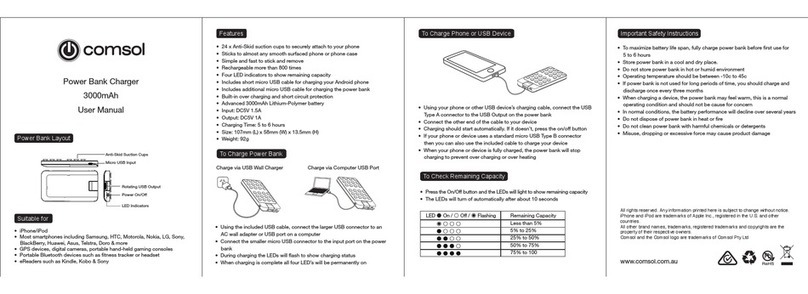

Clean Logix FBHS-MR User manual

USER

MANUAL

English (Original Instrucons)

Updated: 05/12/20

MODEL:

FBHS-MR

Foot Bath Hand Sanizer

FBHS Manual Page 2 of 23 Updated: 05/12/20

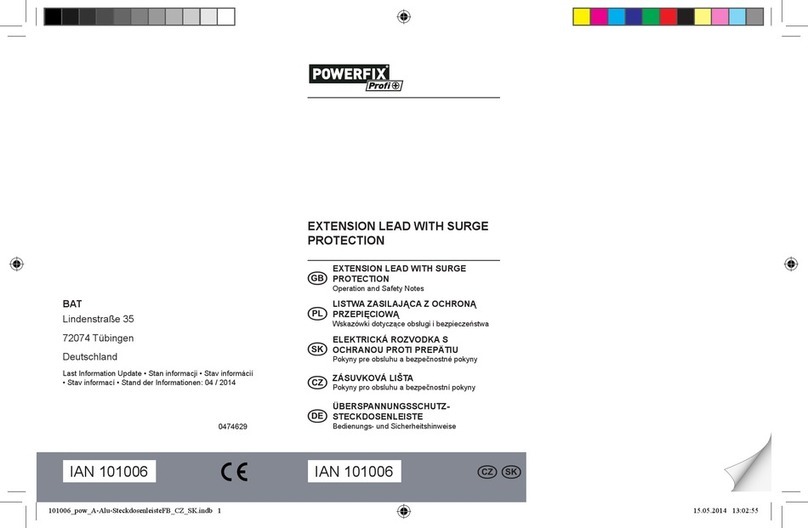

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

!

WARNING:

1. All personnel using this unit must be familiar with

the informaon contained in this manual. Follow all

installaon and maintenance instrucons.

2. Always wear appropriate footwear. Secure or remove

loose items on footwear.

3. Ensure solid foong when operang the unit.

4. Avoid contact of chemicals with skin and eyes. If contact

occurs, see MSDS sheet for further rst aid measures.

5. Follow safety instrucons of chemical manufacturer

(MSDS).

6. Always follow plant and OSHA guidelines about the use

of equipment.

7. Disconnect power before servicing equipment.

8. Always follow safety precauons and obey warning

labels. Failure to do so could result in injury or death.

Table of Contents

System Requirements

Installaon

Physical Set-Up

Plumbing Connecons

Priming

Trac Direcon

Operaon

03

04

06

07

07

08

Cleaning

Maintenance

Troubleshoong

Appendices

Parts Callouts

Electrical Schemacs

P&I Diagram

09

10

12

16

22

23

FBHS Manual Page 3 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Water Supply

• Flow: 5 GPM (3.8L/m) minimum*

• Pressure: 50-60 psi (207-414 kPa)**

• Max Temperature: 70⁰F (4-38⁰C)

3/8" supply piping size recommended

*Minimum pressure must be maintained during

specied water ow!

**For consistent operaon of spray nozzles, a water

pressure regulator and lter is recommended.

Electrical

• 120 VAC Single Phase

• 60 Hz 15 Amps

• Supplied with 8 . power cable with NEMA 5-15P

plug

The FBHS, Foot Bath and Hand Sanizer, applies a

ne mist spray onto the hands through 16 an-drip

nozzles. Concentrated sanizer and water are pre-

mixed in the onboard batch tank before it is applied

to the hands. Dual sensors detect travel direcon

and acvate hand spray when the user enters the

producon area. “Watchdog” mers are programmed

into the system to prevent excessive water loss in the

event of sensor failure. Level switches in both the

foot bath and batch tank detect the liquid level and

automacally replenish as necessary.

Overview

NOTE: Back ow prevenon must be installed

in the water line to this unit. Check local

codes to ensure proper installaon.

System Requirements

!

WARNING:

DO NOT EXCEED maximum water

temperature! Damage can result.

• Construcon: 304L stainless steel (frame). LDPE,

Polypropylene, Fiberglass reinforced Polyester (grate).

• Weight: 200 lb (90.72 kg)

• Dimensions: 48.5" x 47.5" x 46"

(123.2 x 120.6 x 116.8 cm)

• Water Consumpon: 1.5 GPM (3.8 L/m)

• Preset Chemical Diluon Rao: 1:400*

Cleaning Methods

See pages 8 for disassembly and cleaning instrucons.

For chemistry recommendaons:

Specicaons

*NOTE: Unit tested at 70°F using water with

50 psi injector inlet pressure.

!

WARNING:

DO NOT use ammable liquids (i.e. alcohol

based soluons or similar) without diluon.

Use Case Chemical Type

Organic Soils Chlorinated Alkaline or Alkaline based

foaming cleaner

Mineral Buildup Acid based foaming cleaner

NOTE: Chemistry used must be compable

with materials of construcon (listed above).

FBHS Manual Page 4 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

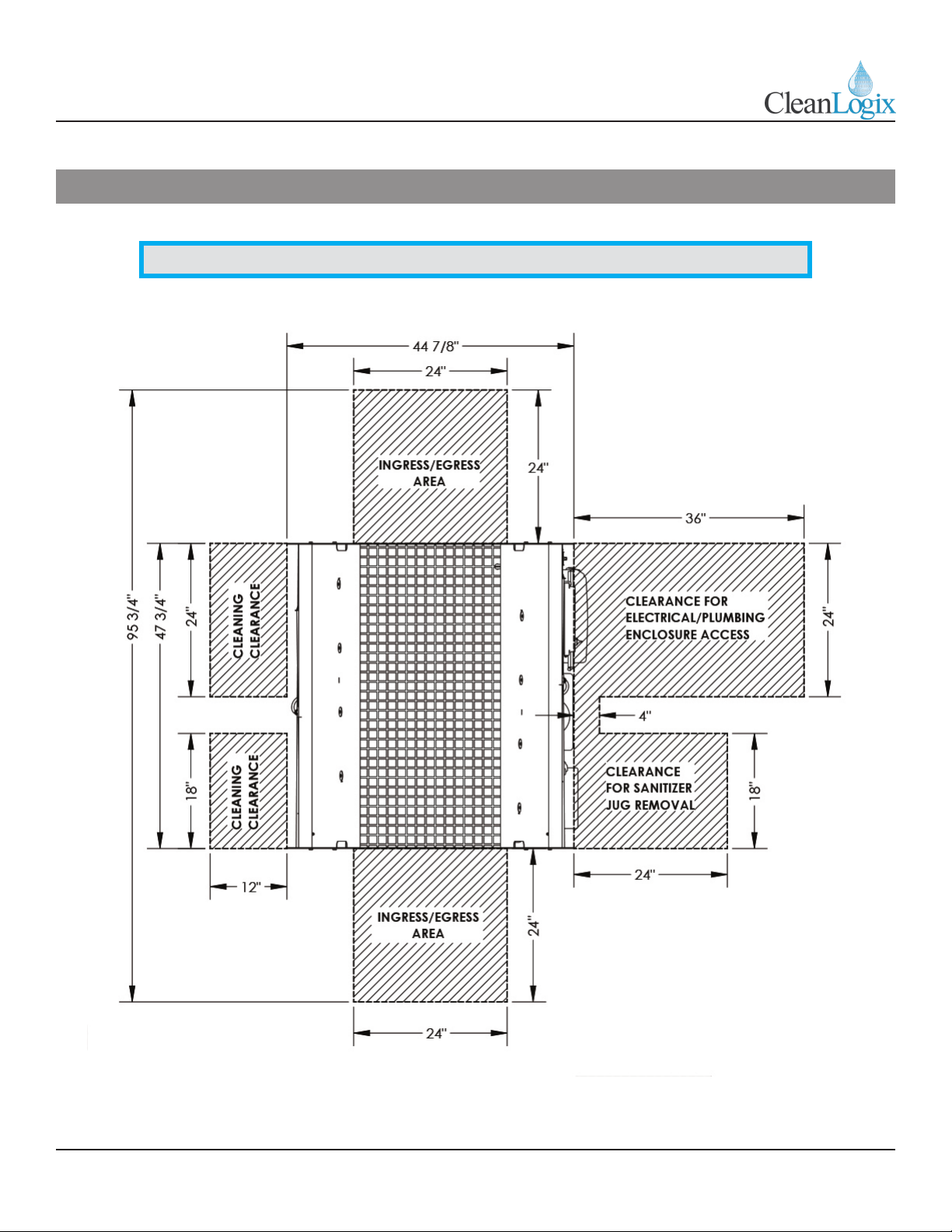

NOTE: For xed installaons, area in front of electrical panel must be clear at least 36"

Installaon

FBHS Manual Page 5 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

NOTE: Trac ow direcon

can be reversed by swapping

wires on inputs I-00 and I-001 of

microcontroller (see electrical

schemac for more informaon).

Installaon

NOTE: Model -MR (Manual Refreash Foot Bath) is for locaons which do not have a

dedicated drain. Foot bath level is maintained by oat switch and is only refreshed

with new sanizer if and when level drops to a point which acvates oat switch.

FBHS Manual Page 6 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Physical Set Up:

1. Set unit in desired locaon.

2. Aspects to consider when deciding on placement:

• Clearance for general use

• Locaon of drain

• Emergency exit paths or egress

• Access to control box

• Connecons for water, electricity, and air

3. Use a level to make sure the unit is stable and

leveled in all direcons [Figure 6.1].

4. Connect unit to electrical supply.

Plumbing Connecons:

1. Using 1/2" LDPE tubing or similar, connect water

to the unit's push to connect ng [Figure 6.2]

2. Using 3/8" LDPE tubing or similar, connect air to

the unit [Figure 6.2].

3. Fill chemical jug with sanizer product and

connect sucon line (label jug for idencaon).

4. If necessary, adjust the diluon rao by selecng

an appropriate metering p (included) and test.

• The unit is pre-congured for a 1:400 diluon

rao.

• The smallest metering p is a yellow p with a

small tube aached. This tube can be trimmed

to alter the diluon rao. [Figure 6.3]

Installaon

NOTE: To move the unit use a pallet jack or a

hi-lo to li from the boom. Pad the forks to

protect the nish. Fig. 6.1: Level and stabilize unit using a leveling device

Capillary

Tube

Addional

Metering Tips

Fig. 6.3: Metering Tips and Capillary Tube

Fig. 6.2: Water and air inlets

Air (3/8")

Water (1/2")

FBHS Manual Page 7 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Installaon

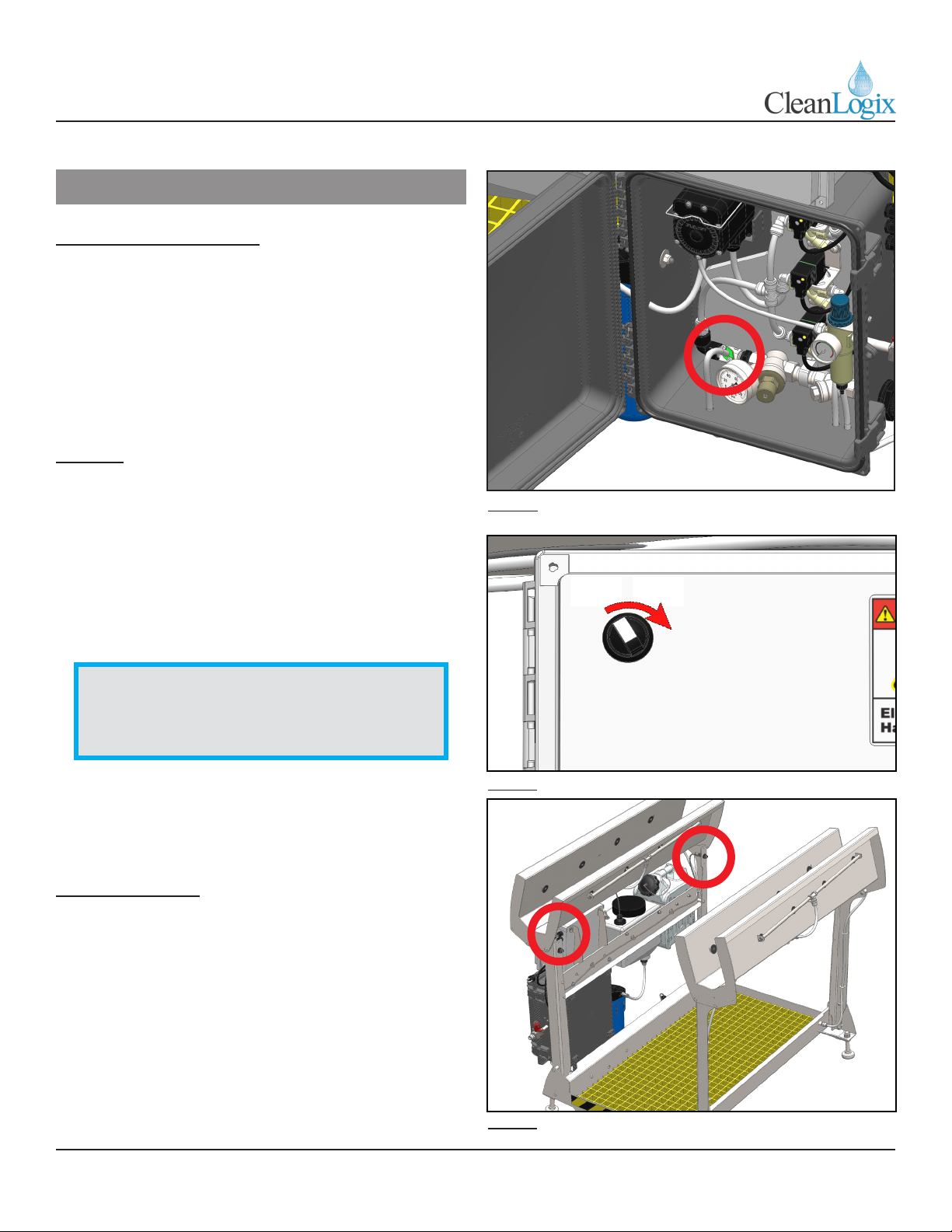

Plumbing Connecons:

• Full length capillary tube results in a diluon

rao of approximately 1:670 at 30-50 psi

water inlet pressure.

• When complete, re-connect soluon lines to

green hose barb of the Venturi Injector located

in plumbing enclosure [Figure 7.1].

Priming

1. Turn switch on control box to ON posion [Figure

7.2].

2. Turn the red-handled compressed air relief valve

on the air inlet to SUP.

3. Prime hand spray system by acvang sensor

at front of unit (either by stepping in front of or

waving your hand) unl soluon begins to spray.

4. Use appropriate means (traon or other) to

ensure sanizer is being mixed into hand spray

and foot bath at the correct ppm.

Trac Direcon

• The hand spray is designed to acvate only when

users are entering the unit from one end. The

default trac direcon is shown in the previous

secon.

• The trac direcon can be changed if desired by

switching the two black wires in terminals I-00

and I-01 on the micro controller (see electrical

schemac for more informaon).

Fig. 7.1: Venturi DEMA Rocket Injector locaon

Fig. 7.2: Controller power switch

OFF ON

Fig. 7.3: Acvaon sensor locaons

NOTE: If the lter cartridge is empty, it may

take 10-20 acvaons of the hand spray

before the lter becomes saturated and the

pump primes.

FBHS Manual Page 8 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

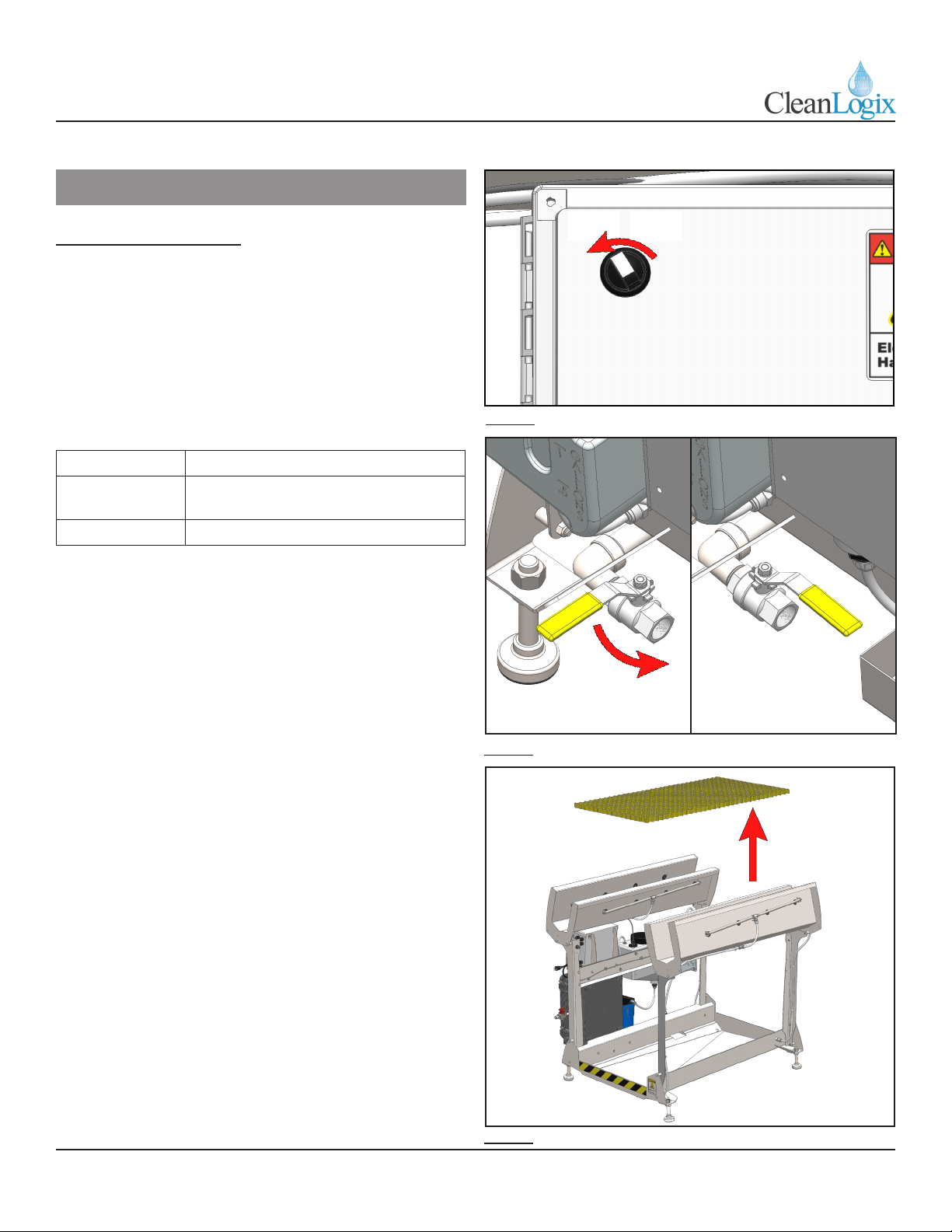

1. Make sure the drain valve is closed [Figure 8.1]

2. Turn the power switch to “ON” [Figure 8.2]

• If the batch tank is low or empty, it should

begin to ll.

• If the foot bath is low or empty, it will begin to

ll aer the batch tank is full.

3. Make sure the red handled air-shuto valve is

turned to “SUP”.

4. Once the foot bath and batch tank are full, the

user may step into the unit.

• The hand spray will acvate as soon as the

user steps into the unit, and will stop one

second aer they step o.

Operaon

NOTE: The hand spray is designed to acvate

only in one trac ow direcon [Figure 8.3].

Flow direcon can be altered if necessary (see

page 7 for more informaon).

Fig. 8.1: Drain valve open (le) to close (right)

Fig. 8.2: Controller power switch

OFF ON

Fig. 8.3: Sensor beam and trac direcon

Sensor

Beam

Trac

Direcon

FBHS Manual Page 9 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

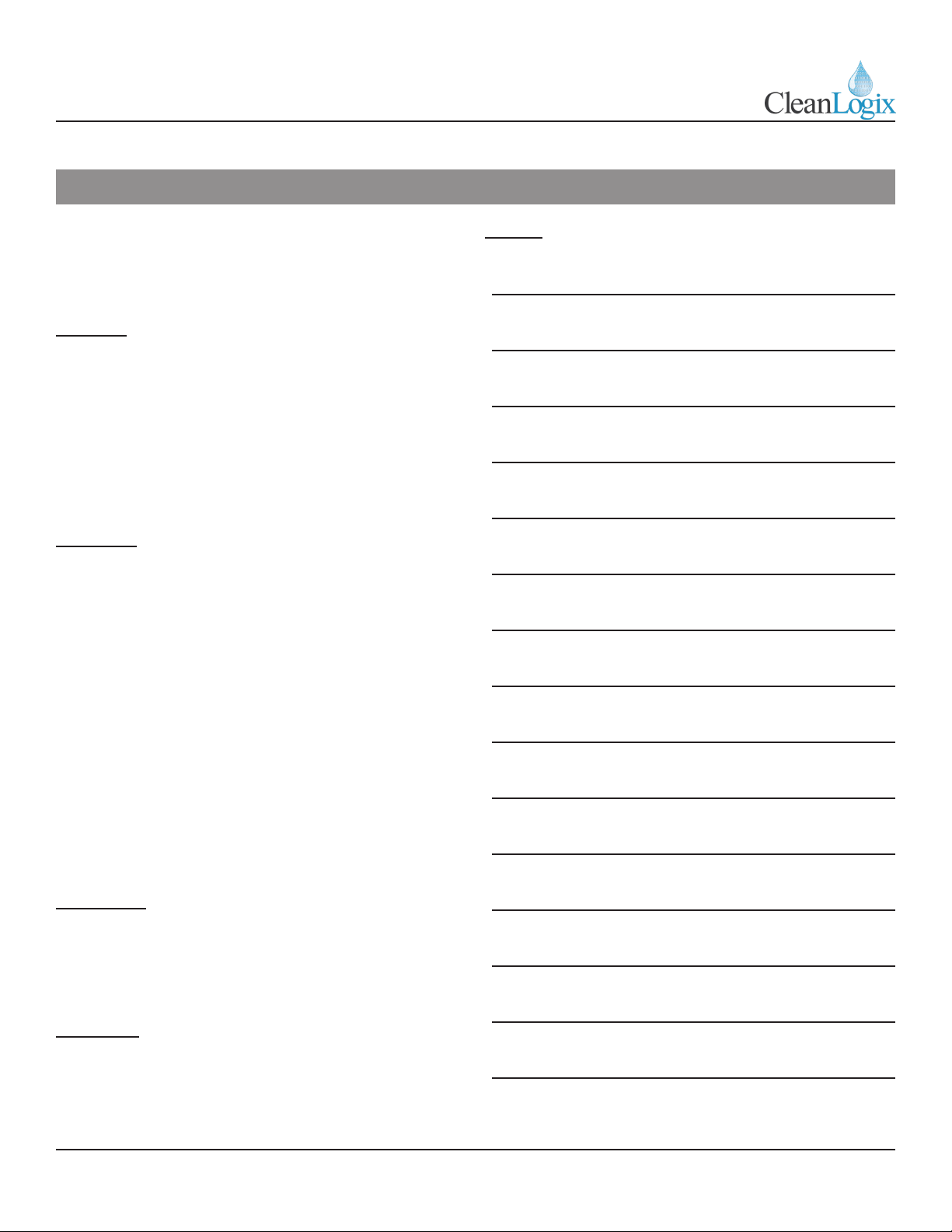

Cleaning Instrucons

1. Turn the power switch to “OFF” [Figure 9.1].

2. Open the drain valve to drain the foot bath [Figure

9.1].

3. Use a cleaner that will not aack 304 stainless

steel or any of the materials listed in the unit

specicaons.

Use Case Chemical Type

Organic Soils Chlorinated Alkaline or Alkaline based

foaming cleaner

Mineral Buildup Acid based foaming cleaner

4. Avoid direct water spray around the control boxes

and wiring entering/exing the control boxes.

5. If necessary, remove the yellow walkway grate to

allow beer cleaning of the tub [Figure 9.3].

Cleaning Procedures

Fig. 9.3: Removing foot grate

Fig. 9.1: Controller power switch

OFF ON

Fig. 9.2: Drain valve closed (le) to open (right)

FBHS Manual Page 10 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Notes:

The following maintenance procedures are

recommended for normal use. Units which see a high

amount of use should be inspected more frequently.

Weekly:

• Check unit for proper sensor and spray funcon.

• Ensure foot grate is secure

• Inspect nozzles for clogs and clean if necessary

• Verify oat switch is funconing properly.

• Check diluon rao.

Monthly:

• Check all fasteners to ensure they are ght.

• Ensure warning labels and decals are present

and in good condion.

• Inspect grate for wear or damage.

• Verify unit is level and

• Inspect electrical enclosure for signs of water

intrusion.

• Inspect sensors for damage.

• Inspect nozzles for damage or wear.

• Inspect electrical cords and plumbing for

damage.

Quarterly:

• Inspect structure for cracked welds or bent

components.

Annually:

• Replace lter (~50,000 acvaons)

Preventave Maintenance

FBHS Manual Page 11 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Preventave Maintenance

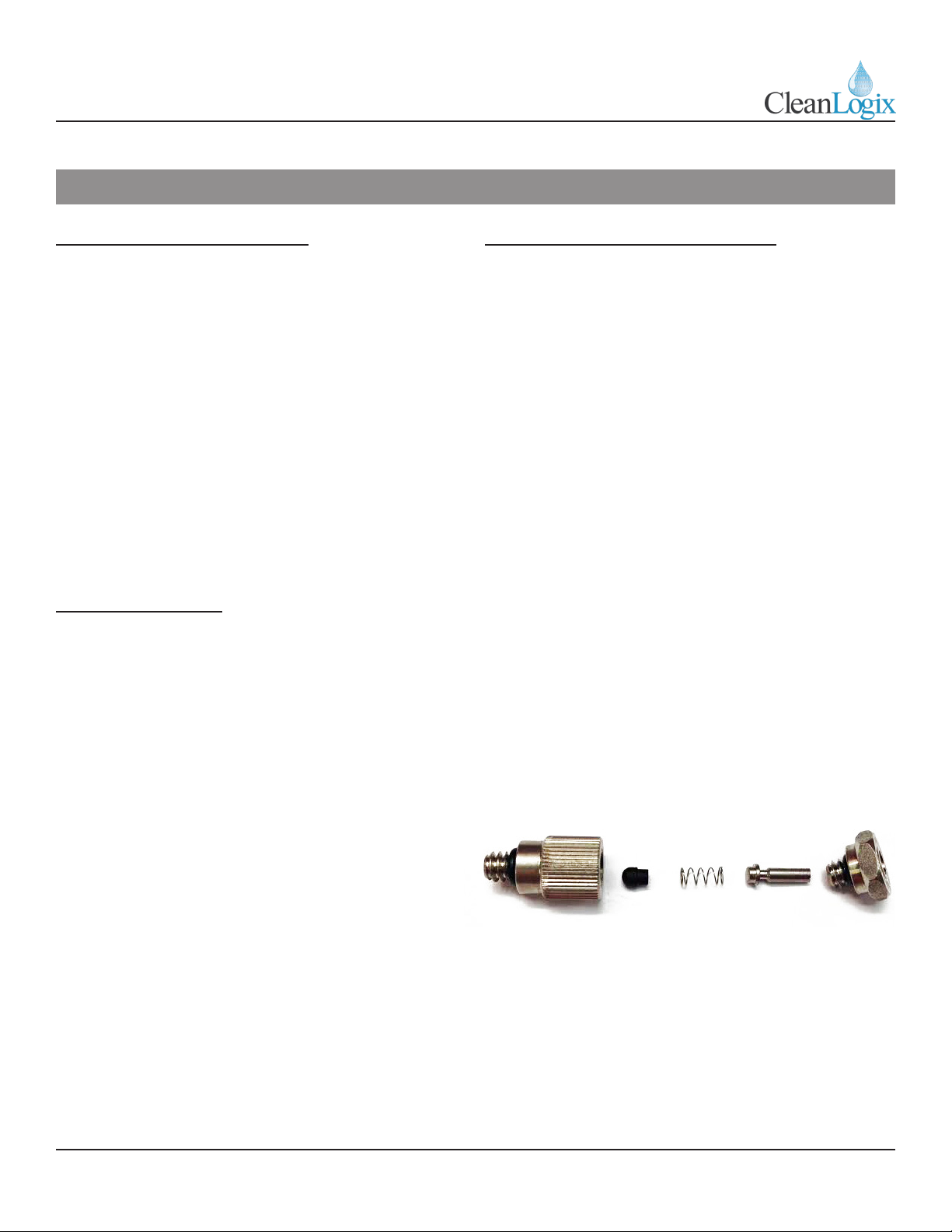

Nozzle Disassembly and Cleaning

1. Unscrew nozzle from outside of trough using

pointer nger and thumb (see parts callout for

more informaon).

2. Remove the rubber shield washer from the nozzle

3. The nozzle can be disassembled by unscrewing

the check valve assembly from the nozzle orice.

• There is a pintle, a rubber bulb and spring

inside the check valve poron of the body.

These parts are VERY small - take cauon not

to lose them! (see below)

4. Clean the body and orice poron of the nozzle

using compressed air and inspect.

5. Re-assemble the nozzle

• Make sure the small rubber p and the pintle

are seated properly inside the spring and are

in the correct orientaon. See image below.

6. Reinstall the shield washer and screw the nozzle

back into the spray bar.

• Finger ghten only! Do NOT use wrenches!

Foot Bath Depth Adjustment

The depth of the foot bath can be adjusted by sliding

the foot bath oat switch assembly up or down.

1. Loosen the screw band clamp which holds the

oat switch.

• Slide oat switch upward to increase the

depth of the bath.

• Slide it downward to decrease the depth.

2. Re-ghten screw band clamp. Do not overghten.

Filter Replacement

The lter should be replaced once per year or

approximately 50,000 acvaons (whichever comes

rst).

1. Turn the switch on the control box to “OFF” to

power down the system.

2. Turn red-handled compressed air relief valve to

“EXH” to exhaust air pressure.

3. Unscrew the blue lter housing and remove lter

4. Install new lter and replace blue housing,

screwing it on hand-ght. Do NOT use a wrench!

FBHS Manual Page 12 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

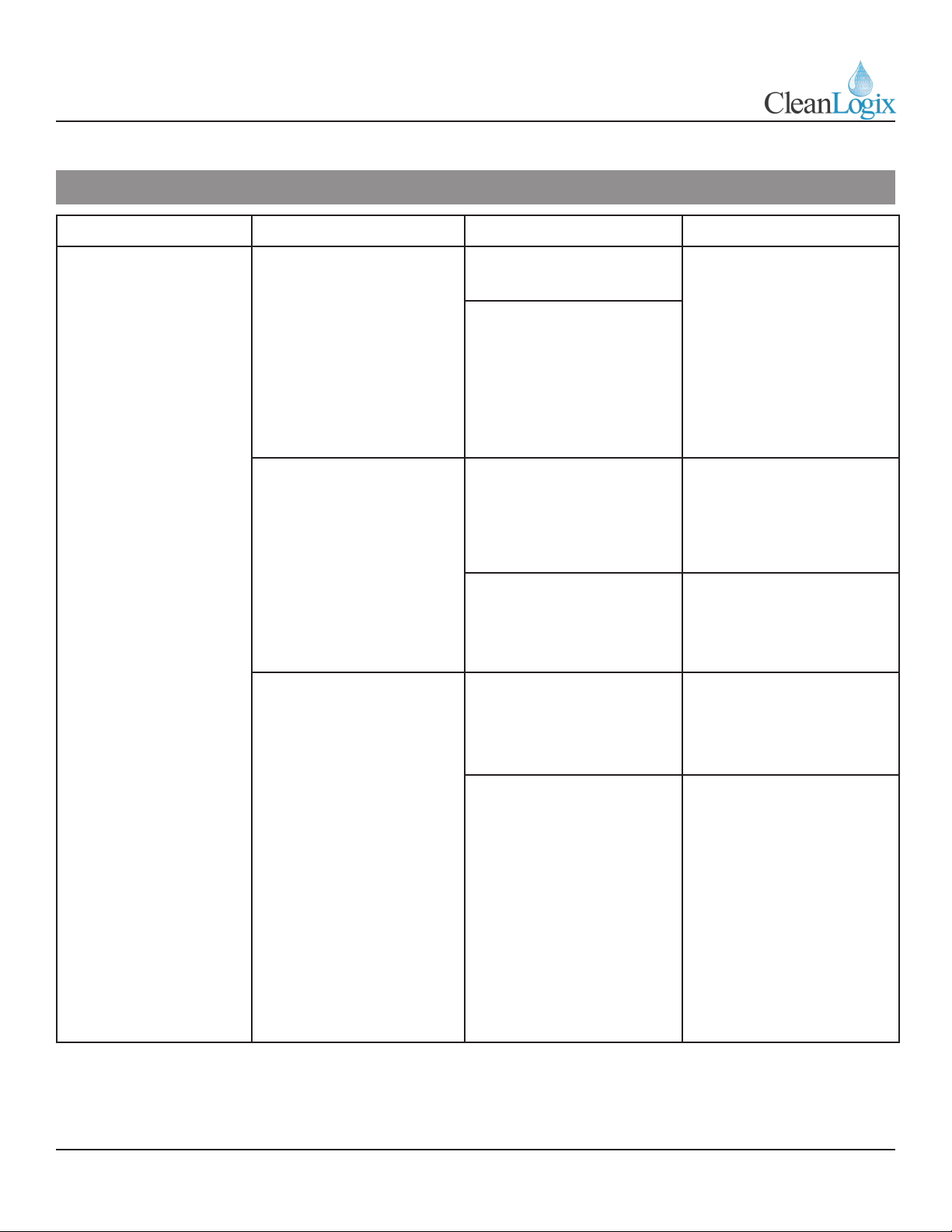

Troubleshoong

Problem Causes Soluons Notes

The foot bath does not

ll

The drain valve was le

open while the unit was

aempng to ll the

foot bath, causing the

controller to me out

Close the drain valve. If the foot bath or batch

tank fail to ll up within

a specic amount of

me, the unit will stop

aempng to ll them

unl it is reset. This

Prevents excessive water

loss in the event of a

failure.

Reset the unit by turning

the power switch to “OFF”

and then back to “ON”.

The water supply is

turned o or pressure is

excessively low

Make sure the water

supply is ON and the water

pressure regulator on the

unit reads at least 50 psi.

Reset the unit by turning

the power switch to “OFF”

and then back to “ON”.

The foot bath solenoid

valve is faulty or clogged

Reset the unit by turning

the power switch to “OFF”

and then back to “ON”.

Wait for the batch tank

to ll, or manually li the

oat switch inside the

batch tank and then check

to see if the orange light

on the foot bath solenoid

coil connector illuminates.

If the light illuminates but

no water ows, repair or

replace valve.

FBHS Manual Page 13 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

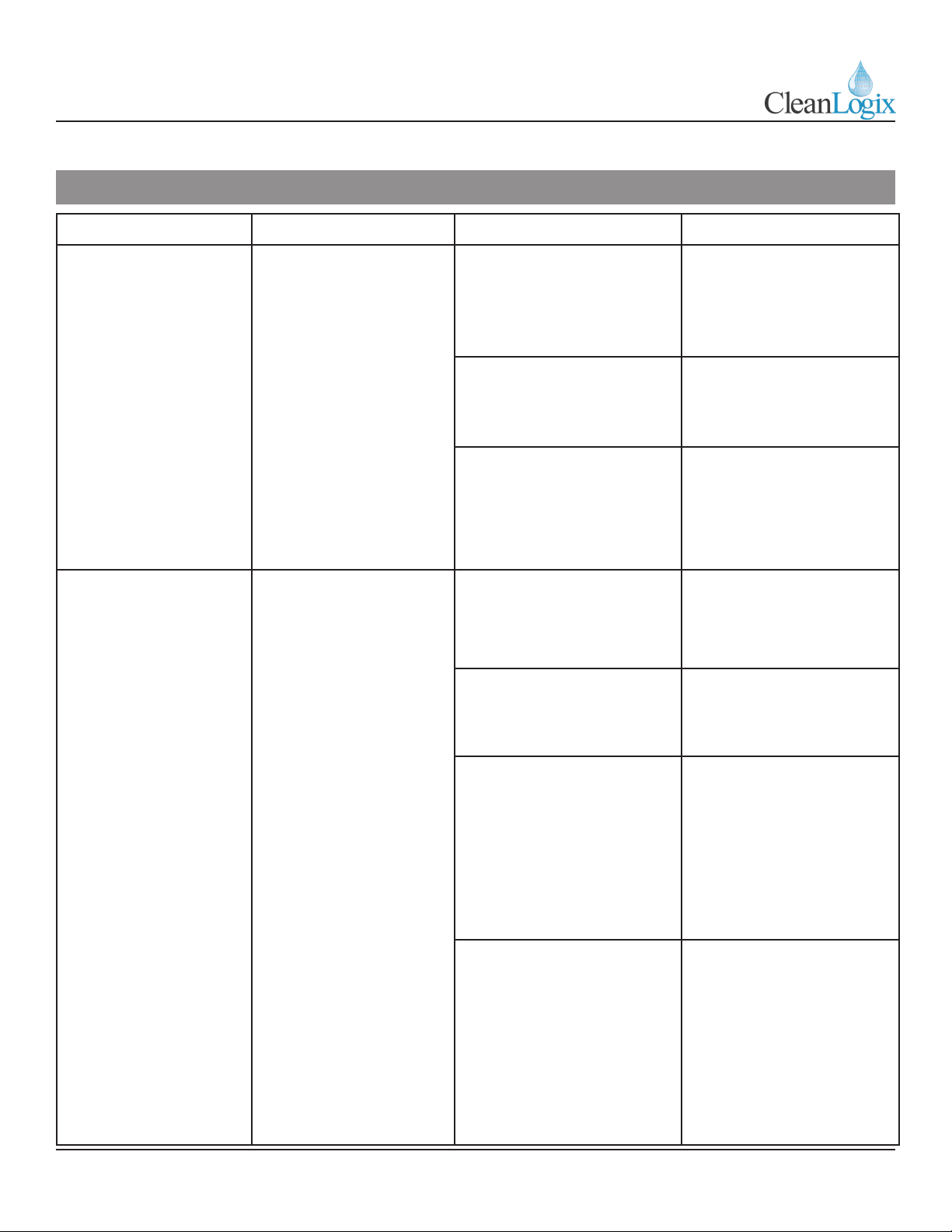

Troubleshoong

Problem Causes Soluons Notes

The foot bath overows The oat switch is faulty

or out of adjustment

Open the drain valve to

lower the water level in

the foot bath such that it is

below the walkway grang.

Reset the unit by turning

the power switch to “OFF”

and then back to “ON”.

Test the oat switch

funcon as detailed in the

maintenance instrucons

and adjust or replace as

necessary.

The hand spray does

not funcon

(See Connued....)

The batch tank is empty

Make sure the water

supply is on and the water

pressure regulator on the

unit reads at least 50 psi.

Reset the unit by turning

the power switch to “OFF”

and then back to “ON”.

Make sure the light on

the batch tank solenoid

coil connector illuminates

and water begins to ow

into the tank. If the light

illuminates but no water

ows, replace the solenoid

valve.

Test the batch tank oat

switch funcon as detailed

in the maintenance

instrucons and adjust or

replace as necessary.

If the foot bath or batch

tank fail to ll up within

a specic amount of

me, the unit will stop

aempng to ll them

unl it is reset. This

prevents excessive water

loss in the event of a

failure.

FBHS Manual Page 14 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

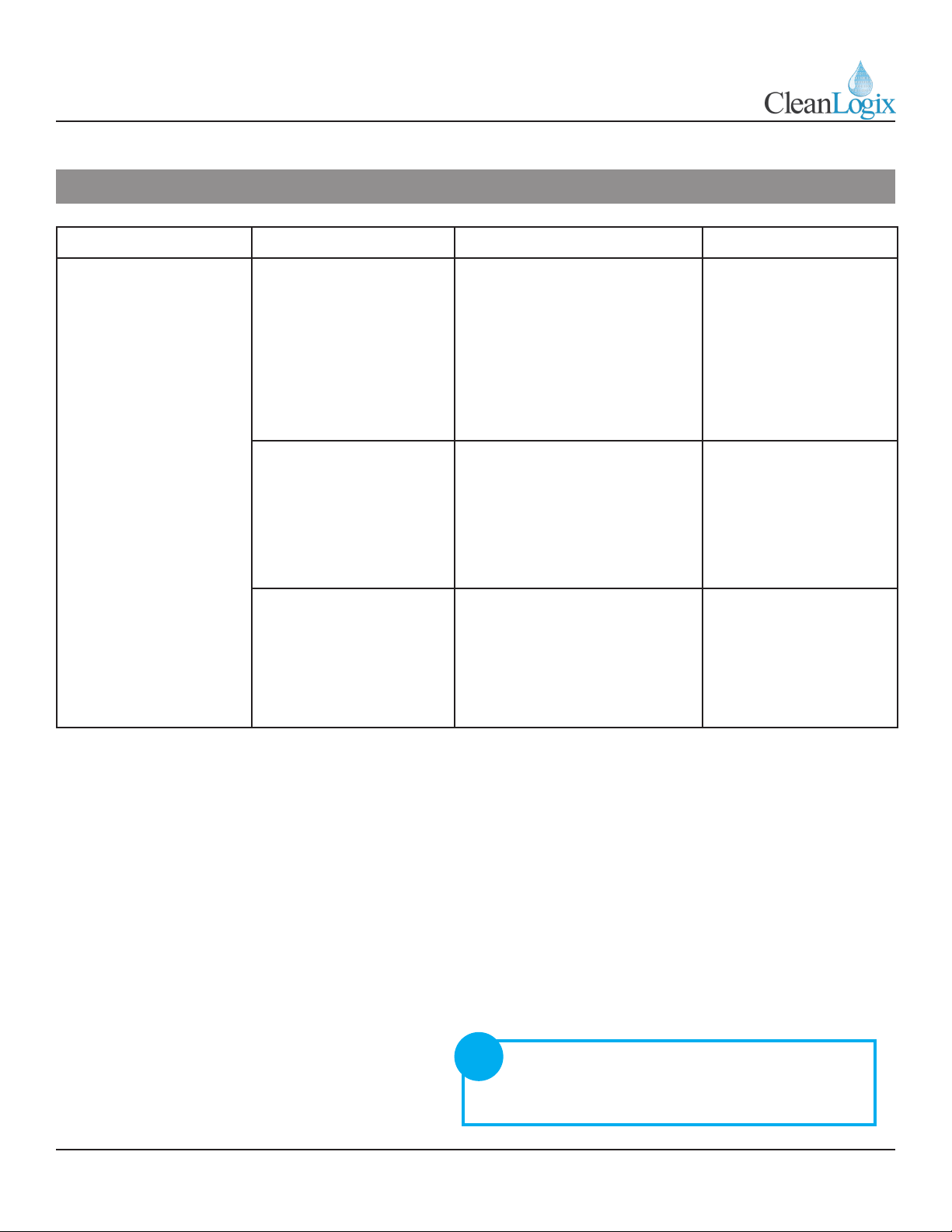

Troubleshoong

Problem Causes Soluons Notes

The hand spray does

not funcon

(connued)

Compressed air supply is

turned o

Make sure the air supply is on

and the red-handled shuto

valve is set to “SUP”. The air

pressure regulator gauge on

the unit should read between

80 and 100 psi.

The hand spray solenoid

valve is faulty or clogged

Check to see if the orange light

on the hand spray solenoid coil

connector illuminates when

the photo eye is tripped. If the

light illuminates but the hand

spray does not acvate, repair

or replace the solenoid valve.

Pump failure

If the hand spray solenoid

valve is open, and compressed

air is supplied to the pump

but it fails to cycle, replace the

pump

Clogged lter

Unscrew the blue lter

housing and check lter or

debris or clogs. Replace the

lter element if necessary.

The batch tank

overows Faulty oat switch

Test the batch tank oat switch

funcon as detailed in the

maintenance instrucons and

replace as necessary.

FBHS Manual Page 15 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Troubleshoong

Problem Causes Soluons Notes

Poor spray

performance, or some

nozzles spray while

others do not

Clogged nozzles

Turn the power switch to

“OFF” and turn the red-

handled air shuto valve to

“EXH”. Clean or replace the

nozzles as detailed in the

maintenance instrucons. Turn

the power “ON” and the air to

“SUP” and test.

Clogged Filter

Unscrew the blue lter

housing and check lter or

debris or clogs. Replace the

lter element if necessary.

Low air pressure

Make sure the pressure gauge

on the air pressure regulator

reads between 80 and 100 psi.

Please contact your equipment representave

or manufacturer for further support.

iMore Informaon?

FBHS Manual Page 16 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

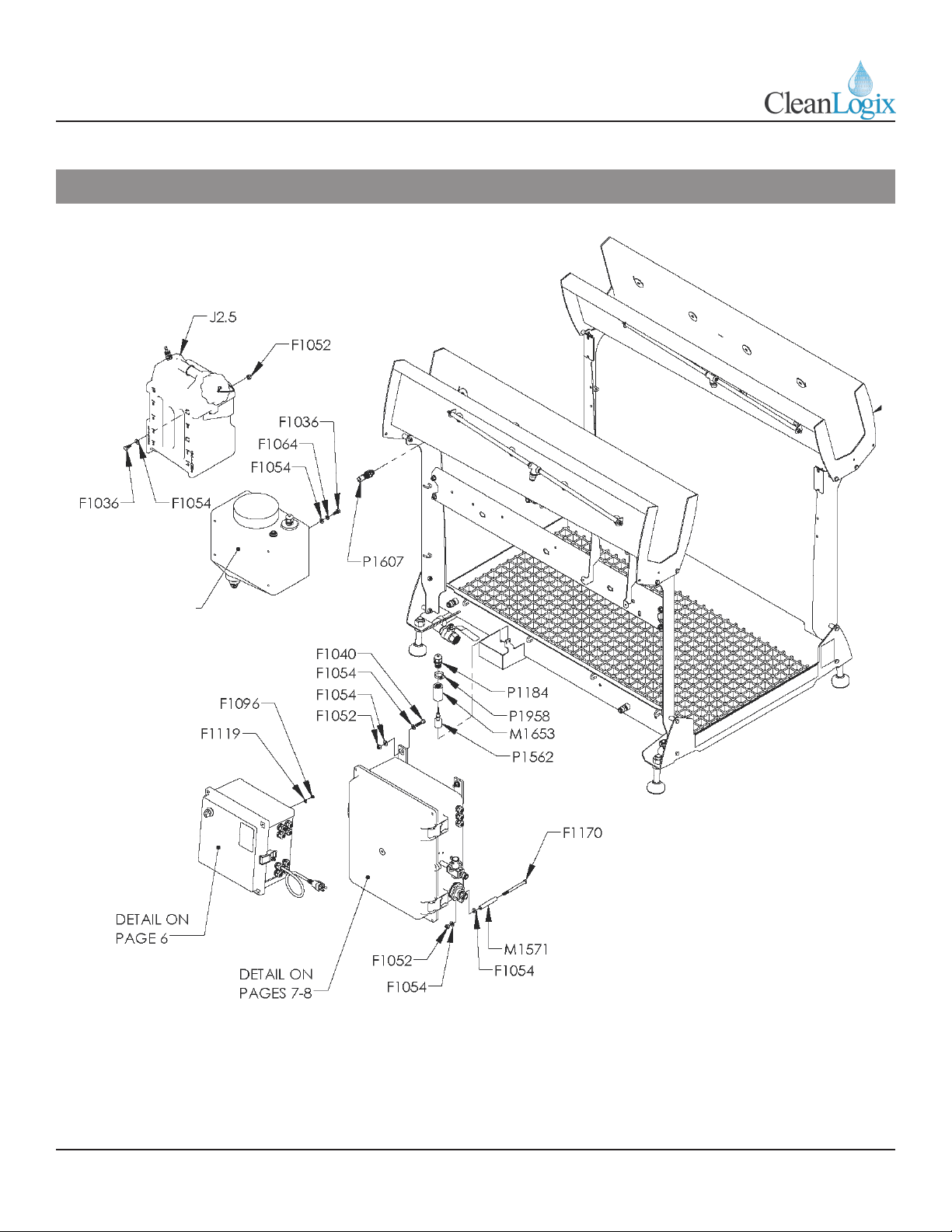

Appendix A - Parts Callout

DETAIL ON

NEXT PAGE

FBHS Manual Page 17 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

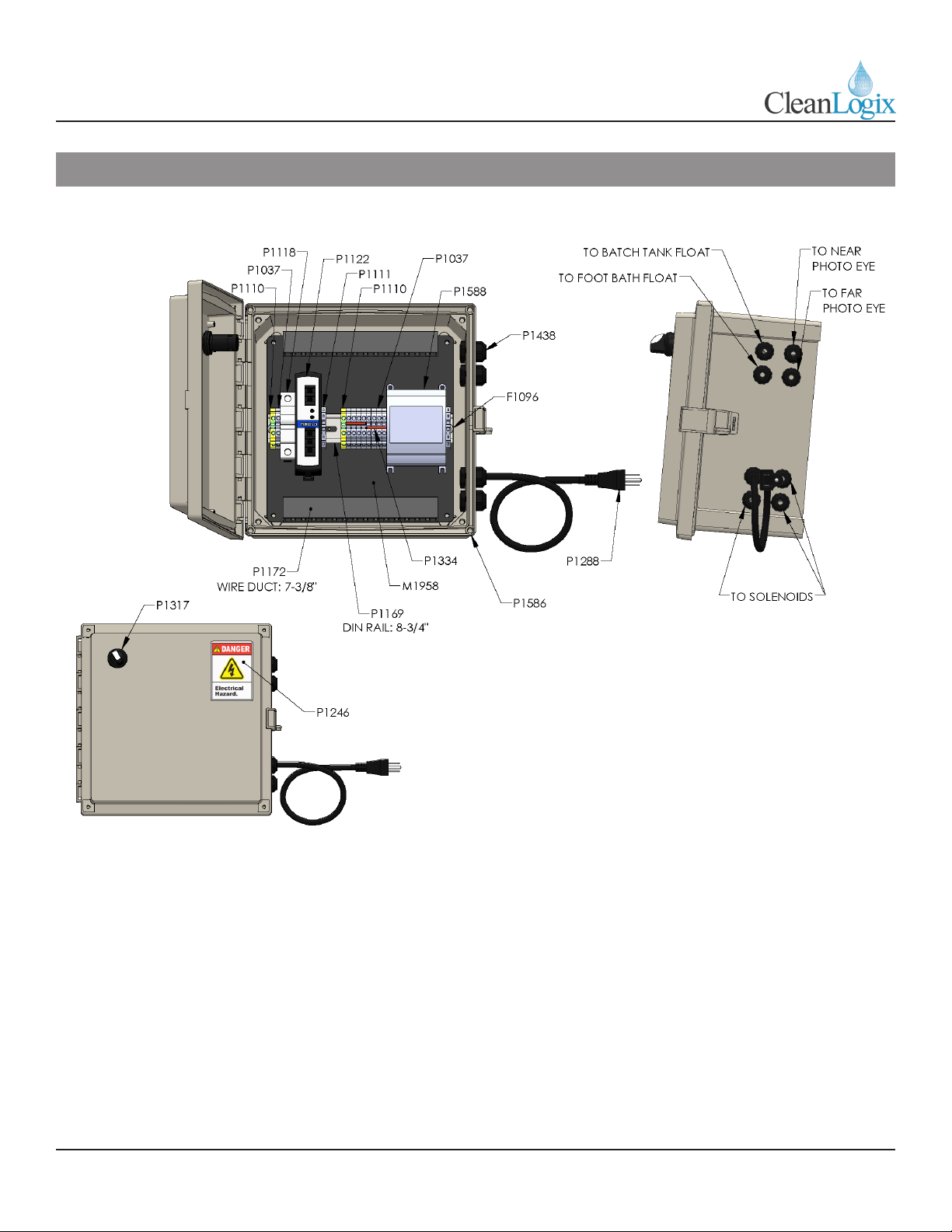

Appendix A - Parts Callout

FBHS Manual Page 18 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Appendix A - Parts Callout

FBHS Manual Page 19 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Appendix A - Parts Callout

FBHS Manual Page 20 of 23 Updated: 05/12/20

USER MANUAL: FBHS-MR

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Appendix A - Parts Callout

PART NUMBER DESCRIPTION

F1012 SCREW MACHINE 10-32 x 5/8 SS PHILLIPS

F1024 SCREW MACHINE 1/4-20 x 3/4 SS PHILLIPS

F1036 BOLT HHC 5/16-18 X 3/4 SS

F1039 BOLT HHC 5/16-18 x 1 SS

F1040 BOLT SHCS 5/16-18 X 1-1/4 SS

F1052 NUT NYLOCK 5/16-18 SS

F1054 WASHER 5/16 SS TYPE A

F1064 WASHER SPLIT LOCK 5/16 SS

F1066 NUT NYLOCK 10-32 SS

F1073 SCREW MACHINE 6-32 x 3/4 SS PHILLIPS PAN HD

F1085 WASHER FENDER 5/16 SS

F1096 SCREW MACHINE 10-32 X 3/8 SS PHILLIPS PAN HD

F1096 SCREW MACHINE 10-32 X 3/8 SS PHILLIPS TRUSS HD

F1119 WASHER #10 SS TYPE A

F1125 NUT NYLOCK 6-32 SS

F1128 WASHER SPLIT LOCK 1/4 SS

F1144 NUT HEX 3/4-10 SS

F1169 BOLT HHC 5/16-18 X 1-3/4 SS

F1170 BOLT HHC 5/16-18 X 4 SS

F1179 WASHER SPLIT LOCK #10 SS

M1134 SOLENOID BRACKET

M1557 FBHS HAND TROUGH WELDMENT

M1559 FBHS TUB WELDMENT

M1562 FBHS UPRIGHT WELDMENT RIGHT

M1563 FBHS UPRIGHT WELDMENT LEFT

M1565 FBHS GRATING

M1566 FBHS SPRAY BAR

M1570 STANDOFF 5/16 X 1/2 X 1 SS

M1571 STANDOFF 5/16 X 1/2 X 3 SS

M1652 FBHS BOX MOUNT WELDMENT

M1653 FLOAT SWITCH COUPLER 1/2" X 2" MACHINED

M1658 FBHS PUMP ENCLOSURE PANEL

M1958 "FBHS CONTROLLER BACK PANEL FIBOX AR1010

P1037 TERMINAL BLOCK 2 POS DIN RAIL

P1103 PIPE TEE 1/4 SS

P1110 TERMINAL BLOCK 2 POS GND DIN RAIL

P1111 END STOP TERMINAL BLOCK

P1118 SUPPLEMENTARY PROTECTOR 5A

P1122 POWER SUPPLY 24VDC 60W

P1136 PIPE HEX NIPPLE 1/2 X 1/2 POLY

P1169 DIN RAIL 35mm X 225mm LONG

PART NUMBER DESCRIPTION

P1172 WIRE DUCT 25X60 X 188mm LONG

P1184 CORD GRIP 1/2 NPT X .095-.260 BLK

P1187 SOLENOID CABLE 18mm DIN 24V

P1202 QUICK FIT ELBOW 3/8 NPT X 3/8" TUBE

P1206 GAUGE 1-1/2" DUAL SCALE

P1207 PIPE PLUG 1/8 SQUARE SS

P1209 QUICK FIT ADAPTER 1/4" NPT X 1/4" TUBE

P1211 QUICK FIT 1/4 NPT X 3/8 TUBE

P1213 MOUNTING BRACKET A33-82

P1214 QUICK FIT 3/8" T JOINT POLYPRO

P1219 QUICK FIT 3/8 NPT X 3/8 TUBE

P1221 QUICK FIT ELBOW 1/4" NPT x 3/8" TUBE

P1267 QUICK FIT BULKHEAD 3/8"

P1270 SHUTOFF/LOCKOUT VALVE 1/4 NPT

P1271 3/8" OD POLYETHYLENE TUBING- NATURAL

P1273 QUICK FIT ADAPTER 1/2" NPT x 1/2" TUBE

P1284 EXTERNAL THREADED FEET 3/4" X 4" 1100 LB.

P1288 POWER CORD 18-3 SO 5-15P

P1302 PIPE NIPPLE 1/4 X 3 SS

P1313 REGULATOR 1/4"

P1317 SWITCH, 2-POS SELECTOR, 2NO, BLK

P1334 JUMPER- 4 POSITION

P1345 PIPE BUSHING 1/2" X 1/8" PP

P1359 QUICK FIT ADAPTER 1/2" NPT X 3/8" TUBE

P1367 2.5 GALLON JUG W/ WALL BRKT

P1397 STRAINER Y 1/2" NPT 316SS 100 MICRON

P1398 PRESSURE REGULATOR WATER 1/2" SS

P1399 PRESSURE GAUGE WRG14

P1405 PIPE CLIP 1/2"

P1408 PIPE NIPPLE 1/2 X 2 SS

P1438 CORD GRIP PG9 X .065-.230 BLK

P1450 PIPE BUSHING 3/4" X 1/2" POLY

P1471 MIST NOZZLE .020 SS FULL CONE WITH CHECK

P1472 PIPE ELBOW STREET 3/4 SS

P1475 BALL VALVE 3/4" SS W/ LOCKING LEVER

P1498 BULKHEAD TANK FITTING 1/2" NPT

P1508 1/4" OD POLYETHYLENE TUBING- NATURAL

P1544 QUICK FIT AIR INLET 1/4" FLOWJET P56

P1562 FLOAT SWITCH SPST PVDF 1/8" NPT

P1564 "WIRE, CONTROL CABLE, 20 AWG, 3-CONDUCTOR,

UNSHIELDED, GRAY PVC JACKET"

Other Clean Logix Accessories manuals