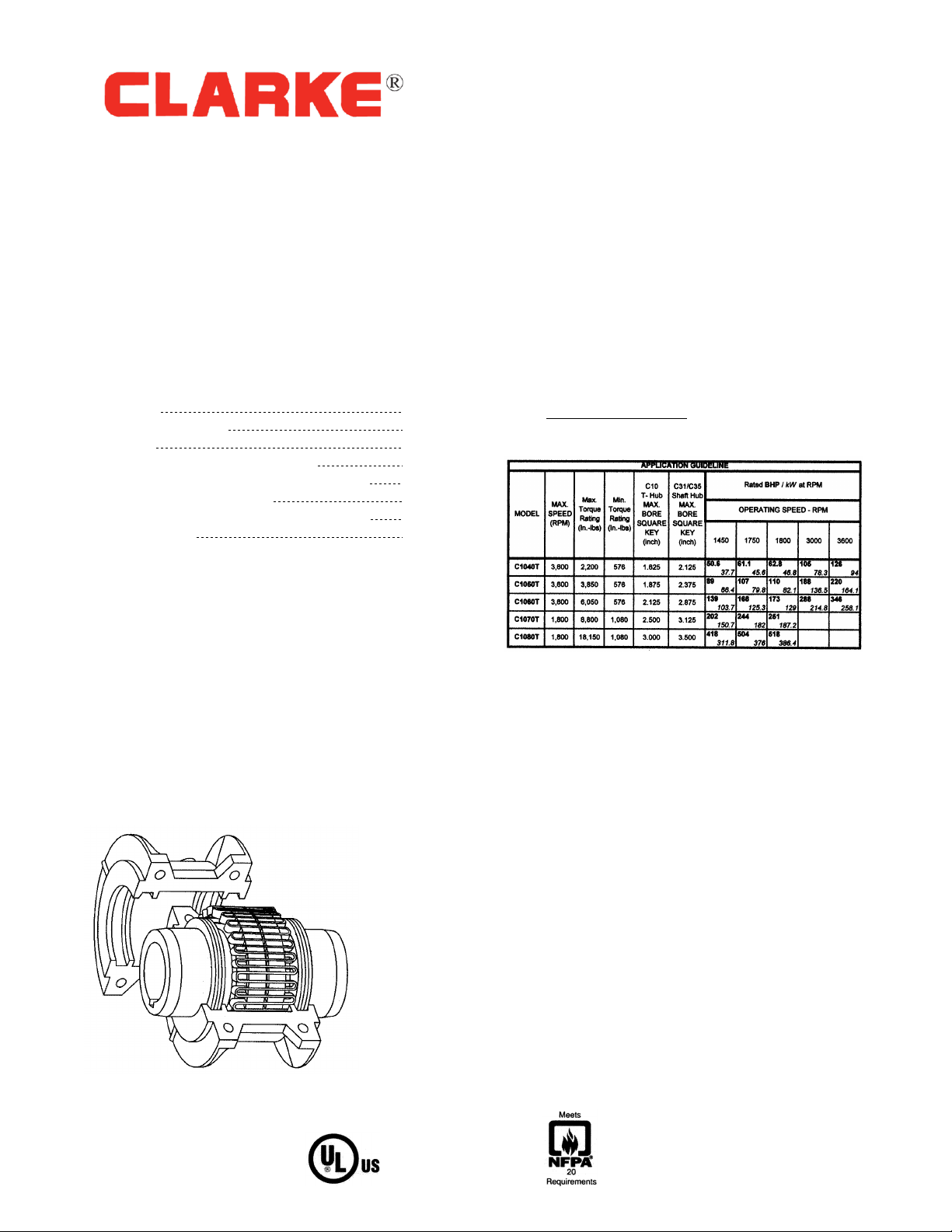

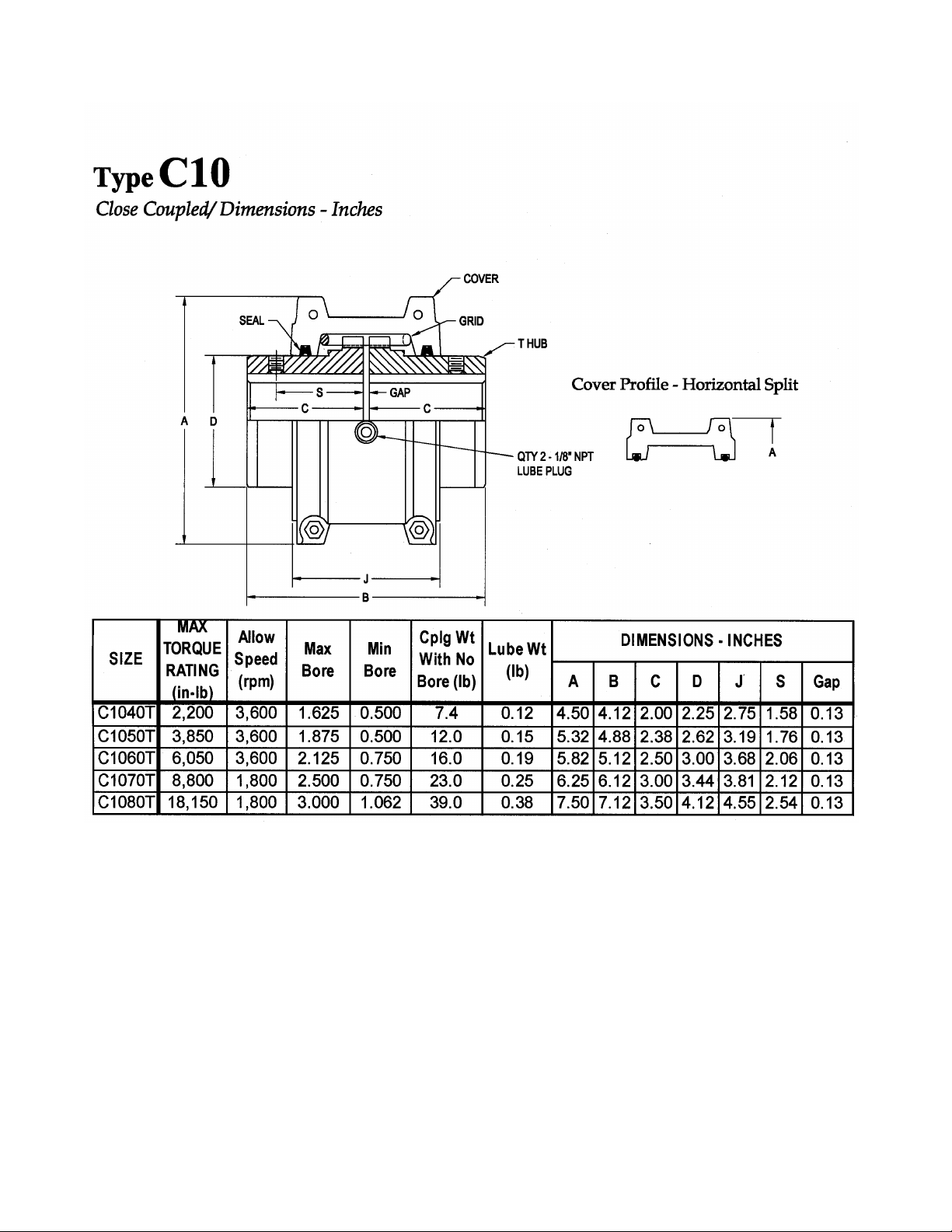

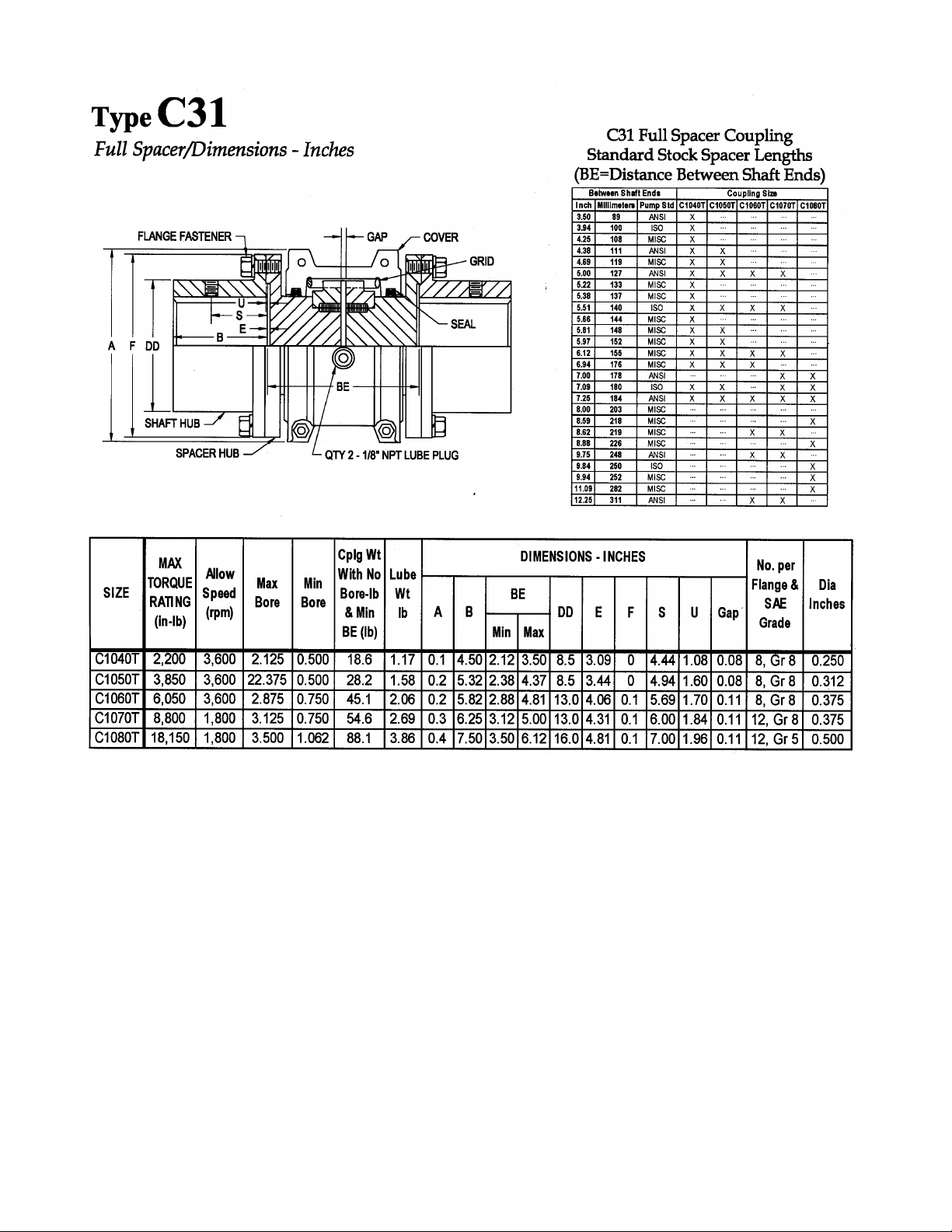

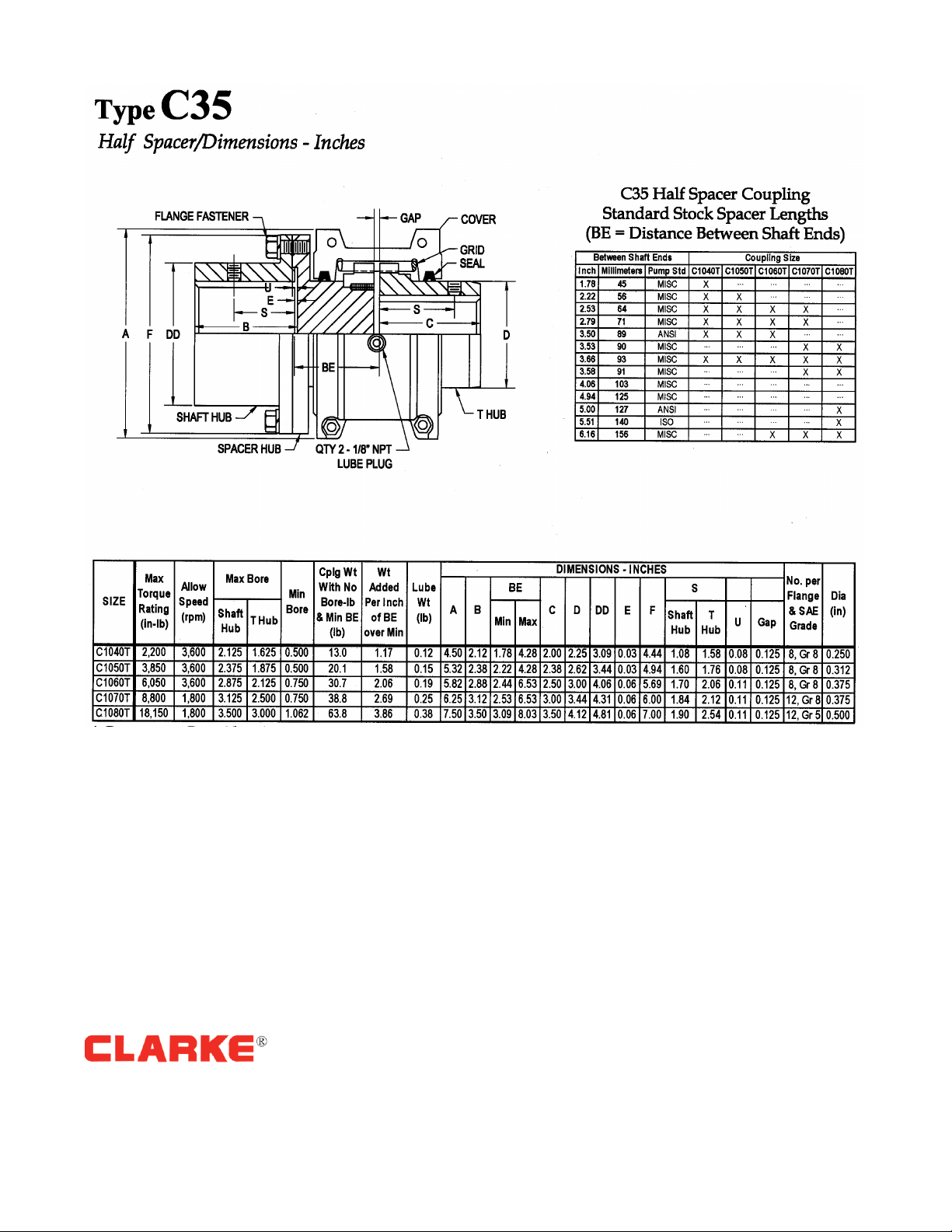

INSTALLATION AND ALIGNMENT OF TYPE C10,

C31 and C35 TAPERED GRID COUPLINGS

Installation

Only standard mechanics tools, wrenches, a straight edge

and feeler gauges are required to install Clarke tapered

grid couplings. Coupling Sizes C1040T thru C1080T are

generally furnished for CLEARANCE FIT with setscrew

over the keyway. Special applications may call for

Interference fit with or without a setscrew over the

keyway.

CLEARANCE FIT HUBS –Clean all parts using a non-

flammable solvent. Check hubs, shafts and keyways for

burrs. Do not heat clearance fit hubs. Install keys, mount

hubs with flange face flush with shaft ends or as

otherwise specified and tighten setscrews.

INTERFERENCE FIT HUBS –Furnished without

setscrews. Heat hubs to a maximum of 275°F (135°C)

using an oven, torch, induction heater or an oil bath. To

prevent seal damage, DO NOT heat hubs beyond a

maximum temperature of 400°F (205°C). When an oxy-

acetylene or blow torch is used, use an excess acetylene

mixture. Mark hubs near the center of their length in

several places on hub body with a temperature sensitive

crayon, 275°F (135°C) melt temperature. Direct flame

towards hub bore using constant motion to avoid

overheating an area.

WARNING: If an oil bath is used, the oil must have a

flash point of 350°F (177°C) or higher. Do not rest hubs

on the bottom of the container. Do not use an open flame

in a combustible atmosphere or near combustible

materials. Heat hubs as instructed above. Mount hubs as

quickly as possible with hub face flush with shaft end.

Allow hubs to cool before proceeding. Insert setscrews

(if required) and tighten.

Maximize Performance and Life

The performance and life of couplings depend largely

upon how you install and maintain them. Before

installing couplings, make certain that foundations of

equipment to be connected meet manufacturers’

requirements. Check for soft foot. The use of stainless

steel shims is recommended. Measuring misalignment

and positioning equipment within alignment tolerances is

simplified with an alignment computer. These

calculations can also be done graphically or

mathematically. Alignment is shown using spacer bar and

straight edge. This practice has proven to be adequate for

many industrial applications. However, for superior final

alignment, the use of dial indicators, lasers, alignment

computers or graphical analysis is recommended.

CAUTION: Consult applicable local and national safety

codes for proper guarding of rotating members. Observe

all safety rules when installing or servicing couplings.

WARNING: Lockout starting switch of prime mover and

remove all external loads from drive before installing or

servicing couplings.

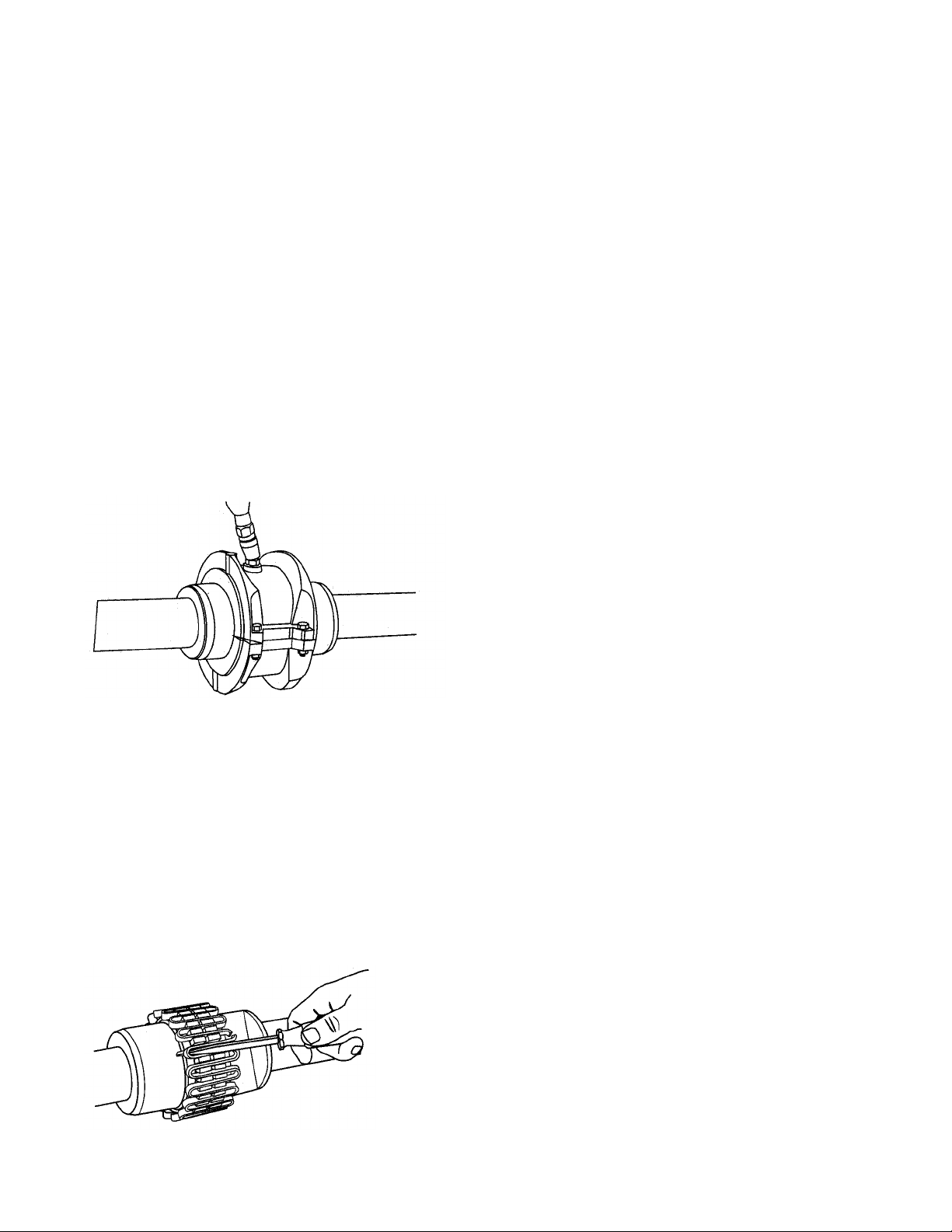

1 –Mount Seals and Hubs

Clean all metal parts using a non-flammable solvent.

Lightly coat seals with grease and place on shafts

BEFORE mounting hubs. If specified, heat interference

fit hubs as previously instructed. Seal keyways to prevent

leakage. Mount hubs on their respective shafts so the hub

face is flush with the end of its shaft unless otherwise

indicated. Tighten setscrews when furnished.

NOTE: Follow the Fire Pump Manufacturer’s

recommendations for baseplate settings, rough alignment

and baseplate grouting prior to performing the following

final alignment steps, 2 and 3.

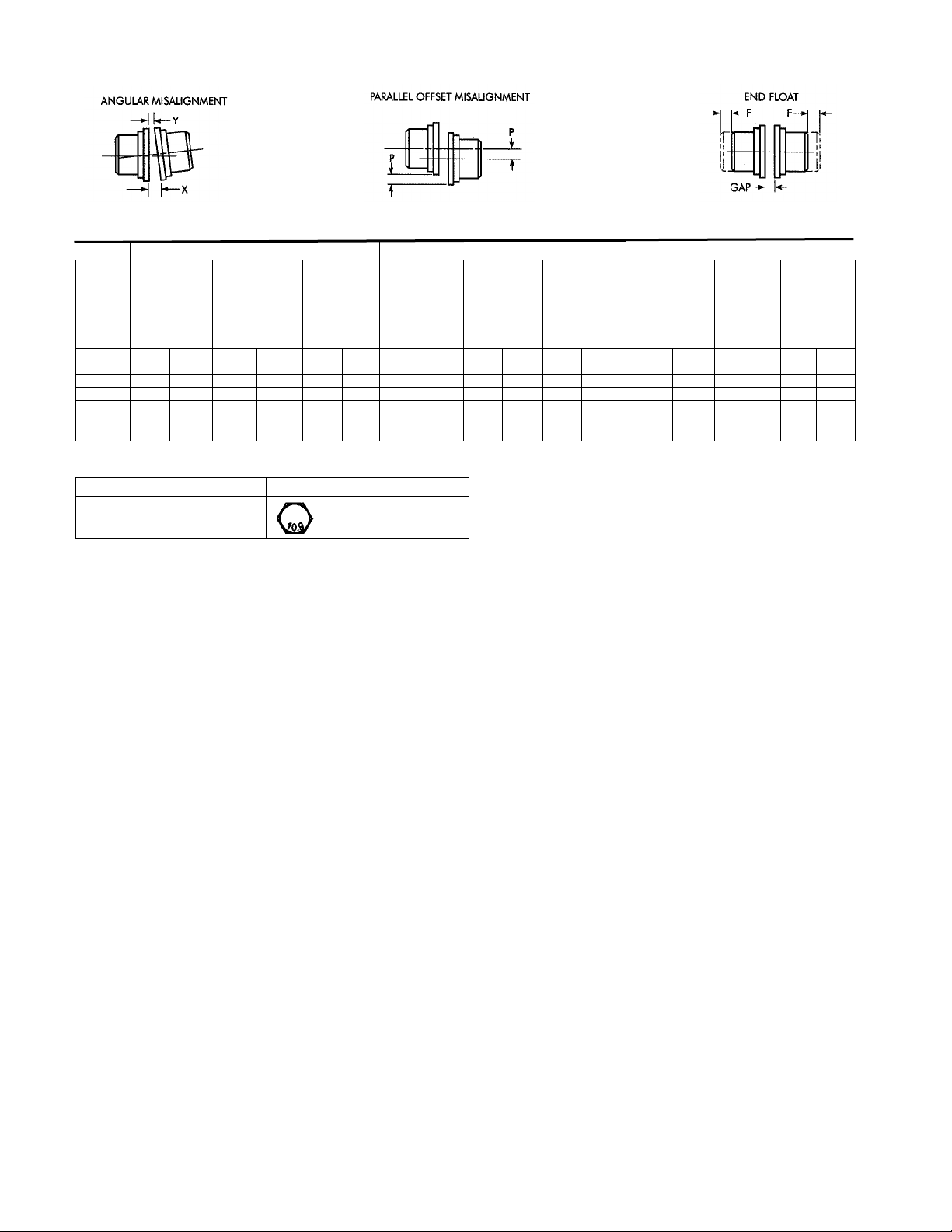

2 –Gap and Angular Alignment (x –y)

Use a spacer bar equal in thickness to the gap specified in

Table 2, Page 5. Insert bar as shown, above, to same

depth at 90° intervals and measure clearance between bar

and hub face with feelers. The difference in minimum

and maximum measurements must not exceed the

ANGULAR installation limits specified in Table 2.