ISO-COP-2

World Precision Instruments i

Copyright © 2016 by World Precision Instruments, Inc. All rights reserved. No part of this publication

may be reproduced or translated into any language, in any form, without prior written permission of

World Precision Instruments, Inc.

CONTENTS

ABOUT THIS MANUAL ................................................................................................................... 1

INTRODUCTION .............................................................................................................................. 2

Sensor Design............................................................................................................................ 2

Notes and Warnings................................................................................................................. 2

Parts List...................................................................................................................................... 3

Unpacking................................................................................................................................... 3

INSTRUMENT DESCRIPTION ........................................................................................................ 5

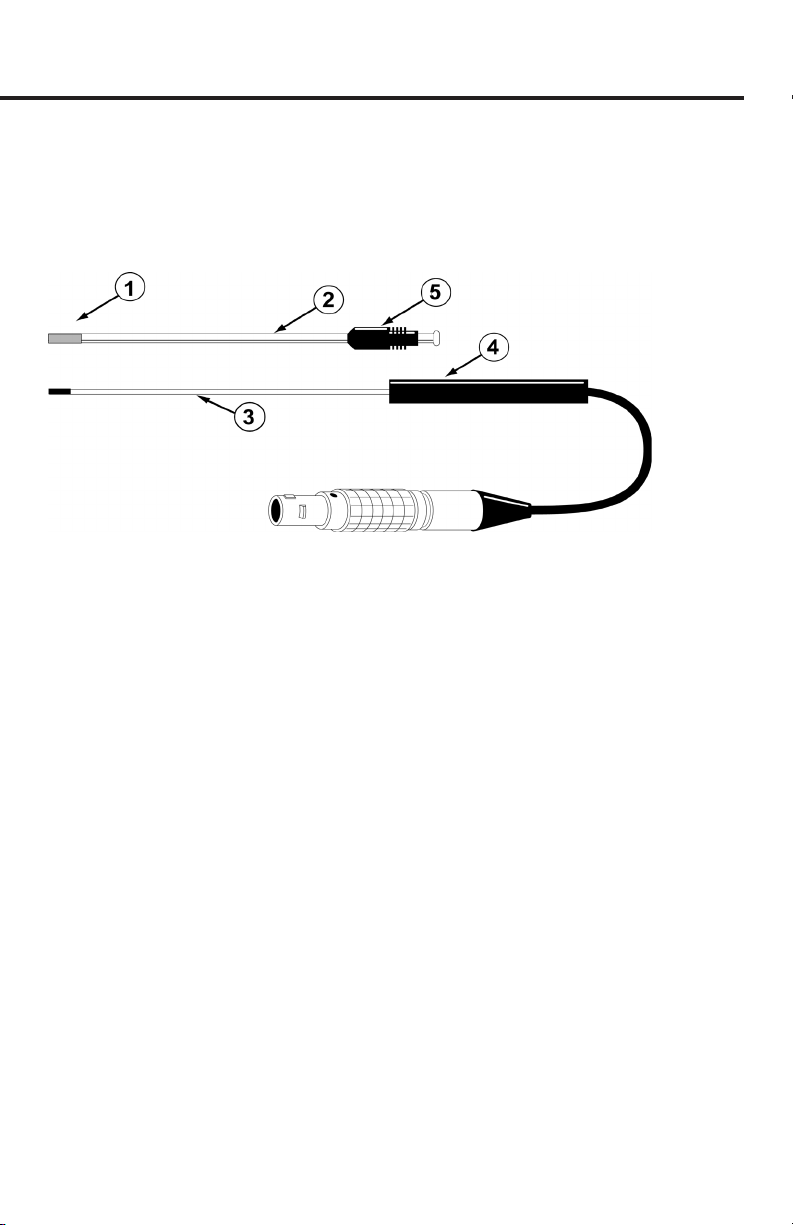

Structure of the Sensor........................................................................................................... 5

OPERATING INSTRUCTIONS......................................................................................................... 6

Environmental Inuences ....................................................................................................... 6

Temperature......................................................................................................................... 6

Electrical Interference ...................................................................................................... 6

Setup ........................................................................................................................................... 6

Polarizing the Sensor .............................................................................................................. 7

SENSOR CARE AND MAINTENANCE........................................................................................... 8

Durability and Handling........................................................................................................... 8

Storing the Sensor.................................................................................................................... 8

Cleaning the Membrane.......................................................................................................... 8

Sterilizing the Membrane........................................................................................................ 9

Replacing the Membrane Sleeve .......................................................................................... 9

ACCESSORIES.................................................................................................................................11

TROUBLESHOOTING ...................................................................................................................12

SPECIFICATIONS............................................................................................................................13

INDEX...............................................................................................................................................14

WARRANTY .....................................................................................................................................15

Claims and Returns ................................................................................................................15

Repairs.......................................................................................................................................15