edc DT 550 User manual

EN - English

DT 550 Rev1.0 May20 Page 1 of 50

Instruction manual

Flow Sensor

DT 550

Foreword

DT 550 Rev1.0 May20 Page 2 of 50

I. Foreword

Dear customer,

thank you very much for deciding in favour of the DT 550. Please read this

installation and operation manual carefully before mounting and initiating the device

and follow our advice. A riskless operation and a correct functioning of the

DT 550 are only guaranteed in case of careful observation of the described

instructions and notes

Table of Content

DT 550 Rev1.0 May20 Page 3 of 50

II. Table of Content

I. Foreword .......................................................................................................................................... 2

II. Table of Content............................................................................................................................... 3

1Pictograms and Symbols ................................................................................................................. 5

2Signalwords according ISO 3864 and ANSI Z 535.......................................................................... 5

3Safety instructions............................................................................................................................ 6

3.1 Intended Use............................................................................................................................. 7

3.2 Installation and commissioning................................................................................................. 7

4Technical data.................................................................................................................................. 8

4.1 Signal circuits............................................................................................................................ 9

4.1.1 Modbus................................................................................................................................ 9

4.1.2 Current output...................................................................................................................... 9

4.1.2.1 Aktive........................................................................................................................... 9

4.1.2.2 Passive ........................................................................................................................ 9

4.1.3 Pulse.................................................................................................................................... 9

4.1.4 Alarm ................................................................................................................................... 9

4.2 Measuring range flow DT 550................................................................................................. 10

4.2.1 Maximum Flow Ranges „Low Speed“................................................................................ 11

1.1.1 Measuring range „Standard Version“ ................................................................................ 13

1.1.2 Measuring range „Max Version“ ........................................................................................ 15

1.1.3 Measuring range „High Speed Version“ ............................................................................ 17

5Dimensions..................................................................................................................................... 19

5.1 Dimension DT 550 .................................................................................................................. 19

6Installation ...................................................................................................................................... 20

6.1 Pipe/tube requirements........................................................................................................... 20

6.2 Inlet / outlet runs...................................................................................................................... 20

6.3 Installation DT 550.................................................................................................................. 21

6.3.1 ½“ welded nipple with ball valve ½“................................................................................... 21

6.3.2 Spot drilling collar with ball valve....................................................................................... 21

6.4 Installation of the Sensor ........................................................................................................ 22

6.4.1 Mounting DT 550 onto the ball valve................................................................................. 22

6.5 Alignment Display (Housing)................................................................................................... 23

6.6 Tightening torques .................................................................................................................. 23

7Connection diagram....................................................................................................................... 24

7.1 Cable glands - clamping ranges ............................................................................................. 24

7.2 Connector pin assignment ...................................................................................................... 24

7.3 Wire connection ...................................................................................................................... 26

7.3.1 General.............................................................................................................................. 26

7.3.2 Power supply..................................................................................................................... 26

7.3.3 Modbus RTU...................................................................................................................... 26

7.3.4 Modbus TCP (Ethernet) Optional PoE .............................................................................. 27

7.3.5 Pulse Output...................................................................................................................... 27

Table of Content

DT 550 Rev1.0 May20 Page 4 of 50

8Operation DT 550....................................................................................................................... 28

8.1Main menu (Home)................................................................................................................ 29

8.1.1 Intialization......................................................................................................................... 29

8.2 Main menu ............................................................................................................................. 29

8.3 Settings.................................................................................................................................. 30

8.3.1 Sensor Setup..................................................................................................................... 31

8.3.1.1 Input / change tube diameter..................................................................................... 31

8.3.1.2 Input / change consumption counter ......................................................................... 32

8.3.1.3 Definition of the units for flow, velocity, temperature and pressure........................... 32

8.3.1.4 Definition of the reference conditions........................................................................ 33

8.3.1.5 Setting of Zeropoint and Low-flow cut off.................................................................. 35

8.3.2 Modbus RTU...................................................................................................................... 36

8.3.3 Modbus TCP (Optional)..................................................................................................... 37

8.3.3.1 Setup ......................................................................................................................... 37

8.3.3.1.1 Network Setup DHCP........................................................................................... 37

8.3.3.1.2 Network Settings static IP..................................................................................... 38

8.3.3.1.3 Modbus TCP Settings........................................................................................... 39

8.3.3.2 Modbus Settings (2001…2005).............................................................................. 40

8.3.3.3 Values Register (1001 …1500) ................................................................................. 40

8.3.4 Pulse /Alarm ...................................................................................................................... 42

8.3.4.1 Pulse output............................................................................................................... 42

8.3.5 User Setup......................................................................................................................... 43

8.3.5.1 Password................................................................................................................... 43

8.3.5.2 Language................................................................................................................... 43

8.3.5.3 Display / Touch.......................................................................................................... 44

8.3.6 Advanced........................................................................................................................... 44

8.3.7 4 -20mA............................................................................................................................. 45

8.3.8 DT 550 Info........................................................................................................................ 47

8.4 MBus ...................................................................................................................................... 48

8.4.1 Change of communication settings ................................................................................... 48

8.4.2 Coding VIF (Value Information Field)................................................................................ 49

8.4.3 Default Settings communication........................................................................................ 49

8.4.4 Default values transmitted................................................................................................. 49

9Supplementary Documentation.................................................................................................. 50

Pictograms and Symbols

DT 550 Rev1.0 May20 Page 5 of 50

1 Pictograms and Symbols

General Warning symbol (Danger, Warning, Caution)

General note

Installation- and Instruction manual to consider (on Nameplate)

Installation- and Instruction manual to consider

2 Signal words according ISO 3864 and ANSI Z 535

Danger!

Imminent danger

As a consequence of incorrect handling: serious personal injury or death

Warning!

Possible hazard

As a consequence of incorrect handling: possible serious injury or death

Caution!

Imminent hazard

As a consequence of incorrect handling: possible personal injury or damage

Note!

Possible hazard

As a consequence of incorrect handling: possible personal injury or damage

Important!

Additional notes, information, tips

As a consequence of incorrect handling: Disadvantages in operation and maintenance,

no danger

Safety Instructions

DT 550 Rev1.0 May20 Page 6 of 50

3 Safety instructions

Please check whether this manual corresponds with the device type.

Please attend to all notes indicated in this instruction manual. It contains essential information,

which has to be followed during installation, operation and maintenance. Therefore this

instruction manual has to be read categorically by the technician as well as by the responsible

user/qualified personnel before installation, initiation and maintenance

Regional and national regulations respectively, have to be observed in addition to this instruction

manual if necessary.

This instruction manual must be available at any time at the operation site of the DT 550.

Ensure that the DT 550 operates within the permissible and listed limits on the nameplate.

Otherwise there is a risk to human and material, and it may occur functional and operational

disturbances

In case of any obscurities or questions with regard to this manual or the instrument please contact

manufacturer.

Warning!

Risk of injury in case of inadequate qualification!

Improper handling can result in significant personal injury and damage.

All activities described in this operating instructions manual must be carried out only by

qualified personnel qualifications described below.

Professionals (Technical staff)

The technical staff is based on his education/training, his knowledge of measurement and control

technology as well of the local regulations, standards and guidelines in the position to do the work as

described and to identify the possible hazards.

Special working conditions require further appropriate knowledge, e.g. of aggressive media.

Caution!

Malfunction of DT 550

Faulty installation and insufficient maintenance may lead to malfunctions of the DT 550 which may

affect the display and open to misinterpretation.

Danger!

Inadmissible operating parameters!

By exceeding or falling short of limits there is a risk for people and material, in addition there may

occur further functional and operational disturbances.

Measures:

•Make sure that the DT 550 operates only within the permissible and listed limits on the nameplate

•Ensure the operation within the performance data of DT 550 in connection with the application

•Do not exceed the admissible storage and transportation temperature.

Additional safety information:

•When installing and operating the relevant national regulations and safety rules must also be

observed.

In gas hazardous areas (explosive media) only the version DT 550 EX must be used.

When using the Flow-/ Consumption sensors DT 550 Ex in gas hazardous areas the special

requirements specified in the Ex documentation must be observed.

Safety Instructions

DT 550 Rev1.0 May20 Page 7 of 50

3.1 Intended Use

The instrument described in this manual is exclusively to use for measuring the thermal mass flow of

gases. At the same time, the gas temperature is measured too.

The DT 550 can be configured for measuring a predetermined range of pure gases or of

gas mixtures.

Consumption measurement of gases such as Air, oxygen, nitrogen, carbon dioxide, argon, etc.

and with ATEX approval explosive gases such as natural gas, methane, propane and hydrogen.

Improper or incorrect use the operational reliability will be canceled. The manufacturer is not liable for

any damage resulting by improper or incorrect use.

3.2 Installation and commissioning

•Installation, electrical installation, commissioning, operation and maintenance of the device

must only be carried by qualified personnel, which were authorized by the plant operator.

The personnel must read the operating instructions and understand and follow their

instructions.

•If carrying out welding work on the pipeline the grounding of the welding unit is not allowed to

be done over the DT 550 itself.

•The installer must ensure that the DT 550 is connected according to the electrical

connection diagrams properly. The sensor must be grounded, unless special protective

measures have been taken (e.g. galvanically isolated power supply)

•The existing/ applicable national regulations governing opening and repair of the device have

to be applied.

•When using the DT 550 (ATEX Version) hazardous areas, in addition with the standard

manual a separate Ex documentation is enclosed. The installation instructions and connection

values indicated in these must also be observed.

•The device fulfills the general safety requirements in accordance with EN 61010-1,

the EMC requirements of IEC / EN 61326 and NAMUR recommendation NE 43.

Technical data

DT 550 Rev1.0 May20 Page 8 of 50

4 Technical data

Measures: mass flow, consumption

flow speed, temperature

Measuring principle: thermal mass flow sensor

Medium temperature range: -40 ... 180°C Probe (ATEX-Version -20°C … 120°C)

Operating temperature range: -20 ... 70 °C

Operating pressure: 50 bar

Power supply: 18 … 36 VDC

Optional: PoE according to IEEE 802.3af, PD Class 2 (max.

6.5W), voltage from 36V to 57V DC

Power consumption: max. 5W

Output: Modbus RTU (acc. EIA/TIA-485 Standard)

2 x 4...20 mA active (optional passive) RL < 500Ohm

galvanically isolated pulse (Pulse weight freely selectable,

Alarm max. 48Vdc 0,5A (Relays: Normally Closed)

optional: Modbus TCP, HART, Profibus DP, ProfiNet,

Accuracy: ± 1,5 % m.v. ± 0,3 % f.s.

Standard version*

(m.v. of meas. value)

(f.s. of full scale)

Accuracy: ± 1,0 % m.v. ± 0,3 % f.s.

Precision version*

(m.v. of meas. value)

(f.s. of full scale)

Repeatability: 0,25% m.v in case of correct mounting (mounting aid,

position, inlet section

Accuracy indications: referred to ambient temperature 22°C +/-2°C, system

pressure 6bar

Response time: t90 < 3s

Display: 2“ TFT Color Display (320 x 240)

Screw in thread: G 1/2“ ISO 228, NPT 1/2“, R 1/2“, PT 1/2“

Material: Housing aluminum die cast,

probe stainless steel1,4571

Protection class IP67

* Reference conditions for Temperature and pressure can be freely set, standard conditions are 0 ° and 1013 mbar.

Technical data

DT 550 Rev1.0 May20 Page 9 of 50

4.1 Signal circuits

4.1.1 Modbus

•According Standard EIA/TIA-485

4.1.2 Current output

4.1.2.1 Active

•Galvanically isolated

•4 … 20 mA

•RL< 500 Ohm

4.1.2.2 Passive

•Galvanically isolated

•4 … 20 mA

•RL< 500 Ohm

•Vin 12-36Vdc

4.1.3 Pulse

•Galvanically isolated (dry contact)

•Passive: 48Vdc , 500 mA

•Max. pulse output freq. 50Hz

4.1.4 Alarm

•Galvanically isolated

•Max. 48Vdc, 500mA

Measuring range

DT 550 Rev1.0 May20 Page 10 of 50

4.2 Measuring range flow DT 550

The flow-/consumption sensor DT 550 is available in 4 different versions:

•Low Speed max. measuring range of 50 m/s

•Standard max. measuring range of 92,7 m/s

•Max–Version max. measuring range of 185.0 m/s

•High speed–Version max. measuring range of 224 m/s

The sensors are programmed to pipe inner diameter of 53,1 mm.

Measuring range Analogoue output Scaling

•Low Speed 0… 323,6 m³/h 4mA = 0 m³h, 20mA = 323,6 m³/h

•Standard 0 … 600 m³/h 4mA = 0 m³h, 20mA = 600 m³/h

•Max–Version 0 ... 1197,59 m³/h 4mA = 0 m³h, 20mA = 1197,59 m³/h

•Highspeed–Version 0 … 1450,06 m³/h 4mA = 0 m³h, 20mA = 1450,06 m³/h

In case of use in other inner pipe diameter the diameter, using the display version, the diameter has

to be set first.

The corresponding scale values for the respective version could be found in sections 4.2.1 to 4.32.4.

Example:

Pipe 1“, Inner diameter 25mm Measuring range Analog output Scaling

•Low Speed 0 … 65,9 m³/h 4mA = 0 m³h, 20mA = 65,9 m³/h

•Grundversion( Standard) 0 … 122,2 m³/h 4mA = 0 m³h, 20mA = 122,2 m³/h

•Max–Version 0 ... 243,88 m³/h 4mA = 0 m³h, 20mA = 243,88 m³/h

•Highspeed–Version 0 … 295,30 m³/h 4mA = 0 m³h, 20mA = 295,30 m³/h

For changing the inner pipe diameter and adjusting the 4…20mA scaling, please refer to chapter

“Operation”.

Measuring range

DT 550 Rev1.0 May20 Page 11 of 50

4.2.1 Maximum Flow Ranges “Low Speed“

Inner diameter

of the pipe

Low Speed (50 m/s)

Full scale value in in Nm³/h

Inch

mm

Air2)

160mm

Ar3)

CO23)

N23)

O23)

N2O3)

Natural

gas3)

Methan

1/2"

16,1

24,6

22,6

38,4

24,3

22,6

23,4

24,1

14,6

3/4"

21,7

48,1

44,2

75,1

47,6

44,2

45,8

47,1

28,4

1"

25,0

65,9

60,6

103,1

65,2

60,6

62,8

64,6

39,0

26,0

71,7

65,9

112,1

70,9

65,9

68,3

70,3

42,4

27,3

79,7

73,2

124,5

78,8

73,2

75,9

78,1

47,1

28,5

87,4

80,4

136,6

86,5

80,4

83,3

85,7

51,7

30,0

97,6

89,7

152,6

96,6

89,7

93,0

95,7

57,7

1 1/4"

32,8

118,0

108,5

184,5

116,8

108,5

112,5

115,8

69,8

36,0

143,6

132,1

224,6

142,1

132,1

136,9

140,9

85,0

36,3

146,2

134,5

228,6

144,7

134,5

139,4

143,4

86,5

1 1/2"

39,3

172,9

159,0

270,4

171,1

159,0

164,9

169,6

102,3

40,0

179,4

164,9

280,4

177,5

164,9

171,0

175,9

106,1

41,9

196,9

181,0

307,8

194,8

181,0

187,7

193,1

116,5

43,1

210,1

193,2

328,5

207,9

193,2

200,3

206,1

124,3

45,8

238,4

219,3

372,8

235,9

219,3

227,3

233,8

141,1

2"

50,0

286,3

263,3

447,6

283,3

263,3

272,9

280,8

169,4

51,2

300,6

276,4

469,9

297,4

276,4

286,5

294,8

177,9

53,1

323,7

297,6

506,1

320,3

297,6

308,6

317,5

191,5

54,5

341,4

313,9

533,8

337,8

313,9

325,5

334,8

202,0

57,5

403,1

370,7

630,3

399,0

370,7

384,4

395,4

238,6

60,0

417,3

383,8

652,5

413,0

383,8

397,9

409,3

247,0

64,2

479,5

441,0

749,8

474,6

441,0

457,2

470,3

283,8

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 12 of 50

Inner diameter

of the pipe

Low Speed (50 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Natural

gas3)

Methan

2 1/2"

65,0

492,2

452,6

769,5

487,1

452,6

469,2

482,7

291,2

70,3

577,8

531,3

903,4

571,8

531,3

550,9

566,7

341,9

71,1

591,0

543,5

924,1

584,9

543,5

563,5

579,7

349,7

76,1

678,7

624,1

1061,2

671,7

624,1

647,1

665,7

401,6

3"

80,0

751,9

691,4

1175,5

744,1

691,4

716,8

737,4

444,9

82,5

799,6

735,3

1250,2

791,3

735,3

762,3

784,2

473,2

84,9

846,8

778,7

1324,0

838,0

778,7

807,3

830,5

501,1

90,0

952,7

876,1

1489,6

942,8

876,1

908,3

934,4

563,8

4"

100,0

1177,6

1082,9

1841,2

1165,4

1082,9

1122,7

1155,0

696,9

107,1

1352,4

1243,7

2114,5

1338,4

1243,7

1289,4

1326,4

800,3

110,0

1426,6

1311,9

2230,5

1411,8

1311,9

1360,2

1399,2

844,2

5"

125,0

1844,5

1696,1

2883,8

1825,3

1696,1

1758,5

1809,0

1091,5

133,7

2110,1

1940,5

3299,2

2088,2

1940,5

2011,8

2069,6

1248,7

6"

150,0

2659,2

2445,4

4157,6

2631,6

2445,4

2535,3

2608,1

1573,6

159,3

2999,2

2758,0

4689,2

2968,0

2758,0

2859,4

2941,6

1774,8

182,5

3941,1

3624,2

6161,8

3900,1

3624,2

3757,4

3865,4

2332,1

190,0

4271,6

3928,2

6678,7

4227,3

3928,2

4072,6

4189,6

2527,8

8"

200,0

4738,8

4357,7

7409,0

4689,5

4357,7

4517,9

4647,7

2804,2

206,5

5051,8

4645,6

7898,4

4999,3

4645,6

4816,4

4954,8

2989,4

10"

250,0

7413,2

6817,1

11590,4

7336,1

6817,1

7067,7

7270,8

4386,8

260,4

8052,4

7404,9

12589,8

7968,7

7404,9

7677,1

7897,7

4765,0

12"

300,0

10687,7

9828,3

16710,1

10576,6

9828,3

10189,6

10482,4

6324,5

309,7

11390,0

10474,2

17808,1

11271,6

10474,2

10859,2

11171,2

6740,1

339,6

13695,5

12594,2

21412,7

13553,1

12594,2

13057,2

13432,4

8104,4

400,0

19000,4

17472,6

29706,8

18802,9

17472,6

18114,9

18635,4

11243,6

500,0

29688,1

27300,9

46416,9

29379,5

27300,9

28304,5

29117,7

17568,1

600,0

42750,8

39313,3

66840,4

42306,5

39313,3

40758,4

41929,6

25298,0

700,0

58188,6

53509,8

90977,1

57583,9

53509,8

55476,8

57070,8

34433,4

800,0

76001,4

69890,3

118827,3

75211,6

69890,3

72459,4

74541,4

44974,3

900,0

96189,3

88454,9

150390,8

95189,7

88454,9

91706,5

94341,5

56920,6

1000,0

118752,2

109203,6

185667,6

117518,1

109203,6

113217,9

116471,0

70272,3

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 13 of 50

1.1.1 Measuring range “Standard Version“

Inner diameter of pipe

Standard Version (92,7 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Methane3)

Natural

gas3)

1/2"

16,1

45,6

41,9

71,3

45,1

41,9

43,4

44,7

27,0

3/4"

21,7

89,1

81,9

139,3

88,2

81,9

84,9

87,4

52,7

1"

25,0

122,2

112,4

191,1

120,9

112,4

116,4

119,9

72,3

26,0

132,9

122,2

207,8

131,5

122,2

126,5

130,3

78,6

27,3

147,7

135,8

230,9

146,1

135,8

140,6

144,8

87,4

28,5

162,0

149,0

253,3

160,3

149,0

154,3

158,9

95,9

30,0

180,9

166,4

282,9

179,0

166,4

172,3

177,5

107,1

1 1/4"

32,8

218,8

201,2

342,1

216,5

201,2

208,4

214,6

129,5

36,0

266,3

244,9

416,4

263,5

244,9

253,6

261,2

157,6

36,3

271,1

249,3

423,9

268,3

249,3

258,2

265,9

160,4

1 1/2"

39,3

320,6

294,8

501,3

317,3

294,8

305,3

314,5

189,7

40,0

332,6

305,8

519,9

329,1

305,8

316,7

326,2

196,8

41,9

365,0

335,6

570,6

361,2

335,6

347,6

358,0

216,0

43,1

389,5

358,2

609,0

385,4

358,2

370,9

382,0

230,5

45,8

442,0

406,5

691,1

437,4

406,5

421,0

433,5

261,6

2"

50,0

530,8

488,1

829,8

525,2

488,1

505,5

520,6

314,1

51,2

557,2

512,4

871,2

551,4

512,4

530,7

546,5

329,7

53,1

600,1

551,8

938,2

593,8

551,8

571,5

588,6

355,1

54,5

632,9

582,0

989,5

626,3

582,0

602,7

620,8

374,5

57,5

747,4

687,3

1168,5

739,6

687,3

711,8

733,1

442,3

60,0

773,7

711,5

1209,7

765,6

711,5

736,8

758,9

457,9

64,2

889,1

817,6

1390,0

879,8

817,6

846,7

872,0

526,1

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 14 of 50

Inner diameter of

pipe

Standard Version (92,7 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Methane3)

Natural

gas3)

2 1/2"

65,0

912,5

839,1

1426,6

902,9

839,1

869,0

895,0

540,0

70,3

1071,2

985,1

1674,8

1060,0

985,1

1020,2

1050,7

633,9

71,1

1095,8

1007,7

1713,1

1084,3

1007,7

1043,5

1074,7

648,4

76,1

1258,3

1157,2

1967,3

1245,2

1157,2

1198,3

1234,2

744,6

3"

80,0

1394,0

1281,9

2179,4

1379,4

1281,9

1327,5

1367,2

824,9

82,5

1482,5

1363,3

2317,7

1466,9

1363,3

1411,8

1454,0

877,2

84,9

1570,0

1443,7

2454,5

1553,5

1443,7

1495,1

1539,8

929,0

90,0

1766,4

1624,3

2761,6

1747,9

1624,3

1682,1

1732,4

1045,3

4"

100,0

2183,3

2007,8

3413,5

2160,5

2007,8

2079,2

2141,4

1292,0

107,1

2507,4

2305,7

3920,1

2481,1

2305,7

2387,8

2459,2

1483,7

110,0

2645,0

2432,3

4135,3

2617,3

2432,3

2518,9

2594,2

1565,2

5"

125,0

3419,6

3144,7

5346,3

3383,8

3144,7

3256,6

3353,9

2023,6

133,7

3912,2

3597,6

6116,5

3871,3

3597,6

3725,7

3837,0

2315,1

6"

150,0

4930,2

4533,7

7708,0

4878,6

4533,7

4695,1

4835,4

2917,4

159,3

5560,5

5113,3

8693,4

5502,3

5113,3

5295,3

5453,6

3290,4

182,5

7306,7

6719,2

11423,6

7230,3

6719,2

6958,3

7166,4

4323,8

190,0

7919,6

7282,8

12381,8

7836,8

7282,8

7542,0

7767,5

4686,5

8"

200,0

8785,7

8079,2

13735,8

8693,8

8079,2

8366,8

8616,9

5199,0

206,5

9366,0

8612,9

14643,2

9268,0

8612,9

8919,4

9186,1

5542,4

10"

250,0

13744,0

12638,9

21487,8

13600,2

12638,9

13088,7

13480,0

8133,1

260,4

14929,1

13728,7

23340,6

14772,9

13728,7

14217,2

14642,3

8834,4

12"

300,0

19815,0

18221,7

30979,4

19607,7

18221,7

18870,1

19434,3

11725,6

309,7

21117,1

19419,1

33015,1

20896,1

19419,1

20110,1

20711,4

12496,1

339,6

25391,4

23349,7

39697,7

25125,7

23349,7

24180,6

24903,6

15025,5

400,0

35226,7

32394,1

55074,4

34858,0

32394,1

33546,9

34549,9

20845,6

500,0

55041,6

50615,8

86053,8

54465,7

50615,8

52417,0

53984,3

32571,2

600,0

79260,0

72886,8

123917,4

78430,6

72886,8

75480,5

77737,4

46902,5

700,0

107881,6

99207,0

168665,4

106752,8

99207,0

102737,4

105809,2

63839,5

800,0

140906,6

129576,5

220297,7

139432,2

129576,5

134187,6

138199,7

83382,2

900,0

178334,9

163995,2

278814,3

176468,9

163995,2

169831,2

174909,1

105530,6

1000,0

220166,6

202463,2

344215,1

217862,8

202463,2

209668,2

215937,1

130284,7

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 15 of 50

1.1.2 Measuring range ʺMax Versionʺ

Inner diameter of

pipe

Max Version (185,0 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Methane3)

Natural

gas3)

1/2"

16,1

91,0

83,7

142,2

90,0

83,7

86,7

89,2

53,8

3/4"

21,7

177,8

163,5

278,0

176,0

163,5

169,5

174,4

105,2

1"

25,0

243,9

224,3

381,3

241,3

224,3

232,5

239,2

144,3

26,0

265,2

243,9

414,6

262,4

243,9

252,8

260,1

156,9

27,3

294,7

271,0

460,8

291,7

271,0

281,0

289,1

174,4

28,5

323,3

297,3

505,5

320,0

297,3

308,3

317,1

191,3

30,0

361,1

332,0

564,5

357,3

332,0

344,3

354,1

213,7

1 1/4"

32,8

436,7

401,6

682,8

432,2

401,6

416,3

428,3

258,4

36,0

531,5

488,7

831,0

526,0

488,7

506,7

521,3

314,5

36,3

541,1

497,6

845,9

535,4

497,6

515,8

530,7

320,2

1 1/2"

39,3

639,8

588,4

1000,4

633,2

588,4

610,0

627,6

378,6

40,0

663,7

610,3

1037,7

656,8

610,3

632,7

650,9

392,7

41,9

728,4

669,8

1138,9

720,8

669,8

694,5

714,4

431,0

43,1

777,3

714,8

1215,4

769,3

714,8

741,1

762,4

460,0

45,8

882,2

811,2

1379,3

873,0

811,2

841,1

865,2

522,0

2"

50,0

1059,2

974,1

1656,1

1048,2

974,1

1009,9

1038,9

626,8

51,2

1112,1

1022,6

1738,7

1100,5

1022,6

1060,2

1090,7

658,1

53,1

1197,6

1101,3

1872,4

1185,1

1101,3

1141,8

1174,6

708,7

54,5

1263,1

1161,6

1974,9

1250,0

1161,6

1204,3

1238,9

747,5

57,5

1491,6

1371,7

2332,1

1476,1

1371,7

1422,1

1463,0

882,7

60,0

1544,1

1420,0

2414,2

1528,1

1420,0

1472,2

1514,5

913,7

64,2

1774,3

1631,7

2774,1

1755,9

1631,7

1691,6

1740,2

1050,0

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 16 of 50

Inner diameter of pipe

Max Version (185,0 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Methane3)

Natural

gas3)

2 1/2"

65,0

1821,0

1674,6

2847,2

1802,1

1674,6

1736,2

1786,1

1077,6

70,3

2137,9

1966,0

3342,5

2115,6

1966,0

2038,2

2096,8

1265,1

71,1

2186,8

2011,0

3419,0

2164,1

2011,0

2084,9

2144,8

1294,0

76,1

2511,2

2309,3

3926,3

2485,1

2309,3

2394,2

2463,0

1486,0

3"

80,0

2781,9

2558,2

4349,5

2753,0

2558,2

2652,3

2728,5

1646,2

82,5

2958,5

2720,6

4625,6

2927,8

2720,6

2820,6

2901,7

1750,7

84,9

3133,1

2881,2

4898,6

3100,6

2881,2

2987,1

3073,0

1854,1

90,0

3525,1

3241,7

5511,5

3488,5

3241,7

3360,8

3457,4

2086,0

4"

100,0

4357,2

4006,9

6812,5

4311,9

4006,9

4154,1

4273,5

2578,4

107,1

5003,9

4601,5

7823,5

4951,9

4601,5

4770,7

4907,8

2961,1

110,0

5278,6

4854,1

8253,0

5223,7

4854,1

5032,6

5177,2

3123,6

5"

125,0

6824,5

6275,7

10670,0

6753,6

6275,7

6506,4

6693,4

4038,4

133,7

7807,5

7179,7

12207,0

7726,4

7179,7

7443,7

7657,5

4620,1

6"

150,0

9839,0

9047,9

15383,2

9736,8

9047,9

9380,5

9650,0

5822,3

159,3

11096,9

10204,6

17349,9

10981,6

10204,6

10579,7

10883,7

6566,7

182,5

14581,9

13409,4

22798,7

14430,4

13409,4

13902,4

14301,8

8628,9

190,0

15805,1

14534,2

24711,1

15640,8

14534,2

15068,5

15501,5

9352,7

8"

200,0

17533,5

16123,6

27413,4

17351,3

16123,6

16716,3

17196,7

10375,5

206,5

18691,7

17188,7

29224,2

18497,4

17188,7

17820,6

18332,6

11060,9

10"

250,0

27428,8

25223,2

42884,5

27143,7

25223,2

26150,4

26901,8

16231,1

260,4

29793,8

27398,1

46582,2

29484,2

27398,1

28405,2

29221,4

17630,6

12"

300,0

39544,5

36364,7

61827,4

39133,6

36364,7

37701,5

38784,8

23400,7

309,7

42143,0

38754,3

65890,2

41705,1

38754,3

40179,0

41333,5

24938,4

339,6

50673,3

46598,7

79227,1

50146,7

46598,7

48311,6

49699,8

29986,2

400,0

70301,3

64648,4

109915,3

69570,8

64648,4

67024,9

68950,8

41601,2

500,0

109845,8

101013,2

171742,6

108704,3

101013,2

104726,4

107735,6

65001,8

600,0

158177,9

145459,0

247309,4

156534,3

145459,0

150806,1

155139,3

93602,6

700,0

215297,7

197985,8

336615,6

213060,5

197985,8

205263,8

211161,8

127403,5

800,0

281205,2

258593,7

439661,2

278283,1

258593,7

268099,7

275803,2

166404,6

900,0

355900,4

327282,7

556446,2

352202,1

327282,7

339313,7

349063,4

210605,9

1000,0

439383,1

404052,7

686970,6

434817,4

404052,7

418905,8

430942,5

260007,2

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 17 of 50

1.1.3 Measuring range “High Speed Version“

Inner diameter of pipe

High Speed Version (224,0 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Methane3)

Natural

gas3)

1/2"

16,1

110,2

101,3

172,2

109,0

101,3

105,0

108,0

65,2

3/4"

21,7

215,3

198,0

336,7

213,1

198,0

205,3

211,2

127,4

1"

25,0

295,3

271,6

461,7

292,2

271,6

281,5

289,6

174,7

26,0

321,1

295,3

502,0

317,8

295,3

306,1

314,9

190,0

27,3

356,9

328,2

557,9

353,1

328,2

340,2

350,0

211,2

28,5

391,5

360,0

612,1

387,4

360,0

373,2

384,0

231,7

30,0

437,2

402,0

683,6

432,7

402,0

416,8

428,8

258,7

1 1/4"

32,8

528,7

486,2

826,7

523,3

486,2

504,1

518,6

312,9

36,0

643,5

591,8

1006,1

636,8

591,8

613,5

631,2

380,8

36,3

655,1

602,4

1024,3

648,3

602,4

624,6

642,5

387,7

1 1/2"

39,3

774,7

712,4

1211,3

766,7

712,4

738,6

759,8

458,5

40,0

803,6

739,0

1256,4

795,2

739,0

766,1

788,2

475,5

41,9

882,0

811,0

1378,9

872,8

811,0

840,9

865,0

521,9

43,1

941,2

865,5

1471,6

931,4

865,5

897,3

923,1

557,0

45,8

1068,1

982,2

1670,0

1057,0

982,3

1018,4

1047,6

632,1

2"

50,0

1282,5

1179,4

2005,2

1269,2

1179,4

1222,8

1257,9

758,9

51,2

1346,5

1238,2

2105,2

1332,5

1238,2

1283,7

1320,6

796,8

53,1

1450,1

1333,5

2267,1

1435,0

1333,5

1382,5

1422,2

858,1

54,5

1529,4

1406,4

2391,2

1513,5

1406,4

1458,1

1500,0

905,0

57,5

1806,1

1660,8

2823,8

1787,3

1660,8

1721,9

1771,4

1068,8

60,0

1869,6

1719,3

2923,2

1850,2

1719,3

1782,5

1833,7

1106,4

64,2

2148,4

1975,6

3359,0

2126,1

1975,6

2048,3

2107,1

1271,3

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Measuring range

DT 550 Rev1.0 May20 Page 18 of 50

Inner diameter of pipe

High Speed Version (224,0 m/s)

Full scale value in in Nm³/h

Inch

mm

Air 2)

Air 3)

Ar3)

CO23)

N23)

O23)

N2O3)

Methane3)

Natural

gas3)

2 1/2"

65,0

2204,9

2027,6

3447,4

2182,0

2027,6

2102,2

2162,6

1304,8

70,3

2588,6

2380,4

4047,2

2561,7

2380,4

2467,9

2538,8

1531,8

71,1

2647,8

2434,9

4139,8

2620,3

2434,9

2524,4

2596,9

1566,8

76,1

3040,6

2796,1

4754,0

3009,0

2796,1

2898,9

2982,2

1799,3

3"

80,0

3368,4

3097,5

5266,4

3333,4

3097,5

3211,4

3303,7

1993,3

82,5

3582,2

3294,2

5600,7

3545,0

3294,2

3415,2

3513,4

2119,8

84,9

3793,6

3488,6

5931,3

3754,2

3488,6

3616,8

3720,8

2244,9

90,0

4268,2

3925,0

6673,3

4223,9

3925,0

4069,3

4186,2

2525,8

4"

100,0

5275,8

4851,5

8248,6

5220,9

4851,6

5029,9

5174,4

3122,0

107,1

6058,8

5571,6

9472,8

5995,8

5571,6

5776,4

5942,4

3585,3

110,0

6391,3

5877,4

9992,8

6324,9

5877,4

6093,5

6268,6

3782,1

5"

125,0

8263,2

7598,7

12919,4

8177,3

7598,8

7878,1

8104,4

4889,8

133,7

9453,4

8693,3

14780,3

9355,2

8693,3

9012,9

9271,8

5594,1

6"

150,0

11913,2

10955,3

18626,2

11789,4

10955,3

11358,0

11684,4

7049,7

159,3

13436,3

12355,9

21007,4

13296,6

12355,9

12810,1

13178,1

7951,0

182,5

17656,0

16236,3

27604,9

17472,5

16236,3

16833,1

17316,8

10448,0

190,0

19137,0

17598,2

29920,4

18938,1

17598,2

18245,1

18769,3

11324,4

8"

200,0

21229,7

19522,7

33192,4

21009,1

19522,7

20240,3

20821,9

12562,8

206,5

22632,1

20812,3

35385,0

22396,9

20812,3

21577,3

22197,3

13392,6

10"

250,0

33211,0

30540,6

51925,1

32865,9

30540,6

31663,2

32573,0

19652,8

260,4

36074,6

33173,9

56402,2

35699,7

33174,0

34393,4

35381,6

21347,3

12"

300,0

47880,9

44030,8

74861,2

47383,3

44030,9

45649,4

46961,1

28333,8

309,7

51027,2

46924,2

79780,5

50497,0

46924,3

48649,1

50047,0

30195,6

339,6

61355,7

56422,1

95929,0

60718,1

56422,3

58496,2

60177,1

36307,5

400,0

85121,6

78277,0

133086,6

84237,0

78277,2

81154,5

83486,4

50371,1

500,0

133002,5

122307,8

207947,8

131620,4

122308,1

126803,9

130447,5

78704,9

600,0

191523,6

176123,3

299444,9

189533,3

176123,7

182597,6

187844,3

113335,0

700,0

260684,8

239723,3

407577,7

257975,9

239724,0

248535,6

255677,0

154261,5

800,0

340486,3

313108,0

532346,4

336948,1

313108,8

324618,0

333945,5

201484,4

900,0

430928,0

396277,3

673750,9

426450,0

396278,4

410844,6

422649,7

255003,8

1000,0

532009,9

489231,3

831791,3

526481,5

489232,6

507215,6

521789,8

314819,5

2) Referred to DIN 1945 / ISO 1217 (20°C, 1000mbar) and compressed air.

3) Referred to DIN 1343: 0°C, 1013,25 mbar

Dimension

DT 550 Rev1.0 May20 Page 19 of 50

5 Dimensions

5.1 Dimension DT 550

Sensor lenght

L [mm]

H [mm]

C1

220

441

C2

300

521

C3

400

621

C4

500

721

C5

600

821

C7

160

381

156 (max)

(max)

138 (max)Ex version

(max)

132 (max)

(max)

H max

L

Installation

DT 550 Rev1.0 May20 Page 20 of 50

6 Installation

6.1 Pipe/tube requirements

•Correctly sized gaskets

•Correct aligned flanges and gaskets

•Diameter mismatch at the pipe junctions should be avoided but must be less than 1mm. For

further information see ISO 14511

•Ensure clean pipes after installation

6.2 Inlet / outlet runs

The principle of thermal Mass flow measurement is very sensitive against disturbances. Therefore, it is

necessary to ensure the recommended inlet and outlet runs.

Table Inlet / Outlet runs

Flow obstruction before the measurement

section

Min length

Inlet run (L1)

Min length

Outlet run (L2)

Slight curve

(ellbow < 90°)

12 x D

5 x D

Reduction

(Pipe narrows to the measurement section)

15 x D

5 x D

Expansion

(Pipe expands to the measurement section)

15 x D

5 x D

90° ellbow or T-piece

15 x D

5 x D

2x ellbow á 90°

in einer Ebene

20 x D

5 x D

2x ellbow á 90°

3-dimensional

35 x D

5 x D

Control valve

45 x D

5 x D

15 x D 5 x D

15 x D 5 x D15 x D

15 x D 5 x D

20 x D 5 x D

35 x D 5 x D

5 x D45 x D

The values represent the min. lengths. In case the min. inlet / outlet runs could not be ensured, it must

be expected to get increased or significant deviations of the measurement values.

Table of contents

Other edc Accessories manuals

Popular Accessories manuals by other brands

Dedrone

Dedrone RF-160 installation manual

SICK

SICK WTS26P operating instructions

Fisher Scientific

Fisher Scientific Isotemp Series user manual

Ceyear

Ceyear 87230 Series quick start guide

Technaxx

Technaxx Power Cube TX-195 operating instructions

Keysight Technologies

Keysight Technologies U2040 X-Series Programming guide

SENSORWORX

SENSORWORX SWX-201-2 Installation & operation instructions

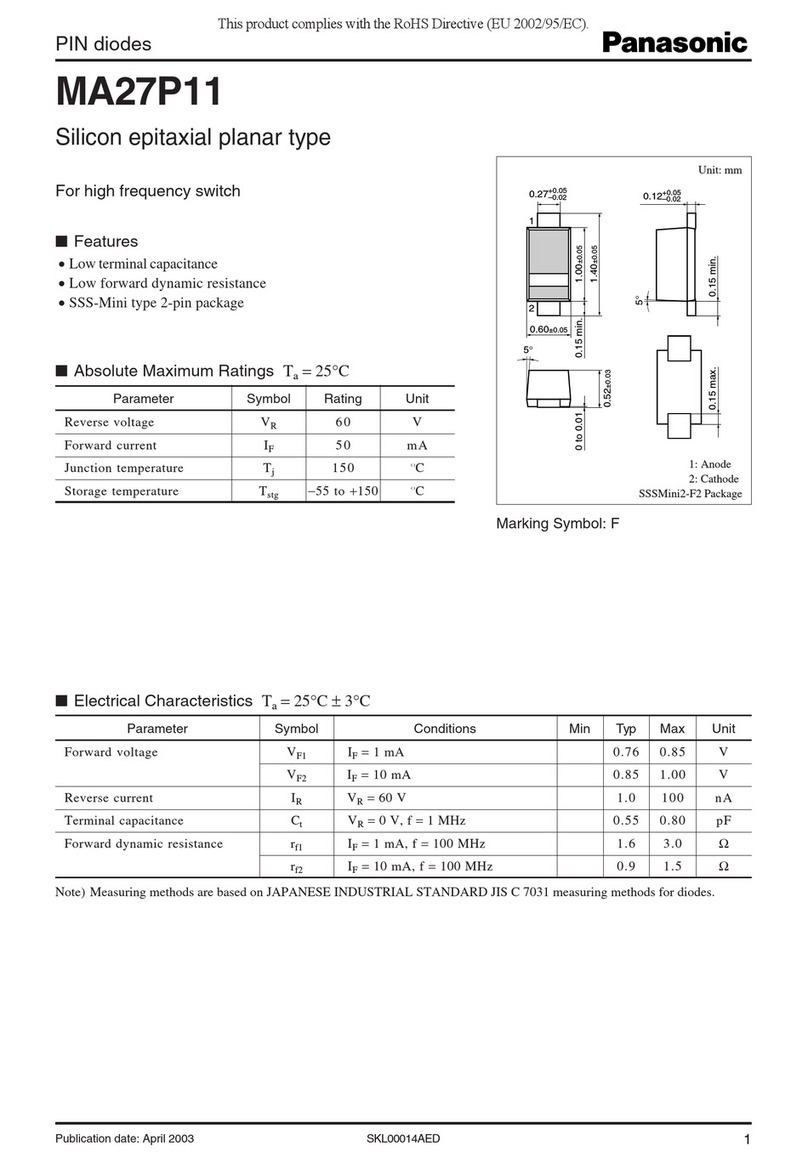

Panasonic

Panasonic MA27P11 Specification sheet

Pepperl+Fuchs

Pepperl+Fuchs UC500-L2-E6-V15 Programming guide

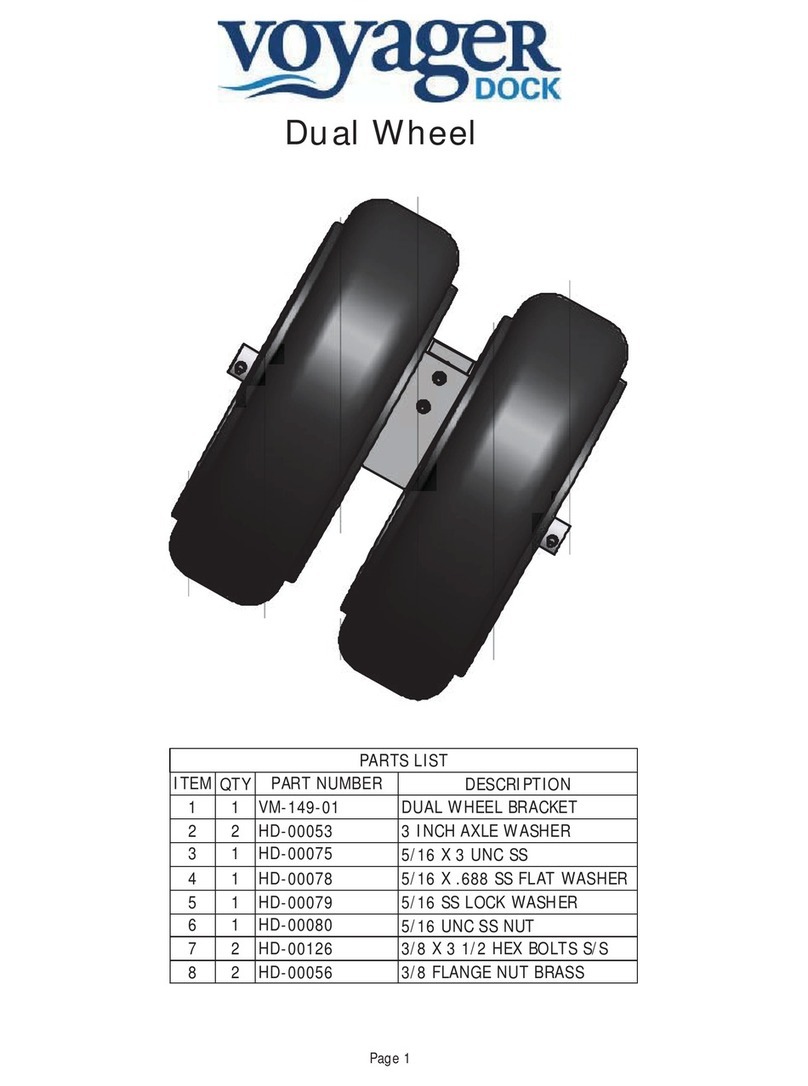

Voyager Dock

Voyager Dock VM-149 instructions

Big Daishowa

Big Daishowa Point Master Pro PMP-10 Operation manual

Baseus

Baseus PPCXZ10 user manual