CLEAN COMFORT AE14-1620-51 User manual

IO-AE14-5 WWW.CLEANCOMFORT.COM 11/15

FILTRATION

FILTRATION

AIR CLEANERS

IMPORTANT: READ AND SAVE THESE INSTRUCTIONS. THIS GUIDE TO BE LEFT WITH EQUIPMENT OWNER.

i

HIGH EFFICIENCY

ELECTRONIC AIR CLEANER

Installation & Operation Manual

MODELS

AE14-1620-51 • AE14-1625-51 • AE14-2020-51

AE14-2025-51 (120 VAC)

AE14-1620-52 • AE14-1625-52 • AE14-2020-52

AE14-2025-52 (240 VAC)

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

2

INTRODUCTION

IO-AE14-5

INTRODUCTION ................................................. 3

What the Air Cleaner Does .............................................3

Features and Benets.....................................................3

How It Works ..................................................................3

SPECIFICATIONS................................................. 4

Components ...................................................................4

Stac Pressure ................................................................5

INSTALLATION ................................................... 5

Locaon ..........................................................................5

Installaon Locaon With Humidier.............................6

Installaon Locaon With Air Condioner .....................6

Installaon Steps ............................................................6

WIRING ...........................................................................7

System Check.................................................................. 7

Operaon........................................................................ 7

CHECKOUT .......................................................... 8

CHECKOUT - Visual..........................................................8

CHECKOUT - Operaonal................................................ 8

MAINTENANCE................................................... 9

Cell and Prelter Cleaning ..............................................9

Cleaning the Collector Cells ...........................................9

Cleaning the Prelters .................................................... 9

Reinstalling the Cells and Prelters ..............................10

Replacing the Carbon VOC lters..................................10

Maintenance Parts ....................................................... 10

TROUBLESHOOTING ........................................ 11

Tesng For High Voltage at Power Board......................11

Measuring High Voltage at Power Board......................11

Tesng Air Proving Switch (APS) .................................. 12

Tesng the 24 V Transformer........................................12

Seng Voltage of Power Board ...................................13

Tesng for Voltage at The Cell ..................................... 13

Tesng Cell for Bad Contacts ........................................13

Tesng Cell with an Ohmmeter ....................................13

SERVICE ............................................................. 16

Replacing a Performance Light .....................................16

Replacing a Power Board.............................................. 16

Replacing the 24 V Transformer ...................................16

Replacing an Air Proving Switch (APS) .........................17

Removing Power Box ...................................................17

Replacing a Tungsten Ionizing Wire..............................17

PARTS LIST ........................................................ 18

LIMITED WARRANTY........................................ 20

Proprietary Notice

This document and the informaon disclosed herein are

proprietary data of Daikin North America LLC. Neither

this document nor the informaon contained herein

shall be reproduced, used, or disclosed to others without

the wrien authorizaon of Daikin North America LLC,

except to the extent required for installaon or

maintenance of recipient’s equipment.

Liability Notice

Daikin North America LLC does not accept any liability

for installaons of air cleaning equipment installed by

unqualied personnel or the use of parts/components/

lters/equipment that are not authorized or approved

by Daikin.

Copyright Notice

Copyright 2015, Daikin North America LLC

All rights reserved.

Our connuing commitment to quality products may

mean a change in specicaons without noce.

© 2015 DAIKIN NORTH AMERICA LLC

Houston, Texas • USA

www.cleancomfort.com

1-800-267-8305 • Fax: 1-416-213-5593

iWARNING!

Before beginning any installaon or modicaon,

be certain that the main line electrical disconnect

switch is in the OFF posion. Unexpected start-up

of system blower may cause serious injury. Tag

disconnect switch with suitable warning labels.

iCAUTION!

Read and follow instrucons carefully. Follow all local

electrical codes during installaon. All wiring must

conform to local and naonal electrical codes.

Improper wiring or installaon may damage air cleaner.

Only a heang/air condioning installer or qualied

service person should install your air cleaner, unless

you are completely familiar with the necessary tools,

equipment and potenal hazards involved. If you plan

to install this air cleaner yourself, please be aware that

the improper use of any tool can be dangerous.

The manufacturer will not assume any responsibility

for failures due to incorrect installaon procedures.

• Homeowners can perform the basic maintenance

funcons of cleaning cells and replacing lters.

• When working on the air cleaner, observe precauons

in the Owner’s Manual, labels aached to the furnace

or air handler, and other safety precauons that may

apply. Follow all safety codes. Wear safety glasses and

work gloves.

READ AND SAVE THESE INSTRUCTIONS

Certied for shock and electrical re hazard only

iWARNING!

This symbol indicates important instrucons. Failure to

heed them can result in serious injury or death.

iCAUTION!

This symbol indicates important instrucons. Failure to

heed them can result in injury or material property damage.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 3

INTRODUCTION

IO-AE14-5

What the Air Cleaner Does

The Clean Comfort AE14 Series of Electronic Air Cleaners help

remove a wide range of airborne parcles as small as 0.06

micron (1/424,000 of an inch).

Features and Benets

• Two aluminum mesh prelters help prevent lint and

large parcles from entering the collecng cells.

• Features a permanent, washable lter system

• Heavy-gauge aluminum collecng cells are durable and

easy to maintain.

• Washing the collecng cells takes only 15 minutes.

• Acvated carbon VOC lters help remove unpleasant

odors (such as those from cooking, smoking, or other

household acvies).

• Helps protect heang/cooling equipment, prolonging the

operang eciency

• Helps improve indoor air quality for a more comfortable

environment, year-round.

• Electronic air-proving switch automacally cycles

air cleaner ON and OFF with the system fan.

• Power switch (orange) indicates when the air cleaner is powered.

• Performance indicator light (green) indicates when

the air cleaner is operang.

• Heavy-gauge galvanized steel cabinet.

• Can be installed in either vercal or horizontal orientaon.

How It Works

This electronic air cleaner operates on the principle of

electrostac precipitaon. Return air ducts of heang and

cooling systems carry airborne parcles to the air cleaner

where the air is treated with four stages of ltraon.

1. The prelter removes all large, visible parcles such as

lint and pet hair.

2. Smaller parcles not caught by the prelters then enter a

two-stage electrostac collecng cell where they are given

a powerful posive electrical charge by the ionizing wires.

3. These charged parcles then enter the collecng area of

the cell where they are aracted to a series of electrically

grounded plates. Parculates become aached to these

plates by electrostac forces, much like iron lings are

aracted to a magnet. They remain aached to the

collecng plates unl they are washed away when the

unit is cleaned as part of its scheduled maintenance.

4. Finally, air exing the collecng cell passes over acvated

carbon VOC lters which help reduce unpleasant odors,

such as those from cooking, smoking or painng.

Figure 1

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

4IO-AE14-5

SPECIFICATIONS

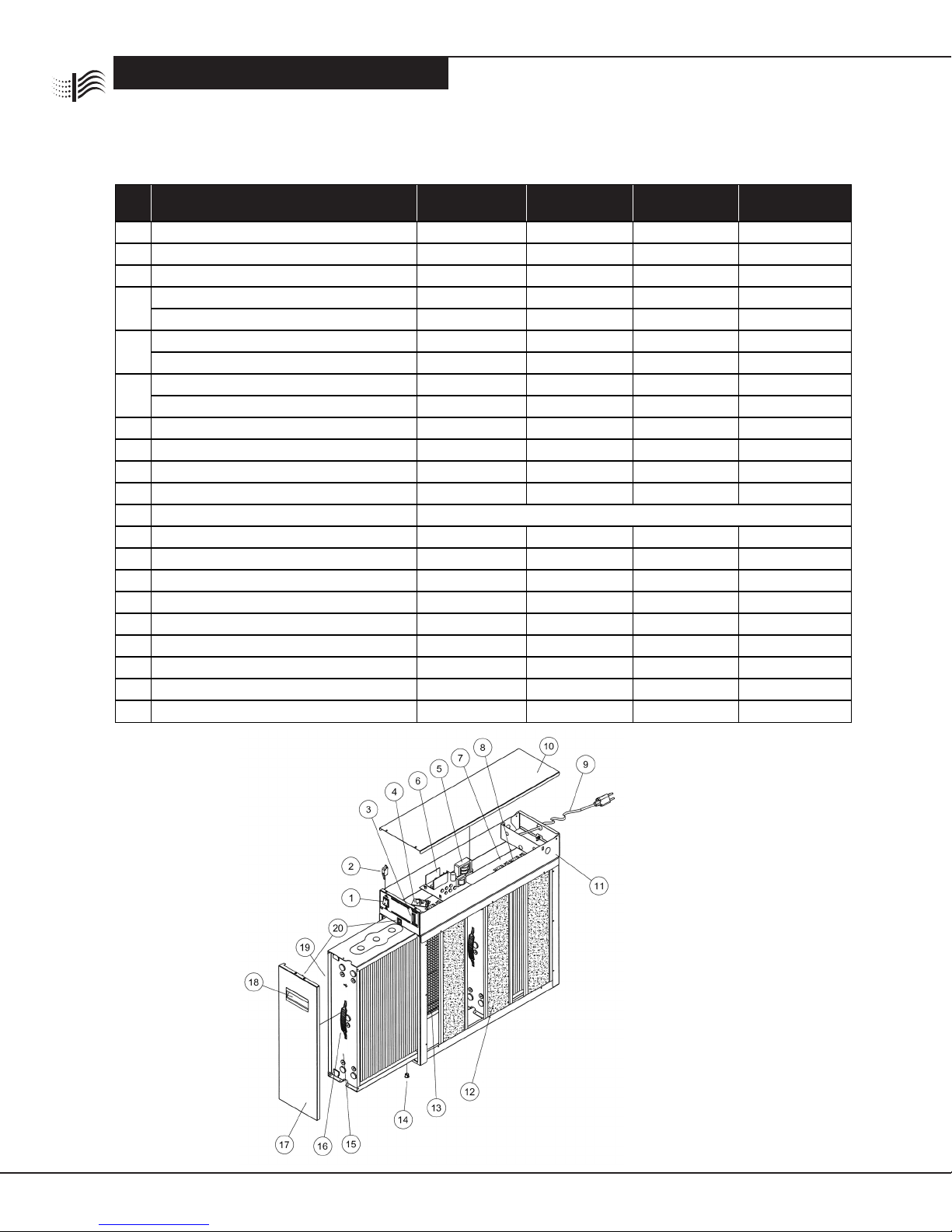

Table 1: Specicaons

Components

Cabinet: Constructed of heavy gauge galvanized steel

to resist corrosion and provide trouble-free installaon.

Holes are provided to facilitate mounng to the

ductwork or air handling equipment.

Power Box: Removable. Contains the power switch,

performance indicator light, safety interlock switch,

high-voltage power board, air-proving switch and

high-voltage contacts.

The power board is equipped with a variable resistor

(potenometer) to adjust high-voltage output. Output

has been pre-set for opmum eciency. As voltage

varies in extreme condions of dryness, humidity, or

proximity to hydro towers, raising or lowering

potenometer allows for proper voltage output.

Air-Proving Switch (APS): Integrated. Automacally

cycles air cleaner ON and OFF with the system fan.

The APS will detect airow (fan on) and energize the

air cleaner.

Collecng Cells: Consist of an ionizing secon and a

collector plate secon. The arrow on the cell must point

toward the system fan (in the direcon of the airow).

Prelters: Constructed of aluminum mesh to prevent lint

and large parcles from entering the collecng cells.

Carbon VOC Filters: Remove odors. Maximum of (3)

carbon VOC lters can be used at the same me.

120V MODELS AE14-1620-51 AE14-1625-51 AE14-2020-51 AE14-2025-51

240V MODELS AE14-1620-52 AE14-1625-52 AE14-2020-52 AE14-2025-52

House Size Area

(typical)

up to 2400 ²

up to 223 m²

up to 3000 ²

up to 279 m²

up to 3000 ²

up to 279 m²

up to 4000 ²

up to 372 m²

Airow

up to 1200 CFM

up to 2040 m³/hr

up to 1400 CFM

up to 2380 m³/hr

up to 1400 CFM

up to 2380 m³/hr

up to 2000 CFM

up to 3400 m³/hr

Duct Size

16 x 20 in

40.5 x 51.0 cm

16 x 25 in

40.5 x 63.5 cm

20 x 20 in

51.0 x 51.0 cm

20 x 25 in

51.0 x 63.5 cm

Unit Weight

35 lbs

15.9 kg

37 lbs

16.8 kg

37 lbs

16.8 kg

41 lbs

18.6 kg

Input Voltage

AE14-XXXX-51 models

AE14-XXXX-52 models

120 V 60 Hz

220 V 50 Hz

120 V 60 Hz

220 V 50 Hz

120 V 60 Hz

220 V 50 Hz

120 V 60 Hz

220 V 50 Hz

Power Consumpon

(when operang)

30 Was

30 Was

30 Was 30 Was

Opons Available • Power Cord • Power Cord • Power Cord • Power Cord

Cercaons: C22.2 NO. 187-09 (R2014) – CSA Standard for Electrostac Air Cleaners UL 867 UL Standard for Electronic Air Cleaners.

This device is cered for shock and electrical hazard only

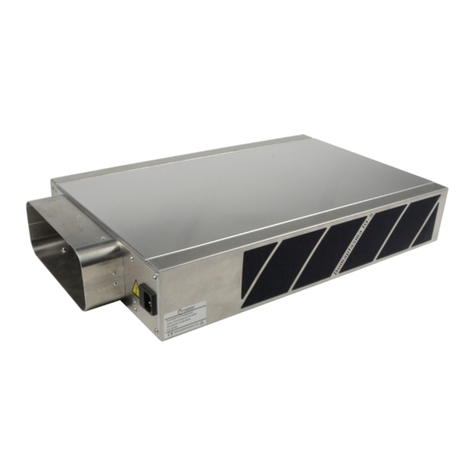

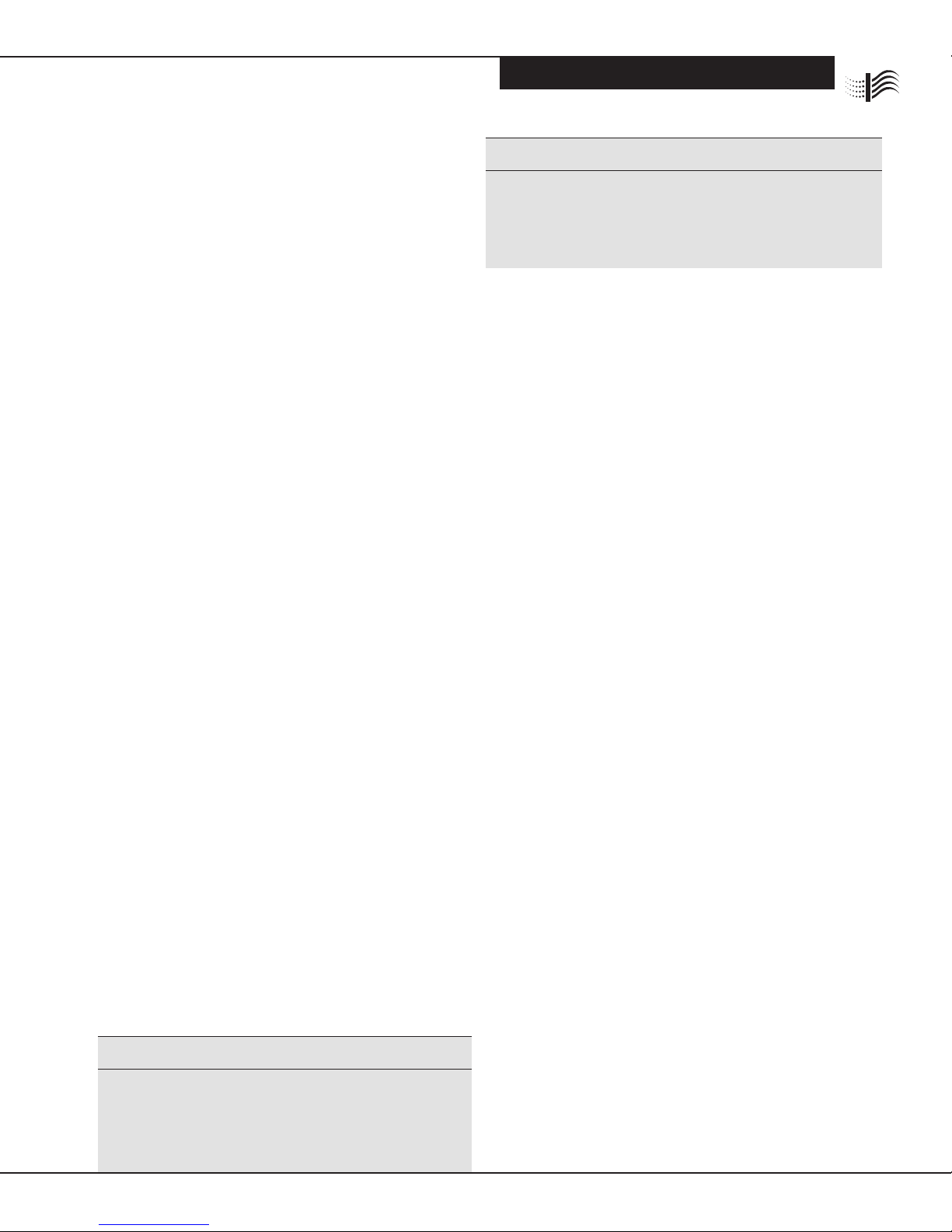

Figure 2

Collecting cells (2)

Prefilters (2)

Cabinet

Power box

Performance

indicator light

Power switch

Door

Activated carbon VOC

filters (3)

Figure 2: Air Cleaner Components

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 5

IO-AE14-5

INSTALLATION

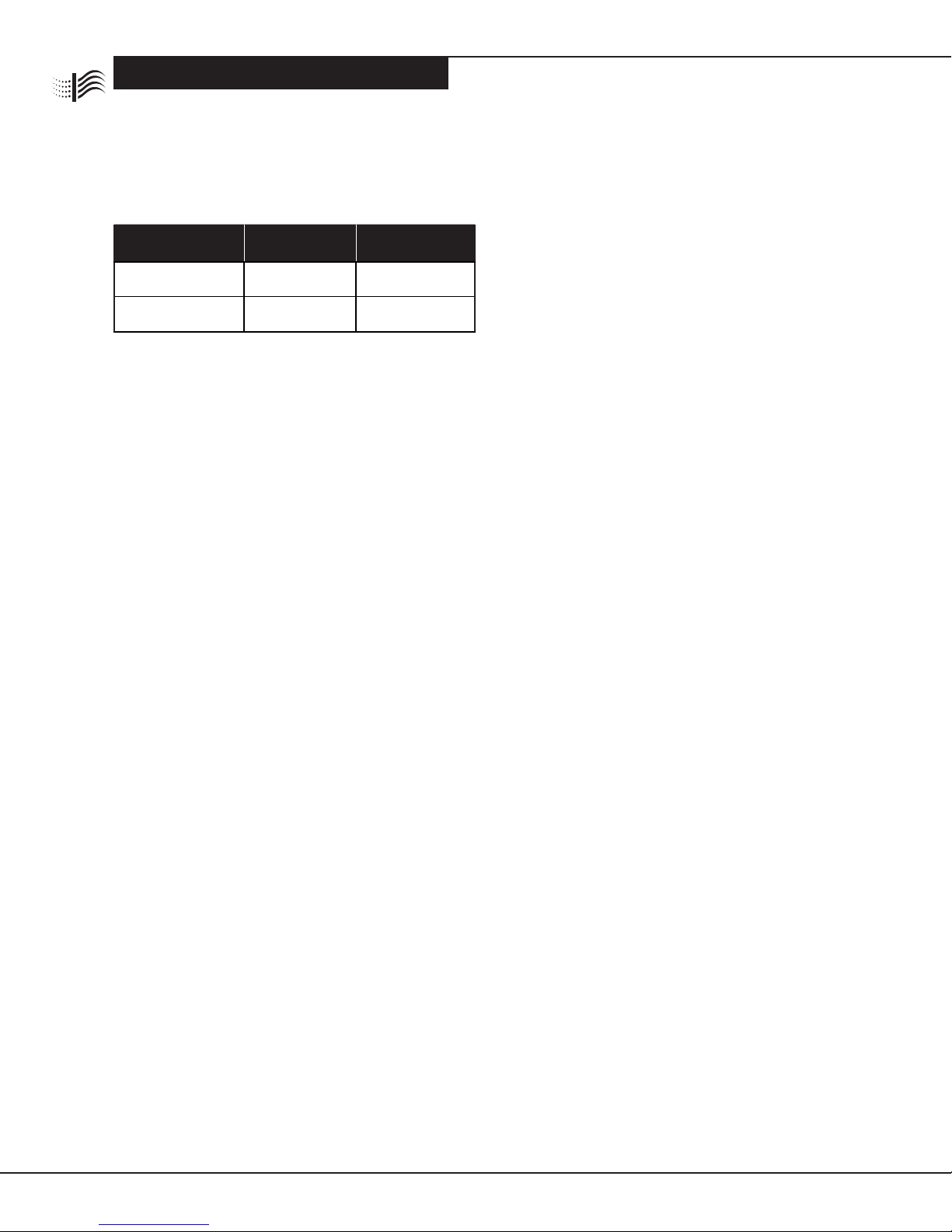

100% Airow

No Carbon

VOC Filters

100% Airow

With Carbon

VOC Filters

40% Airow

No Carbon

VOC Filters

40% Airow

With Carbon

VOC Filters

0.158 0.250 0.030 0.060

Static Pressure

The stac pressure drop across the air cleaner will vary

with CFM and whether the carbon VOC lters have been

installed in the unit.

Table 2: Pressure Drop (Inches w.c.)

Installation

Locaon:

The air cleaner must only be installed in the return air duct,

as close to the fan compartment as possible. This locaon

provides the most even airow across the collecng cells

and helps the air cleaner to keep the system motor, blower,

and cooling coil clean. The installaon can be vercal or

horizontal. When choosing a locaon, there must be ade-

quate room to wire the air cleaner and remove prelters,

collecng cells, and power box for maintenance.

Note: Once the air cleaner has been installed, do not allow

the placement of any device such as a new hot water heater,

water soener, gas pipe, or electrical cable

to be put 24 in. (61 cm) in front of or within

6 in. (15 cm) from top of air cleaner. This

distance is needed to allow access for the

removal of lters and air cleaner parts, which

are necessary for maintenance or servicing.

Dimensions — in (cm)

MODEL A B C D E F G H

AE14-1620-51

AE14-1620-52

19.8

(50.4)

15.9

(40.5)

23.2

(58.9)

13.1

(33.3)

20.7

(52.5)

1.3

(3.2)

23.7

(60.2)

21.2

(53.9)

AE14-1625-51

AE14-1625-52

19.8

(50.4)

15.9

(40.5)

26.1

(66.3)

13.6

(34.6)

24.1

(61.2)

1.0

(2.5)

26.6

(67.7)

25.8

(65.4)

AE14-2020-51

AE14-2020-52

24.7

(62.8)

20.8

(52.9)

21.2

(53.9)

18.0

(45.7)

18.7

(47.5)

1.3

(3.2)

21.7

(55.2)

21.2

(53.9)

AE14-2025-51

AE14-2025-52

24.7

(62.8)

20.8

(52.9)

25.8

(65.4)

18.0

(45.7)

23.3

(59.1)

1.3

(3.2)

26.3

(66.8)

25.8

(65.4)

Table 3: Air Cleaner Dimensions

Figure 3: Pressure Drop across Air Cleaner

2.80

Figure 4: Dimensions

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

6IO-AE14-5

INSTALLATION

Figure 5: Air Cleaner

Installaon Locaon

Allow 24 in. (60 cm) clearance for maintaining air cleaner

Allow 6 in. (15 cm) clearance for power box removal.

Installation Location with Humidier

A humidier should be installed in the furnace warm

air duct. However, it may be installed in the return duct

without causing problems to the air cleaner. Care must

be taken to ensure that the humidier does not leak, as

this may cause arcing and a mineral deposit to build up

on the collecng cells.

An atomizing type humidier should be installed

downstream from the air cleaner. If the atomizing type

humidier is installed upstream, high humidity, salts and

minerals may decrease the eciency of the collecng

cells and cause service problems.

If the atomizing type humidier must be installed

upstream, the following precauons should be taken:

1. Atomizing type humidier must be installed as far

from the air cleaner as possible.

2. Collecng cells must be washed frequently to

prevent a mineral deposit build-up.

Installation Location with Air Conditioner

Whenever possible, the air cleaner should be installed

upstream of the cooling coil. This locaon will clean the

air before it reaches the evaporator coil.

Installation Steps

1. Remove exisng equipment lter (if present) and

clean blower compartment: Thoroughly clean the

blower compartment, since your air cleaner can not

remove accumulated dirt from the blower chamber

and distribuon ducts.

2. Open air cleaner access door. Slide lters and

collecng cells out of cabinet.

3. Installing the cabinet: Holes are provided to aach

cabinet to ductwork or equipment. If the adjoining

ductwork is anged, install the screws so that the

screw heads are inside the cabinet. This will help

prevent damage to prelter and carbon VOC lters

during removal for cleaning. Never put screws or

rivets into the removable power box.

4. Transions: If the air duct does not t the air cleaner

opening, a gradual transion is recommended to

reduce air turbulence through the air cleaner and

ensure its ecient operaon. A maximum of 20° of

expansion, or approximately 4 inches per running foot

(10 cm per 30 cm ), is recommended for each side of

the transion ng.

Do not reduce ductwork size to t a smaller

air cleaner. This will increase the velocity of

airow and may decrease cleaning eciency.

5. Turning vanes: If the air cleaner is installed adjacent

to an elbow or angle ng, eld-installed turning

vanes are recommended to improve air distribuon

across the collecng cells.

6. Seal the joints in the return air system: All joints

between the air cleaner, the heang / cooling

equipment and the return air duct should be sealed

to prevent dust from entering the clean air stream.

7. Replace the prelters in the track on the air entering

side of the air cleaner. Place new carbon VOC lters

into the air cleaner. Space lters evenly across the

discharge opening of air cleaner. Never put more

than 3 carbon VOC lters in the air cleaner, as this

may cause a problem with airow.

The collecng cells are placed between the tracks, with

the arrow on cell poinng towards the fan. The cell

handle may need to be reposioned if the airow is in

a dierent direcon than the le to right set up. The

handle should face the door. Close access door.

iWARNING!

Electrical shock can cause injury or death. Be certain main

line disconnect switch is OFF before wiring.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 7

IO-AE14-5

WIRING

Wiring

Wiring should only be performed by qualied personnel.

All wiring must comply with all applicable codes and

standards. The voltage of the power source must match

the voltage indicated on the air cleaner. The air cleaner

must operate ONLY when the system fan is running.

Make sure the air cleaner is properly grounded.

If the air cleaner is equipped with a cord and plug, the air

cleaner can be plugged into an outlet within 6 feet of the

unit. Do not use an extension cord if the outlet is too far

away. Have an electrician wire in a new outlet closer to

the air cleaner.

If the air cleaner is not equipped with a cord, then wire the

air cleaner directly to a power source, as indicated on the

rang label, preferably to the same source that is supplying

power to the furnace or air handler. The APS will power the

air cleaner when there is sucient airow to acvate the

sensor. See Figure 5.

Note: The ORANGE power switch will be lit even if there

is no airow.

This 120VAC air cleaner may only be wired to the EAC

contacts on the system module if these contacts carry

120 VAC power. Before wiring this air cleaner to the system

module, check the specicaons of the furnace or air

handler to ensure the system module has sucient unused

capacity to power this air cleaner with the fan operang in

all condions. The air cleaner uses approximately 30 Was

when operang. Some systems do not power the EAC

contacts on the system module on low speed.

System Check

Perform the following system check before operaon.

1. Replace prelters, collecng cells and carbon VOC

lters. Close the access door.

2. Turn air cleaner power switch ON. Ensure system

fan is operang. Both the power switch light and

performance indicator light should be lit. The power

switch light indicates the air cleaner has unit voltage.

The performance indicator light shows that the

air cleaner is operang.

Note: There may be some arcing or snapping sounds from

the collecng cells. This is normal when the unit is new.

In about two weeks, as the sharp edges of the cells become

smoother, the arcing will disappear.

Operation

The air cleaner will run as long as there is adequate airow

through the ducts. The air cleaner will not run if the system

fan is o.

To improve the performance of your air cleaner, these

simple steps are recommended:

3. Run your heang/cooling system fan connuously,

on low speed if available, since your air cleaner only

removes parculate maer when the system fan is

operang.

4. Ensure there are no obstrucons to airow (for

example, from furniture or carpets) in front of the

return air grilles so that air moves freely to the heang/

cooling equipment.

5. Check for proper operaon of the system fan.

Figure 6: Air Cleaner Schemac

(with Air-Proving Switch)

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

8

CHECKOUT

IO-AE14-5

When operang normally, with the fan running, the air

cleaner should have both the orange power switch

light and the green performance indicator light ON. If the

fan is running and the lights are not on, see the Trouble-

shoong Guide for probable causes and remedies.

iCAUTION!

For most troubleshoong, the cells should be removed

from the air cleaner. A short in one of the cells will cause

the power board to shut down and the performance light

will stay o. Unless otherwise directed, remove the cells

from the unit when tesng.

iWARNING!

Electronic air cleaners use high voltage (low amperage)

power. Only trained personnel should perform service.

Electric shock can cause injury or death.

iWARNING!

When performing LIVE tests in the power box, NEVER touch

any components inside the air cleaner other than what is

menoned in the tests. Components carry dangerous

voltages and extreme care must be taken.

CHECKOUT – Visual

Visually check the air cleaner installaon to verify that:

• The arrows on the front of the collector cells are

poinng in the direcon of the airow.

• The aluminum mesh prelter is installed on the

upstream side of the air cleaner and the acvated

carbon VOC lters are on the downstream side.

• The handles on the collector cells are facing the front

of the air cleaner cabinet.

• The collector cells and aluminum prelters are clean

and dry.

• All joints in sheet metal between the air cleaner and

the heang and cooling system are sealed.

• Previously-installed furnace lter has been

removed (if present) and blower compartment

has been cleaned.

When you have performed the preceding physical

checkout, proceed to do the operaonal checkout

that follows:

CHECKOUT – Operational

1. Replace any access doors removed during the

Installaon.

2. Toggle the air cleaner power switch to the ON

posion and energize the furnace or air handler

(system) fan.

3. Verify that the orange power switch is ON (lighted).

The orange light shows that there is power supplied

to the air cleaner.

4. Verify that the green performance indicator light

is ON. The green light shows that the high voltage

power supply is working correctly.

5. Turn OFF the system fan. The green light should go

OFF aer a few seconds, but the orange light should

remain ON.

6. For furnaces or air handlers with a mul-speed fan,

air cleaner operaon should be veried by repeang

steps 3 through 5 for each fan speed.

7. For any issues related to air cleaner performance,

refer to Troubleshoong and Service secons in this

manual.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 9

MAINTENANCE

IO-AE14-5

Maintenance

It is important to perform regularly-scheduled mainte-

nance of the air cleaner. For best performance of the air

cleaner and to keep airow restricon low, it is recom-

mended that the collector cells be cleaned at least twice a

year or when the stac pressure across the air cleaner

reaches 0.5 inches w.c. If you nd signicant loading of

parculates on the collector cells when you perform the

rst cleaning, clean the cells more frequently. The prel-

ters should be cleaned regularly and the post lters should

be replaced at least twice per year.

Cell and Prelter Cleaning

The collecng cells and prelters must be cleaned on a

regular basis for best performance of the air cleaner.

As the collector cells become coated with trapped

parculates, the cleaning eciency of the air cleaner is

reduced and the resistance to airow (stac pressure) is

increased. The recommended frequency of cleaning will

depend on several factors, including number of family

members, pets, acvies (such as cooking or woodwork-

ing), leaving the windows open and smoking. Use the

Cleaning Record to help keep track of scheduled cleanings.

Cleaning the Collector Cells

1. Remove access door, collecng cells and prelters.

2. Place cells in a laundry tub. Rinse with hot water

(maximum 120°F/49°C) and spray completely with

DAX Detergent (or a non-chlorine, non-corrosive,

non-abrasive liquid household detergent). Allow de-

tergent to run down both sides of plates and ionizing

wires. Let stand for 5 minutes or ll up laundry tub

with water and DAX Detergent, and dunk cells up and

down unl water is dirty.

3. If dirt remains on the cell plates, let the cells soak in a

soluon of DAX Detergent and water for 30 minutes.

4. When the collector cells are clean, drain the tub

and rinse cells thoroughly with hot water (maximum

120°F/49°C).

5. Remove accumulated parculate from the ionizing

wires with an old toothbrush. Slide the brush bristles

over the wire and gently drag the brush up and down

the wire once. Be very careful when cleaning the

wires as they become very brile with age and can be

very sharp. Tilt collector cells on a 45° angle on their

short side.

6. Tilt collector cells on a 45° angle on their short side,

with arrows poinng sideways. Allow to dry com-

pletely, approximately 12-24 hours. Drying me can

be reduced by using a hair dryer on the collector cells

before replacing them in the air cleaner cabinet.

7. Do not place the cells in the air cleaner if they

are wet.

Cleaning the Prelters

1. To clean the prelters, rst vacuum the upstream side

to remove larger trapped parcles.

2. Then, wash the prelters with DAX Detergent, rinse

and let dry. Do not wash in the same water as

collecng cells.

iWARNING!

Make sure to turn air cleaner and system fan OFF before

performing any maintenance or removing any components.

iCAUTION!

Metal edges of the air cleaner collector cells, ionizing wires

and system ductwork are very sharp and can cause personal

injury. Carefully handle the cell or wear protecve gloves to

avoid cuts from metal edges.

iCAUTION!

Damage to cells may occur if improperly handled or washed.

Do not wash cells in a dishwasher. Never use any object to

clean between the cell plates, as this may cause damage to

plates or ionizing wires. Never place cell in oven to dry.

The edges of the cell may be sharp – handle with care.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

10

MAINTENANCE

IO-AE14-5

Reinstalling the Cells and Prelters

1. Once dry, inspect the cells for broken ionizer wires

and bent collector plates. Repair as necessary or

contact an authorized Clean Comfort service

technician to repair.

2. Re-insert the prelters into the upstream

prelter guides.

3. Re-insert the collector cells into the guides in the

boom center of the air cleaner cabinet; the airow

arrow points downstream (towards the furnace or

air handler) and the handle faces outward.

4. Firmly close the access door and turn power switch

ON. If the performance light does not come on or

arcing occurs, turn air cleaner OFF and allow air from

system fan to dry cells completely.

Replacing the Carbon VOC Filters

1. The acvated carbon VOC lters help remove odors

and light gases from the air exing the air cleaner.

They should be replaced every six months, or more

frequently with heavy use and should be done as part

of the scheduled cleaning when the cells and prelters

are cleaned. Carbon VOC Filters are NOT washable.

2. Replacement carbon VOC lters are available in the

same size and conguraon as the original unit. They

can be purchased from your Clean Comfort authorized

service technician.

1. Turn air cleaner power switch OFF

2. Turn OFF system fan

3. Open access door

4. Remove collecng cells from air cleaner

5. Remove the used carbon VOC lters from air cleaner

6. Put new carbon VOC lters into air cleaner. Space lters

evenly across the discharge opening of air cleaner.

Never put more than 3 carbon VOC lters in the air

cleaner, as this may cause a problem with airow.

Figure 7: DAX Detergent and Carbon VOC Filters are available

from your installer or dealer.

Maintenance Parts

Item Part #

DAX 32 oz Spray Bole AEP-FS9900

Replacement Carbon VOC Filters:

AE14-1620-51,-52 (Set of 3) AEP-1156-3

AE14-1625-51,-52 (Set of 3) AEP-1156-3

AE14-2020-51,-52 (Set of 3) AEP-1856-3

AE14-2025-51,-52 (Set of 3) AEP-1856-3

Cleaning Record

The collecng cells and prelters must be cleaned on a

regular basis for the air cleaner to funcon at its peak

eciency. The frequency of cleaning will vary from

one house to another. On average, the cells should be

cleaned every 3 months. Use the chart below to keep

track of your cleaning schedule.

Cleaning Record

Date Cleaned Performed by

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 11

TROUBLESHOOTING

IO-AE14-5

1. Remove both cells from the air cleaner cabinet.

Replace the cabinet door.

2. Toggle the air cleaner’s orange power switch ON,

and turn the HVAC fan ON.

3. If the green performance indicator light is sll OFF,

check the power board for an arc to ground at HV1

or HV2. Refer to Troubleshoong secon ①.

4. If there is a good arc and the performance indicator

light is sll OFF, then replace the light. Refer to Service

secon A “Replacing a Performance Light”.

If the performance indicator light comes ON, check

the cells for a fault. Refer to Troubleshoong secons

④, ⑤, and ⑥.

5. If there is no arc, test the output voltage of the

transformer. Refer to Troubleshoong secon ④.

If there is transformer output, replace the power

board. Refer to Service secon B) “Replacing a

Power Board”If there is no transformer output,

check for output of the APS. Refer to Troubleshoong

secon ③.

• If there is output from the APS, replace the trans-

former (refer to Service secon C) “Replacing the

24 V Transformer”) and retest the power board for

an arc. Refer to Troubleshoong secon ①.

• If there is no output from the APS, jumper terminals

3 & 4 on the APS and retest the output. If there is

APS output with the jumper installed, replace the

APS. Refer to Service Secon D) “Replacing an Air

Proving Switch (APS).

6. If there is sll no output from the APS, check the output

voltage from the power switch.

7. If there is no voltage from the power switch, test the input

to the switch. If there is input, replace the power switch.

8. If there is no input to the switch, check the interlock

switch and the supply voltage.

Troubleshooting

The air cleaner, when operang normally with the fan

running, should have both the orange power switch light

and the green performance indicator light ON. If the fan is

running and the lights are not on, follow instrucons below

for probable causes and remedies.

Quick Check (Orange Power Switch Light ON, Green

Performance Indicator Light OFF)Detailed Troubleshooting

① Tesng For High Voltage at Power Board

With the collecng cells out of the unit, the door on the unit

and the system fan on high speed, turn the air cleaner ON.

With a long shaed screwdriver with a plasc handle, short

between the grounded side of the power box and the HV1

terminal of the power board. If you draw a good spark,

there is high voltage from the power board.

② Measuring High Voltage at Power Board

A high voltage meter capable of measuring up to 10,000

VDC is required to test the voltage.

iCAUTION!

For most troubleshoong, the cells should be removed

from the air cleaner. A short in one of the cells will cause

the power board to shut down and the performance light

will stay OFF. Unless otherwise directed, remove the cells

from the unit when tesng.

iWARNING!

When performing LIVE tests in the power box, NEVER

touch any parts other than what is menoned in the tests.

Components carry dangerous voltages and extreme care

must be taken.

1. The air cleaner should be ON with the cells installed,

the door closed and the system fan running.

The air cleaner should be on at least 5 minutes

to allow voltage to stabilize. The cells and ionizing

wires must be clean.

2. Remove the cover from power box.

3. Connect the ground of the high voltage meter to an

unpainted surface in the power box.

4. Check terminals HV1 and HV2 on the power board to

determine if voltage is present. See Table 3 for values

If no voltage is present, remove both cells from the

air cleaner and replace door. Recheck the voltage at

HV1 and HV2

If voltage is present, the problem is with one of the

cells or the wiring to the copper contacts.

With a ashlight, look into the cabinet to check

condion of the copper contacts.

If the contacts are not bent, replace one cell and

retest voltage. If cell is OK, test the other cell. If the

problem is with a cell, see Troubleshoong secons

⑥, ⑦, and ⑧.

If there is no voltage with both cells removed,

check the power board, APS and transformer to

make sure that they are funconing correctly.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

12

TROUBLESHOOTING

IO-AE14-5

MODEL Max. Voltage on

Plates (KVDC)

Max. Voltage on

Ionizer (KVDC)

AE14-1620-51

AE14-1625-51 4.8 - 5.3 (HV1) 7.2 - 8.0 (HV2)

AE14-2020-51

AE14-2025-51 4.8 - 5.2 (HV1) 7.2 - 7.8 (HV2)

Table 4: Power Board Voltage Sengs (with load)

The voltage will be higher without the cells in the unit.

③ Tesng Air Proving Switch (APS)

The APS sensor must sit in the plasc bushing to operate

correctly. The sensor is very sensive and operaon may

be aected by cold ambient temperatures, an HRV/ERV,

or a fresh air duct connected to the return air duct just

upstream of the air cleaner.

The APS uses a triac in its output circuit, which aects the

voltage sine wave. Measuring voltage with a regular digital

voltmeter may give a false reading. To check the output

from the APS, use a true RMS (root mean square) meter to

measure the output at terminals 1 and 4 of the APS. The

output should be between 102 and 115 VAC or 205-230

VAC, depending on the airow across the sensor

When the air cleaner is turned on without airow, the APS

sensor heats up, and aer 20-30 seconds opens the circuit

to turn OFF the power board. When the fan starts up (the

sensor is cooled), the circuit will close, the power board is

turned on, and the performance light will come on within

a few seconds.

The light on the power switch will be lit even when the

APS is open.

If the power board fails to come on with the fan on, check

that the sensor is properly seated in the boom of the

plasc bushing, in the front of the power box. To check the

APS for proper operaon remove the collecng cells, turn

the unit ON without the fan on. The power board should

come on immediately, and then turn OFF in 20-30 seconds

as the sensor heats up. To check sensor, blow directly on

it lightly. This should acvate the power board within 10

seconds. Service the sensor carefully. The sensor leads

are live. If the APS does not turn the power board and

performance indicator on, by-pass the APS by placing a

jumper between wires 3 & 4 on the APS. This removes the

APS from the circuit.

Note: If the airow through the air cleaner is less than

360 CFM, the APS sensor may not have enough airow

to acvate the air cleaner. In very low airow applicaons,

the air cleaner may need to be controlled by wiring it to

the EAC contacts on the system control module. In this

case, the APS must be disabled by connecng terminals

3 and 4 together.

See Wiring secon for informaon on how to wire the

air cleaner to the EAC contacts on the furnace or air

handler control module.

If there are no EAC contacts on the system control

module or they are not powered on low speed then a

relay will have to be installed to acvate the air cleaner

when the fan starts. The APS will have to be disabled.

④ Tesng the 24 V Transformer

1. Remove power box cover.

2. Disconnect the leads of the 24 V transformer from the

power board. See Fig. 5. Do not short leads.

3. The air cleaner should be ON. The system fan should

be running on high speed. The access door should be

closed.

4. Measure voltage across the leads with a voltmeter.

Voltage should read 25 - 28 VAC.

5. If no voltage is present, check operaon of the APS.

6. Reconnect leads to the power board.

7. Replace power box cover.

⑤ Seng Voltage of Power Board

High voltage can be adjusted with high voltage

potenometer if required. See Table 4 below.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 13

TROUBLESHOOTING

IO-AE14-5

Voltage on the power board may drop below required level

when installaon area is too damp, too cold, or if there is a

leakage of water from a humidier. Voltage on power board

may be too high when installaon area is too dry or too hot,

or home is in close proximity to hydro towers or situated in

remote farm land areas. By adjusng the HV Adj. potenom-

eter, the voltage can be set to opmum level. A high voltage

meter capable of measuring 10,000 VDC is required. To test

and adjust voltage level, perform the following procedure:

1. Turn the air cleaner OFF.

2. Remove the power box cover.

3. Connect the ground of the high voltage meter to an

unpainted surface in the power box.

4. Turn ON the air cleaner and wait 5 minutes before

checking voltages to allow voltages on cells to stabilize.

The cells and ionizing wires must be clean.

5. Measure the voltages at HV1 and HV2 on the

power board.

6. Adjust the HV Adj. potenometer unl the voltage

reading matches the voltage in Table 3. Adjusng the

potenometer clockwise decreases the voltage and

turning counter-clockwise increases the voltage.

7. Turn OFF the air cleaner.

8. Remove the high voltage meter.

9. Replace the power box cover.

10. Turn ON the air cleaner.

Seng Approximate Voltage without High Voltage Meter

A high voltage meter should be used to set the high

voltage. If one is not available, this method can be used.

This will only set an approximate voltage. Aer using this

method, the voltage should be reset with a high voltage

meter as soon as possible.

1. Remove power box cover.

2. Turn the HV Adj. potenometer fully counter-clockwise.

The air cleaner may arc or snap at this point.

3. Turn the HV Adj. potenometer clockwise unl the

arrow is at the half way point.

4. Replace power box cover.

⑥ Tesng for Voltage at The Cell

1. Open access door to air cleaner.

2. The cells must be in the air cleaner for this test

and the system fan should be on high speed.

3. Turn the air cleaner ON and press the safety

interlock switch lever.

4. Place a plasc handled screwdriver into the

direcon arrow slot. Do not apply excessive force.

5. If there is a good snap, then there is high voltage at the cell.

⑦ Tesng Cell for Bad Contacts

1. Open access door to air cleaner.

2. The cells must be in the air cleaner for this test and the

system fan should be on high speed.

3. Turn the air cleaner ON and press the safety interlock

switch lever.

4. Place a plasc handled screwdriver into the direcon

arrow slot. Do not apply excessive force.

5. There should be an inial snap when the plates are

shorted, then no sound. If a hissing occurs, then there

is a bad contact. Look along the top of the cell, with the

short sll in place. If there is a small arc between the

cell top and copper contact, then that is the bad contact.

Pull cell out and gently pull the copper contact down.

6. If an arc is not seen and there is a bad contact, then the

problem may be an internal contact in one of the cells.

7. Let up on safety interlock.

8. Close access door.

⑧ Tesng Cell with an Ohmmeter

To test the cell for a dead short or a bad contact, an

ohmmeter can be used.

Always discharge the cell with a screw driver before

tesng with an ohmmeter.

1. With the ohmmeter set on its lowest scale, take a

reading between the top center contact of the cell

and the ionizing ngers on the boom of the cell.

You should have connuity. If you do not, then there

is a bad contact between the center contact and the

top set of ionizing ngers.

2. Test the resistance between the top center contact

and the cell frame. You should read innite resistance.

If not, you have a short in the ionizing secon.

3. Take a reading between the two outside contacts on

the top of the cell. You should have connuity. If you

do not, then there is a bad contact between one of the

contacts to the live cell plate. Test each top outside

contact to the last plate in the cell to determine which

contact is not mang properly.

4. Test the resistance between the outside contacts

and the cell frame. You should read innite resistance.

If not, you have a short in the collecng secon.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

14

TROUBLESHOOTING

IO-AE14-5

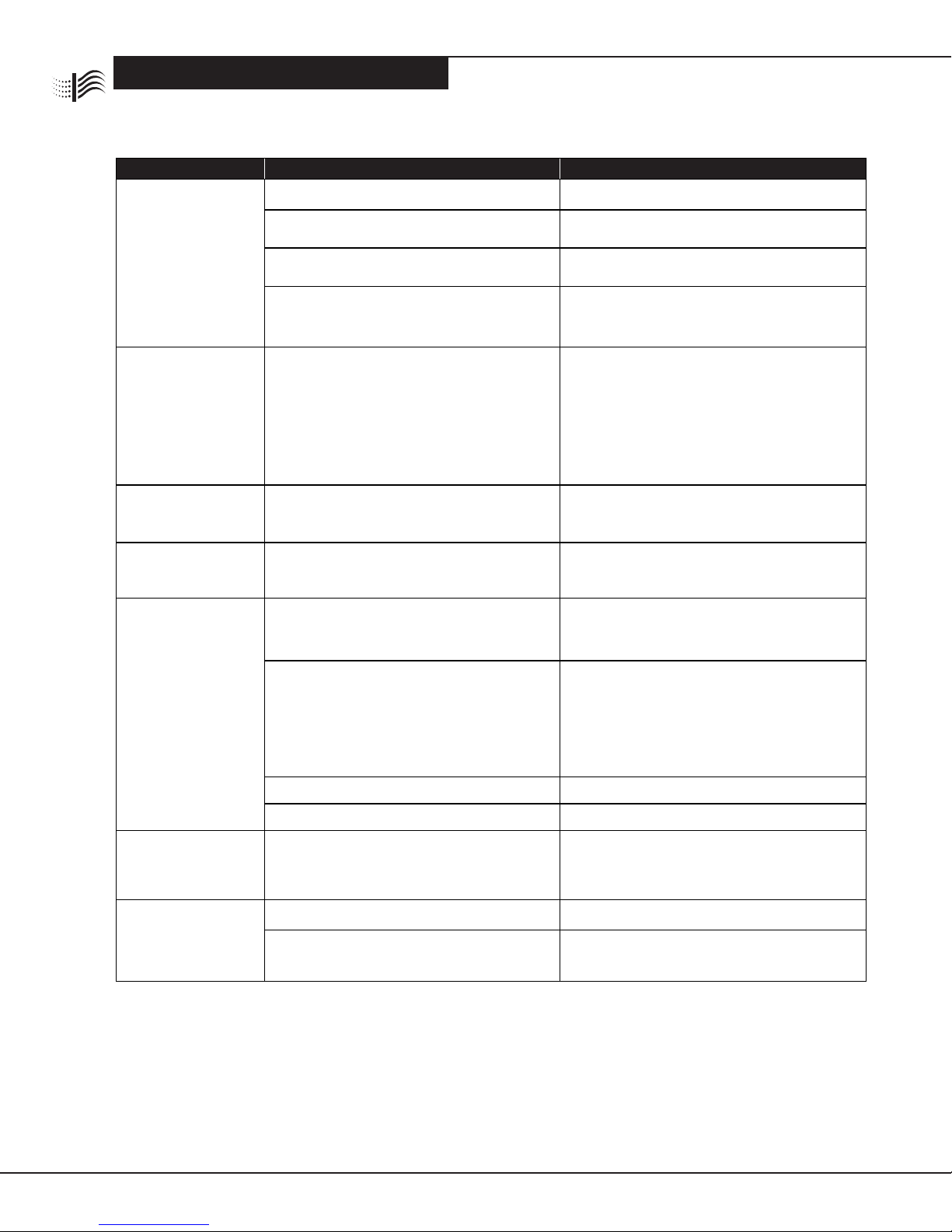

Table 5 Troubleshoong Guide

Problem Probable Causes Remedy

Unit does not

funcon correctly.

Power light and

performance

indicator light

are OFF.

System fan is not on. Turn system fan on.

Wiring improperly connected. Check wiring or verify that plug is inserted in

receptacle and receptacle is powered.

Defecve power switch. Check power switch for connuity with ohmmeter.

Replace if defecve.

Defecve safety interlock. Remove door and press safety interlock with a

screwdriver. If lights come on, bend interlock lever

towards front and close door.

Unit does not

funcon correctly.

Power switch light is

ON and performance

indicator light is OFF.

Short in cells due to:

1. Broken ionizing wire.

2. Large parcles wedged between cell plates.

3. Cells washed recently and are sll wet.

4. Cell end plate insulator is dirty or damaged.

5. Cell plate(s) are bent.

1. Remove wire or wire fragments. Replace.

2. Shake large parcles out or wash cell.

3. Allow cells to dry completely.

4. Clean or replace end plate insulator.

5. Straighten plates with pliers.

Defecve performance indicator light.

Determine whether high voltage is present by tesng

power board ② If voltage is present, replace

performance indicator light.

Defecve power board. Adjust high voltage potenometer on power board

counter-clockwise. If high voltage is not present,

replace power board.

Air Proving Switch (APS) sensor is

burnt out.

Remove power box lid and blow lightly for 10

seconds on APS sensor at boom of power box.

If light does not come on, replace APS.

Air Proving Switch is not geng enough airow

across the sensor.

Check that sensor is located in the plasc bushing

at the front of the power box.

Check that the return duct is installed ush to the

top and front edge of the air cleaner duct opening.

Ensure there is a minimum of 360 CFM of air to

the air cleaner.

O board 24V transformer is not working. Verify output of transformer. Replace if necessary.

Defecve power switch. Verify output of switch. Replace if necessary.

Power switch light is

OFF and performance

indicator light is ON.

Defecve power switch light. Replace power switch.

Cell makes loud

hissing noise

or causes radio

interference.

Internal cell contacts are not touching plates. Test contacts and repair.

Copper contacts on high voltage tray not making

good connecon on cell. With needle-nose pliers, gently pull contacts down

or replace contacts.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 15

TROUBLESHOOTING

IO-AE14-5

Cells arcing

excessively

(power light and

performance

indicator light ON

or ashing).

Cells wet from washing. Allow cells to dry completely.

Parcles lodged in cell or broken ionizing wire. Wash cell. Shake parcle out of cell. Replace wire,

if necessary.

Ducts were not cleaned prior to installaon of

air cleaner. Clean ducts.

Cell plates are bent. Remove cells and adjust to original spacing using

needle-nose pliers.

Dirty cells. Wash cells and clean ionizing wires.

Voltage is too high. Adjust high voltage potenometer on power

board clockwise.

High voltage wires are on wrong

copper contact. Reposion high voltage wires on proper contact

(see Fig. 6).

Internal contact on cell out of alignment. Realign cell contact.

Humidier (if installed) is leaking water on

air cleaner. Repair humidier. If possible, move humidier to

dierent locaon.

Cells arcing

excessively at top

of cell near copper

contacts (power light

and performance

indicator light ON).

Copper contact on high voltage contact board is

broken or bent upward. If possible, pull down contacts with needle-nose

pliers or remove power box and replace contacts.

Cells not collecng

dirt (power light

and performance

indicator light ON).

Arrow on cells not poinng towards fan blower. Reposion cell handle and place cell in properly.

System fan is on “Automac” seng

(air cleaner not on connuously) Use “Fan On” system fan seng for connuous

fan operaon.

Not enough voltage on collecng cells. Adjust high voltage potenometer counter-

clockwise on power board.

Ozone odor Cell plates are bent. Straighten with needle-nose pliers.

Loose or broken ionizing wire. Replace wires.

Dirty cells. Wash cells and clean ionizing wires.

Air cleaner is on when system fan is not running.

Air cleaner wired incorrectly or air proving switch

is defecve.

Check operaon and wiring of air switch and air

cleaner.

Incoming voltage is higher than rated input. Adjust high voltage potenometer clockwise on

power board.

Air cleaner is oversized for house. Not enough

airow to cover surface area of cells. Use correct size of air cleaner.

Home is extremely dry. Repair or install central humidier.

White dust Clean lint dust is too heavy to remain airborne. Keep fan running connuously. Ensure that return

air grilles are not obstructed.

Gaps around air cleaner. Seal or use duct tape around air cleaner cabinet.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

16 IO-AE14-5

SERVICE

Service

A) Replacing a Performance Light

Before replacing the performance light, turn OFF power

to the air cleaner at the source.

1. Remove the power box cover.

2. Disconnect the performance light wiring connected

to the LED terminals on the power board. Carefully

cut the wire es from the wire bundle.

3. Push the light out through front of power box.

4. Push the new light into the power box.

5. Connect the wiring to the LED terminals on the power

board. P3 - red; P4 - black. Route the wires away from

the high voltage wires or contacts.

6. Replace cover.

7. Return power to air cleaner. Test light.

B) Replacing a Power Board

Before replacing the power board, turn OFF power to the

air cleaner at the source or remove the plug.

1. Remove the power box cover.

2. Make note of posion of wires connected to the

LED, HV1, HV2 and 24 V terminals, then disconnect

these wires.

3. Remove the three hex nuts from the power board.

4. Remove the power board from the studs.

5. Place the new board onto studs with the 24 volt input

close to the transformer.

6. Replace the hex nuts removed in Step 3. Ensure the

star washer is in place over the steel spacer at the

ground locaon on the power board. For proper

grounding, the washer must be located on the top of

the steel spacer, under the power board.

7. Reconnect wiring to LED, HV1, HV2, and 24 V

terminals on the new power board.

8. Return power to air cleaner. Test power board.

9. Replace power box cover.

C) Replacing the 24 V Transformer

Before replacing the transformer, check the resistance

across the power board’s 24 V input terminals, without

the transformer connected. Resistance should read

above 20K ohms with an analog meter and above 4M

ohms with a digital meter. If the resistance readings are

below these values, the power board may be the cause of

the transformer failure.

Before replacing the 24 V transformer, turn OFF power to

the air cleaner at the source.

1. Remove power box cover.

2. Disconnect the secondary leads from the transformer

to the 24 V terminals on the power board. See Fig. 5.

3. Cut the primary leads (to the APS) close to the

transformer.

4. Remove the 2 hex head nuts from the transformer

studs.

5. Remove the transformer.

6. Place new transformer over studs and re-install 2 hex

head nuts to secure into place.

7. Connect secondary leads (white) to the 24 V terminals

on the power board (P1 & P2).

8. Wire nut primary leads from APS (cut in Step 3) to the

primary leads of the new transformer.

9. Replace power box cover.

10. Turn ON the power to the air cleaner and test

Note: The power board voltage has been set before

shipping. It is not usually necessary to reset the voltage

to the new load. If you do need to adjust the voltage,

refer to ⑤Seng Voltage of Power Board in the

Troubleshoong secon for more informaon.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 17

IO-AE14-5

SERVICE

D) Replacing an Air Proving Switch (APS)

Before replacing the performance light, turn OFF

power to the air cleaner at the source.

1. Disconnect wiring from terminals 1, 2, 3, and 4 on the

APS. See Fig. 6.

2. Remove the circuit board from the studs by removing

the two nuts. Do not remove the spacers.

3. Install the new APS on the studs and secure with the

nuts. Ensure sensor protrudes only to the boom of the

plasc bushing.

4. Connect wiring to terminals on APS. Wiring from the

power switch is connected to terminals 2 and 3. Wiring

to the transformer is connected to terminals 1 and 4.

5. Test the new APS.

E) Removing Power Box

1. Turn the main system switch OFF or disconnect the

power cord.

2. Remove the power box cover.

3. If the unit does not have a cord, disconnect the source

wires to the air cleaner. Cap o the wires so the system

can sll be operated.

4. Remove the two nuts holding the power box to the

cabinet.

5. Slide the power box forward then up to remove it from

the cabinet.

6. If you are removing the power box for any length of

me, tape a cover over the top opening to prevent air

from entering into the system.

F) Replacing a Tungsten Ionizing Wire

Replacement wires are cut to the correct length and have

eyelets at each end for easy replacement.

1. Turn OFF power to air cleaner.

2. Remove cell from air cleaner.

3. Remove all parts of broken wire from the cell.

If necessary, the cell may be used temporarily with

one wire missing unl a replacement is received.

4. Place one end of the loop over the nger at the boom

of the cell.

5. Using needle-nose pliers, grip the other end of wire near

the boom of the top loop. Pull the wire up toward the

top nger. As you apply tension, the boom nger will

give, allowing the placement of the loop around the

top nger.

6. Install cell in air cleaner.

7. Return power to air cleaner.

8. Test cell for proper operaon.

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM

18

PARTS LIST

IO-AE14-5

Table 6: Air Cleaner Components List

For more informaon on ordering parts, call 1-800-267-8305 or your installing contractor.

Figure 8: Air Cleaner Component View

#Part Descripon

AE14-1620-51

AE14-1620-52

AE14-1625-51

AE14-1625-52

AE14-2020-51

AE14-2020-52

AE14-2025-51

AE14-2025-52

1 Power Switch

R1-0205 R1-0205 R1-0205 R1-0205

2 Safety Interlock Switch

R1-0202 R1-0202 R1-0202 R1-0202

3 Performance Indicator Light (Green LED)

R1-0123 R1-0123 R1-0123 R1-0123

4 Air Proving Switch - 120VAC models

D1-0217 D1-0217 D1-0217 D1-0217

Air Proving Switch - 220VAC models

D1-0217E D1-0217E D1-0217E D1-0217E

5 24 Volt Transformer - 120VAC models

D1-053D D1-053D D1-053D D1-053D

24 Volt Transformer - 220VAC models

D1-053E D1-053E D1-053E D1-053E

6 Power Board - 120VAC models

D1-055D D1-055D D2-055D D2-055D

Power Board - 220VAC models

D1-055E D1-055E D2-055E D2-055E

7 Fibreboard (with 4 Copper Contacts)

D0-0521 D1-0521 D2-0521 D8-0521

8 Copper Contact

R1-9925 R1-9925 R1-9925 R1-9925

9 Cord Assembly (Oponal)

R1-062D R1-062D R1-062D R1-062D

10 Cover for Power Box

D0-0509 D1-0509 D0-0509 D1-0509

11 Power Box Complete (No Cover) Depends on opons with power box

12 Carbon VOC Filters (Set of 3)

AEP-1156-3 AEP-1156-3 AEP-1856-3 AEP-1856-3

13 Prelter

R0-0855 R1-0855 R2-0855 R8-0855

14 Cell Guide (Plasc)

R1-0603 R1-0603 R1-0603 R1-0603

15 Collecng Cell

D0-0400 D1-0400 D2-0400 D8-0400

16 Cell Handle

R1-0484 R1-0484 R1-0484 R1-0484

17 Door (with Plasc Clip & Handle)

D0-0632 D1-0632 D2-0632 D2-0632

18 Door Handle (Plasc)

R1-0634 R1-0634 R1-0634 R1-0634

19 Ionizing Wire

D1-0443 D1-0443 D2-0443 D2-0443

20 Male & Female Door Clip Set

R1-0636 R1-0636 R1-0636 R1-0636

SERVICE

FILTRATION

FILTRATION

WWW.CLEANCOMFORT.COM 19

IO-AE14-5

NOTES:

20 WWW.CLEANCOMFORT.COM IO-AE14-5

FILTRATION

FILTRATION

AIR CLEANERS

CLEAN COMFORT™ ELECTRONIC AIR CLEANER

LIMITED FIVE YEAR WARRANTY

This Clean Comfort™ product is warranted by Daikin North

America LLC (“Daikin”) to the original owner to be free from

defects in material and workmanship, under normal use and

maintenance, within its listed capacity, for a period of ve years

from the date of purchase, except however, for the prelters

and carbon VOC lters, which will have to be replaced from

me to me depending upon the use. This Clean Comfort™

product must not have been moved from the site of original

installaon. Daikin’s exclusive obligaon, and the owner’s

sole remedy, under this warranty shall be for Daikin to supply,

without charge through a Daikin authorized service dealer,

a replacement for any covered part of the Air Cleaner which

is found to be defecve and is returned by the owner or a

qualied servicing Daikin dealer prepaid, together with the

serial number, date of installaon, and proof of purchase. If the

date of installaon is unknown, Daikin will guarantee the unit

for a period of sixty (60) months from the date of manufacture

listed on the product’s rang plate. Any part replaced pursuant

to this warranty is warranted only for the unexpired poron of

the warranty term applying to the original part.

THIS WARRANTY DOES NOT COVER ANY LABOR OR OTHER

COSTS incurred for diagnosis, repairing, removing, installing,

shipping, servicing, or handling of either defecve parts or

replacement parts.

LIMITATIONS - THE EXPRESS WARRANTY CONTAINED HEREIN

IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WAR-

RANTIES INCLUDING WARRANTIES OF MERCHANTABILITY ARE

LIMITED TO THE DURATION OF THE WARRANTY DESCRIBED

HEREIN. THE EXPRESS WARRANTY MADE HEREIN MAY NOT

BE ALTERED, ENLARGED, OR CHANGED BY ANY DISTRIBUTOR,

DEALER OR OTHER PERSON WHATSOEVER.

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH

OF ANY WARRANTY, WHETHER EXPRESS OR IMPLIED, FOR ANY

OTHER CONTRACT BREACH, OR FOR NEGLIGENCE OR OTHER

TORT, INCLUDING BUT NOT LIMITED TO LOSSES OF PROPERTY

ARISING OUT OF THE FAILURE OF THIS EQUIPMENT TO OPERATE

FOR ANY REASON WHATSOEVER, ARE EXCLUDED.

Some states and provinces do not allow limitaons on how

long an implied warranty lasts or the exclusions of conse-

quenal or incidental damages, so the above limitaons and

exclusions may not apply to you. This warranty gives you

specic legal rights and you may also have other rights which

vary from state to state or province to province.

DAIKIN WILL NOT BE RESPONSIBLE FOR:

1. Normal maintenance including cleaning of electronic collect-

ing cells and replacement of prelters and carbon VOC lters

as outlined in the Installaon and Maintenance Instrucons.

2. Damage or repairs needed as a consequence of any mis-

applicaon, faulty installaon, abuse, improper servicing,

unauthorized alteraon, or improper operaon.

3. Damage as a result of oods, winds, res, lightning,

accidents, corrosive atmosphere, or other condions

beyond the control of Daikin.

4. Parts not supplied or designated by Daikin.

5. Products installed outside the connental U.S.A., Alaska,

Hawaii and Canada.

Model No.

Serial No.

Date Of Installation

Installed By

Owner’s Name & Address

ATTENTION INSTALLING CONTRACTOR: IF FAILURE SHOULD

OCCUR, DO NOT RETURN PRODUCT TO THE DISTRIBUTOR.

CALL THE TOLL-FREE HOTLINE 1-800-267-8305.

Daikin North America LLC

351 North Rivermede Road

Concord, ON L4K 3N2

FOR TECHNICAL ASSISTANCE, CALL THE AIR CLEANER

HOTLINE TOLL FREE 1-800-267-8305

Our connuing commitment to quality products may mean a change in specicaons without noce.

© 2015 DAIKIN NORTH AMERICA LLC

Houston, Texas • USA

Email: info@cleancomfort.com • 1-800-267-8305 • Fax: 1-416-213-5593

This manual suits for next models

7

Table of contents

Other CLEAN COMFORT Air Cleaner manuals

Popular Air Cleaner manuals by other brands

CLEANAIRE

CLEANAIRE CAHP-50 02 Series instruction manual

Sencor

Sencor SDH 1210WH Translation of the original user manual

Wizard

Wizard Lion instruction manual

KRUEGER

KRUEGER PAC Series Installation, operation and maintenance manual

Solution Ozone

Solution Ozone MAP-APSO01 user manual

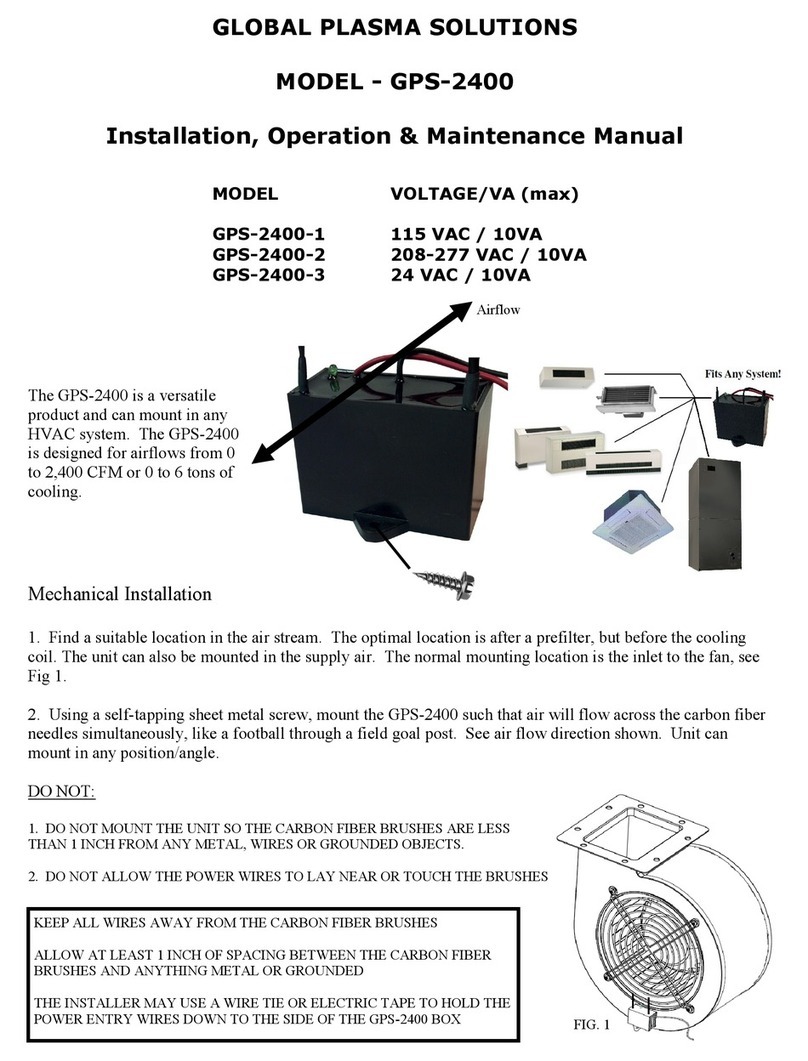

GLOBAL PLASMA SOLUTIONS

GLOBAL PLASMA SOLUTIONS GPS-2400 Installation, operation & maintenance manual