Classic AutoAir Flex FIt Series User manual

Installation Manual

Custom Colder The Climate Control System

DOCUMENT #1-1090

©2016 ClassicAutoAir / 07.16

©

©

You have just purchased the highest quality, best performing

A/C system ever designed for your classic vehicle.

To obtain the high level of performance and dependability our systems are known for, please pay close attention to the

following instructions. Our installation steps and procedures are derived from a long history of research and

development and the combined experience achieved thru thousands of successful installations (and feedback from

customers like you). Please remember that our #1 goal is that you’ll have a successful installation and a system that

performs at a very high level for many years to come.

Before starting, read the instructions carefully, from beginning to end, and follow the proper sequence. On the next

page you’ll find a safety and general checklist that you should read before starting your installation.

Again, thank you from our entire staff.

CLASSIC AUTO AIR

Page 1

Check List, Pre-Installation:

Procedures, During Installation:

Before beginning the installation check the shipping box for the correct components. YOUR BOXED UNIT INCLUDES A LIST OF

MAJOR COMPONENTS AND A LIST OF BAGGED PARTS. We have a 5 stage check process to make sure you have everything you’ll

need.

If your vehicle has been or is being modified, some procedures will need to be adjusted to fit your particular application.

A basic cleaning of the engine compartment and interior before beginning will make things go more smoothly.

Check condition of engine mounts. Excessive engine movement can damage hoses to A/C and/or heater.

Before starting, check vehicle interior electrical functions (interior lights, radio, horn, etc). Make a note of anything that does not work as

it’s supposed to. During the installation you might find the opportunity to repair or upgrade non-working or out of date components.

When you’re ready to start the installation, DISCONNECT THE BATTERY FIRST.

Drain the radiator. Retain the coolant and reuse, or dispose of properly.

SAFETY FIRST: Wear eye protection while drilling/cutting, deburr sharp edges, and never get in a hurry or force a part.

Tools: Your installation only requires the basic tools everyone has in their garage, nothing exotic or specific to A/C or Heat equipment.

Fittings: Use one or two drops of mineral oil (supplied with your kit) on ALL rubber o-rings, threads and rear of bump for o-ring where

female nut rides. Do not use thread tape or sealants.

Measure twice (or more), cut once

Should you have any technical questions, or feel you have defective components (or missing items), call us immediately,

we will be glad to assist you. Our toll-free number is listed on every page, we’re here to help!

YOU CAN NOW BEGIN THE INSTALLATION...

CLASSIC AUTO AIR

Page 2

The air conditioning system in your car is comprised of a compressor,

condenser, expansion valve, receiver/drier, and evaporator. Refrigerant (also

known as Freon) is compressed in the compressor. In the condenser, gas is

cooled to a liquid state and travels to the expansion valve. As the liquid refrigerant

goes through the expansion valve it rapidly cools in the evaporator. A fan blows

over the evaporator and cools the air that blows out your vents

Evaporator with Blower Fan

In order to remove the heat from the air in the vehicle, the

A/C evaporator allows the refrigerant to absorb the heat from the air passing over it. The blower fan

moves cool air out into the car interior.

Compressor

The compressor pumps and circulates the refrigerant through the system.

Condenser

The condenser is a heat exchanger mounted at the front of the vehicle. Heat drawn

out of the interior of the car is expelled here.

Receiver/Drier

The drier not only dries refrigerant, it also filters the refrigerant and stores it

under certain operating conditions.

High Pressure Switch

A pressure switch is used to shut down the system if high or low

pressure is detected, basically it acts as a safety switch.

A Basic Overview of Automotive A/C....

Receiver

Drier

Compressor

Evaporator Unit

Expansion Valve

Condenser

Suction

Valve Discharge

Valve

Firewall

OUTSIDE AIR

COLD AIR INTO VEHICLE

AIR FROM INSIDE VEHICLE

GROUND

POWER

SUCTION HOSE

DISCHARGE HOSE

LIQUID HOSE

1

1

2

3

4

5

2

3

4

5

COOLED AIR

CLASSIC AUTO AIR

Page 3

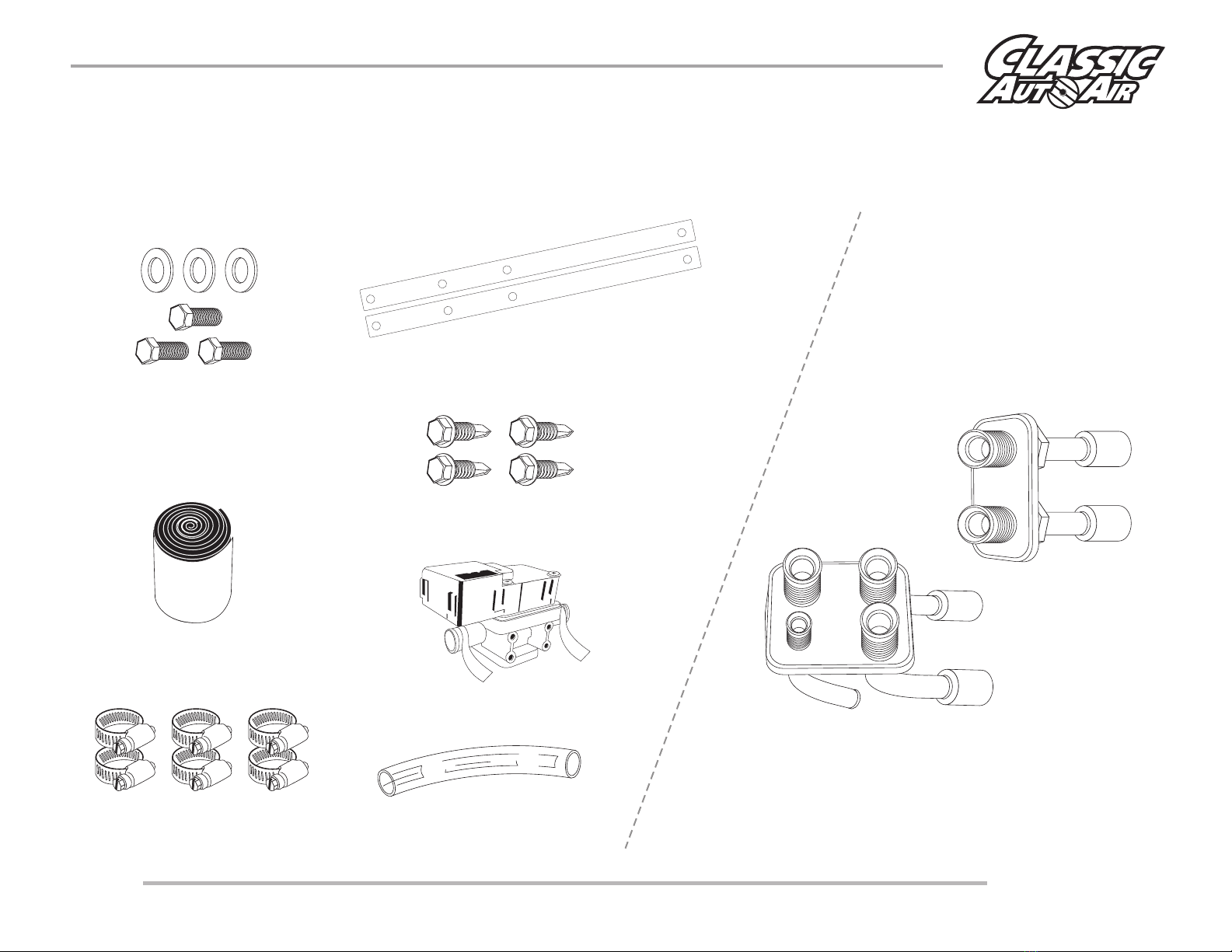

THESE ARE THE PARTS YOU WILL FIND IN BAG KIT A

You will use all of these parts and hardware during the next series of installation steps.

Electronic Water Control Valve

Six Worm Gear Clamps

Three 1/4 - #20 x 1" Bolts

and Washers

Clear Plastic Drain Tube

Refrigerant Tape

If you purchased these

OPTIONAL bulkhead plates they

will be located in unit box.

CLASSIC AUTO AIR

Page 4

Two Installation Brackets

Four #10 - 16 x 3/4" Tek Screws

H

E

A

T

E

R

C

O

R

E

W

A

T

E

R

P

U

M

P

CLASSIC AUTO AIR

Page 5

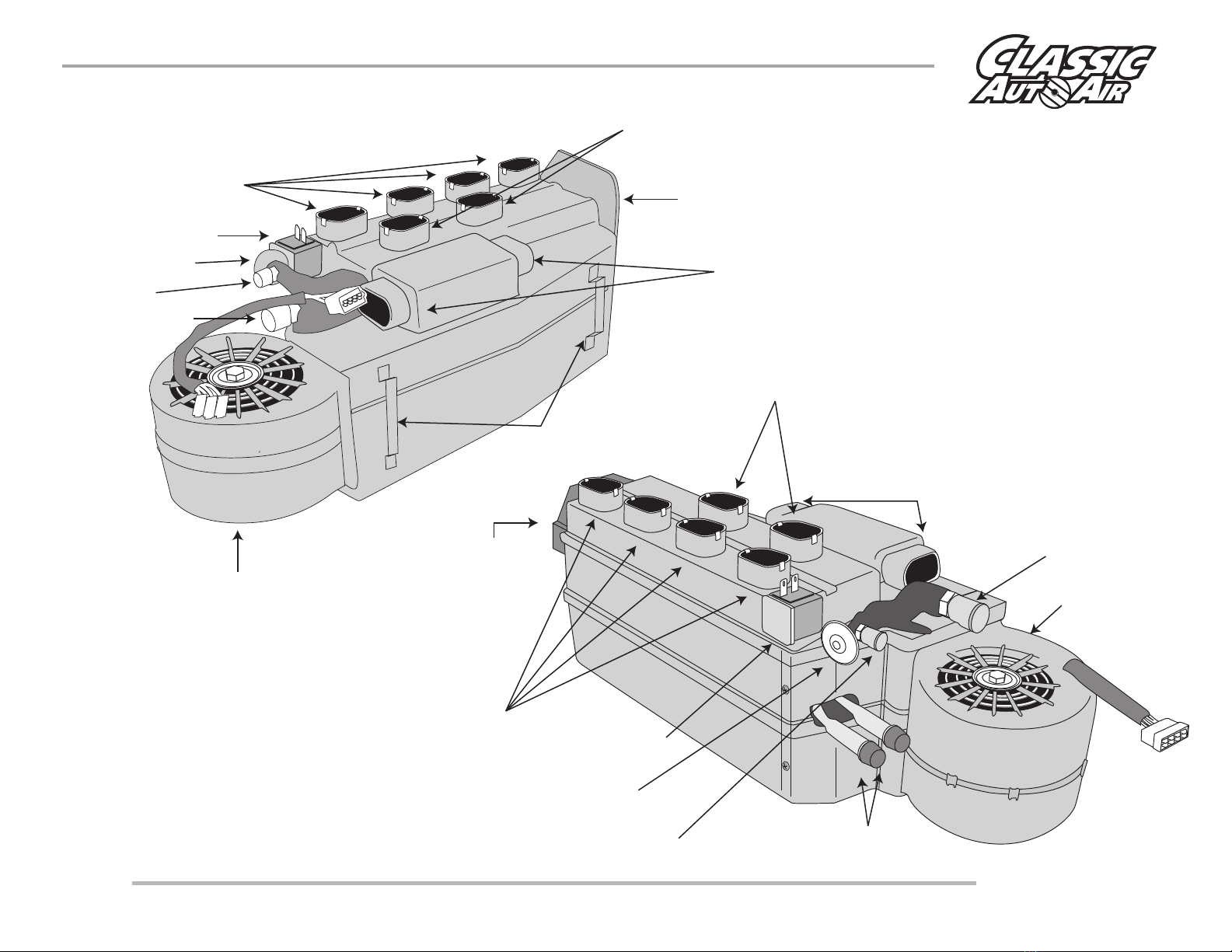

Floor Hose Connection

Thermostat

Blower Motor

Actuator Motors

Expansion Valve

Blower Motor

Dash Hose Connections

Actuator

Motors

Suction Line

Heater Hose Connections

Thermostat

Defrost Hose Connections

Expansion Valve

Liquid Pressure

Line

Liquid Pressure

Line

Dash Hose Connections

Mounting Brakets

Floor Hose Connection

Suction Line

Defrost Hose Connections

Calibration Key

Blue

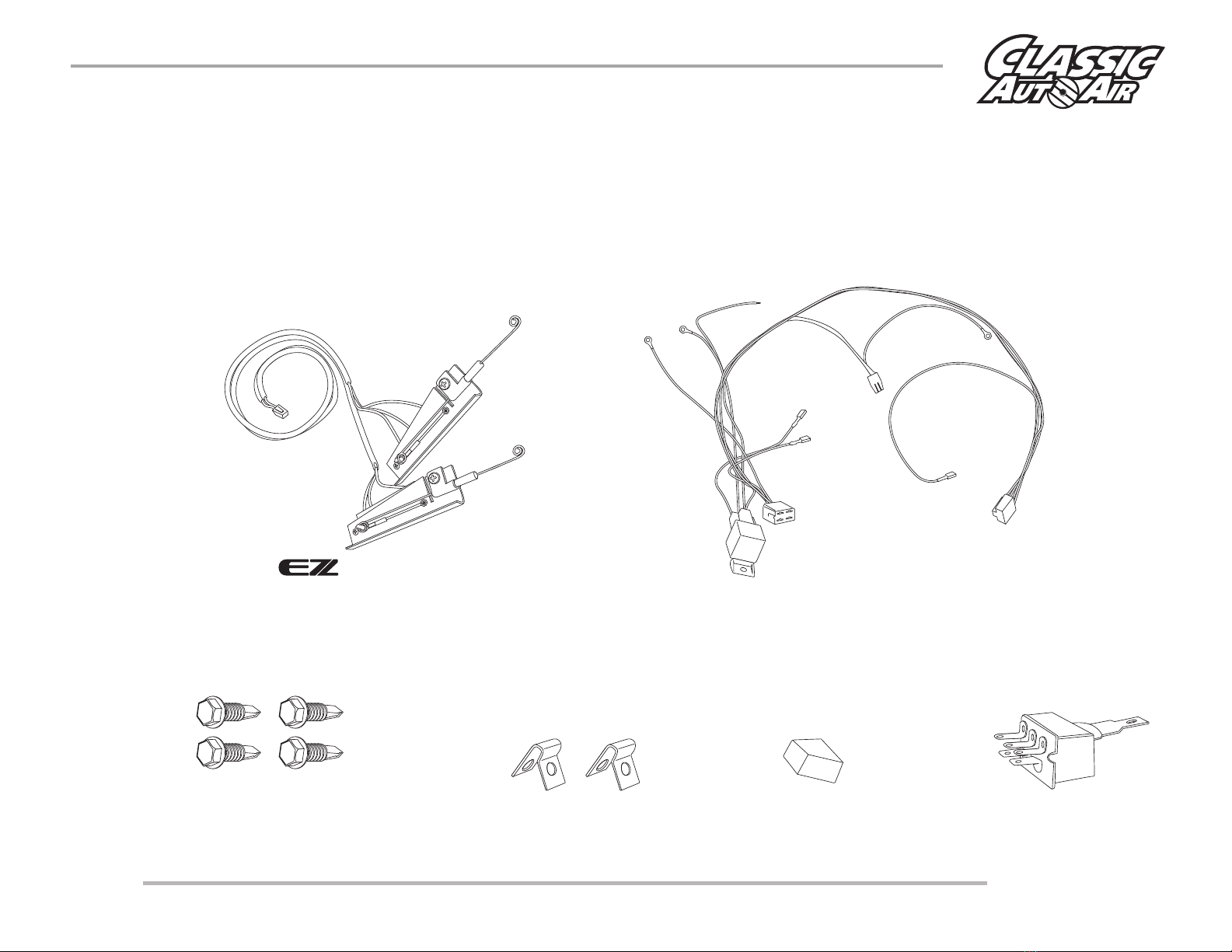

THESE ARE THE PARTS YOU WILL FIND IN BAG KIT B

You will use all of these parts and hardware during the next series of installation steps.

FACE/FLOOR

POWER

CONTROL

WATER VALVE

DEFROST

The ECU will be attached for shipping

purposes to the body of the

main unit. You will need to detach and mount

near your evaporator unit.

Harness System

Yellow

Orange

Two #10 - 16 x 3/4" Tek Screws

CLASSIC AUTO AIR

Page 6

NOTE: Illustrations NOT shown actual size

Blower Switch

Blower Switch Knob

Two - Cable Clips

CONTROLS

You will use these parts and hardware during the next series of installation steps.

Wiring Harness -

Power Supply

GroundGround Ground

OEM Power

Supply

ECU

Pressure Switch

(engine compartment)

Thermostat

Relay

Blower Switch

Connection

Fan

Plug

Four #10 - 16 x 3/4" Tek Screws

CLASSIC AUTO AIR

Page 7

Cable Integrators

EZ CABLE INTAGRATOR WITH LEVER SWITCH

NOTE: Illustrations NOT shown actual size

Two - Cable Clips

CONTROLS

You will use these parts and hardware during the next series of installation steps.

Rotary Wiring Harness -

Power Supply

GroundGround Ground

OEM Power

Supply

ECU

Pressure Switch

(engine compartment)

Thermostat

Relay

Blower Switch

Connection

Fan

Plug

Four #10 - 16 x 3/4" Tek Screws

CLASSIC AUTO AIR

Page 8

Cable Integrators

Rotary Blower Switch Rotary Blower Switch Knob

EZ CABLE INTAGRATOR WITH ROTARY SWITCH

NOTE: Illustrations NOT shown actual size

CONTROLS

You will use these parts and hardware during the next series of installation steps.

Wiring Harness -

Power Supply

GroundGround Ground

OEM Power

Supply

ECU

Pressure Switch

(engine compartment)

Thermostat

Relay

Blower Switch

Connection

Fan

Plug

Four #10 - 16 x 3/4" Tek Screws

CLASSIC AUTO AIR

Page 9

BILLET CONTROLS

Billet Controls

OFF 1

2

3

Adapting to OEM Contols:

If you specified our EZ Wire Cable system, we’ve included all the parts necessary for you to retain your OEM controls and adapt to your new A/C system. In order to

do this, you’ll need to remove your OEM temperature control head and move it to a workbench and follow thru the steps listed below. Because there is such a wide

variety of controls, these steps may have to be modified to adapt your particular controls. Adhere to some simple rules and you’ll be done in a short amount of time.

•Step 1: Remove the OEM blower switch and discard. Attach the included blower switch to your control head in place of the OEM switch. This may require some

fabrication.

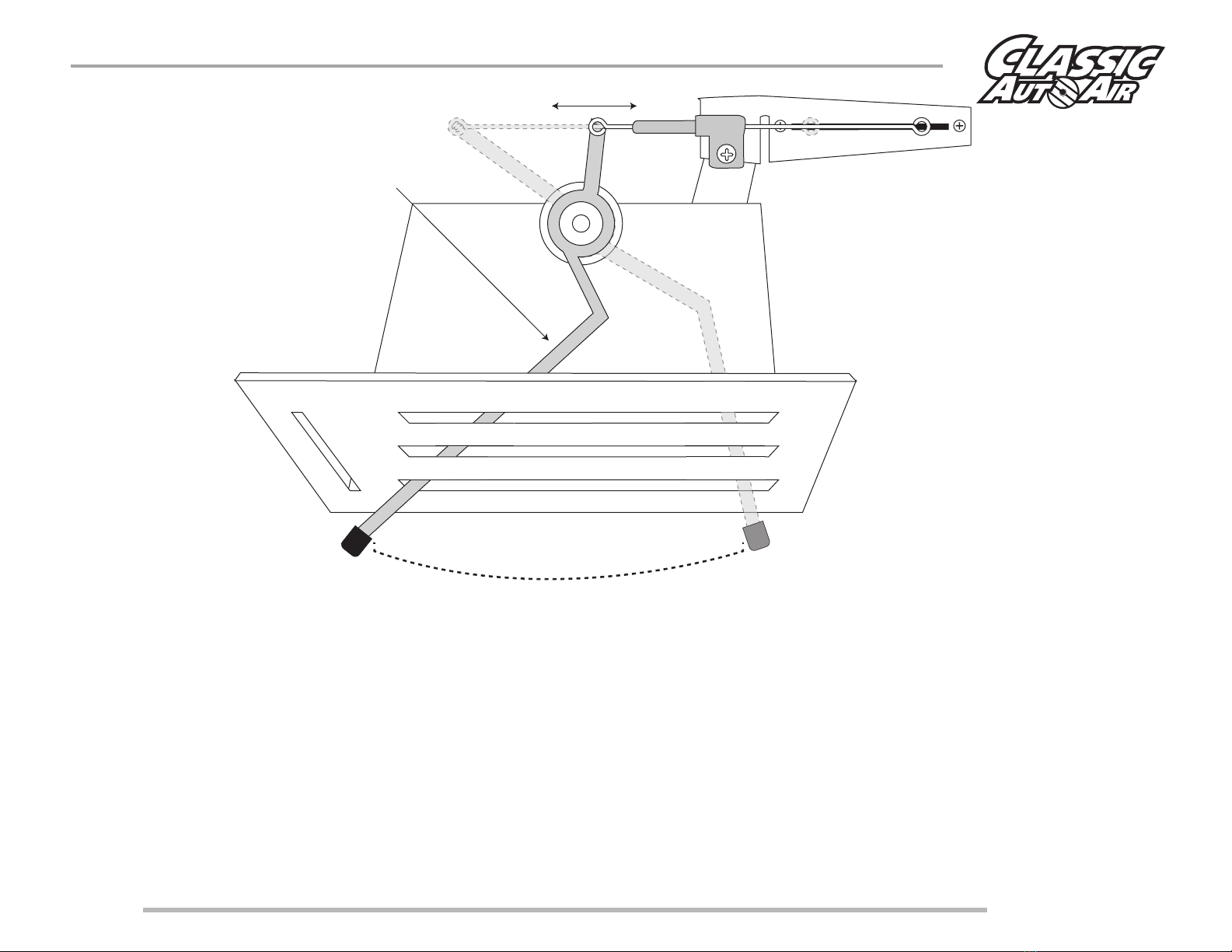

•Step 2: Looking at your OEM controls, identify which lever you want to use to control TEMPERATURE and which to control the MODE. Then from the back of the

control head, mark the appropriate levers with masking tape and their intended function (i.e. mode and temp).

•Step 3: Attach the included cable clips to each adaptor as shown in. You’ll use the these cable adaptors to secure the integrators to your OEM control head, or

you may have to attach the integrators in another manner. v

•Step 4: Position our EZ Wire Cable Adaptors in a manner that the wire-ends can be secured to the appropriate lever ends, and when you move the OEM levers

from one extreme to the other that the wire can move the actuators in a smooth and straight manner. The most important aspect is that your OEM levers,

which ever two you choose to use, move their entire possible distance of travel (when viewed from the front of the control head).

CLASSIC AUTO AIR

Page 10

FULL MOTION

EZ CABLE INTERGRATOR WILL BE

CALIBRATED TO MOTION OF OEM ARM.

OEM CONTROL MODIFICATIONS

Bench Calibration Steps 1

1

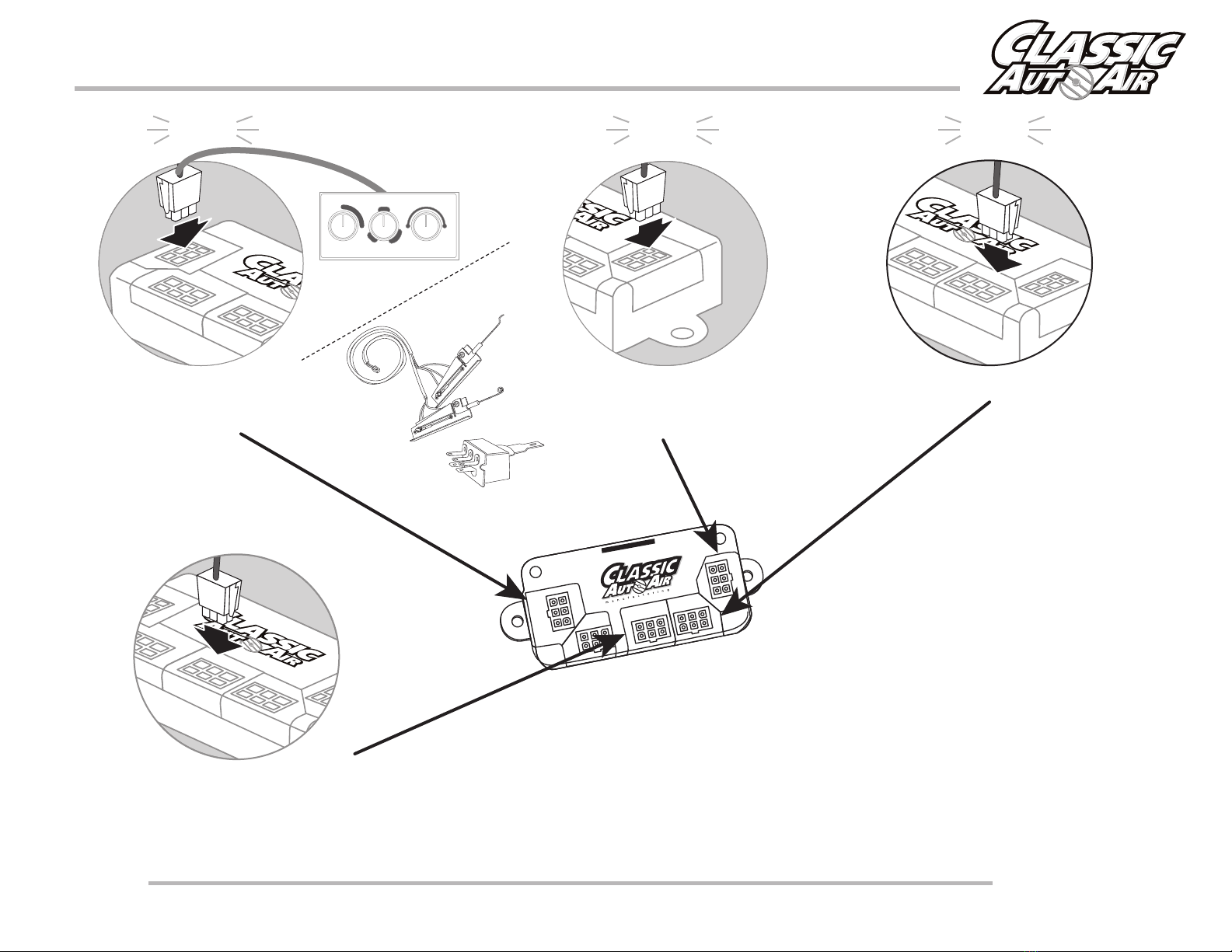

Connect Yellow Harness into Defrost/Heat Servo Motor

Connect Blue Harness into Dash Servo Motor

Click!

CLASSIC AUTO AIR

Page 11

Bench Calibration Steps 2 thru 5

FACE/FLOOR

POWER

CONTROL

WATER VALVE

DEFROST

2

Connect Yellow Harness into Face / Floor Port on ECU

Power

Control Water Valve

Face/Floor Defrost

Click!

3

Connect Orange Harness into Water Valve Port on ECU

Next route other end of harness out of firewall

opening

Power

Control Water Valve

Face/Floor Defrost

Click!

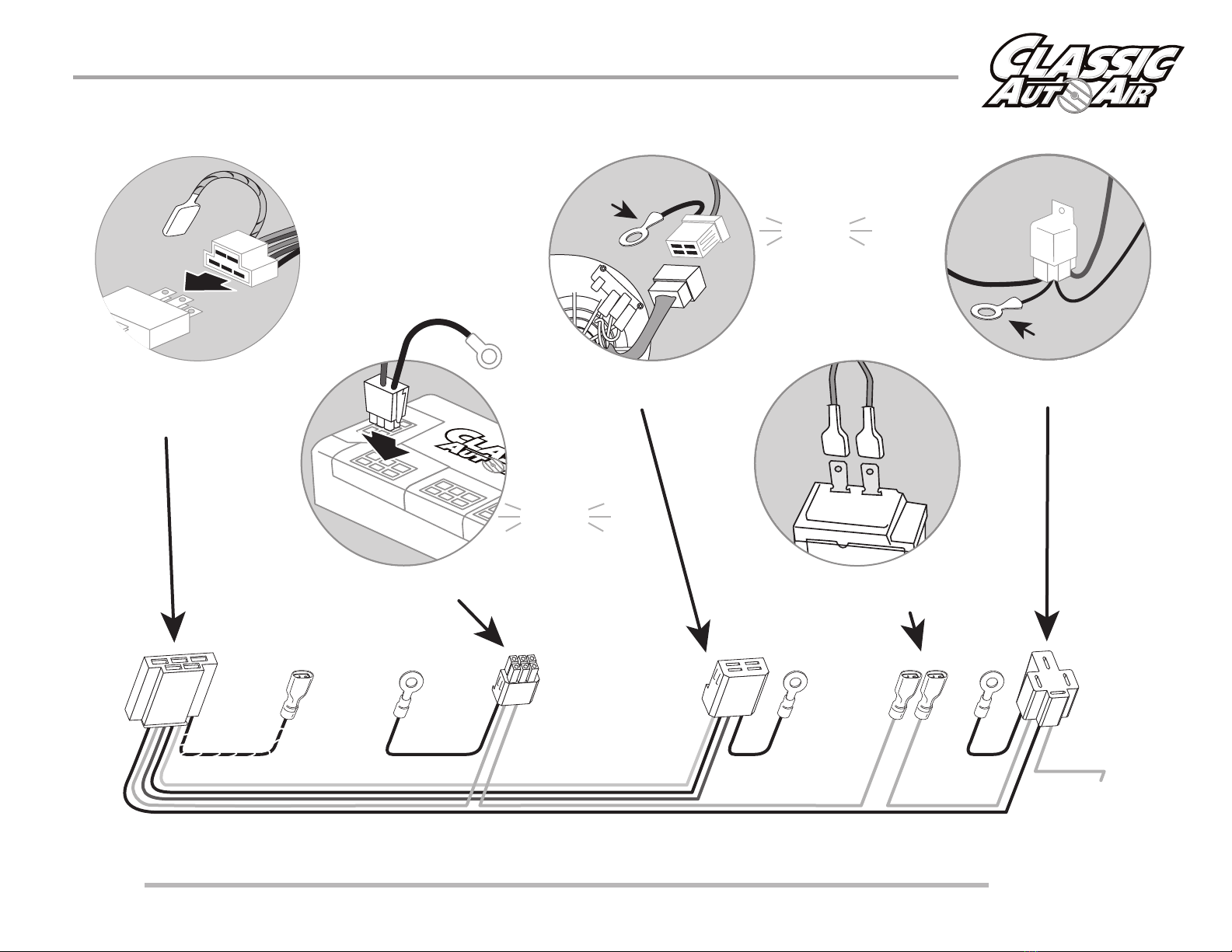

The next step is to utilize the main

wiring harness and the two

wire control harnesses we’ve

included, wiring per this diagram.

You have three ground wire

connections on the main harness

to make, one relay to secure, and

one power supply to connect to

your OEM fuse box. The wiring

harneses are color coded, just

follow the connections as

specified.

4

5

Click!

From your Controls,

Connect Green Harness into

Control Port on ECU

Power

Control Water Valve

Face/Floor Defrost

CLASSIC AUTO AIR

Page 12

Connect Blue Harness into Defrost Port on ECU

Power

Control Water Valve

Face/Floor Defrost

CLASSIC AUTO AIR

Page 13

2

3

4

15

12V

Power

Control Water Valve

Face/Floor Defrost

Grd -

Grd

Grd

Connect both BLUE leads into thermostat

(either lead into either terminal)

Connect ground.

Connect corresponding Fan Switch

harness to the Bower Switch on Controls

Connect Power lead

to 12V.

Connect corresponding fan motor harness.

Connect ground.

Connect red tagged power harness to POWER port on ECU.

Connect ground.

Grd -Grd -

12V Power

(20 amp fuse) Grd -

(Single white lead

is to be connected to the

pressure switch on the drier)

Click!

Click!

THE FOLLOWING BENCH CALIBRATION & OPERATION PAGES

ARE FOR BILLET AND SPECIALTY CONTROLS.

IF YOU PURCHASED A EZ CABLE INTEGRATOR SET UP

PLEASE SKIP TO PAGES 18-22.

ATTENTION

CLASSIC AUTO AIR

Page 14

OFF 1

2

3

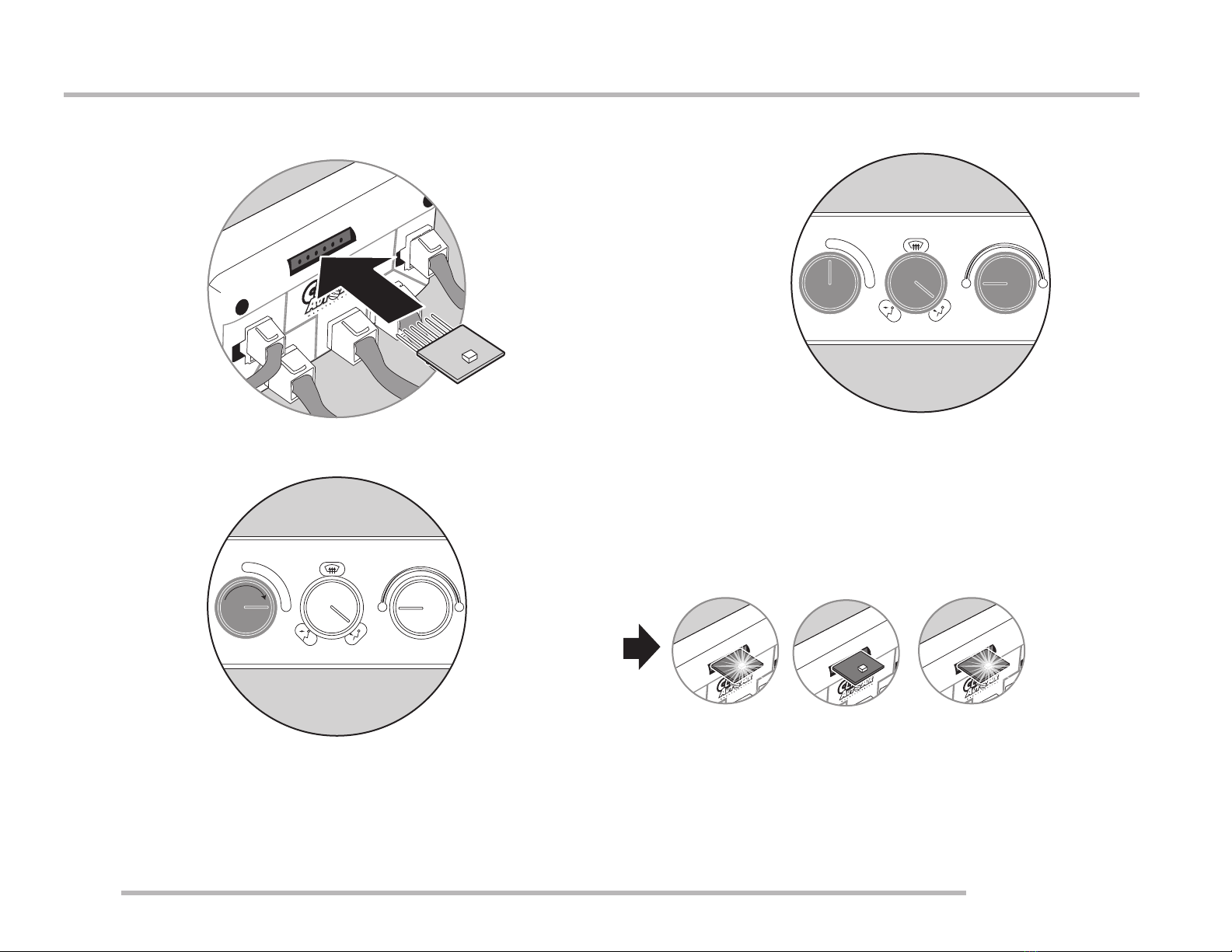

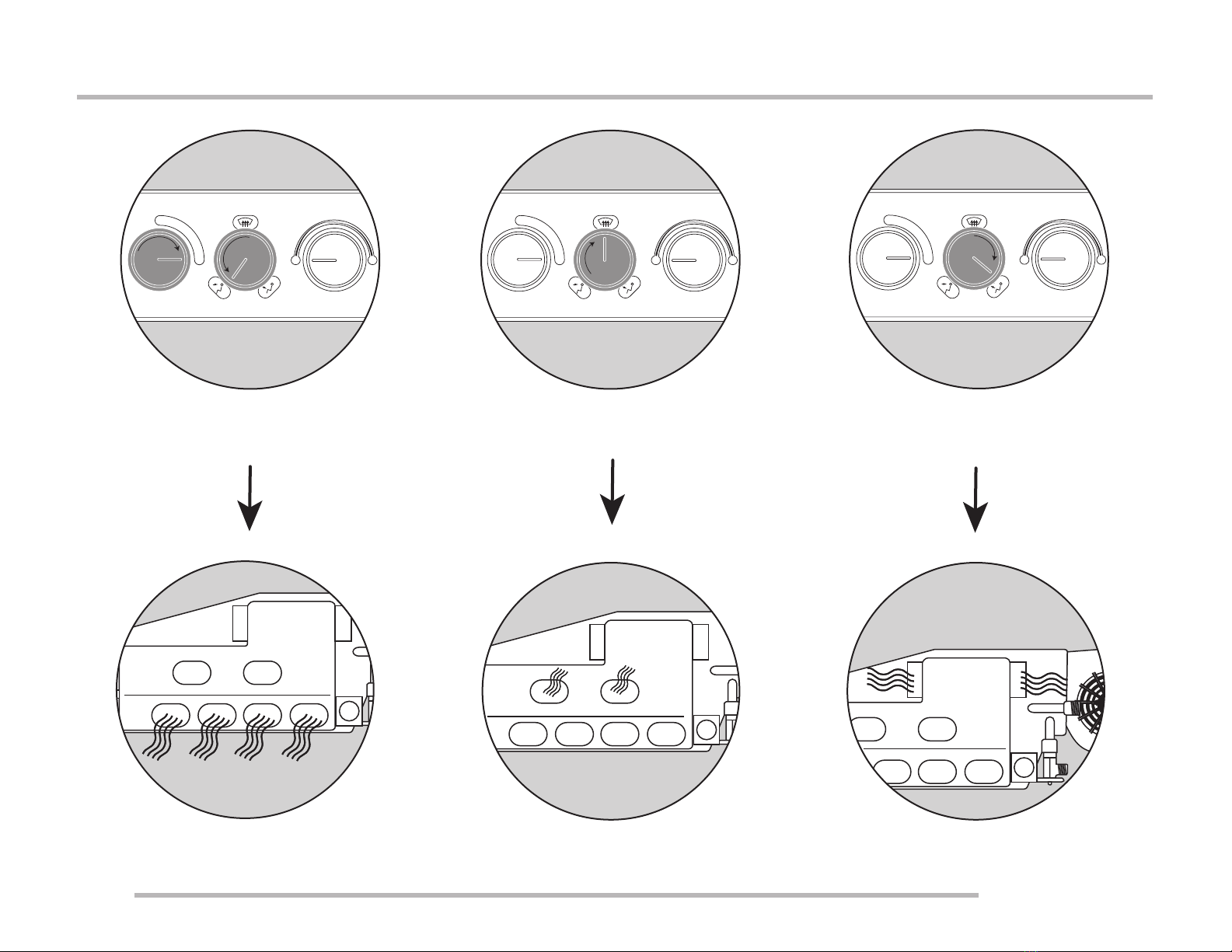

BENCH CALIBRATION & OPERATION •Calibration, Steps 1 thru 3

CLASSIC AUTO AIR

Page 15

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED OFF

1

3

Insert Calibration Key as shown (LED side up) into 6-pin

connection in ECU

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

YOU WILL SEE...

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED ON

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED ON

Calibration KeyCalibration Key

2

Start by positioning the knobs as shown:

Fan: Off

Mode: Floor

Temp: Cold

Move Fan Knob to High...

OFF 1

2

3C H

OFF 1

2

3C H

BENCH CALIBRATION & OPERATION •Calibration, Steps 4 and 5

CLASSIC AUTO AIR

Page 16

4

5

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED OFF

Move MODE knob to DASH

in one motion

AFTER YOU MOVE THE KNOB YOU WILL SEE...

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED ON

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED OFF

Move TEMP knob to HOT

in one motion

AFTER YOU MOVE THE KNOB YOU WILL SEE...

OFF 1

2

3C H

OFF 1

2

3C H

BENCH CALIBRATION & OPERATION •Calibration, Steps 6 thru 8

CLASSIC AUTO AIR

Page 17

6

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

7

8

CONTROL

POWER

DEFROST

WATER VALVE

FACE/FLOOR

Calibration KeyCalibration Key

LED OFF

Move FAN knob to OFF

REMOVE CALIBRATION KEY FROM ECU AND

STORE IN A SAFE PLACE

You will be able to hear the

internal door(s) move back

and forth and feel air

coming out of the outlets

OFF 1

2

3C H

BENCH CALIBRATION & OPERATION •Function Test, Steps 1 thru 3

CLASSIC AUTO AIR

Page 18

2 3

Move FAN knob to HIGH

Move MODE knob to DASH

Move MODE knob to DEFROST Move MODE knob to FLOOR

AIR OUT OF DASH VENTS AIR OUT OF DEFROST VENTS AIR OUT OF FLOOR

1

OFF 1

2

3C H

OFF 1

2

3C H

OFF 1

2

3C H

This manual suits for next models

1

Table of contents

Other Classic AutoAir Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Whelen Engineering Company

Whelen Engineering Company SA315 installation guide

Diode Dynamics

Diode Dynamics Demon Eyes installation guide

Innovate Motorsports

Innovate Motorsports PSB-1 user manual

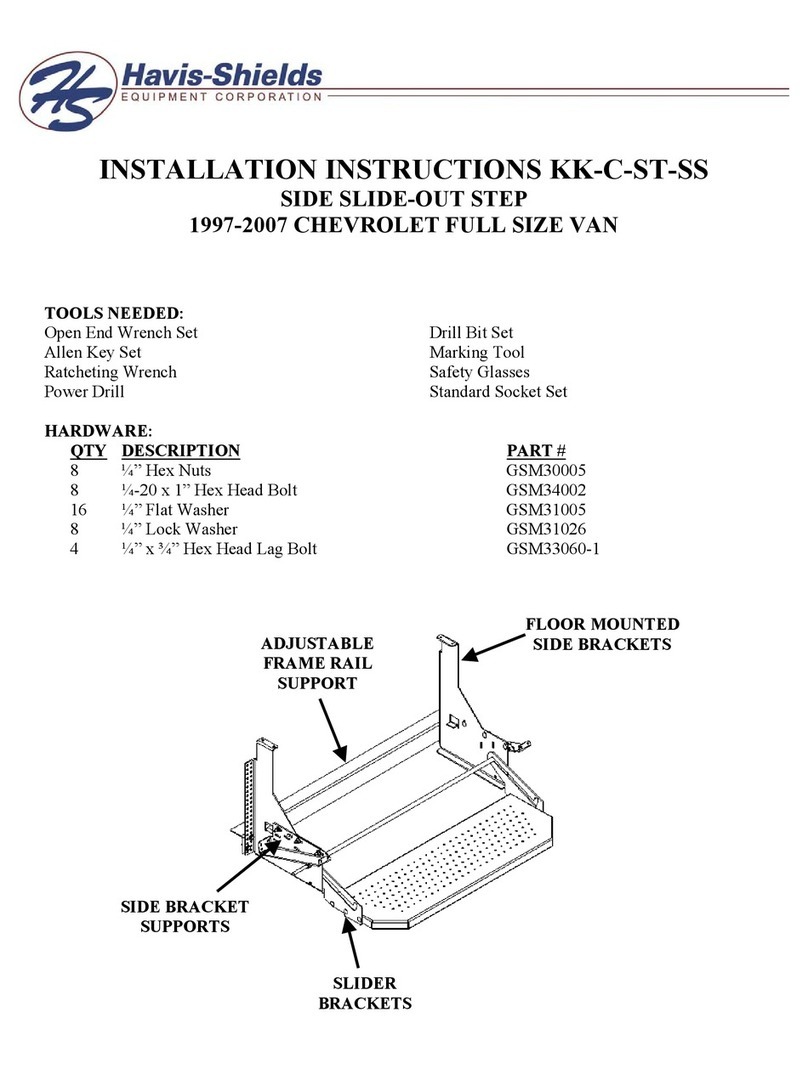

Havis-Shields

Havis-Shields Side Slide-Out Step 1997-2007 Chevrolet Full Size Van... installation instructions

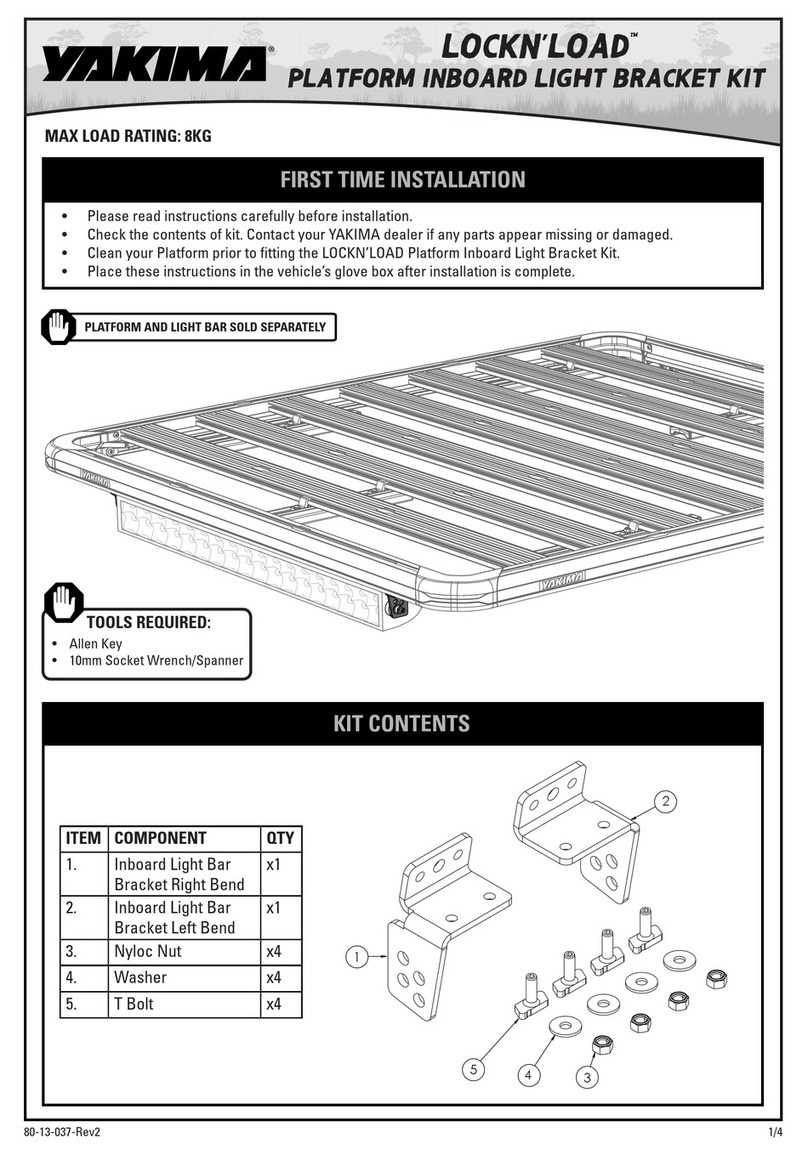

Yakima

Yakima LOCKN'LOAD instructions

Dobinsons

Dobinsons BU59-3506 installation guide