3

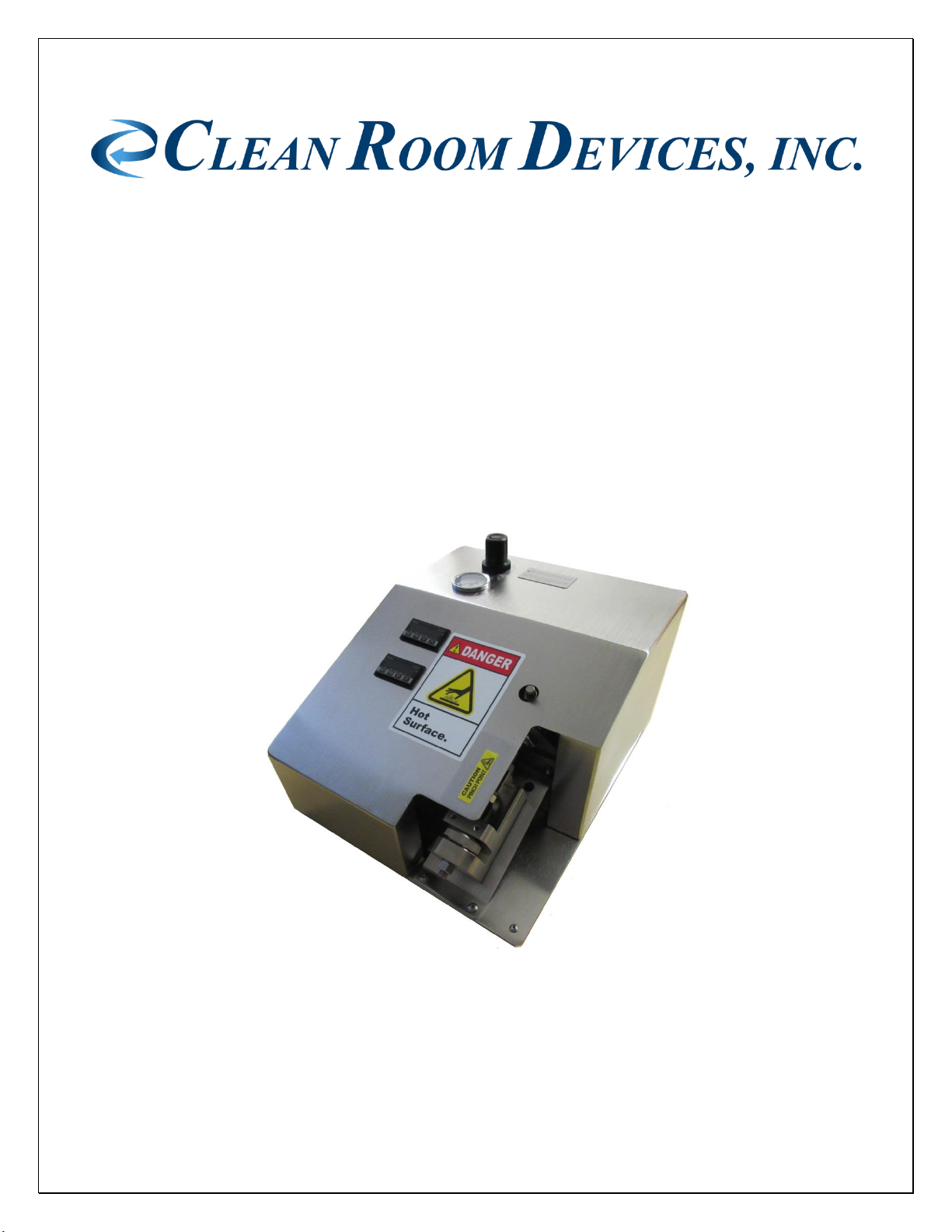

1.0 General Product & Safety Information

1.1 Product Information

The CRD216SS is designed to expand stiffer tubing such as nylon, polyethylene,

polypropylene and Teflon tubing. With the heater off, the unit can also expand flexible

tubing up to a durometer of Shore A 85 (Shore D 35), including any non-metallic braided

materials

The minimum/maximum inside tube diameter is .040” –1/2”

The unit operates up to a temperature of 350 °F

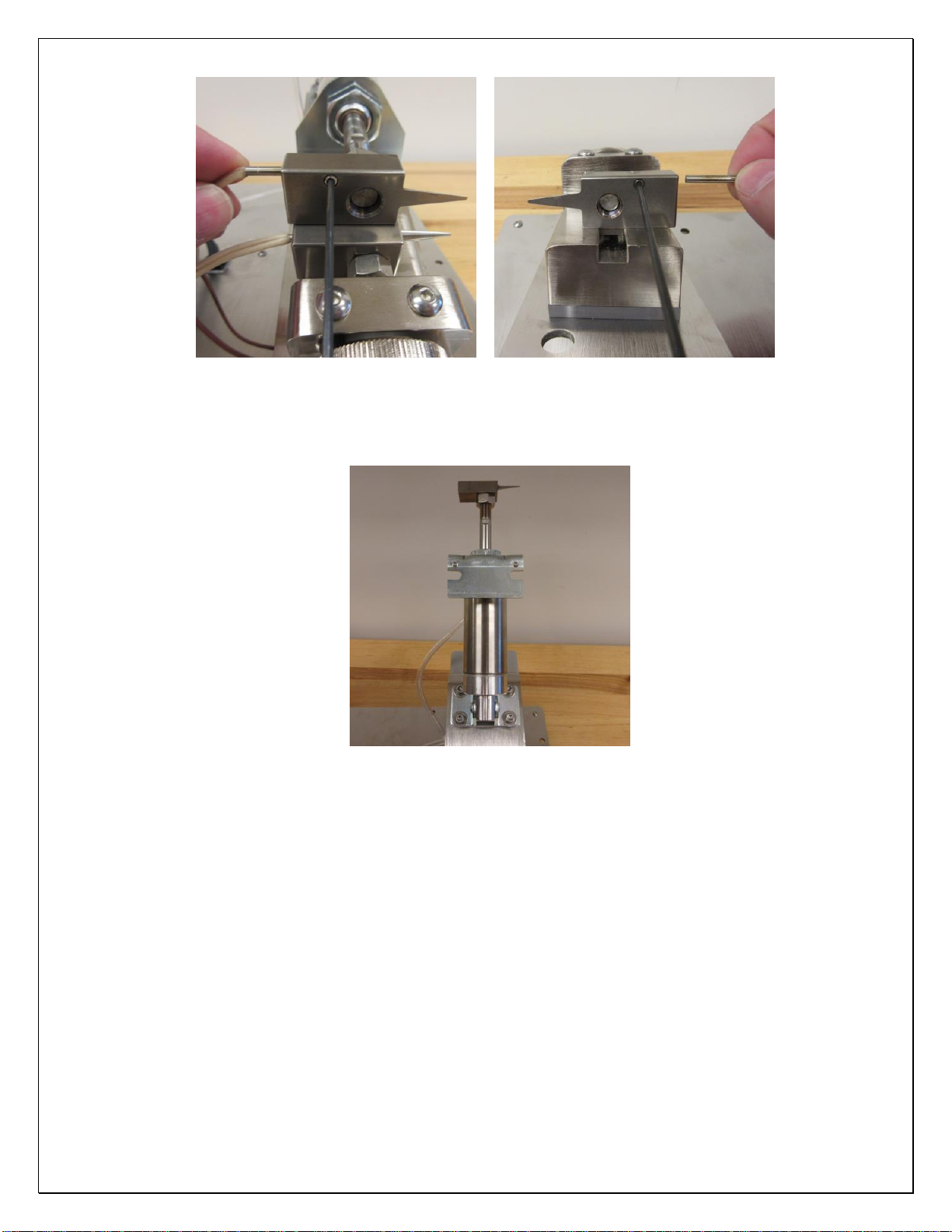

The standard jaw sets are universal and are designed to be used with an inside diameter

range of .040” to 1/2". Other jaw sets are available that are optimized for a specific size

(see accessories page at www.cleanroomdevices.com or call Clean Room Devices, Inc.).

The unit design allows for simple operator adjustment

1.2 Safety Information

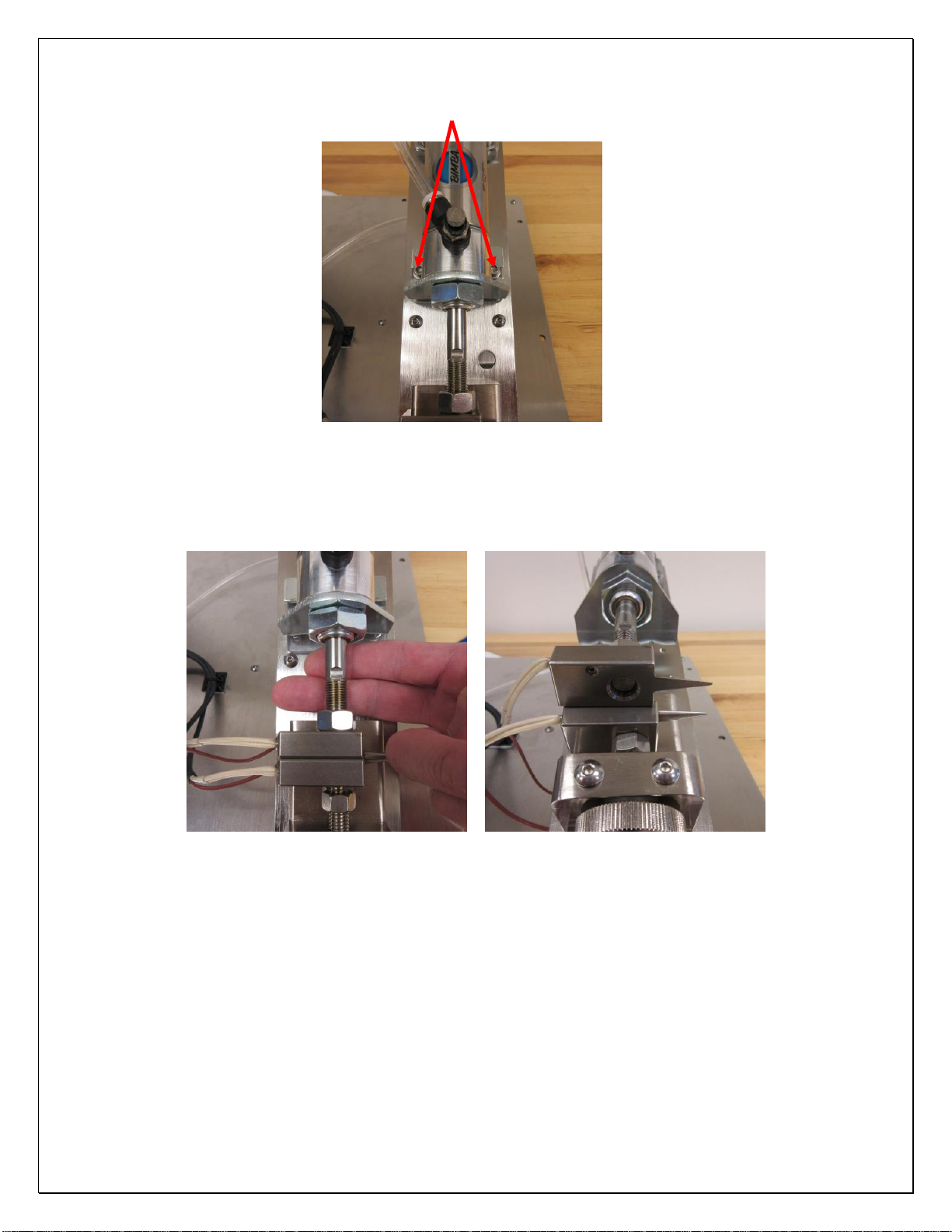

This product uses an air cylinder and foot pedal to pneumatically actuate and expand the

jaws. The unit is not intended to expand anything other than flexible tubing.

Avoid placing your fingers between the upper jaw block and the air cylinder

mounting bracket while operating unit, sufficient pressure exists to cause personal

injury.

After heating up, the metallic areas in and around the jaws will be extremely hot.

Avoid direct contact with the jaw set while the heater is on. Surface will be hot

enough to cause severe burns.