Clean Water J-PRO-22 Installation manual

Rev-042123

J-PRO-22 Proportional Citric Acid Installation Guide

Thank you for purchasing a Clean Water System!

Please review this start-up guide entirely before beginning to install your system and follow the

steps outlined for best results.

Specications:

Pumps 0.1 to 22 gallons of solution per day

Injects into line pressures up to 110 PSI

Dual voltage. 110V or 220V, works on either voltage.

Uses maximum 22 watts of power.

Dimensions:

5-gallon model: 10” x 10” x 15”. Height including pump is 26”

15-gallon model: 14.5” wide x 24”, height including pump is 35”.

35-gallon model: 18” wide x 33”, height including pump is 44”.

CITRIC ACID CAN DAMAGE CLOTHING AND IRRITATE SKIN

AND EYES.

USE RUBBER GLOVES AND EYE PROTECTION WHEN HANDLING.

NOTE ABOUT 220V INSTALLATIONS: This pump is dual voltage right out of the box and

works on 110v OR 220v.

If you plan to install to run on 220v-240v, we recommend cutting o plug and either hard-

wiring to 220v circuit OR installing a 220v plug-end.

This pump is intended for indoor use, or for outdoors if protected from sunlight and freezing.

Watch Installation Video on Youtube

https://youtu.be/uMd0Zqi0ddw

Questions?

Call us toll-free: 1-888-600-5426 or 1-831-462-8500

See more information on our website: www.cleanwaterstore.com/resources

Rev-042123

J-PRO-22 Proportional Citric Acid Installation Guide

Table of Contents

J-Pro-22 Metering Pump Warranty and Returns 4

Conditions Not Covered by the Warranty 4

Pre-Installation 4

Installation Over-View Steps 5

How Your Citric Acid Injection System Works 6

J-PRO-22 Installation Instructions 7

Mount Pump to Solution tank 7

How to Connect Tubing & Fittings 7

Install Discharge Side Tubing 8

Install Suction Tubing from Pump to Solution Tank 9

Connect Tubing from Degassing Port (“Kicker Port”) 10

Connect the Cables (wiring) for the J-PRO-22 Pump 11

Prime & Start the Pump with Water First 11

Program and Pump Settings 12

How to Select the Citric Acid Solution Strength and Pump Setting 12

Need Assistance? 14

Spare Parts 14

www.cleanwaterstore.com 4

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

J-Pro-22 Metering Pump Warranty and Returns

Your pump comes with a 1 Year Warranty from date of delivery.

If your pump fails under warranty, please call or email our oce to obtain a Returns Good

Authorization Number before sending us back the pump for repair or replacement under the

warranty. No returns can be accepted without an RGA number.

The Warranty covers repair and/or replacement of the metering pump but not shipping costs.

While defects are rare, we do our best to respond to warranty returns fast as we can. Please

allow 3 to 5 business days after pump has been returned for your pump to be repaired or a new

one supplied under the warranty agreement.

Shipping charges are not covered under warranty. A at fee of $9.95 each way will be charged

for ground shipping (continental US). Any expedited shipping (overnight, 2-day, etc.) is the

customer’s responsibility.

Conditions Not Covered by the Warranty

Power surges or outages that cause pump failure are not covered under warranty.

Surge protection is strongly recommended. If a pump is returned for warranty replacement

and the cause of failure is determined to be from a voltage spike, the pump does not qualify

for replacement. This is the leading cause of failure. Pump failure during, or because of, power

failure is not covered under warranty.

This pump is intended for indoor use only. The pump must never be exposed to freezing

temperatures, direct sunlight, or rain. If the cause of failure is determined to be from exposure

to any of these environments, the pump does not qualify for replacement and will not be

covered under warranty.

For Returns Contact Clean Water Systems & Stores Inc. 2806-A Soquel Ave Santa Cruz, CA

95062831-462-8500 [email protected]

Pre-Installation

1. Review your packing list and make sure you have received all the parts before

beginning installation.

2. If you turn o the water to the house and you have an electric water heater, shut o

the power to the water heater before beginning installation in case water heater is

accidentally drained.

3. Pick a suitable location for your Citric Acid system on a dry level spot where it won’t be

exposed to freezing temperatures or direct sunlight. Maximum line pressure is 100 PSI.

4. Get all plumbing parts together before beginning installation.

www.cleanwaterstore.com 5

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

Installation Over-View Steps

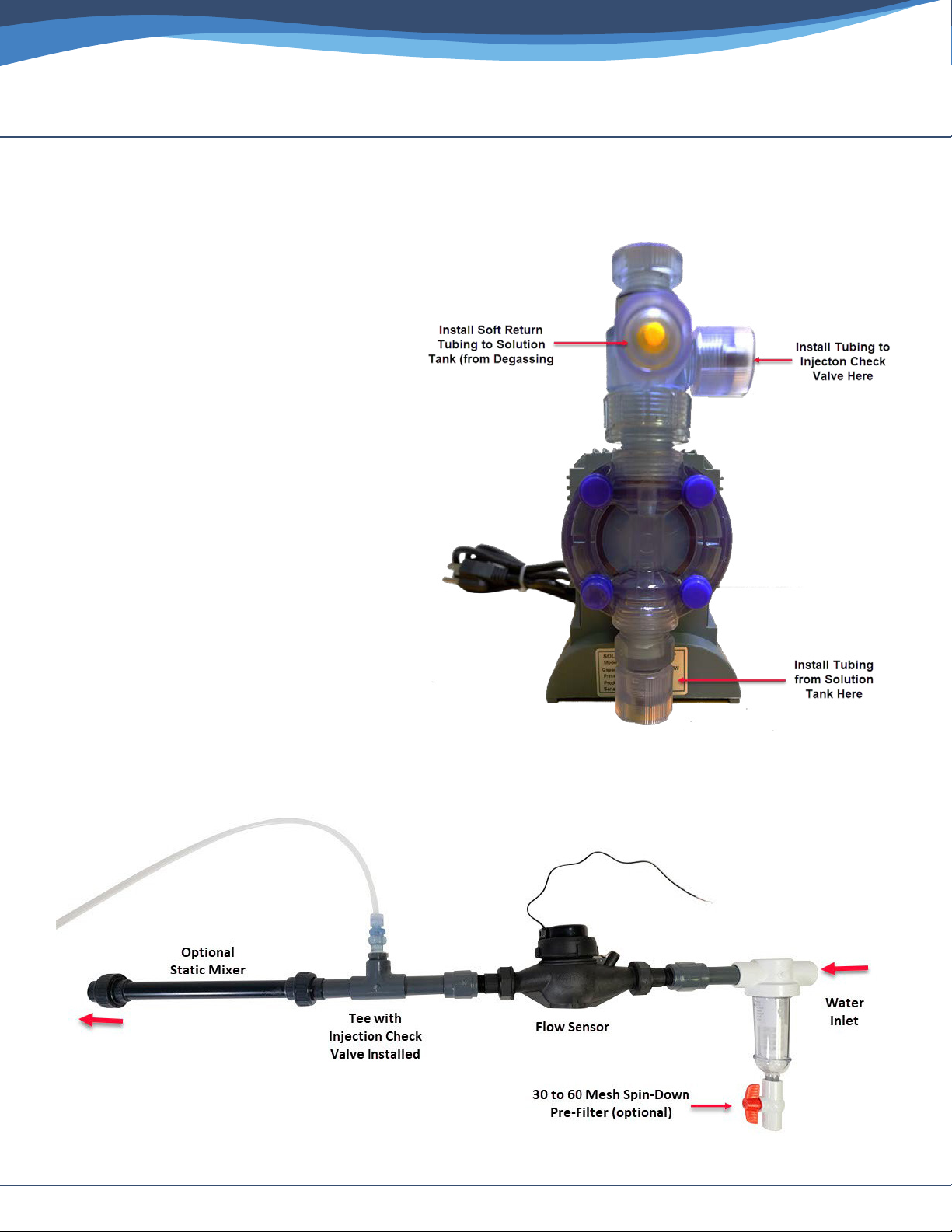

1. Install the Flow Sensor horizontally

with the display facing up in a

location where it is easy to connect

with the J-PRO-22 pump and

electrical outlet.

2. Install the Citric Acid injection valve

(included with your order) after the

ow sensor into a tee in your pipe.

3. Install ow sensor and injection

valve after existing pressure tank (if

you have a pressure tank).

4. Connect the ow sensor cable to

the Citric Acid Pump cable, follow

steps below in this guide to set the

pump to automatic.

5. Plug the JPRO-22 into a wall outlet

and follow steps later in this guide

to program and set pump.

6. Now, when there is water owing

through the Flow Sensor, the

JPRO-22 pump will pump Citric Acid

solution based on the ow of water.

www.cleanwaterstore.com 6

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

How Your Citric Acid Injection System Works

Install the Flow Sensor horizontally with the display facing up in a location where it is easy to

connect with the J-PRO-22and electrical outlet. Attach meter cable to pump per instructions

below. Whenever water ows through ow sensor, a precise amount of Citric Acid will

be injected.

Example Installation with Optional Contact Tank

Example Installation with Optional Static Mixer & Spin-Down Pre-Filter

www.cleanwaterstore.com 7

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

J-PRO-22 Installation Instructions

While you can mount the pump on a shelf above the solution tank, it is strongly advised to

mount the pump directly on top of the solution tank. If the tubing from the foot valve to the

suction side of the pump exceeds 60”, the unit will not have enough lift force to stay primed.

Mount Pump to Solution tank

Place pump on tank. Mark where the anchor holes

will be drilled. Drill pilot holes with a small drill bit

so that the pump can be mounted on the tank with

two wood or sheet metal screws.

We recommend screwing them in after the pump

has been primed and the tubing has been hooked

up for easiest installation.

Mark the holes for the suction tube and the

degassing return line and drill holes.

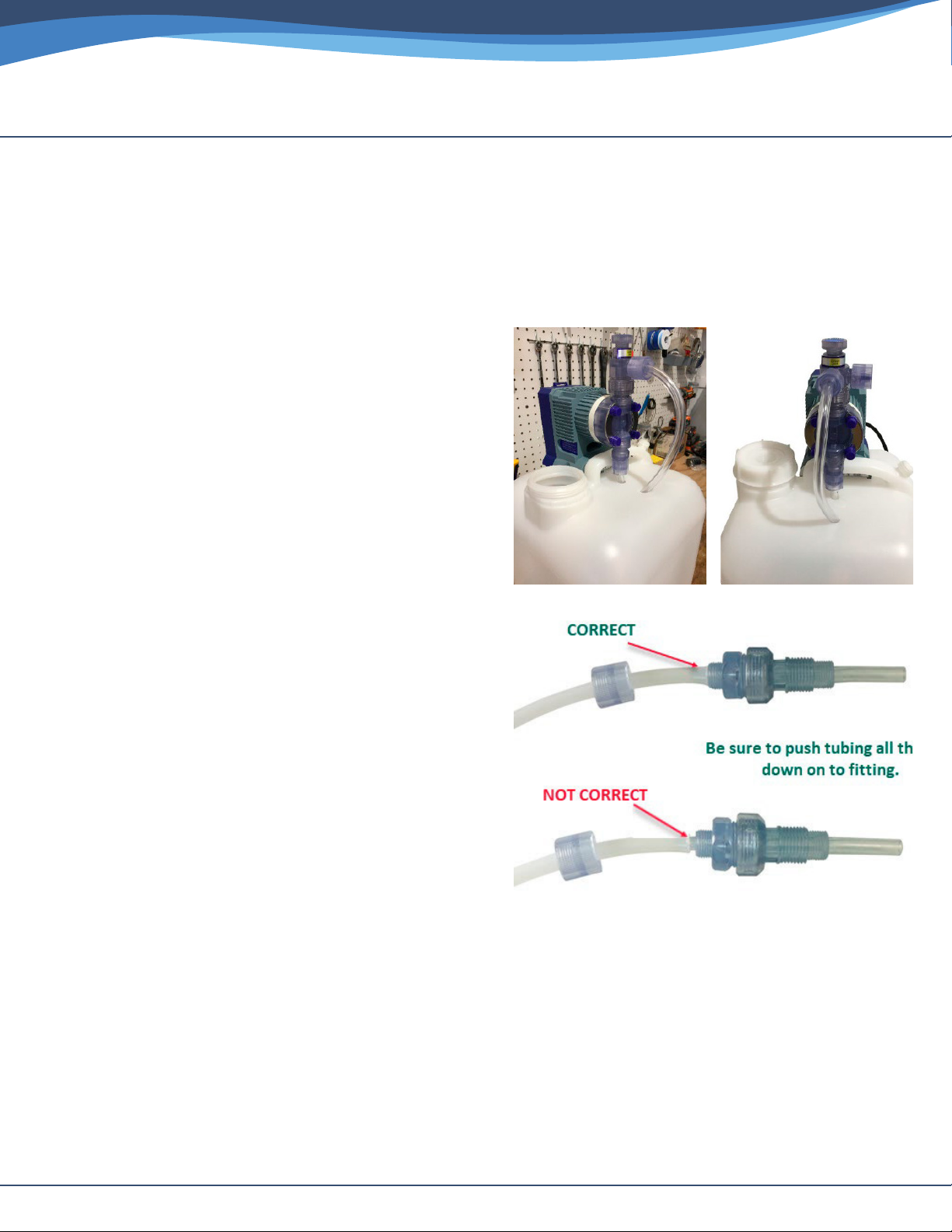

How to Connect Tubing

& Fittings

Note: Warming tube ends with hot water or a

hair dryer helps with tubing installation.

• Trim the end of the tubing square (cut with a

new box cutter blade).

• Slide the connector nut onto the tube.

• Push the tubing over the conical tting until the

tubing is ush against the end of the tting.

• Screw the connector nut on, hand tight.

• Do not use Teon tape/ paste on the tubing

tting connections.

Use the harder/stier translucent tubing for connection from discharge-side (12 o’clock)

to the injection check valve.

Use the softer clear tubing for the foot valve to suction-side (6 o’clock) connection.

www.cleanwaterstore.com 8

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

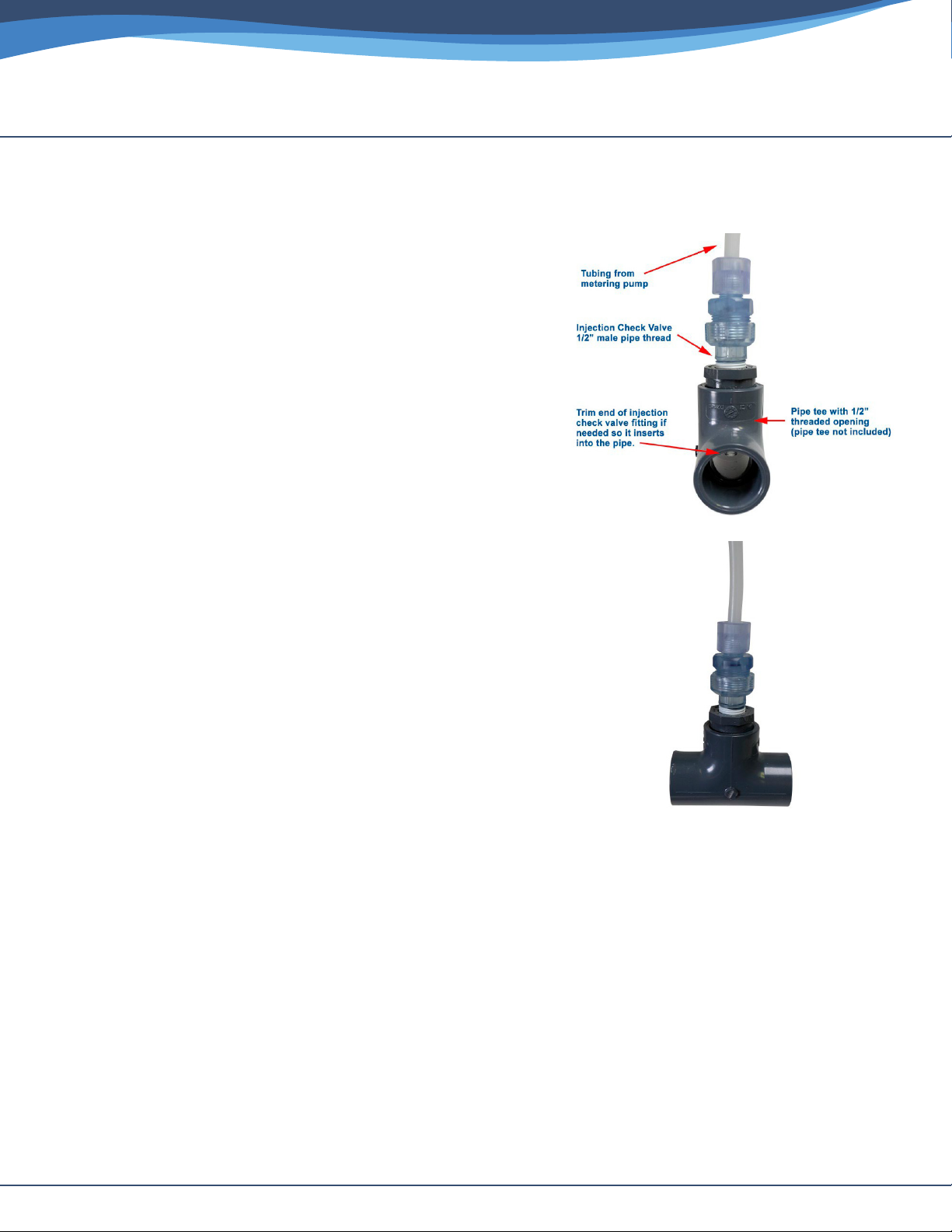

Install Discharge Side Tubing

This is the tubing that goes from the pump discharge

(outlet) to injection check valve in pipe tee.

1. Shut o well pump or water supply and de-pressurize

service pipe.

2. Install injection check valve by installing a pipe tee

in your pipe that has a ½” NPT tting, where you can

screw in the injection check valve (included with your

J-PRO-22 pump).

3. Wrap Teon tape on the ½” pipe threads of the

injection check valve and apply a light coating of white

Teon pipe paste and install into Tee tting.

4. Trim the end of the injection check valve tting so that

the end will be in the center of the service pipe.

5. Make sure to install injection check valve in to pipe

directly. If the end of the check valve is not in the

service pipe, it will not work. Do not install a ball valve,

or any length of pipe run, coming o the tee.

6. Using a hack saw or cutter, trim the end of the

injection check valve if needed, so it inserts into the

water pipe as shown.

7. Install tubing that came with your pump and connect

pump to injection check valve.

8. Cut tubing to desired length with enough slack to avoid kinks.

Injection check valve can be installed into PVC, copper or other piping.

Suction

Ceramic

Connector

Foot

www.cleanwaterstore.com 9

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

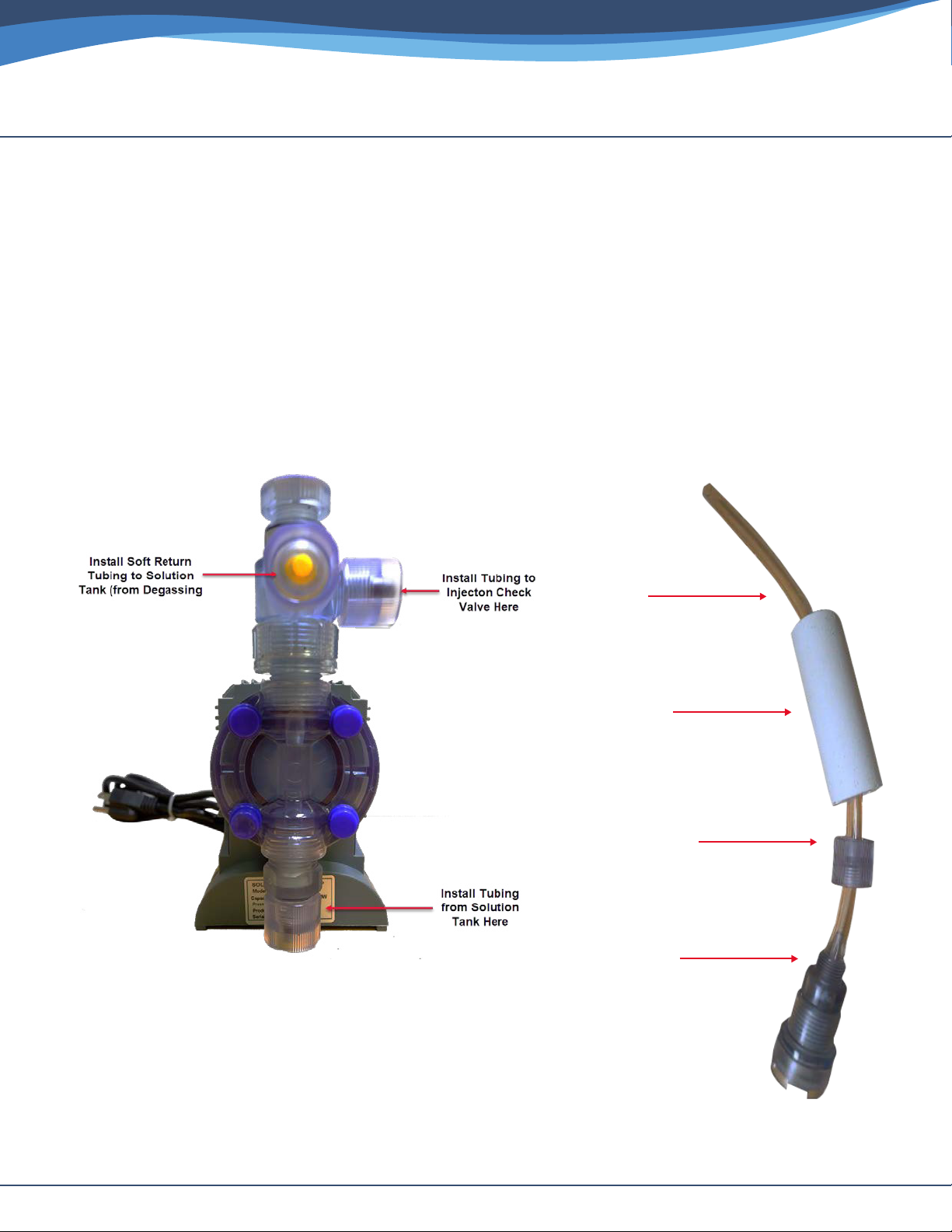

Install Suction Tubing from Pump to Solution Tank

Connect hard tubing from foot valve in Solution Tank to Inlet/ Suction side of metering pump

1. Measure the tubing from the outside of the solution tank to ensure it will be 2-3” from the

bottom of the solution tank.

2. Do not allow weight to sit at the bottom of the tank. Connect tubing to the foot valve and put

the ceramic weight on.

3. Run the tubing up through the hole and connect to the Inlet/ Suction side of pump

www.cleanwaterstore.com 10

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

Connect Tubing from Degassing Port (“Kicker Port”)

You can use the soft tubing for this run, connect tubing to the degassing port tting (labeled on

the pump as “Kicker Port”) and pass tubing through the hole you drilled down into the tank 4-6”.

www.cleanwaterstore.com 11

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

Connect the Cables (wiring) for the J-PRO-22 Pump

1. Flow Meter Cable WHITE wire Connects to Pump Cable

RED wire (trim back, disregard other color wires)

2. Flow Meter Cable BLUE wire connects to Pump Cable

GRAY wire. (trim back, disregard other color wires)

3. Solder or connect the wires with wire nuts, or

electrical tape and then seal with shrink wrap or

electrical tape.

Prime & Start the Pump with

Water First

1. Add 4 gallons of distilled or puried or softened to solution tank.

2. Adjust the 2FV “kicker port” (which is the Degassing Valve) so it is open approximately ½ to 1

turn counter-clockwise.

3. Plug the pump in to electrical outlet.

4. Pump will be in Manual Mode, with the % at 100%

5. “Motor” light will be Green. “Auto” light will be o.

6. Press the ON-OFF button, pump will start pumping.

7. You will quickly see water being pumped up the suction tube and out the degassing tube.

8. After the pump is primed, close the degassing valve. The valve shall remained closed for

normal operation.

9. After the pump has been in operation for an hour or so, you should check the liquid end of

the pump (back end) and re-tighten the four stainless steel Allen-head screws on the head in

a crisscross fashion. Take care not to overtighten as you may damage the pump.

www.cleanwaterstore.com 12

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

Program and Pump Settings

NOTE: When making programming changes to the pump, you must wait at least 15 seconds for

the updated changes to be stored in the memory. Making additional changes or shutting o

power to the pump prior to this waiting period will default back to the original settings.

When rst plugged in, pump display will read “100” and be in Manual (non-pulse) mode.

“MOTOR” light will be green.

1. Press and hold the SET button for several seconds until “AUTO” light turns green.

2. Now press and hold both the SET button and UP Arrow button for a moment and release.

3. Using UP Arrow button only, adjust to 6, which gives you six pump strokes for each gallon of

water owing through the ow meter. If you get into negative numbers, you must scroll the

down arrow key to zero in order to scroll up to positive numbers.

4. After you have selected the number of strokes per gallon, press and release the Set button to

conrm the setting.

5. Finally press the ON-OFF button once, and now your pump is in automatic mode.

Note: Check to see if pump is operating correctly by running the water and comparing pump

actuations vs. programmed strokes per gallon of water owing through the meter.

During Auto mode, numbers appearing on the readout have no meaning or direct correlation to

amount of solution being injected.

Later you can adjust it higher (or lower) depending on the desired chlorine residual. For more

information on that, see example calculations below.

How to Select the Citric Acid Solution Strength and

Pump Setting

• The goal of a properly functioning Citric Acid injection system is to reduce the pH of your

water to the 7 to 8 pH range.

How Much Citric Acid Should Be Injected?

For citric acid, a good starting point is 1 lb of citric acid (2 cups) dissolved in one gallon of soft or

pure water. Warm water dissolves more rapidly.

Pulses Per Gallon setting on pump: Set to 6 to start.

Test the pH, and then either turn up the pump if the pH is not low enough, or add another 1/2

gallon of water if it is too low.

www.cleanwaterstore.com 13

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

Troubleshooting and Maintenance

Most problems occur with the connections, it can sometimes be hard to push the tubing onto

the cones, sometimes ttings are over-tightened, or people use Teon tape and paste on ttings

that do not need it.

Remember, above all, if the pump pumps in manual mode (makes a ka-thunk, ka-thunk sound),

then it works.

Is pH too Low? Too much Citric Acid?

Adjust the strokes per gallon down to 1 or 2, and/or make the Citric Acid solution more diluted

by adding more distilled water.

If you cannot get it to prime, it is either because a tting is too loose, too tight, or not

installed correctly.

If you see the water going up and down in the tubing, this indicates the foot valve is not tight, or

you installed the pump too high above the solution tank, or you mounted the pump improperly.

Sometimes, as mentioned earlier in the guide, it is because the four Allen head bolts on the

pump head have loosened, and need to be tightened, do not over-tighten.

If the solution has lled up the tubing, but it is not discharging, make sure the de-gas is opened,

and then close it until the point when it starts pumping.

The tubing going from the outlet/discharge to injection check valve will twitch

and move at the same time the pump triggers, that is how you can conrm you are

pumping solution.

If this does not work, remove the discharge-to-injection check valve tubing from the outlet

tting, and see if it strokes out of the top- if it does, this indicates that the problem is in the

injection check valve, or that you are trying to pump against greater than 100 psi.

Winterizing: do not let the J-PRO-22Pump or tubing freeze. If you need to winterize, drain the

Citric Acid solution tank and discard Citric Acid solution. Place the suction of the pump into a

bucket of clean water and allow the pump to run until the J-PRO-22Pump is free of any Citric Acid

solution. Remove the suction from the water and allow the pump to pump dry. Pump is ready to

store.

NOTE: when diluting the Citric Acid, use only distilled water, water from a reverse osmosis

system, or at least softened water. Do not use untreated well water.

P7007550

Injection

Check Valve

P7007540

Diaphragm

Replacement

P7007570

Foot Valve

www.cleanwaterstore.com 14

J-PRO-22 Proportional Citric Acid Installation Guide

Rev-042123

Need Assistance?

Call us at: 831-462-8500

Spare Parts

These installation parts are included with initial order, but you may wish to have spares on hand,

or replace the injection check valve, foot valve or diaphragm later.

Table of contents

Popular Water Pump manuals by other brands

Velp

Velp F30620198 instruction manual

Harbor Freight Tools

Harbor Freight Tools Drummond 63320 Owner's manual & safety instructions

Giant

Giant GP7622 Operating instructions/ repair and service manual

GORMAN-RUPP

GORMAN-RUPP SUPER T SERIES Installation, operation and maintenance manual

KSB

KSB Rotex Installation & operating manual

Beretta

Beretta Hydro Unit M Installation and owner's manual

Grundfos

Grundfos CM series Installation and operating instructions

WITA

WITA HE OEM 4 40 Series operating instructions

SFA

SFA SANICOM 1 installation instructions

STA-RITE

STA-RITE PNB-1L owner's manual

Grundfos

Grundfos UNILIFT AP35B Installation and operating instructions

Kamoer

Kamoer KSP-F01A-DC user manual