Clarry CST User manual

Report number: 0397PS001S

Tested to ULI482-2011

CST & CSS Models

Owners Manual

Installation and Operating Instructions

Revision A.8.2 Jan. 6, 2015

Clarry Pellet Stove, LLC

P.O. Box 2097

Battle Ground, WA 98604

1-844-4CLARRY

Clarry® Pellet Stove

This product is patented under US Patent #8020547

and Canadian Patent # CA2604313

Made in the USA

Clarry® is a registered trademark of Clarry Pellet Stove, LLC

2.

NOT FOR USE IN

MANUFACTURED HOMES,

MOBILE HOMES,MOTOR HOMES

OR CAMPING TRAILERS.

INTENDED USE MAY

INCLUDE RESIDENTIAL HOMES,

TENTS, HUNTING CABINS ORLINE

SHACKS, ICE FISHING HOUSES

AND DETACHED SHOP

STRUCTURES WHERE ELECTRICITY

MAY NOTBE AVAILABLE.

We welcome you as a new owner of the Clarry® Pellet Stove, CST or

CSS model. This manual will explain the installation, operation and

maintenance of this pellet-burning heater. Please familiarize yourself

with this Owner’s Manual before operating your stove and save it for

future reference. We offer our continual support and guidance to help

you achieve the maximum benefit and enjoyment from your stove.

IMPORTANT INFORMATION

No other Clarry® Pellet Stove has the same serial number as yours.

The serial number will be needed in case you require service of any type.

Model: CST/CSS

Serial Number:

Purchase Date:

Purchased From:

To receive full warranty coverage, you will need to show evidence of

the date you purchased your stove. We suggest that you attach your

bill of sale to this page so that you will have all of the information you

need in one place, should the need for service or information occur.

3.

WARNING

INTRODUCTION

PLEASE READ THIS ENTIRE MANUAL

BEFORE INSTALLATION AND USE OF

THIS PELLET

FUEL-BURNING HEATER.

Failure to follow these instructions

could result in property damage,

bodily injury, or even death.

Contact local building or fire

officials about restrictions

and installation inspection

requirements in your area.

INSTALLER: AFTER INSTALLATION,

GIVE THIS MANUAL TO THE

HOMEOWNER AND EXPLAIN

OPERATION OF THIS STOVE.

SAVE THESE INSTRUCTIONS.

4.

SAFETY PRECAUTIONS

•Do not operate your stove if you

smell smoke coming from it.

•Use only liquid gel or wax/sawdust fire starter

according to the stove’s operating instructions.

Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids to

start or “freshen up” a fire in this heater. Keep all such

liquids well away from the stove while it is in use.

•CAUTION: DO NOT ATTEMPT TO RESTART THE

STOVE WHILE THE STOVE BODY IS STILL HOT. THE

GEL FIRE STARTER MAY VAPORIZE RESULTING IN

FLAME FLARE UP CAUSING BODILY INJURY.

•Never try to repair or replace any part of the stove

unless instructions are given in this manual. All other

work should be done by a trained technician.

•Contact your local building officials to obtain

a permit and information on any installation

restrictions or inspection requirements in your

area. The makers cannot anticipate every possible

method of using the stove. Notify your insurance

company of this stove installation, as well.

•This stove must be properly installed to prevent

the possibility of a structural fire. The instructions

must be strictly adhered to. Do not use makeshift

methods or compromises in the installation.

•The exhaust system must be completely airtight and

properly installed. It is recommended that the stove

vent joints be sealed with high temperature sealant.

•Your stove requires periodic maintenance and

cleaning (see “Maintaining Your Stove”).

•Failure to maintain your stove may lead to smoke spillage.

•Allow the stove to cool before carrying

out any maintenance or cleaning.

•Disposal of Ashes – Ashes should be placed in a steel

container with a tight fitting lid. The closed container

of ashes should be placed on a noncombustible floor

or on the ground, well away from all combustible

material, pending final disposal. If the ashes are

disposed of by burial in soil or otherwise locally

dispersed, they should be retained in the closed

container until all cinders have thoroughly cooled.

•This stove is designed and approved for pelletized

wood fuel only. Any other type of fuel burned in

this stove will void the warranty and safety listing.

•Keep foreign objects out of the hopper.

•Do not place clothing or other flammable

items on or near the stove.

•The exhaust system should be checked at least

twice a year for any build-up of soot or creosote.

•DO NOT TOUCH THE HOT SURFACES OF THE STOVE.

EDUCATE ALL CHILDREN OF THE

DANGER OF A HIGH-TEMPERATURE STOVE.

YOUR CHILDREN SHOULD BE CLOSELY SUPERVISED

WHEN THEY ARE IN THE SAME ROOM AS THE STOVE.

•Clarry Pellet Stove LLC grants no warranty

implied or stated, for the installation or

maintenance of your heater, and assumes no

responsibility for any consequential damages.

•When this heating appliance is not properly

installed, a fire may result. To reduce the risk

of fire, follow the installation instructions.

•Contact local building or fire officials about restrictions

and installation inspection requirements in your area.

* Heating capacity will vary

depending on the exterior wall

material, degree of insulation,

and the outside temperature. It

is also affected by the fuel size,

quality, and moisture level.

** Fuel: This unit is designed for

wood pellets that comply with the

standards set by the Association of

the Pellet Fuel Industry (density of

at least 40 lbs. per cubic foot, 1/4”

to 5/16”diameter, length no greater

than 1 ½”, 8200 BTU’s/lb., moisture

under 8% by weight, ash under

1% by weight, and salt under 300

parts per million). If the fuel does

not comply with this standard, the

unit may not operate as designed.

OUR STOVES OPERATE BEST USING

PELLETS WITH <6% MOISTURE

CONTENT. DO NOT REUSE PELLET

FUEL THAT HAS NOT BEEN STORED

IN A MOISTURE PROOF CONTAINER.

PELLETS NOT STORED IN THIS

MANNER MAY DRAW MOISTURE

AND WILL NOT BURN PROPERLY.

CST HEATING SPECIFICATIONS:

Approximate Maximum Heating Capacity (in square feet): 1000 sq. ft.*

Approximate Burn Rate (pounds per hour): 5.0**

Approximate Burn Time: 8 hours**

Hopper Capacity: 40 pounds

Stove Weight: 100 pounds assembled

5.

Note

1.) DIMENSIONS AND SPECIFICATIONS: CST Model

FIGURE 1 CST MODEL

* Heating capacity will vary

depending on the exterior wall

material, degree of insulation,

and the outside temperature. It

is also affected by the fuel size,

quality, and moisture level.

** Fuel: This unit is designed for

wood pellets that comply with the

standards set by the Association of

the Pellet Fuel Industry (density of

at least 40 lbs. per cubic foot, 1/4”

to 5/16”diameter, length no greater

than 1 ½”, 8200 BTU’s/lb., moisture

under 8% by weight, ash under

1% by weight, and salt under 300

parts per million). If the fuel does

not comply with this standard, the

unit may not operate as designed.

OUR STOVES OPERATE BEST USING

PELLETS WITH <6% MOISTURE

CONTENT. DO NOT REUSE PELLET

FUEL THAT HAS NOT BEEN STORED

IN A MOISTURE PROOF CONTAINER.

PELLETS NOT STORED IN THIS

MANNER MAY DRAW MOISTURE

AND WILL NOT BURN PROPERLY.

EPA COMPLIANCE:

The CST and CSS model stoves

are EPA exempt from

Phase II requirements.

6.

Warning

CSS HEATING SPECIFICATIONS:

Approximate Maximum Heating Capacity (in square feet): 500 sq. ft.*

Approximate Burn Rate (pounds per hour): 4.5 lbs/hr.**

Approximate Burn Time: 10 hours**

Hopper Capacity: 40 pounds

Stove Weight: 65 pounds assembled

1.) DIMENSIONS AND SPECIFICATIONS: CSS Model

Note

FIGURE 1.1 CSS MODEL

READ THIS ENTIRE MANUAL

BEFORE YOU INSTALL AND USE THE

CLARRY® PELLET STOVE.

PACKING LIST

•CST or CSS Stove Body

•Ash Drawer

•Stainless Steel Grate

•Damper Door and Grate Access Door

•Pellet Hopper

•Owners Manual

•Door Latch Tool

•4 Legs

•1 ea. 4”-90° elbow required for Sierra model only to clear hopper

IMPORTANT - THE FOLLOWING MATERIALS NEED TO

BE PURCHASED FOR FINAL ASSEMBLY:

1. Enough 4” 28 gauge black Stove Pipe (D.1) to complete flue installation.

2. One or more 4”45/90 degree elbows may be needed to complete tent side

wall installations.

3. A directional wind cap may be used at the top of the stove pipe. No other

device, such as a China Hat can be used.

STOVE ELEMENTS (SEE FIGURE 2)

A) Stove Body (A),

which includes the Grate (A.1),

Ash Drawer (A.2),

and Grate Access Door (A.3) with Damper Door (A.3.1)

B) Four (4) Legs (B) and four (4) Set Screws (B.1)

C) Hopper (C). Holds the wood pellets

D) Stove Pipe.

D.1) 1 -Ea. 4” 45/90° elbows required for CSS Model only to clear hopper

7.

Before You Begin

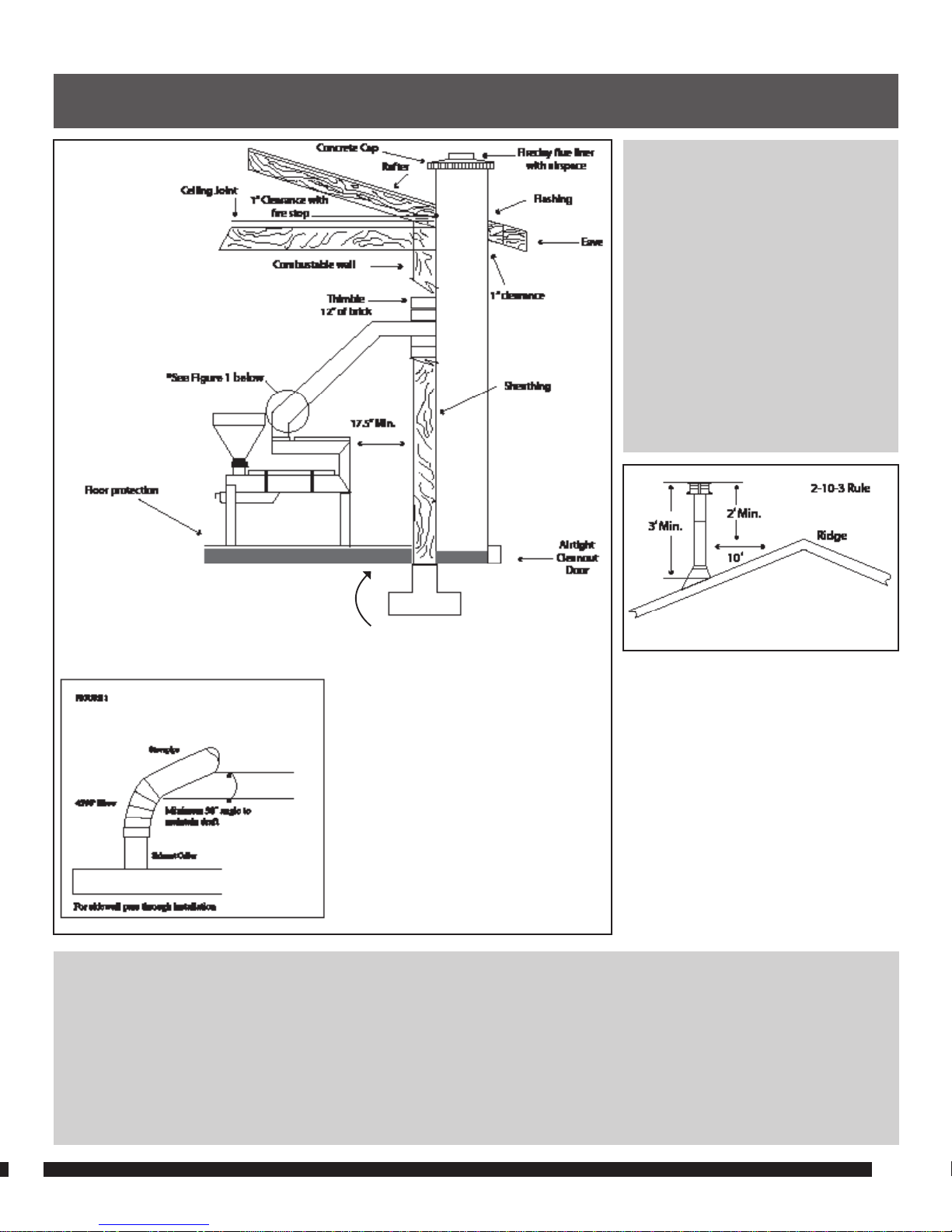

2.) INSTALLATION: Setting up the Stove

8.

Assembly

1. Tip the stove body (A) on end, insert the legs (B) and loosely tighten the set screws. (B.1)

2. Move the stove (A) into the upright position. Adjust the legs (B) so that the stove is level. Finish tightening the set screws (B.1).

3. Lift fire chamber access door (A.3) and slide grate (A.1) into the fire chamber in body (A). Push in firmly until it stops

against the pellet delivery chute. Insert damper door (A.3.1) in access door (A.3) guide rails. Close both doors.

4. Insert the 4” 28 gauge sheet metal stove pipe (D) into the 4”exhaust collar in body (A). The CSS Model will require a 4”

45/90° elbow offset to clear the hopper for a vertical installation. Make sure you have the proper configuration for a

ceiling/roof opening or sidewall opening. See FIG. 9, page 17.

5. Put the pellet hopper (C) into the 3”collar in body (A). The manual shut off gate (C.1) should be closed.

WARNING: FAILURE TO FOLLOW THIS PROCEDURE MAY CAUSE THE STOVE TO “OVER FIRE”.

SEE PAGE 18 FOR AN EXPLANATION OF “OVER FIRING”

FIGURE 2

NEVER REDUCE THE

MINIMUM CLEARANCE DIMENSIONS

SHOWN

IN FIG. 3.1 AND FIG. 3.2.

•Prior to placing the Clarry® Pellet Stove in your structure, you must

burn the stove in for 20 minutes, to set the stove paint.

•Assemble the stove in an outdoor location according to

the directions above; bring it to operating temperature,

or to the point where the paint stops smoking.

•Make sure that any time you light the stove outdoors the chimney is not

positioned directly under a low hanging tree branch or near a structure.

•Once the stove has been burned in and cooled down, it is ready to install.

INSTALLATION OPTIONS

The Clarry® Pellet Stove is approved for an interior vertical through

the roof installation; horizontal through the wall to exterior vertical

installation and retrofit to existing masonry chimney installation.

NOTE: When using horizontal through the wall installation, floor

protection material must extend under the chimney connector

(the 28 gauge stove pipe) from the back or side of stove to the

wall. Floor protection width must be a minimum 2”wider on each

side of chimney connector, for a total minimum width of 8”.

PRE-INSTALLATION RECOMMENDATION

Sketch out a detailed plan of the installation including dimensions. Then

verify the dimensions with the requirements listed in this manual.

When determining the location of the stove, locate the ceiling trusses

(for vertical penetrations). You may wish to adjust the stove position slightly to

ensure the vent does not intersect with a framing member, but never reduce the

minimum clearance dimensions shown on the next page in FIG. 3.1 and FIG. 3.2.

STOVE PLACEMENT

Place the stove on non-combustible floor protection using wall clearance

dimensions for a straight (Fig. 3.1) or corner installation (Fig. 3.2)

Stove must be placed so that no combustibles are within, or can swing

within (doors, drapes, etc.), 36”of any surface of the stove. Heater

and floor protection must be installed on a level, secure floor.

9.

WARNING

2.) INSTALLATION: “Burning In” the Stove

FIGURE 3.1

FIGURE 3.2

The heater must be installed on a non-combustible floor protector extending the full width and depth of the heater

and extending 18” in front beyond the pellet hopper and 8” outside of the legs, minimum 30˝ wide by 56˝ deep.

Minimum 1” thick with (k=0.84) (R=1.19) (BTU)(in)/(ft2)(hr)(of ).

How to determine if alternate oor protection materials are acceptable.

All floor protection must be non-combustible (i.e., metals, brick, stone, mineral fiber boards, etc.). Any organic materials

(i.e., plastics, wood paper products, etc.) are combustible and must not be used. The floor protection specified

includes some form of thermal designation such as R-value (thermal resistance) or k-factor (thermal conductivity).

10.

2.) INSTALLATION: Floor Protection Requirements

PROCEDURE

1. Convert specification to R-value:

i. R-value given - no conversion needed.

ii. k-factor is given with a required thickness (T) in inches:

iii. K-factor is given with a required thickness (T) in feet:

iv. r-factor is given with a required thickness (T) in inches: R = r x T

2. Determine the R-value of the proposed alternate floor protector.

i. Use the formula in step (1) to convert values not expressed as “R”.

ii. For multiple layers, add R-values of each layer to determine overall R-value.

3. If the overall R-value of the system is greater than the R-value of the specified floor protector, the alternate is acceptable.

EXAMPLE: The specified floor protector should be 3/4-inch thick material with a k-factor of 0.84. The proposed alternate is 4”

brick with an r-factor of 0.2 over 1/8”mineral board with a k-factor of 0.29.

Step (a): Use formula above to convert specification to R-value.

Step (b): Calculate R of proposed system. 4” brick of r = 0.2, therefore:

1/8” mineral board of k = 0.29, therefore:

RTOTAL = RBRICK + RMINERAL BOARD = 0.8 + 0.431 = 1.231

Step (c): Compare proposed system RTOTAL of 1.231 to specified R of 0.893. Since proposed system RTOTAL is greater than

required, the system is acceptable.

DEFINITIONS

Btu

)F

o

)(hr)(

2

(ft

R =

12xK

)F

o

)(hr)(

2

ft(

(Btu)(in)

k ==

)F

o

)(hr)(

2

ft(

(Btu)(ft)

K =

k

1

)in)(Btu(

)F

o

)(hr)(

2

(ft

r =

=

DO NOT CONNECT THE STOVE VENT TO

A VENT SERVING ANY OTHER APPLI-

ANCE OR STOVE.

DO NOT INSTALL A FLUE

DAMPER IN THE EXHAUST VENTING

SYSTEM OF THIS UNIT.

SEE FIG. 4, FIG.5, FIG.6, FIG. 7, FIG. 8, AND FIG. 9

• This stove must be connected to:

1) A chimney complying with the requirements for type HT Chimneys

in the standard for Chimneys, Factory-Built, Residential Type and

Building Heating appliance, UL 103,

OR,

2) A code –approved masonry chimney with a flue liner.

• A source of fresh air into the room must be provided.

• Stove vent must maintain a minimum 36” clearance to any

combustible material or at clearance specified by the vent

manufacturer if the requirement is greater than 36”.

• Do not connect the stove vent to a vent serving any other appliance or stove.

• Do not install a flue damper in the exhaust venting system of this unit.

STOVE VENT TYPE

• Four inch (4”) 28 gauge sheet metal single wall stove pipe.

INSTALLING THE STOVE VENT

• Sealing each vent section by injecting a liberal amount of high

temperature sealant into the gap between sections is recommended.

• Insert stove pipe (D) into the 4”vent collar on the stove body (A)

and fasten with 3 sheet metal screws. See FIG. 4. The CSS Model

will require a 4”45/90° elbow offset to clear the hopper.

• Use a listed ceiling support/fire stop spacer when passing

through combustible ceiling framing (see FIG. 5 and FIG. 7).

CHECK LOCAL BUILDING CODES FOR SPECIFIC REQUIREMENTS.

• Interior installations, with no ceiling, may pass through a framed opening

maintaining a minimum 18”clearance from combustible materials (see FIG 8).

• Use a listed wall thimble when passing the stovepipe horizontally

through combustible materials (see FIG. 6 and 9).

CHECK LOCAL BUILDING CODES FOR SPECIFIC REQUIREMENTS.

• Use no more than 180 degrees of elbows (two 90 degrees, or two 45

degree and one 90 degree elbow, etc.) Maximum horizontal run is 36”.

• Consult your local building codes for clearances, thimbles

and connections required when connecting the Clarry

Pellet Stove to an exiting or new masonry chimney.

11.

WARNING

2.) INSTALLATION: Venting Requirements

DO NOT CONNECT THIS

UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

DO NOT CONNECT TO ANY

AIR DISTRIBUTION DUCT

OR SYSTEM.

FACTORY BUILT CHIMNEY

When a metal prefabricated

chimney is used, the manufacturer’s

installation instructions must be

followed. You must also purchase

(from the same manufacturer)

and install the ceiling support

package or wall pass-through and

“T” section package, fire stops

(where needed), insulation shield,

roof flashing, etc. Maintain proper

clearance to the structure as

recommended by the manufacturer.

The chimney must be the required

height above the roof or other

obstructions for safety and proper

draft operation. See page 14 for

chimney termination requirements.

The chimney connector is a single walled pipe used to connect the stove to

the chimney. For use with the Clarry® Pellet Stove, the chimney connector

MUST be 4” in diameter, with a minimum thickness of 28 gauge black steel.

Aluminum and galvanized steel pipe is not acceptable for use with the

Clarry® Pellet Stove. These materials cannot withstand the extreme

temperatures of a wood pellet fire and can give off toxic fumes when heated.

DO NOT USE THE CONNECTOR PIPE AS A CHIMNEY.

Each chimney connector or stove pipe section must be installed to the stove

flue collar and to each other with the male (crimped) end toward the stove.

See FIG 4.

This prevents any amount of condensed or liquid creosote from run-

ning down the outside of the pipe or the stove top. All joints, in-

cluding the flue collar connection must be secured with three sheet

metal screws to ensure that the sections do not separate.

For the best performance the chimney connector should be as short and direct

as possible, with no more than two 90° elbows. The maximum horizontal run

is 36” and a recommended total length of stove pipe should not exceed 10

feet. Always slope horizontal runs upward ¼”per foot toward the chimney.

No part of the chimney connector may pass through an attic or roof space,

closet or other concealed space, or through a floor ceiling. All sections of

the chimney connectors must be accessible for cleaning. Where passage

through a wall or partition of combustible construction is desired, the instal-

lation must conform to NFPA 211, and is also addressed in this manual.

12.

WARNING

2.) INSTALLATION: Chimney Connection

FIGURE 4

FIGURE 5

CHIMNEY HEIGHT TYPICAL FOR ALL

INSTALLATIONS

A masonry chimney or a listed

factory-build chimney must be the

required height above the roof and

any other nearby obstructions. The

chimney must be at least 3’ (90 cm)

higher than the highest point where

it passes through the roof and at

least 2’ (60 cm) higher than the

highest part of the roof or structure

that is within 10’ (305 cm) of the

chimney, measured horizontally.

13.

2.) INSTALLATION: Chimney Connection

FIGURE 6

MASONRY CHIMNEY

Ensure that a masonry chimney meets the minimum standards of the National Fire Protection Association (NFPA) by having it

inspected by a professional. Make sure there are no cracks, loose mortar or other signs of deterioration and blockage. Have

the chimney cleaned before the stove is installed and operated. When connecting the stove through a combustible wall to a

masonry chimney, special methods are needed. Refer to Combustible Wall Chimney Connector Pass-Throughs on page 14.

See note page 9 for floor

protection extention under

chimney connector.

DO NOT TERMINATE THE CLARRY

PELLET STOVEVENT PIPE HORIZONTALLY.

CHIMNEY TERMINATION

• Must have a directional wind cap

(to prevent water from entering).

• Minimum 3’ clearance from any forced

air intake of any other appliance.

• Minimum 1’ clearance horizontally from

combustible wall.

• Must be a minimum of 3´ above the

roof, or 2´ above the roof ridgeline with

10´ of roof penetration.

• Minimum 5’ clearance from any

door opening.

COMBUSTIBLE WALL CHIMNEY CONNECTOR PASS-THROUGHS

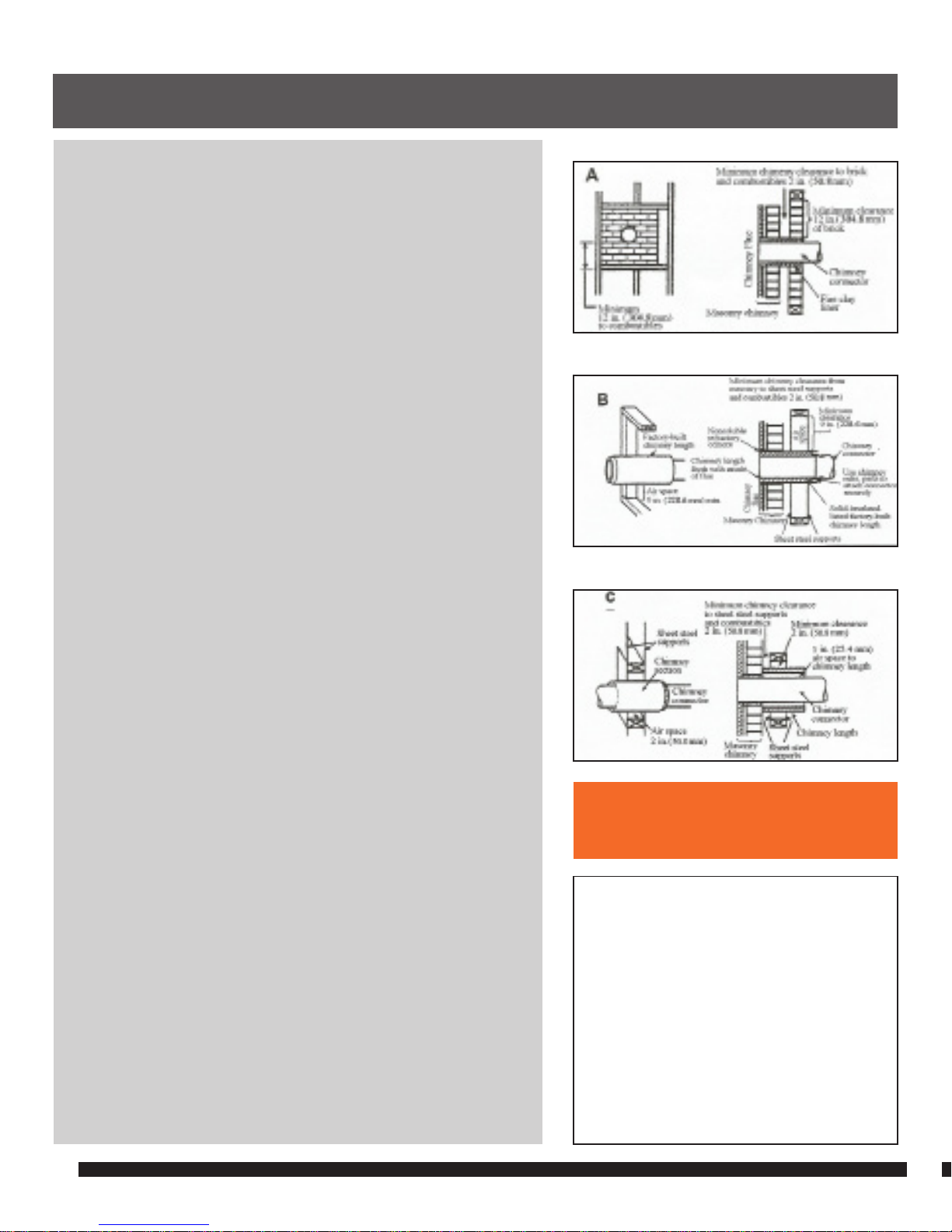

METHOD A.

12” (304.8 mm) Clearance to Combustible Wall Member: Using a

minimum thickness 3.5” (89 mm) brick and a 5/8” (15.9 mm) minimum

wall thickness clay liner, construct a wall pass-through. The clay liner

must conform to ASTM C315 (Standard Specification for Clay Fire

Linings) or its equivalent. Keep a minimum of 12” (304.8 mm) of brick

masonry between the clay liner and wall combustibles. The clay liner

shall run from the brick masonry outer surface to the inner surface

of the chimney flue liner but not past the inner surface. Firmly

grout or cement the clay liner in place to the chimney flue liner.

METHOD B.

9” (228.6 mm) Clearance to Combustible Wall Member: Using a 4”

(152.4 mm) inside diameter, listed, factory-built solid-pak chimney

section with insulation of 1” (25.4 mm) or more, build a wall pass-

through with a minimum 9”(228.6 mm) air space between the

outer wall of the chimney length and wall combustibles. Use sheet

metal supports fastened securely to wall surfaces on all sides, to

maintain the 9” (228.6 mm) air space. When fastening supports to

chimney length, do not penetrate the chimney liner (the inside wall

of the solid-pak chimney). The inner end of the solid-pak chimney

section shall be flush with the inside of the masonry chimney

flue, and sealed with a non-water soluble refractory cement. Use

this cement to also seal to the brick masonry penetration.

METHOD C.

2” (50.8 mm) Clearance to Combustible Wall Member: Start with

a solid-pak listed factory built chimney section at least 12” (304

mm) long, with insulation of 1”(25.4 mm) or more, and an inside

diameter of 6”(2 inches [51 mm] larger than the 4” [152.4 mm]

chimney connector). Use this as a pass-through for a minimum

24-gage single wall steel chimney connector. Keep solid-pak

section concentric with and spaced 1” (25.4 mm) off the chimney

connector by way of sheet metal support plates at both ends

of chimney section. Cover opening with and support chimney

section on both sides with 24 gage minimum sheet metal supports.

See that the supports are fastened securely to wall surfaces on

all sides. Make sure fasteners used to secure chimney flue liner.

NOTES:

1. Connectors to a masonry chimney, excepting method B, shall

extend in one continuous section through the wall pass-through

system and the chimney wall, to but not past the inner flue liner face.

2. A chimney connector shall not pass through an attic or roof

space, closet or similar concealed space, or a floor, or ceiling.

14.

Section2.) INSTALLATION: Chimney Connection

METHOD C.

METHOD B.

METHOD A.

15.

2.) INSTALLATION: Interior Vertical Installations

FIGURE 7

CSS

16.

2.) INSTALLATION: Interior Vertical Installations

FIGURE 8

CSS

17.

2.) INSTALLATION: Interior Horizontal Installation

FIGURE 9

See note page 9 for floor

protection extention under

chimney connector.

NEVER USE GASOLINE, GASOLINE-TYPE

LANTERN FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID, OR SIMILAR LIQUIDS

TO START OR “FRESHEN UP”A FIRE IN

THIS STOVE. KEEP ALL SUCH LIQUIDS

WELL AWAY FROM THE STOVE WHILE

IT IS IN USE.

WARNING: FAILURE TO FOLLOW THIS

PROCEDURE CAN LEAD TO “OVER

FIRING”THE STOVE. IF THE SIDES OF

THE FIRE CHAMBER GLOW CHERRY

RED, THE STOVE IS BEING “OVER

FIRED”!“OVER FIRE”CAN CAUSE

DAMAGE TO THE STOVE,

AND MAY RESULT IN

CAUSING A FIRE AT THE

SURROUNDING SURFACES.

OPERATING INSTRUCTIONS REFER TO FIGURE 2.)

1. Fill the hopper (C) with one 40-lb. bag of “PREMIUM or Super Premium” pellets.

This unit is designed for wood pellets that comply with the standards set by

the Association of the Pellet Fuel Industry (density of at least 40 lbs. per cubic

foot, 1/4”to 5/16” diameter, length no greater than 1 ½”, 8200 BTU’s/lb., moisture

under 8% by weight, ash under 1% by weight, and salt under 300 parts per

million). If the fuel does not comply with this standard, the unit may not operate

as designed. Our stoves operate best using pellets with <6% moisture content.

2. Open the shut off gate (C.1), allowing the pellets to drop into position in the

firebox. Note: Tighten the setscrew (C.2) in the shut off gate to avoid misplacing

the shut off gate (C.1).

3. Next, open the ash drawer (A.2). A few pellets will have fallen through the

fire grate. That’s OK. Squeeze a liberal amount of liquid gel fire starter, or stack

several wax/sawdust fire sticks into the drawer, aiming at the center of the

drawer. Light it with a match, then push the drawer in until you reach the

first notch (A.2-2), the fire starting position and push the door (A.3) into the

notch. This is also the final burning position and will allow some air control

for the fire. Make sure damper door (A.3.1) completely covers the opening in

grate access door. (.3)

WARNING: FAILURE TO FOLLOW THIS PROCEDURE WILL LEAD TO “OVER FIRING”THE

STOVE. IF THE SIDES OF THE FIRE CHAMBER GLOW CHERRY RED, THE STOVE IS BEING

“OVER FIRED”!“OVER FIRE”CAN CAUSE DAMAGE TO THE STOVE, AND MAY RESULT IN

CAUSING A FIRE AT THE SURROUNDING SURFACES.

4. Air Control – The stove will reach maximum heating capacity with the Damper

Door (A.3.1) closing off the control air opening. Once the stove has reached

full heating capacity, begin to slide the Damper Door (A.3.1) up exposing the

opening in the Grate Access Door (A.3). Adjust to personal comfort. Exposing

the entire 1”x 5” opening allows the stove to operate at a much

lower temperature.

5. As fuel is consumed, pellets will continue to slide down into the firebox and

your fire will continue to burn. One 40-lb. bag will burn for approximately

eight (8) hours.

18.

WARNING

3.) OPERATION: Operating Instructions

DANGER: FIRE HAZARD AND CARBON

MONOXIDE HAZARD

HEAT OUTPUT

Temperatures exceeding 900 degrees in the fire chamber and 500 degrees at the

heat exchanger are reached in 15 minutes. Do not touch the stove, or place any

combustible materials within 36 inches.

DANGER – Fire Hazard/Carbon Monoxide Hazard

1. This stove may start other fires. Never operate this stove in places without a

fresh air source or in places that contain or may contain volatile and inflammable

liquids or vapors. Never operate this stove where airborne combustibles or

products such as gasoline, solvents, paint thinners, or unknown chemicals may

be found.

2. This stove consumes air (oxygen) and produces carbon monoxide. Using this

product in unventilated or enclosed areas, without a source of fresh air make up,

may cause injury or death.

3. Carbon Monoxide poisoning may be accompanied by symptoms such as

watery eyes, fatigue and dizziness. If you experience these symptoms while

using this product, get fresh air immediately.

4. Ensure the stove fire is out and cool before emptying the contents. Pellet embers

and ash can smolder and remain very hot for a long period time without smoke.

5. Ashes should be placed in a metal container with a tight fitting lid. The closed

container of ashes should be placed on a noncombustible surface or on the

ground, well away from all combustible materials, pending final disposal. If the

ashes are disposed of by burial in soil or otherwise locally disposed, they

should be retained in the closed container until all cinders have been

thoroughly cooled.

SHUTTING DOWN THE STOVE

1. Close the manual shut off gate (C.1) to keep any more pellets from sliding into

the firebox. Re-tighten the set screw (C.2). The fire should go completely out in

about 20 minutes.

2. Ensure the stove fire is out and cool before emptying the contents.

Using the Door Latch Tool provided, remove the ash drawer to empty the ashes.

3. It is important to leave the Ash Drawer (A.2) open in the operating position

notch (A.2-1) to allow air to continue to enter the firebox until the fire has

completely burned all of the pellets. Closing the ash drawer prior to completely

burning all of the pellets may cause the fire to smolder and put smoke into your

shelter due to lack sufficient air to completely burn all of the remaining pellets.

SEE MAINTENANCE INSTRUCTIONS THAT FOLLOW, FOR PROPER

DISPOSAL OF ASHES.

19.

WARNING

3.) OPERATION: Operating Instructions

CLEANING THE STOVE WHEN YOU’RE USING IT FOR AN EXTENDED PERIOD IS

EXTREMELY IMPORTANT.

1. After every use, remove the ash from the ash drawer.

Note: Ashes should be placed in a metal container with a tight fitting lid. The

closed container of ashes should be placed on a noncombustible floor or on the

ground, well away from all combustible materials, pending final disposal. If the

ashes are disposed of by burial in soil or otherwise locally dispersed, they should

be retained in the closed container until all cinders has been thoroughly cooled.

2. Remove the grate daily and clean it with a wire brush.

3. Soot and Fly-ash: Formation and Need for Removal. The products of

combustion will contain small particles of fly-ash. The fly-ash will collect in

the exhaust venting system and restrict the flow of the flue gases. Incomplete

combustion, such as occurs during startup, shutdown, or incorrect operation

of the stove will lead to some soot formation which will collect in the exhaust

venting system. The exhaust venting system should be inspected at least twice

every year to determine if cleaning is necessary.

4. Creosote: Formation and Need for Removal. When wood is burned slowly, it

produces tar and other organic vapors, which combine with expelled moisture

to form creosote. The creosote vapors condense in the relatively cool chimney

flue of a slow-burning fire. As a result, creosote residue accumulates on the flue

lining. When ignited, this creosote makes an extremely hot fire.

5. The chimney and chimney connector should be inspected at least once every

two months during the heating season to determine if a creosote buildup has

occurred. If it has accumulated, it should be removed to reduce the risk of a

chimney fire.

20.

4.) MAINTAINING THE STOVE

This manual suits for next models

1

Table of contents

Popular Pellet Stove manuals by other brands

Horus

Horus AQUA 14.0 Operating, installation and maintenance manual

Harman

Harman Accentra Freestanding Pellet Stove Installation & operating manual

Harman

Harman XXV owner's manual

RED

RED GARDENIA Use and maintenance manual

Avalon

Avalon Arbor owner's manual

Osburn

Osburn 5000 Installation and operation manual

Thelin

Thelin ECHO PELLET E.I. Installation and operating instructions

Kozi

Kozi BayWin owner's manual

Centrometal

Centrometal CentroPelet ZS10 Technical instructions

Hudson River

Hudson River DAVENPORT owner's manual

Heatilator

Heatilator ECO-ADV-PS35 owner's manual

Quadra-Fire

Quadra-Fire SANTAFE-MBK installation manual