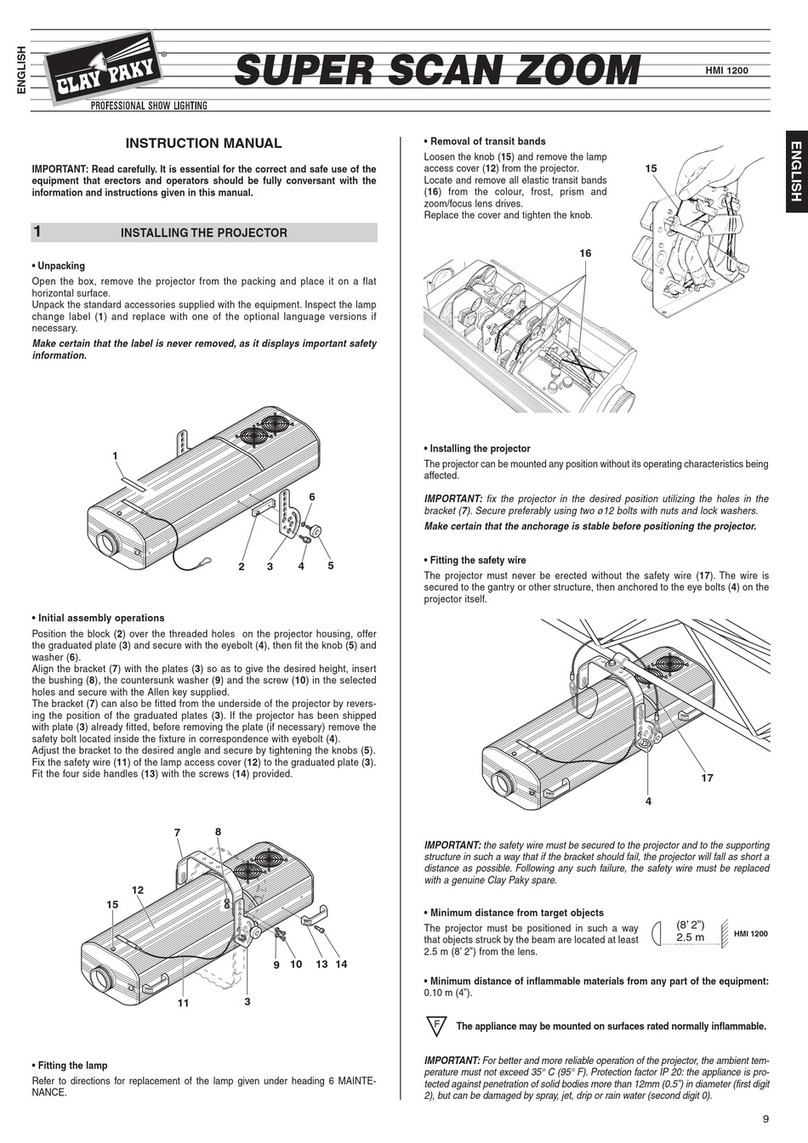

15

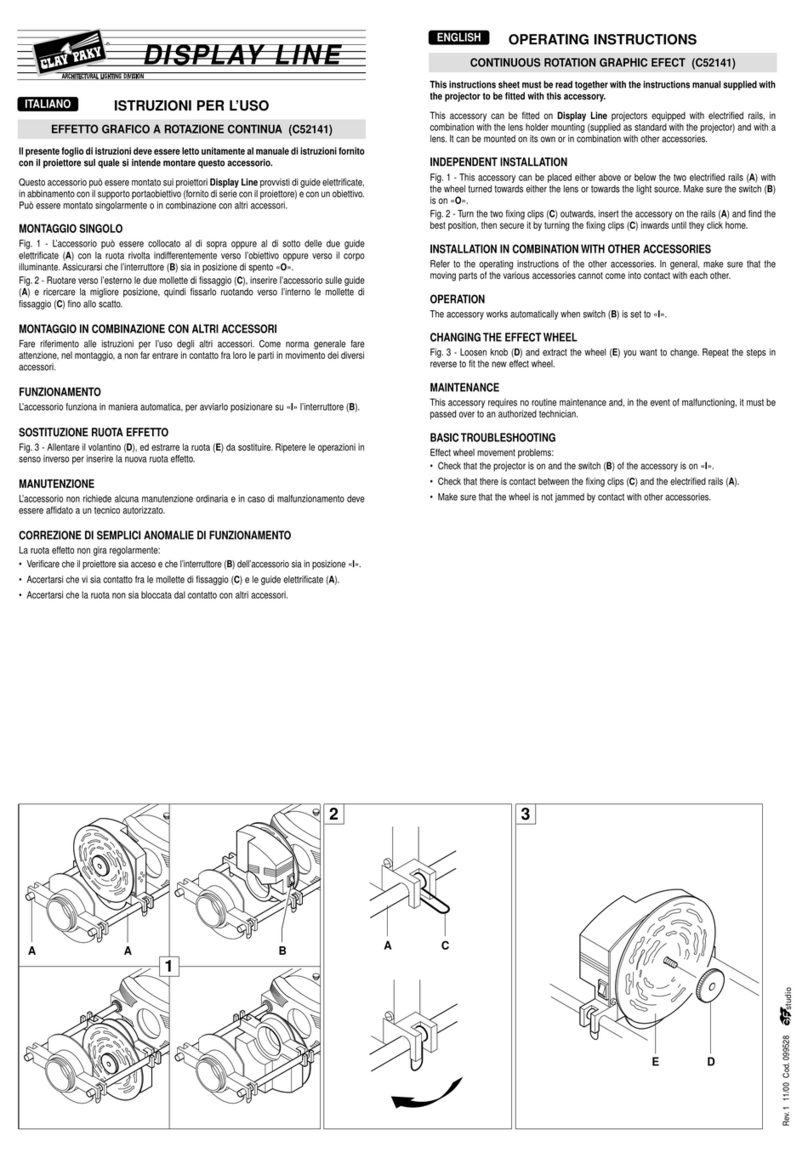

IMPORTANT: for uniform distribution of the light beam, the lamp must be positioned

so that the glass pip (39) on the bulb does not coincide with the optical axis of the

projector.With this in mind, locate the pip as high up as possible.

CAUTION: The projector uses a high pressure discharge lamp with

external starter.

- When fitting a new lamp, read the manufacturer’s instructions carefully.

- The lamp must always be changed without delay if damaged or deformed

by heat.

• Routine cleaning

To maintain the light output of the

projector undiminished, parts that

tend to accumulate dust and

grease must be cleaned periodi-

cally.

In most circumstances, the projec-

tor will give long and trouble-free

service if these simple guidelines

are followed.

To remove dirt from the lenses

and filters, use a soft cloth moist-

ened with any liquid detergent

suitable for cleaning glass.

IMPORTANT: do not use solvents or alcohol.

Parts that need cleaning frequently.

Parts that need cleaning monthly.

The gobo wheel can be cleaned with a

paintbrush.

Internal components should also be given

a general clean once a year, dislodging

dust and dirt with a brush and removing it

simultaneously with a vacuum cleaner.

• Lubrication of mirror head

clutches

Check periodically that the grease

applied to the mirror pan and tilt

clutches is in good condition; if not,

remove and regrease with Kernite

LUBE-K-AC (p/n 104034/801) to

ensure smooth and even movement

of the mirror.

42

43

44

41

40

•

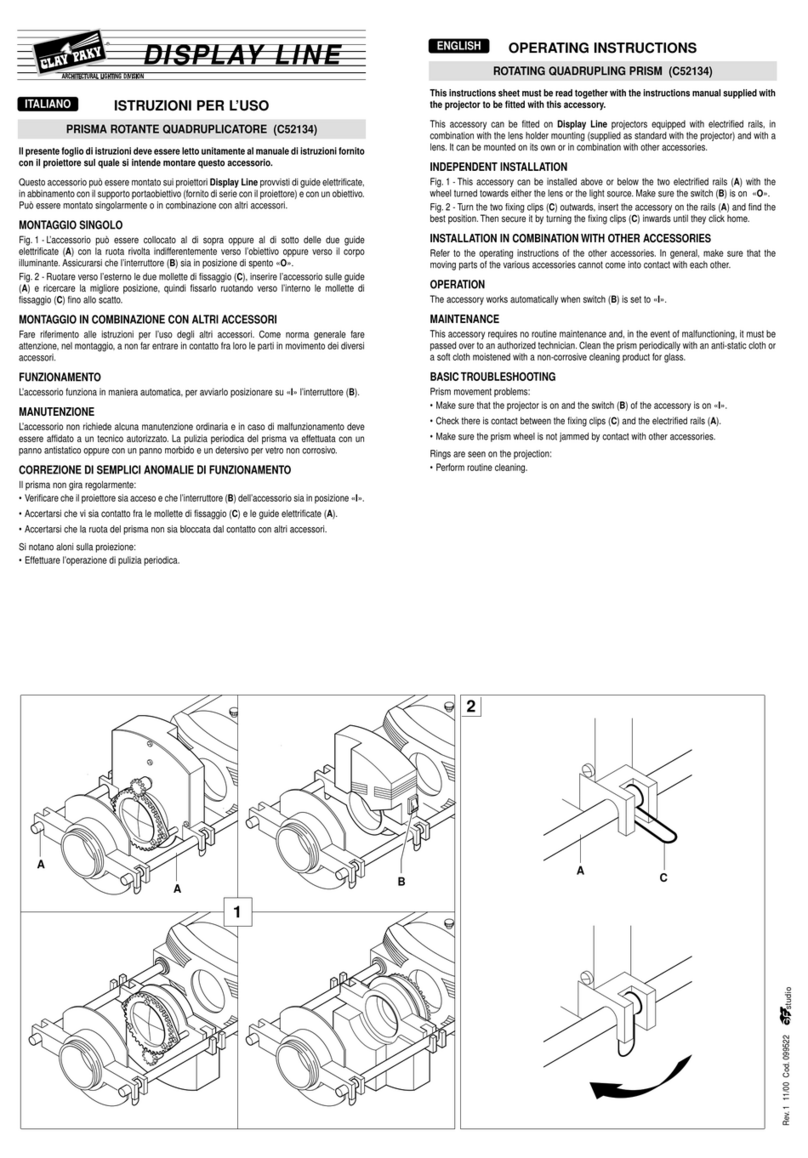

Changing the colour filters

Having opened the projector, identi-

fy the filter to be changed, grip firm-

ly between thumb and forefinger and

push against the spring clip (40) until

free of the fixed clips (41).

Bend the filter outwards and

remove.

Offer the new filter to the spring clip

(40) and anchor behind the fixed

clips (41).

• Changing metal gobos

Having opened the projector, identi-

fy the gobo to be replaced and push

gently toward the clips (42) until

free.

Take the selected replacement from

the holder (43) on the gobos/iris

plate.

Offer the new gobo to the two clips,

push gently and locate behind the

third, checking for flatness.

• Changing dichroic/photo gobos

Having opened the projector, identi-

fy the dichroic gobo to be replaced

and push gently until the spring (44)

is free of its seat.

Take care that the spring does not

drop into the projector. Replace the

gobo and locate the spring (44),

inserting the two ends first and then

making secure by pressing on the

remaining part of the spring.

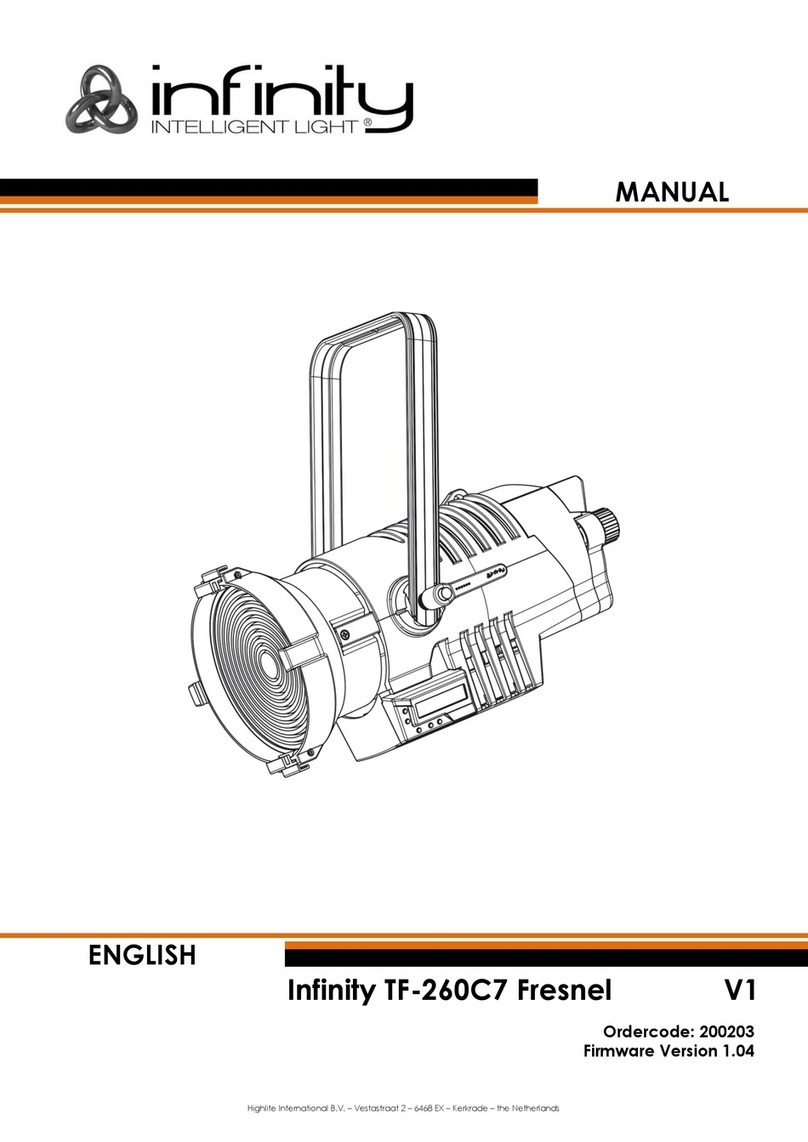

• Changing the lamp

Open the projector, loosen the two side nuts (37) of the lamp to be changed and

remove it from the supports (38).

Remove the new lamp from its packaging, loosen the two side nuts (37) and locate

the lamp in the supports (38). Finally, retighten the nuts.

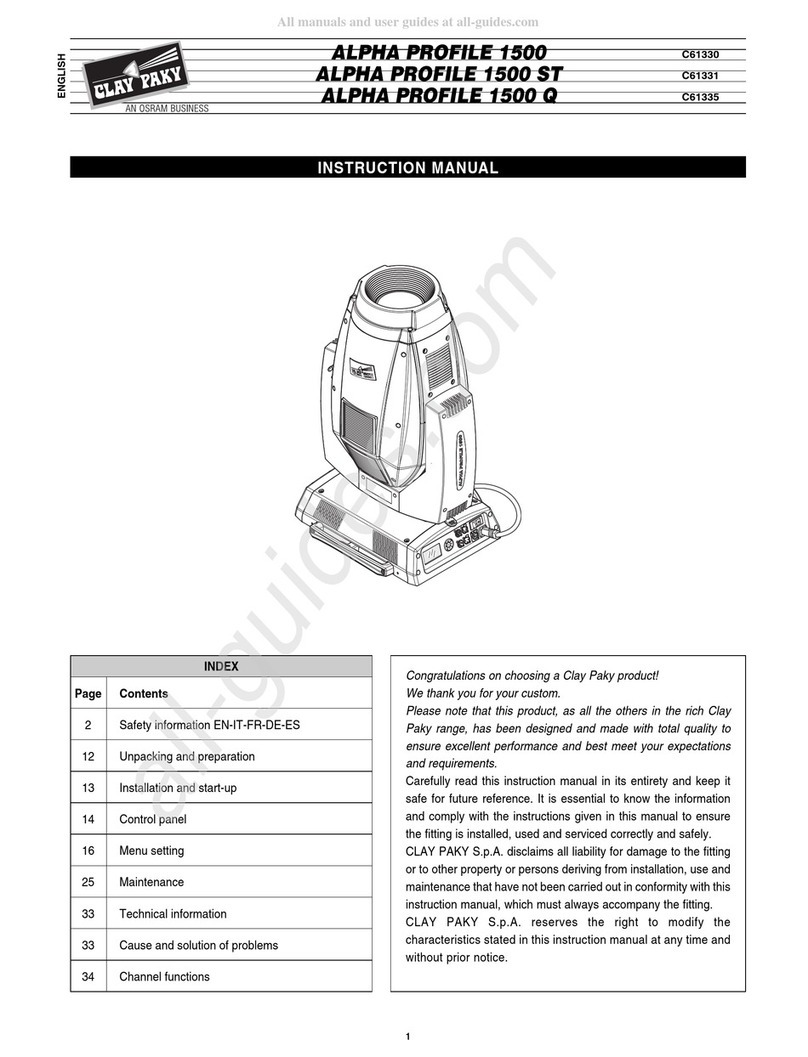

MAINTENANCE

7

136121615

37

38

IMPORTANT: isolate the projector from the electrical power supply before com-

mencing maintenance work of any description.

The maximum temperature on the outer surface of the projector under normal

operating conditions is 90 °C (194° F). After switching off, do not remove any part

of the projector for at least 10 minutes, as indicated on the lamp change label (1).

Once this time has elapsed, the risk of a lamp exploding is practically zero.

If the lamp needs changing, wait a further 20 minutes to avoid the risk of burns.

In the event of a lamp exploding, the appliance is designed to prevent fragments

of glass from being scattered. Lenses and clear filters supplied with the appliance

must be fitted at all times, and if visibly damaged must be replaced promptly with

genuine spares.

• Opening the projector

Free the lamp access cover (12) by loosening the knob (36), and/or loosen the

knob (15) to allow removal of the effects cover (16). Once the necessary work

has been completed, refit the cover and retighten the knob.

39 37

ENGLISH

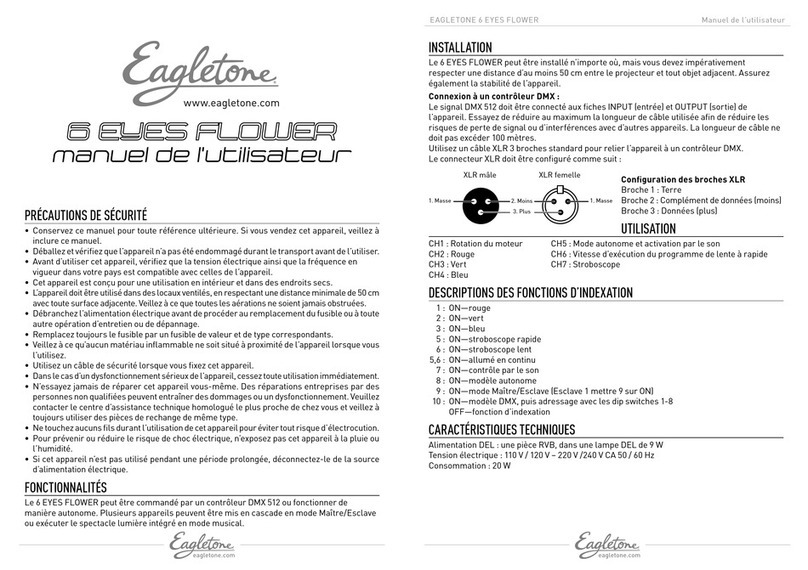

• Lubrication

To ensure that rotating gobos and

prisms continue to operate smoothly,

the bearings should be lubricated with

oil every six months: use only Kernite

LUBE-K-AHT (p/n 164028/801).

Apply the oil using a syringe with a fine

needle.Avoid over-lubricating, as excess

oil could be spattered during rotation.

The rails of the focusing mechanism

should be cleaned and lubricated using

a cloth moistened with Kernite WAY-LUBE

oil (p/n 172063/801).