CleanCraft KM 625 User manual

Sweeper

Operating Instructions

KM 625

KM 825

KM 625 KM 825

2KM Series | 1.02

Imprint

Product identification

Sweeper Item number

KM 625 7302162

KM 825 7302182

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.cleancraft.de

Information regarding the operating instructions

Original instruction

Edition: 25.03.2021

Version: 1.02

Language: English

Author: FL/RL

Information regarding the copyright

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The company Stürmer Maschinen GmbH is the sole ow-

ner of the content of these operating instructions. For-

warding and reproduction of this document as well as

use and notification of its content is not permitted without

explicit consent. Infringements will lead to claims for da-

mages.

Subject to technical modifications and error.

Content

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Costumer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Qualification of the staff ...................................... 5

2.4 Personal protective equipment ........................... 5

2.5 General safety regulations................................. 5

2.6 Safety instructions Battery.................................. 6

2.7 Safety data sheets .............................................. 6

2.8 Safety markings on the machine ........................ 6

3 Intended Use ........................................... 7

3.1 Misuse ................................................................ 7

3.2 Residual risks ..................................................... 7

4 Technical Data......................................... 7

5 Type Plate ................................................ 7

6 Scope of Delivery.................................... 8

7 Optional Accessories ............................. 8

8 Transport, Packaging, Storage .............. 8

8.1 Packaging........................................................... 9

8.2 Storage ............................................................... 9

9 Description .............................................. 9

9.1 Description of control panel ............................... 9

10 Assembling.......................................... 10

11 Commissioning ................................... 11

11.1 Operating the charger..................................... 11

12 Operation ............................................. 12

12.1 Adjusting the side brush ................................. 12

13 Care, Maintenance and Repair........... 12

13.1 Care by cleaning............................................. 12

13.1.1 Emptying the dirt collection container....... 12

13.1.2 Clean pre-filter.......................................... 13

13.1.3 Clean main filter ....................................... 13

13.2 Maintenance and Service/Repair.................... 14

13.2.1 Replacing the sweeping brush .................. 14

13.2.2 Replacing the main sweeper roller ............ 15

14 Disposal, Recycling of old Equipment..

15

14.1 Decommission ................................................ 15

14.2 Disposal of electrical equipment..................... 15

14.3 Disposal via municipal Collecting points......... 15

15 Troubleshooting.................................. 16

15.1 Display error codes........................................ 16

15.1.1 Programming............................................. 16

15.1.2 Programmierungsanleitung ....................... 16

16 Spare Parts .......................................... 17

16.1 Ordering spare parts....................................... 17

16.2 Spare parts drawings...................................... 18

16.2.1 Spare parts drawings KM 625 ................... 18

16.2.2 Spare parts drawings KM 825 .................. 20

17 Electrical Circuit Diagrams ................ 22

17.1 Electrical circuit diagram KM 625 ................... 22

17.2 Electrical circuit diagram KM 825 ................... 23

18 EC - Declaration of Conformity.......... 24

Introduction

KM Series | 1.02 3

1 Introduction

You have made a good choice by purchasing the

CLEANCRAFT Sweeper.

Read the operating manual thoroughly before com-

missioning the machine.

It gives you information about the proper commission-

ing, intended use and safe and efficient operation and

maintenance of your Sweeper.

The operating manual is part of the Sweeper package.

Always keep this operating manual in the location where

your Sweeper is being operated. All local accident pre-

vention regulations and general safety instructions for

the operating range of your Sweeper must also be com-

plied with.

Illustrations in this operating manual serve the general

understanding and may deviate from the actual design.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the

Sweeper. Any application beyond those described is not

permitted without the written approval of Stuermer Ma-

schinen GmbH. For the protection of our products, we

shall register trademark, patent and design rights, as this

is possible in individual cases. We strongly oppose any

infringement of our intellectual property.

1.2 Costumer service

If you have questions about your machine or technical in-

formation, please contact your dealer. There you will be

happy to help with expert advice and information.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair-Service:

Fax: 0049 (0) 951 96555-111

Email: service@stuermer-maschinen.de

Internet: www.cleancraft.de

Spare parts orders:

Fax: 0049 (0) 951 96555-119

Email: ersatzteil[email protected]

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards and

rules, the state-of-the-art technology and our longterm

knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-ti-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task-ba-

sed safety notes are included in the paragraphs of the in-

dividual phases of life.

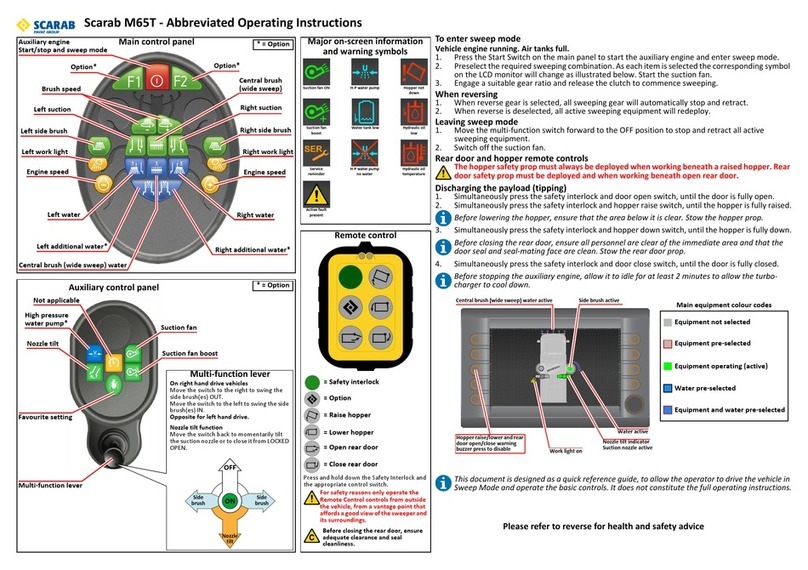

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

4KM Series | 1.02

Safety

Tips and recommendations

To reduce the risk of personal injury and property da-

mage and to avoid dangerous situations, the safety inst-

ructions in this manual must be observed.

2.2 Obligations of the operating com-

pany

The operating company is the person who operates the

Sweeper for business or commercial reasons by herself,

or leaves it to a third party for use or application, and who

bears the legal product responsibility for the protection of

the user, the staff or for third parties.

Obligations of the operator:

If the machine is used in the commercial sector, the ope-

rator of the machine is subject to the legal obligations for

occupational safety.

For this reason, the safety instructions in this operating

manual as well as the safety, accident prevention and

environmental protection regulations applicable to the

area of application of the machine must be observed.

The following applies in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use of the Swee-

per. She must implement these in form of opera-

ting manuals for the operation of the Sweeper.

- During the entire lifetime the Sweeper, the opera-

ting company must verify whether the operating

manuals prepared by her correspond to the current

status of the regulations, and must adapt these if

necessary.

- The operating company must unambiguously regu-

late and determine the responsibilities for installa-

tion, operation, troubleshooting, maintenance and

cleaning.

- The operating company must ensure that all per-

sons who work with the Sweeper, have read and

understood this manual. Furthermore she must in-

struct the staff in regular intervals and inform them

about the hazards.

Furthermore the operating company is responsible to

keep the Sweeper always in a technically flawless state.

Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices checked

regularly for their good working order and their in-

tegrity.

WARNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not avoi-

ded.

Tips and recommendations

This symbol highlights useful tips and recommendati-

ons as well as information for efficient and trouble-

free operation.

Safety

KM Series | 1.02 5

2.3 Qualification of the staff

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator

The operator is instructed by the operating company ab-

out the assigned tasks and possible risks in case of im-

proper behaviour. Any tasks which need to be performed

beyond the operation in the standard mode must only be

performed by the operator if it is indicated in these inst-

ructions and if the operating company expressively com-

missioned the operator.

Electrically qualified person

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

independently recognize and avoid possible dangers.

Qualified personnel

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

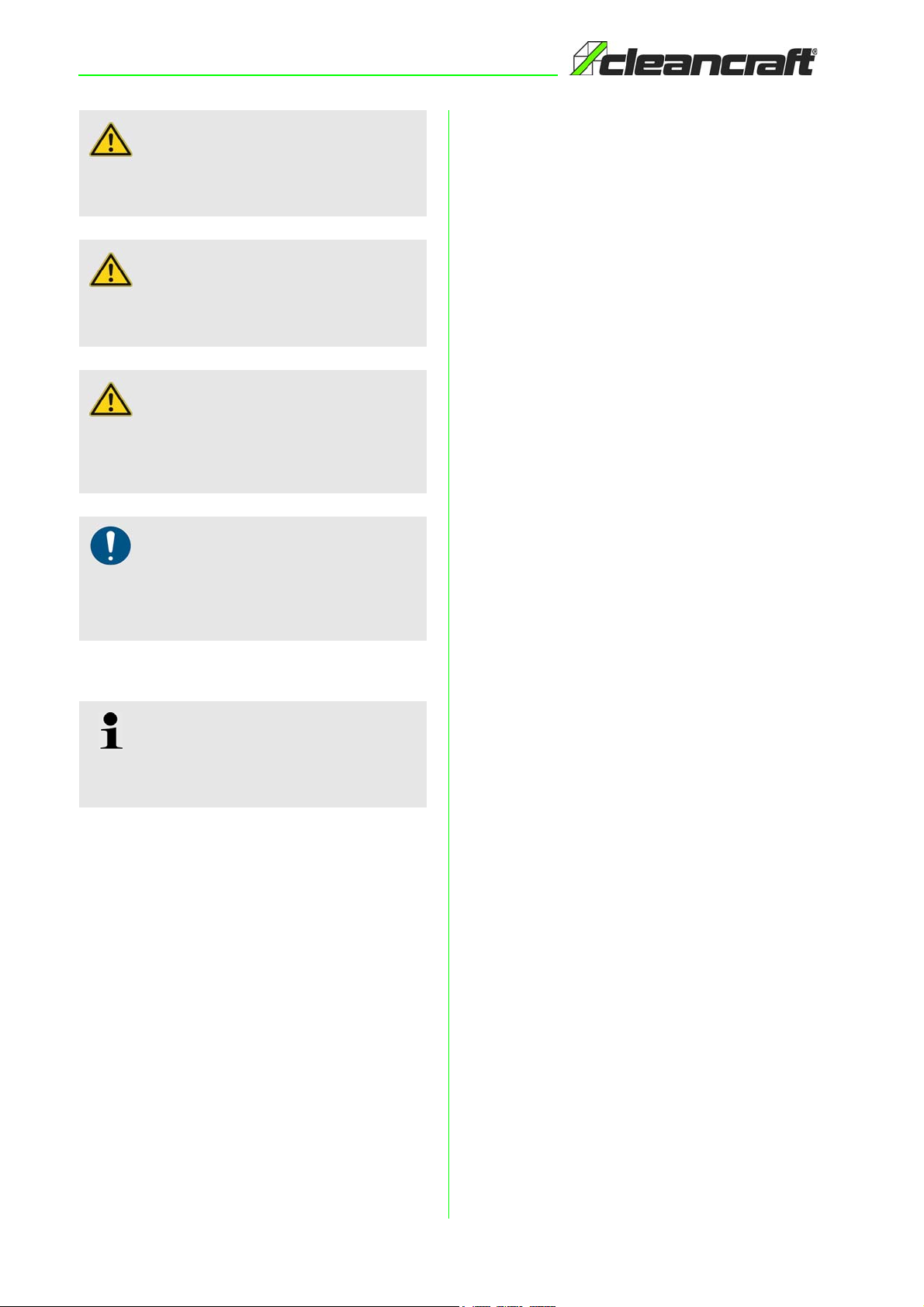

2.4 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while wor-

king. The staff member has to wear personal protective

equipment while performing different tasks on and with

the machine which are indicated in the individual para-

graphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 General safety regulations

Please note the following:

- Never work without guards and keep them in good

working order.

- Always keep the sweeper and its working environ-

ment clean.

- Do not modify the sweeper's design or use it for pur-

poses other than those for which it was designed by

the manufacturer.

- Never work under the influence of diseases that im-

pair concentration, fatigue, drugs, alcohol or medica-

tion.

- Keep children and persons unfamiliar with the

sweeper away from its working environment.

- Persons with reduced physical, sensory or mental ca-

pabilities must not use the machine unless they are

supervised and instructed by a carer.

- Only use the sweeper in accordance with these in-

structions.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the single-disc machine and expose

themselves and others to the danger of severe or let-

hal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the wor-

king area.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fal-

ling parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6KM Series | 1.02

Safety

- Do not sweep up gel, liquid, flammable, explosive, in-

candescent and harmful substances with the

sweeper.

- Do not sweep up liquids.

- The machine is only intended for sweeping on paved

areas. The sweeping environment must not be wet.

- Never put hands or feet on or under rotating parts.

- Before each use, make sure that there are no dama-

ged parts on the sweeper.

- Damaged parts must be replaced immediately to

avoid sources of danger.

- Hold the machine firmly during operation.

- Do not expose the machine to rain or snow.

- Be aware of all power lines, electrical circuits, water li-

nes and other mechanical hazards in your work area,

especially those hazards below the work surface that

are hidden from the operator's view and may come

into contact unintentionally.

- Do not use your sweeper in places where there is a

risk of fire or explosion; e.g. in the presence of flam-

mable liquids, gases or dust.

- Make sure that the brushes do not block during opera-

tion. Prolonged blocking of the brushes can damage

the appliance.

- Replace defective parts immediately. Only use origi-

nal spare parts.

- Do not make any changes, additions or conversions

to the sweeper.

- If damage occurs to the machine, stop using it and

have it repaired or contact our customer service.

- If you sweep in glass or broken pieces, wear protec-

tive goggles and gloves.

- Use robust gloves to remove glass and other sharp

objects from the dirt container.

- Operate the sweeper only with the dirt bin and filter

correctly fitted.

- Only drive at low speed on sloping or slippery sur-

faces.

- The machine must not be used for transporting per-

sons or objects.

- Wear a dust mask, safety goggles and protective

gloves in dusty areas.

- Do not disassemble the machine or attempt to repair it

yourself.

- Only use original spare parts and accessories.

2.6 Safety instructions Battery

- Disconnect the battery and charger before working on

the machine.

- Do not smoke when working on or adjusting the bat-

tery.

- If the charger cable is damaged, it must be replaced

by the manufacturer, authorised dealer or equally

qualified personnel.

- Do not use batteries that are not intended for use with

the machine.

- Never use a defective charger or charging cable to

charge the battery.

- Be careful not to short-circuit the battery terminals or

cause a spark.

- Keep the battery away from open flames.

- To avoid fire or explosion, check the batteries and

charger for damage before use.

- Do not use the machine with a damaged battery.

- Remove damaged batteries from the machine and

dispose of them safely. Do not throw the battery away

with household waste, but dispose of it in accordance

with local laws and regulations.

2.7 Safety data sheets

Safety data sheets on hazardous goods can be obtained

from your specialist dealer or by calling +49 (0)951/

96555-0. Specialist dealers can find safety data sheets in

the download area of the partner portal.

2.8 Safety markings on the machine

The Sweeper has safety markings and instructions (Fig.

1) which must be observed and followed.

Fig. 1: Safety markings

Damaged or missing safety symbols on the machine can

lead to incorrect actions with personal injury and damage

to property. The safety symbols attached to the machine

must not be removed. Damaged safety symbols must be

replaced immediately. From the moment when the signs

are not immediately recognisable and comprehensible at

first sight, the machine must be taken out of operation

until the new signs are attached.

Intended Use

KM Series | 1.02 7

3 Intended Use

The sweeper is designed exclusively for sweeping dirt, dry

waste and dust on hard floors outdoors and indoors or car-

peted floors indoors. The machine may only be used in ac-

cordance with its intended purpose. Any other use beyond

this is not in accordance with the intended use.

Intended use also includes compliance with all the informa-

tion in these instructions.

Stürmer Maschinen GmbH accepts no liability for design

and technical modifications to the sweeper.

Claims of any kind for damage due to improper use are ex-

cluded.

3.1 Misuse

3.2 Residual risks

Even if all safety instructions are observed and the

sweeper is used according to the instructions, there are

still residual risks, which are listed below:

- Risk of injury to upper limbs (e.g. hands, fingers).

- Risk of fire if the battery is incorrectly connected.

- Never clean floors with a height gradient greater than

that indicated on the machine.

- Do not use at altitudes above 2000m.

4 Technical Data

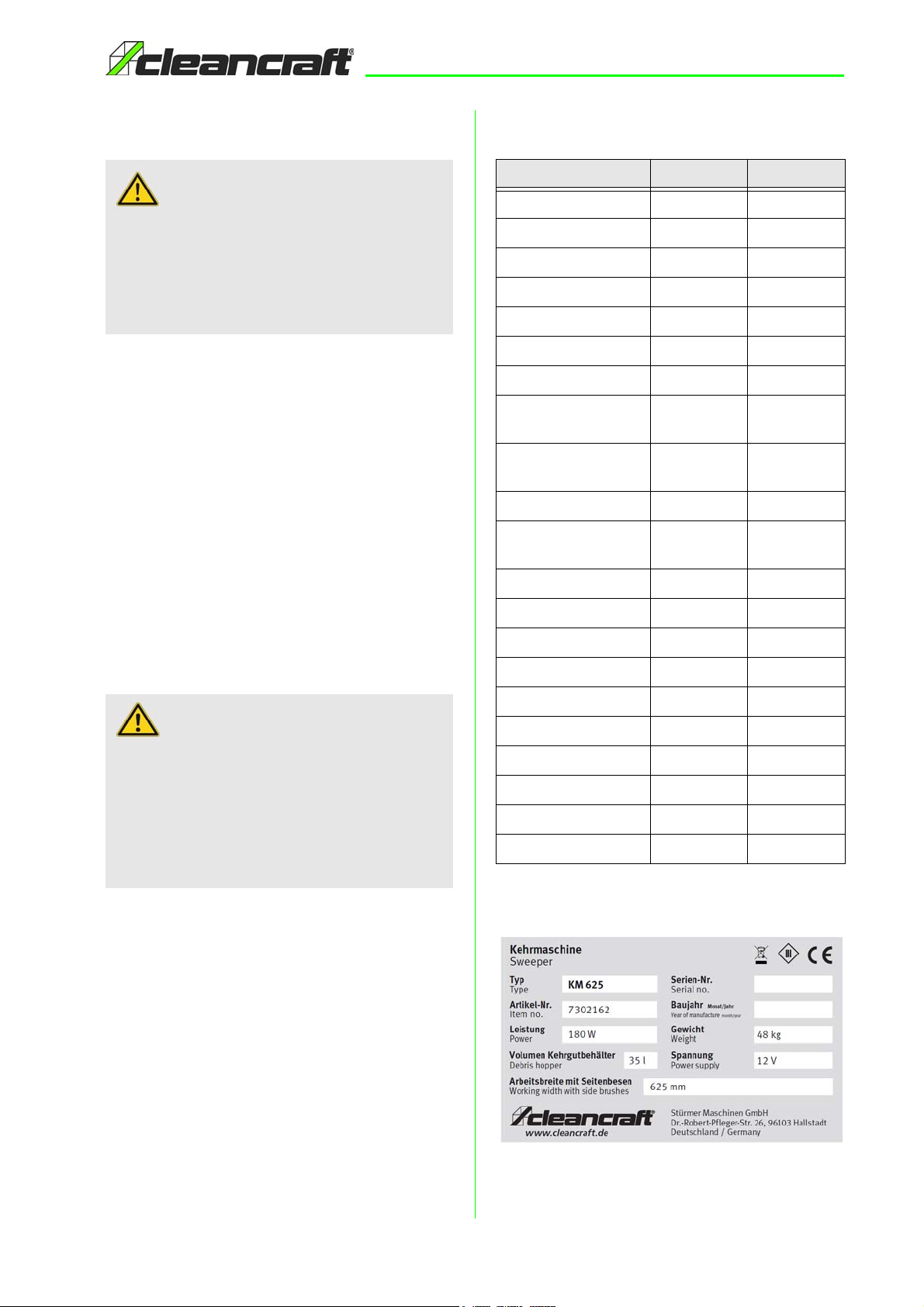

5 Type Plate

Fig. 2: Type plate KM 625

ATTENTION!

Any modification of the appliance is prohibited. In

addition to invalidating the warranty, the modification

may result in fire and injury, including mortal danger,

to the user. The manufacturer accepts no liability for

damage caused to property or persons as a result of

failure to comply with these instructions or misuse of

the appliance.

ATTENTION!

Risk of misuse!!

A mususe on Sweeper can lead to dangerous situati-

ons or damage to the device.

- Only operate the Sweeper in the performance range

specified in the technical data.

- Never bypass or override the safety devices.

- Only operate the scrubber-drier in a technically per-

fect condition.

Model KM 625 KM 825

Length 1033 mm 1033 mm

Width / Depth 615 mm 815 mm

Height 994 mm 994 mm

Weight 48 kg 53 kg

Working capacity 2180 m²/h 2600 m²/h

Cleaning surface 625 m² 825 m²

Operational capacity 2180 m²/h 2600 m²/h

Working width with

central brush

405 mm 660 mm

Working width with

side brushes

625 mm 825 mm

Speed 0 - 3,5 km/h 0 - 3,5 km/h

Maximum ramp gra-

dient

2% 2%

Debris hopper 35 l 45 l

Speed brushes 550 rpm 550 rpm

Brush diameter 200 mm 200 mm

Total power 0,18 kW 0,18 kW

Sound pressure level 56 dB(A) 56 dB(A)

Vibration level 1,3 m/s² 1,40 m/s²

Protection class IPX3 IPX3

Power supply 12V battery 12V battery

Battery lifetime 110 min 110 min

Battery charge time 8 hours 8 hours

8KM Series | 1.02

Scope of Delivery

6 Scope of Delivery

Scope of delivery KM 625 and KM 825

- Battery 12V 42Ah AGM

"You can receive the safety data sheet from your spe-

cialist dealer or by calling Tel: +49 (0)951/96555-0"

- On-board charger 12V 5Ah

- Side broom

- Main sweeping roller

- Plate filter

7 Optional Accessories

KM 625

- Main sweeper roller soft

item number: 7310000

- Main sweeper roller medium

item number: 7310001

- Main sweeper roller hard

item number: 7310002

- Side broom

item number: 7310010

- Plate filter

item number: 7310015

- Polyester plate filter

item number: 7310016

- AGM battery 12V 42 Ah

item number: 7310020

KM 825

- Main sweeper roller soft

item number: 7310005

- Main sweeper roller medium

item number: 7310006

- Seitenbesen

item number: 7310010

- Plate filter

item number: 7310015

- Polyester plate filter

item number: 7310016

- AGM battery 12V 42 Ah

item number: 7310020

8 Transport, Packaging, Sto-

rage

Transport

Improper transport of individual devices, unsecured de-

vices stacked on top of each other or next to each other

in packed or already unpacked condition is accident-

prone and can cause damage or malfunctions for which

we do not grant any liability or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently dimensioned industrial truck to

the installation site.

General risks during internal transport

Devices may only be transported by authorized and qua-

lified persons. Act responsibly during transport and al-

ways consider the consequences. Refrain from daring

and risky actions.

Gradients and descents (e.g. driveways, ramps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route for

possible danger points, unevenness and disturbances

as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points must

be inspected before transport. The removal of danger

spots, disturbances and unevenness at the time of trans-

port by other employees leads to considerable dangers.

Careful planning of internal transport is therefore essen-

tial.

CAUTION!

Injuries caused by parts falling over or off a forklift,

pallet truck or transport vehicle.

Only use means of transport that can carry the total

weight and are suitable for it.

CAUTION: DANGER OF TIPPING!

The device may be lifted unsecured by a maximum

of 2cm.

Employees must be outside the danger zone, the

reach of loads. Warn employees and, if necessary,

advise employees of the hazard.

Description

KM Series | 1.02 9

8.1 Packaging

All used packaging materials and packaging aids are re-

cyclable and should be taken to a materials recycling de-

pot to be disposed of.

The delivery packaging is made of cardboard, so please

dispose carefully by having it chopped up and given to

the recycling collection.

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). Deliver these substances to a

collection point for recyclable materials or to the waste

disposal company which looks after your region.

8.2 Storage

Store the sweeper in a dry, clean and frost-free environ-

ment. If the machine is not used for more than one

month, disconnect the red and black battery connection

cable.

9 Description

Fig. 3: Description KM 625

1 Control panel

2 Push handle

3 Swivel castor

4 Sweeping brush

5 Running wheel

6 Dirt collecting container

9.1 Description of control panel

Fig. 4: Control panel

1 On / Off button

Button for switching the machine on and off.

2 Display

Numerical display indicating voltage or operating time.

3 Button for toggling between indicating voltage /

operating hours and operating minutes. minutes

Numerical display button: Pressing the button displays the

machine voltage, as well as the hours (one press) and mi-

nutes (two presses) of machine operation.

4 On / Off button for selecting the operating mode for

light soiling

On-off button for selecting the operating mode: By pres-

sing the button, two different operating modes can be

selected: Mode 1 for light soiling and Mode 2 for intensive

soiling.

5 On-off button for selecting the operating mode for

intensive soiling

On-off button for selecting the operating mode: By pres-

sing the button, two different operating modes can be

selected: Mode 1 for light soiling and Mode 2 for intensive

soiling.

6 Battery charge status indication

LED's for indicating the battery charge status. LED lights

up green when the battery is charged, red when it is

discharged and yellow when it is in reserve or recharge

status.

7 Button for manual activation of the filter shaker

With the button the filter shaking can be activated. This

function is in addition to the automatic shaking that occurs

every 3 minutes.

1

2

3

4

5

6

10 KM Series | 1.02

Assembling

8 Button for switching off the automatically active in-

take fan

Intake fan: The intake fan is automatically switched on du-

ring working operation. The switch is thus used when it is

necessary to switch off the fan during machine operation.

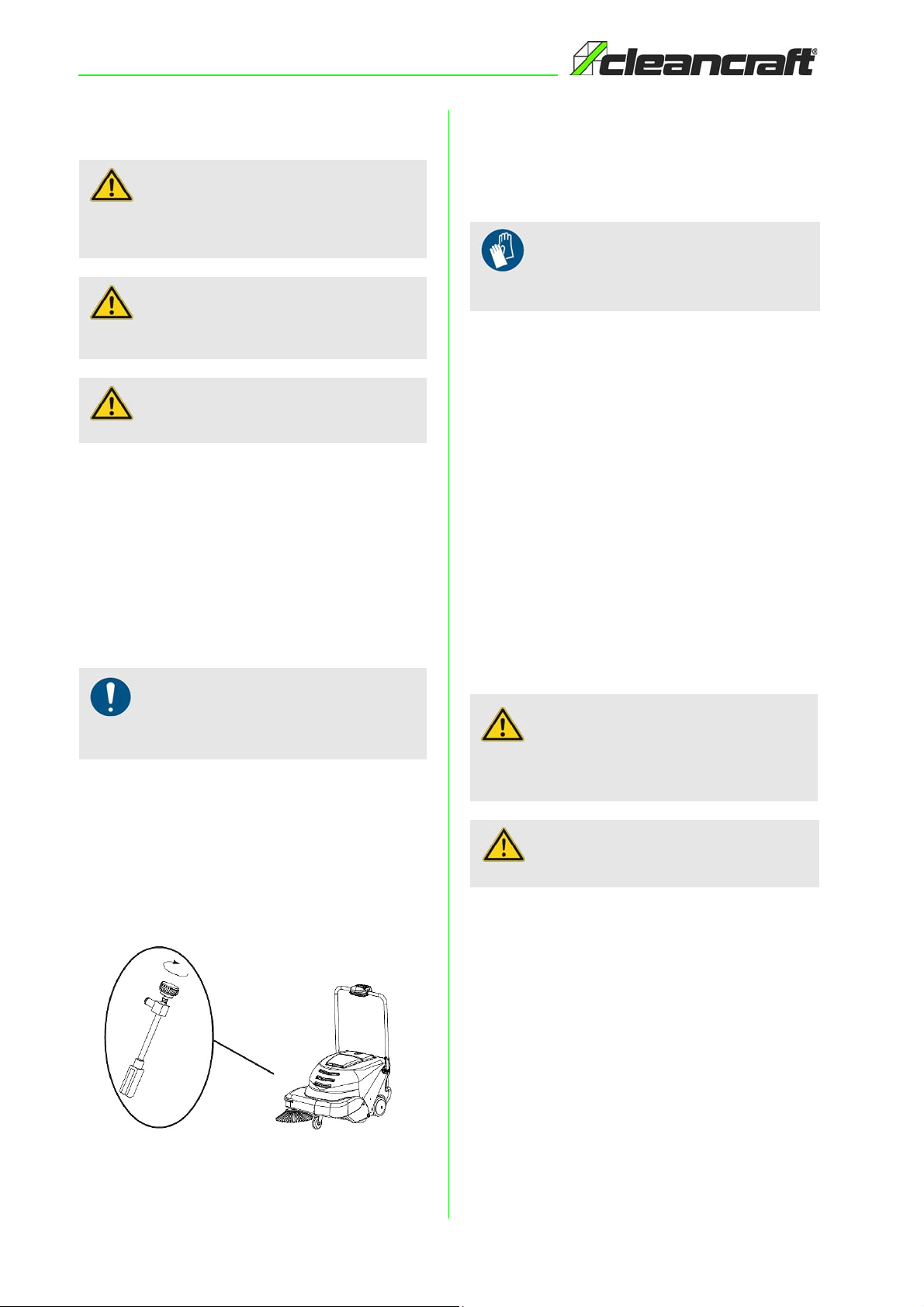

10 Assembling

Unpack the machine carefully and avoid movements that

could cause damage.

After removing the packaging, check the condition of the

components. If any damaged parts are found, contact an

authorised dealer immediately.

Proceed as follows to assemble the sweeper:

Step 1: Remove the packaging of the sweeper and

check that there is no damage to the machine.

Step 2: Check that the scope of delivery is complete.

Step 3: Lift the machine at the front and slide the

sweeping brush onto the shaft..

Fig. 5: Mounting the sweeping brush

Step 4: Unlock the clamping device of the push bar.

Fig. 6: Unlocking the clamping device

Step 5: Pull out the push bar to the desired height.

Fig. 7: Adjusting the push bar

Step 6: Clamp the clamping device of the push bar.

Step 7: Check the lever for lifting the suction lip for cor-

rect assembly. (model KM 825 only).

Fig. 8: Lever for lifting the suction lip

unlocking

Handle clamping device

Commissioning

KM Series | 1.02 11

Step 8: Remove the top cover of the sweeper to access

the battery.

Step 9: Connect the two cables with each other. Make

sure the cables are connected correctly . (Red to

Red and Black to Black)

Fig. 9: Connect battery

11 Commissioning

After all assembly and preparation operations have been

carried out, the sweeper can be used. To obtain the best

performance and avoid damage to the machine, be sure

to follow the instructions in the manual carefully.

- Do not use the machine to pick up cables, ropes,

threads, water or other liquids.

- If there is a lot of waste on the floor (paper, leaves,

etc.), push up the front of the machine by pushing

the handlebar downwards.

- To collect hard and bulky rubbish, lift the suction lips

with the lever on the handle (Fig.8). As far as pos-

sible, do not operate the sweeper with the suction lip

lifted, as this leads to poorer cleaning results.

- At the end of the work, switch on the filter shaker.

11.1 Operating the charger

Fig 9.1: Charger fuse

As soon as the battery of the machine is discharged, the

red LED on the control panel lights up and all machine

functions switch off automatically. The operator must

therefore switch off the machine and start the charging

process by connecting the charger plug to the machine

and the power supply. During the charging process, the

yellow LED lights up on the display. When charging is

complete, the green LED lights up. The charger plug can

now be pulled out and the machine can be used again.

ATTENTION!

The machine is not designed for use on wet floors.

However, if the machine is used in moderately damp

areas (accumulation of moisture on the floor), it is

essential to switch ON the suction filter to avoid filter

damages. No guarantee is given in case of damage

to the machine due to vacuuming of wet waste.

black

black

red

red

ATTENTION!

Be careful not to switch on the sweeper until the bat-

tery is fully charged. Stopping the charging process

before the battery it is fully charged may shorten the

battery's life.

NOTE!

The fuse of the charger is 2.5 A.

Fuse 2,5A

12 KM Series | 1.02

Operation

12 Operation

Step 1: Switch on the unit by pressing the ON/OFF button.

Step 2: Check that the green LED is lit and that the bat-

tery is charged.

Step 3: Select the appropriate operating mode:

- On / Off switch 1 for light soiling and smooth floors.

- On / Off switch 2 for heavy dirt, cement, smooth as-

phalt or carpeted floors.

12.1Adjusting the side brush

Depending on the application and wear, the side brush can

be adjusted by using the adjustment screw (Fig. 10). Re-

move the top cover and turn the adjustment screw clock-

wise to increase the distance to the ground. Turn the adju-

stment screw anticlockwise to decrease the distance.

Fig. 10: Side brush adjustment

13 Care, Maintenance and Repair

13.1Care by cleaning

The sweeper must always be kept in a clean condition.

- Clean the sweeper only with a dry or damp cloth. Do

not use aggressive chemicals or scouring agents for

cleaning.

- Remove foreign objects such as leaves, twigs, etc.

from the brushes.

- Do not wash the brushes with hot water.

- Regularly check the drive belts for correct fit and ten-

sion.

- Store the sweeper indoors in a dry place protected

from dust, dirt and extreme temperatures.

- Keep metal parts dry to avoid or minimise corrosion.

- Avoid sweeping in long strings or ropes, as the brus-

hes can become tangled and damaged. If a rope or

thread becomes tangled, please remove the rever-

sing roller.

13.1.1 Emptying the dirt collection container

Before removing the dirt collection container, make sure

that the machine is switched off.

Step 1: Unlock the locking clamp of the dirt collection con-

tainer.

Step 2: Pull the handle to remove the container.

Step 3: Empty the container.

Step 4: Clean the dirt collection container and put it back

into the sweeper.

Step 5: Tighten the locking clamp of the dirt collection

container.

ATTENTION!

The machine must only be used by authorised per-

sonnel. Do not leave the machine unattended when it

is switched on.

ATTENTION!

Empty the dirt collection container regularly to ensure

safe work operation.

CAUTION!

Do not use the sweeper in wet areas!

NOTE!

When using operation mode 2, the battery working

time of the machine is reduced.

Wear protective gloves

Wear suitable protective gloves for cleaning to pro-

tect against injury.

ATTENTION!

Clean all parts of the sweeper when you finished

working with the machine. Empty the container and

wipe it with a cloth.

ATTENTION!

Never use the sweeper without dirt collection container.

Care, Maintenance and Repair

KM Series | 1.02 13

Fig. 11: Emptying the dirt collecction container

13.1.2 Clean pre-filter

The filters are essential and fundamental machine parts

for proper operation. By cleaning the filters correctly,

your machine will perform at its best.

Step 1: Remove the dirt collection container.

Step 2: Unlock both metal clips of the pre-filter.

Step 3: Remove the pre-filter.

Step 4: Clean the pre-filter and let it dry if necessary.

Step 5: Insert the pre-filter and secure it with the two metal

clamps.

Step 6: Replace the dirt collection container and clamp it

firmly.

13.1.3 Clean main filter

The main filter can be cleaned in three ways:

Automatic filter shaker

During operation, the filter shaker switches on automati-

cally every 3 minutes.

Switching on the filter shaker manually

A simple operation is enough to clean the filter. Press

and hold the PUSH-button (7) for a few seconds and

repeat this action 4 to 5 times. It is recommended to per-

form this operation at the end of each work cycle.

If the machine is used in dusty environments, the manual

filter shaker should be used more frequently.

Manual cleaning of the main filter

The filter should be cleaned every 20 working hours. If the

filter shaker alone is not enough, the filter can be cleaned

manually. Before carrying out any work on the machine,

make sure that it is switched off and that all functions are

deactivated.

Step 1: Remove the dirt collection container.

Step 2: Remove the main filter.

Step 3: Shake out the filter or clean it with compressed air.!

Step 4: Replace the main filter.

Step 5: Replace the dirt collection container and clamp it

in place.

Fig. 12: Clean main filter

Wear protective goggles!

Risk of eye injuries. Always wear safety goggles when

cleaning the components. Particular care is required by

using compressed air.

14 KM Series | 1.02

Care, Maintenance and Repair

13.2 Maintenance and Service/Repair

Regularly check the belt of the machine for good fit. Re-

place the belt if it is worn.

Regularly check the brushes for wear and replace them if

necessary.

Maintenance intervals:

If the hand sweeper does not work properly, contact a

specialist dealer or our customer service. You will find

the contact details in chapter 1.2 Customer service.

13.2.1 Replacing the sweeping brush

Step 1: Switch off the machine.

Step 2: Lift the machine at the front.

Step 3: Press in the two tabs on the sweeping brush and

pull it out downwards.

Step 4: Insert the new sweeping brush and press it in un-

til it is locked in place.

Fig. 13: Replacing the sweeping brush

ATTENTION!

Maintenance and repair work must always be carried

out by qualified personnel; any damaged parts may only

be replaced with original spare parts.

ATTENTION!

Unplug the battery and the charger before carrying out

maintenance work on the machine.

On delivery

Daily

Every 10 hours

Every 20 hours

Every 50 hours

Every 100 hours

Check the functionality of all

components XXXXXX

Empty and clean the dirt col-

lection container X

Remove and clean the pre-fil-

ter X

Check the seals X

Check the main filter (clean, if

necessary) X

Check bolts and nuts for tight-

ness X

Check wear of the rollers and

brushes X

Check the belt tension X

ATTENTION!

Maintenance and repairs must always be carried out

by qualified personnel. Any damaged parts must only

be replaced with original spare parts.

Disposal, Recycling of old Equipment

KM Series | 1.02 15

13.2.2 Replacing the main sweeper roller

Step 1: Switch off the machine.

Step 2: Tilt the machine backwards until the handle tou-

ches the ground.

Step 3: Turn the sweeper roller until a black push button

is visible on the right side.

Fig. 14: Push button on the sweeper roller

Step 4: Press the black push-button to unlock the

sweeper roller.

Step 5: Remove the sweeper roller by pulling it down-

wards.

Step 6: Insert the new sweeper roller into the guide from

below.

Fig. 15: Insert new sweeper roller

Step 7: Stand the machine up again.

14 Disposal, Recycling of old

Equipment

In your own interests and in the interest of the environ-

ment, please ensure that all components of the machine

are disposed of in the proper and approved way.

14.1Decommission

Immediately decommission disused machines in order to

avoid later misuse and endangering of the environ-ment

or personal safety.

- Eliminate all environmentally hazardous operating ma-

terials from the used device.

- If required, disassemble the machine into easy-to-

handle and usable components and parts.

- Dispose of machine components and operating ma-te-

rials by the disposal channels provided.

14.2Disposal of electrical equipment

Please note that electrical appliances contain a variety of

recyclable materials as well as environmentally harmful

components.

Make sure that these components are disposed of sepa-

rately and properly. In case of doubt, please contact your

municipal waste disposal.

If necessary, the help of a specialized waste disposal

company can be used for the treatment..

14.3Disposal via municipal Collecting

points

Disposal of used electrical and electronic equipment (to be

applied in the countries of the European Union and other

European countries with a separate collection system for

this equipment).

The symbol on the product or its packaging in-

dicates that this product should not be treated

as normal household waste, but should be ta-

ken to a collection point for the recycling of

electrical and electronic equipment. By helping to dispose

of this product correctly, you are protecting the environ-

ment and the health of those around you. The environment

and health are endangered by incorrect disposal. Material

recycling helps to reduce the consumption of raw materials.

For more information about recycling this product, contact

your local council, municipal waste disposal service or the

shop where you purchased the product.

16 KM Series | 1.02

Troubleshooting

15 Troubleshooting

15.1Display error codes

15.1.1 Programming

Your machine has factory set for optimal operation so no

further adjustments are necessary. However, if any of

the following codes appear: P1.x, P2.x or SF.x (x= value

between 0 and 9), follow the programming instructions to

reset the display. Operating the machine with settings

other than the factory settings may cause operational

problems.

15.1.2 Programming guide

If the display indicates P1.0, P2.1 or SF.3, switch the

machine off and on again to reset the display (these are

the factory settings). If the display shows higher values

than above (e.g. P1. "5", P2. "7", SF. "9"), proceed as

follows:

To call up the factory settings, switch on the machine,

press the display switch and hold it pressed for at least 3

seconds (battery/time symbols). P1.x will appear on the

display. The value P1 should be "0" (e.g. P1.0). If the

value is greater than "0", press the intake fan push but-

ton until P1.0 appears on the display. Press the display

switch again to display the next code. The value P2.x

should be "1" (e.g. P2.1). Press the push button of the in-

take fan to achieve the correct setting. Press the display

button to show the last code. The code should be SF.3. If

the value is not "3", press the filter shaker button until

SF.3 appears on the display. To exit the programming

function, switch off the machine.

NOTE!

If you cannot fix the problems with your sweeper by

yourself, please contact your local Cleancraft dealer.

Please write down the following information regarding

the sweeper or the operating instructions so that we

can support you in the best manner.

- Model name of the machine

- Serial number of the machine

- Year of manufacture

- Exact description of the error

Fault Remedy

Unsatisfactory

sweeping result

1. Empty the dirt collection con-

tainer

2. Adjust the height of the main

brush

3. Clean or replace the main

brush

4. Replace drive belt

5. Adjust / replace / clean side

brush

6. Adjust the height of the side

brush

Code Fault Remedy

C22 Protection of the

sweeper roller

against short-cir-

cuits: All functions

stops.

Switch the machine

OFF and then ON

again.

C14 Heat dissipator for

high temperatures.

Switches on at a

temperature above

90 °C.

The machine is re-

set as soon as the

temperature drops

below 80 °C.

FS0 Roller/brush worn

out.

Replace roller/

brush.

SP1 Defective brush. Is activated when

the brushes stop

three times within

one minute. Fault

can be reset by

switching off the

machine.

Yellow

LED

lights

up

Reserve state of

the battery

You can continue

operating the ma-

chine. Just for refe-

rence, the battery is

being charged.

Red

LED

flashes

Empty battery All machine functi-

ons are interrupted.

Switch off the ma-

chine and charge

the battery.

P1.X Push-button pro-

gramming of opera-

ting mode 1 activa-

ted.

See "programming"

chapter below

P2.X Push-button pro-

gramming of opera-

ting mode 2 activa-

ted.

See "programming"

chapter below

SF.X Filter shaker pro-

gramme setting is

activated.

See "programming"

chapter below

Code Fault Remedy

Spare Parts

KM Series | 1.02 17

16 Spare Parts

16.1 Ordering spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for requests or

orders of spare parts:

- Type of device

- Item No.

- Position No.

- Year of construction

- Quantity

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare parts orders without the information mentioned

above cannot be considered. If the shipping method is

not specified, shipping will be at the discretion of the sup-

plier.

Details of the unit type, item number and year of manu-

facture can be found on the type plate attached to the

sweeper.

Example

The battery for the KM 625 sweeper must be ordered.

The battery has the number 39 in spare parts drawing 1.

When ordering spare parts, send a copy of the spare

parts drawing (1) with the marked component (battery)

and marked position number (39) to the authorised de-

aler or the spare parts department and provide the follo-

wing information:

- Type of device: Sweeper KM 625

- Item number: 7302162

- Spare parts drawing: 1

- Position number: 39

DANGER!

Risk of injury due to incorrect spare

parts!

The use of incorrect or faulty replacement parts may

cause danger to the operator and cause damage and

malfunction.

- Only use original spare parts from the manufacturer

or replacement parts approved by the manufacturer.

- In case of doubt, always contact the manufacturer.

Loss of warranty

The manufacturer's warranty will become null and

void if non-permissible spare parts are used.

18 KM Series | 1.02

Spare Parts

16.2 Spare parts drawings

The following drawings should help in case of service to identify necessary spare parts. To order, send a copy of the parts

drawing with the parts marked to your authorized dealer.

16.2.1 Spare parts drawings KM 625

Spare parts drawing 1

Fig. 16: Spare parts drawing 1 KM 625

Spare Parts

KM Series | 1.02 19

Spare parts drawing 2

Fig. 17: Spare parts drawing 2 KM 625

20 KM Series | 1.02

Spare Parts

16.2.2 Spare parts drawings KM 825

Spare parts drawing 1

Fig. 18: Spare parts drawing 1 KM 825

This manual suits for next models

1

Table of contents

Other CleanCraft Blower manuals

Popular Blower manuals by other brands

GARDTECH

GARDTECH GT10007/GY8900 manual

Fantom

Fantom PT199H owner's manual

EINHELL

EINHELL BG-EL 2301 E Original operating instructions

Kongskilde

Kongskilde Multiair 3000 user manual

Terramite

Terramite TSS46 Operator's handbook, maintenance, service & parts manual

stayer

stayer MULTI L20 operating instructions