CleanCraft AUKM 600 User manual

AUKM 600

Sweeping Machine

AUKM 600

Operating Instruction

AUKM 600

Imprint

Product identification

Manufacturer

CLEANCRAFT

Sweeping Machine

AUKM 600

Stürmer MaschinenGmbH

Dr.-Robert-Pfleger-Str. 26

D-96103Hallstadt

Artikelnummer:7305060

Fax: 0049 (0) 951 96555 -55

E-Mail:

Internet: info@cleancraft.de

www.cleancraft.de

Indications regarding the operating instructions

Copyright information

Original Instructions

Edition:17.08.2017

Version: 1.01

Language:English

Author: FL

Copyright © 2017 Stuermer Maschinen GmbH, Hallstadt, Germany.

The contents of these operating instructions are the sole property of the

company Stürmer Maschinen GmbH.

Passing on as well as copying of this document, the use and distribution of

its content are prohibited if not explicitly permitted. Contraventions are

liable to compensation.

Subject to technical modifications and error.

2

The descriptions contained in this document are not binding.

The company therefore reserves the right to make any modifications at any time to

elements, details, or accessory supply, as considered necessary for reasons of

improvement or manufacturing/commercial requirements.

The reproduction, even partial, of the text and drawings contained in this document is

prohibited by law.

The company reserves the right to make any technical and/or supply modifications.

The images are for reference purposes only, and are not binding in terms of design

and supply.

SYMBOLS USED IN THEMANUAL

Open book symbol with an"i"

Indicates the need to consult the instruction manual

Open book symbol

Used to tell the operator to read the manual before using the

machine

Warning symbol

Carefully readthe sections marked with this symbol and observe

the indications, for the safety of the operator and the machine

Warning symbol

Indicates danger of gas exhalation and leakage of corrosive

liquids

Warning symbol

Indicates the danger of fire.

Do not go nearwithfree flames

Warning symbol

Indicates that the packed product should be handled with

suitable lifting means that comply with the legal requirements

Disposal symbol

Carefully read the sections marked with this symbol for machine

disposal

3

CONTENTS

ON CONSIGNMENT OF THEMACHINE....................................................................................................................................................6

INTRODUCTORY COMMENT....................................................................................................................................................................6

IDENTIFICATION DATA............................................................................................................................................................................6

TECHNICAL DESCRIPTION......................................................................................................................................................................6

INTENDED USE........................................................................................................................................................................................6

SERIAL NUMBER PLATE.........................................................................................................................................................................6

TECHNICAL DESCRIPTION......................................................................................................................................................................7

SYMBOLS USED ON THE MACHINE........................................................................................................................................................8

GENERAL SAFETY REGULATIONS.......................................................................................................................................................10

MACHINE PREPARATION......................................................................................................................................................................11

1. HANDLING OF THE PACKEDMACHINE.................................................................................................................................................................11

2. HOW TOUNPACK THE MACHINE..........................................................................................................................................................................11

3. HOW TOMOVE THE MACHINE...............................................................................................................................................................................11

4.HANDLEBAR CONTROL COMPONENTS.................................................................................................................................................................12

5. STEERING COLUMN COMPONENTS .......................................................................................................................................................................12

6.

7.

FOOTBOARDCOMPONENTS..................................................................................................................................................................................12

8. FRONT COMPONENTS..........................................................................................................................................................................................13

9. SIDE COMPONENTS..............................................................................................................................................................................................13

10.

REAR COMPONENTS OFTHE MACHINE...............................................................................................................................................................13

11. BATTERYTYPE ...................................................................................................................................................................................................13

12.

13.

BATTERYMAINTENANCE AND DISPOSAL..........................................................................................................................................................14

14.

FITTINGTHEBATTERIES INTO THEMACHINE....................................................................................................................................................14

15.

16.

CONNECTING THE BATTERIES AND BATTERY CONNECTOR ..............................................................................................................................16

17.

18.

BATTERY CHARGER CONNECTION (WITHOUT BC).............................................................................................................................................17

19.

BATTERY CHARGER CONNECTION (WITH BC)....................................................................................................................................................19

20.

BATTERY CHARGE LEVELINDICATOR ..............................................................................................................................................................19

HOUR METER.........................................................................................................................................................................................................19

WORKING FORWARD SPEED................................................................................................................................................................................19

BLINKING LIGHT (OPTIONAL)................................................................................................................................................................................19

HEADLIGHTS..........................................................................................................................................................................................................19

PREPARING TOWORK..........................................................................................................................................................................20

21.PREPARING TOWORK.......................................................................................................................................................................................20

WORK......................................................................................................................................................................................................21

22.STARTINGWORK .................................................................................................................................................................................................21

23.EMERGENCYBUTTON..........................................................................................................................................................................................23

24.EMPTYINGTHE DEBRISHOPPER.......................................................................................................................................................................23

AT THE END OFWORK..........................................................................................................................................................................25

DAILY MAINTENANCE...........................................................................................................................................................................27

25.CLEANING THE CENTRAL BRUSH.......................................................................................................................................................................27

26.CLEANING THE SIDE BRUSH................................................................................................................................................................................28

4

IMPRINT......................................................................................................................................................................................................2

CONTENTS.................................................................................................................................................................................................4

30.SIDE BRUSHADJUSTMENT...................................................................................................................................................................................32

31.CENTRAL BRUSHFLAP ADJUSTMENT.................................................................................................................................................................32

32.CENTRALBRUSH REPLACEMENT......................................................................................................................................................................33

33.SIDEBRUSH REPLACEMENT..............................................................................................................................................................................34

TROUBLESHOOTING..............................................................................................................................................................................35

34.THE MACHINE DOES NOTSTART.........................................................................................................................................................................35

35.THE MACHINE DOES NOTCLEAN WELL...............................................................................................................................................................35

36.THE MACHINE LIFTS DUSTDURING OPERATION................................................................................................................................................35

37.EXCESSIVEORALTERED NOISE OFTHE CENTRALBRUSH.............................................................................................................................35

38.EXCESSIVEORALTERED NOISE OFTHESIDE BRUSH.....................................................................................................................................35

DISPOSAL..............................................................................................................................................................................................36

CHOOSING AND USING THE BRUSHES................................................................................................................................................36

EC DECLARATION OF CONFORMITY.....................................................................................................................................................47

5

WEEKLY MAINTENANCE.......................................................................................................................................................................29

27.CLEANING THE PANELFILTER...........................................................................................................................................................................29

28.CLEANINGTHE FABRICFILTER (OPTIONAL).....................................................................................................................................................30

29.CLEANING THE DEBRIS HOPPER......................................................................................................................................................................31

EMERGENCY MAINTENANCE..................................................................................................................................................................32

SPARE PARTS DRAWING.......................................................................................................................................................................... 37

WIRING DIAGRAM ..................................................................................................................................................................................... 46

ON CONSIGNMENT OF THEMACHINE

When the machine is consigned to the customer, an immediate check

must be performed to ensure all the material mentioned in the shipping

documents has been received, and also to check the machine has not

suffered damage during transportation. If this is the case, the carrier

must ascertain the extent of the damage at once, informing our

customer service office. It is only by prompt action of this type that the

missing material can be obtained, and compensation for damage

successfully claimed.

INTRODUCTORY COMMENT

Even the best machines will only work well if used correctly and kept in

good working order. We therefore suggest you read this instruction

booklet carefully and read it again whenever difficulties arise while using

the machine. If necessary, remember that our assistance service

(organised in collaboration with our dealers) is always available for

advice or direct intervention.

IDENTIFICATION DATA

For technical assistance or to request replacement parts, always give

the model, the version and serial number written on the serial number

plate.

TECHNICAL DESCRIPTION

The FSR are ride-on sweeping machines, powered electrically (with

traction batteries) or with an internal combustion (endothermic) engine,

for thecleaning of both internal and external surfaces with tiled, concrete

or asphalt floors.

The machine must operate on dry surfaces, and if necessary can also

work on wet surfaces making sure the vacuum action is not active. The

machine features a central brush for the collection of brushed up

material, a side brush for cleaning edges and corners, a vacuum system

with filter to avoid raising dust, and a debris hopper that can be manually

removed by means of a mechanical leverage.

INTENDED USE

The sweeping machine is designed to clean both inside and outside

surfaces with tiled, concrete and asphalt floors, for professional use in

industrial, commercial and public places. The machine is only suitable

for use in closed (or at least covered) places. The machine is not

suitable for use in the rain, or under water jets. It is FORBIDDENto use

the machine for picking up dangerous dusts or inflammable liquids within

places with a potentially explosive atmosphere. In addition, it is not

suitable as a means of transport for people or objects.

SERIAL NUMBER PLATE

The serial number plate is located at the rear of the steering column,

and indicates the general characteristics of the machine, in particular the

serial number of the machine.The serial number is an extremely

important piece of information and should always be provided together

with any request for assistance or to purchase spare parts.

6

TECHNICAL DESCRIPTION

UM

AUKM 600

Workingwidth without side brush

mm

580

Workingwidth with right side brush

mm

790

Workingwidth with left and right side brush

mm

1000

Workingcapacity, up to(2SL version with twoside brushes)

m

2

/h

5100

Central brush

Ø mm

260

Side brush

Ø mm

400

Central brush rpm

rpm.

550

Side brush rpm

rpm

65

Central brush motor V/W 24/380

Side brush motor V/W 24/90

Traction motor V/W 24/300

Vacuum motor V/W 24/400

Filter shaker motor V/W 24/80

Total power W 1250

Front wheel ((number / (diameterx width)) No. / (∅mm x mm) 1 / (175x60)

Rear wheel ((number / (diameter x width)) No. / (∅mm x mm) 1 / (225x69)

Workingforward speed km/h 4.8

Maximum gradient % 10

Filter surface area (optional fabric filter) m22.2

Filter surface area (paper filter) m23.2

Debris hopper volume dm320

Steering diameter mm 3600

Machine length mm 1450

Machine height mm 1030

Machine height withblinkinglight mm 1000

Machine width mm 840

Battery compartment (l x w x h) mm 340x174x310

Rated battery voltage V 12

Battery weight kg 36.5

Unladen machine weight (without batteries) kg 175

Machine weight during transport (machine + batteries + brushes) kg 248

Machine weight in running order (machine + batteries + brushes +

operator) kg 323

Sound pressure level (ISO 11201) - L pA dB (A) 60.5

Uncertainty KpA dB (A) 1.4

Hand vibration level (ISO 5349) m/s2<2.5

Body vibration level (ISO 2631) m/s2<0.5

7

SYMBOLS USED ON THE MACHINE

Main switch symbol (version B)

Used on thesteering column to indicatethe key switch for machine operation on (I) or off (0)

Horn symbol

Used toindicate the acoustic alarm button.

Symbol of the reverse movement selector.

Used toindicate the buttonfor engagingthe reverse gear.

Filter shaker symbol.

Used on theinstrument panel to indicate the button that starts the vibrating shakeron the filter unit.

Symbol denoting vacuum motor.

Used on theinstrument panel to indicate the button that commands thedeactivation ofthe vacuum motor.

Central brush movement symbol (idle position)

Used on the rear of thesteering column to indicate themovement lever of the central brush.

Central brush movement symbol (working position)

Used on therear of the steeringcolumn to indicatethe movement lever of the central brush.

8

SYMBOLS USED ON THEMACHINE

Side brush/es movement symbol (idle position)

Used on therear of the steeringcolumn to indicatethe movement lever of the side brush/es.

Side brush/es movement symbol (working position)

Used on therear of the steeringcolumn to indicatethe movement lever of the side brush/es.

Indicates the risk of crushed hands

Indicates the risk of burns due to the hot surface

Indicates the maximum gradient

Open book symbol

Used totell the operator to read the manual before using themachine.

9

GENERAL SAFETY REGULATIONS

The regulations below must be carefully followed in order to avoid harm to the operator and damage to the machine.

WARNING:

•Read the labels on the machinecarefully. Do notcover them for any reason and replace them immediately if they become damaged.

•The machine must be usedexclusively by authorised and trained personnel.

•The machine is designed for dry useonly.

•Do not usethe machine onsurfaces with an inclination greater than the one shown on the plate.

•The machine is not suitable for cleaning rough or uneven floors. Do not use the machine on slopes.

•In the event of danger, quickly intervene onthe emergency button or the handle located on the battery connector.

•Before carrying out any maintenance work, switch off the machine and disconnect the battery connector.

•Children must be supervised to ensure they do not play with the device.

•Duringthe working of the machine, pay attention to other people and especially to children.

•Only use the brushes supplied with the machine, or those specified in the "CHOOSING AND USING THE BRUSHES" paragraph of the instruction

manual. Theuse of other brushes couldcompromise safety levels.

WARNING:

•The machine is not suitable for use by children and persons with reduced physical, mental and sensory capabilities, or people who lack experience and

knowledge.

•The machine must not be used orstored outdoors, in damp conditions or directly exposedto rain.

•The storage temperature must be between -25°Cand +55°C; do not storeoutdoors in damp conditions.

•Conditions ofuse: room temperature between 0°°C and 40°°C withrelative humidity between 30 and 95%.

•The socket for the battery charger cable must have aprescribed earth connection.

•Adapt the speed tothe adhesion conditions.

•Do not usethe machine as a means oftransport.

•The machine does notcauseharmful vibrations.

•Do not usethe machine in an explosive atmosphere.

•Do not usethe device to collect dangerous powders.

•The machine isnot suitablefor cleaning carpets.

•Do not place any liquid containers on the machine.

•Avoidworking with the brushes when themachine isstanding still, so as not todamage the floor.

•In the event of a fire, use a powder extinguisher. Do not usewater.

•Do not knock against shelving or scaffolding, where there is a danger of falling objects. The operator must always be equipped with the appropriate

safety devices (gloves, shoes, helmet, goggles, etc.).

•If the machine does not work properly, check this isnot caused by failure to carry out routine maintenance. Otherwise, askfor intervention of the

authorised technical assistance centre.

•If you need to replaceany components, request the ORIGINAL spare parts from anAuthorised dealer and/or Retailer.

•Restore all electrical connections after any maintenance interventions.

•Before using the machine, check that all the hatches and covers are positioned as shown inthis Use and Maintenance Manual.

•Do not remove any protection devices which require the use of tools in order to be removed.

•Do not wash the machine with direct water jets orwith pressurised water, nor withcorrosive substances.

•Have themachine checked by an authorised technical assistance centre every year.

•When disposing of consumablematerials, observe the laws and regulations inforce.

•When your machine has reached the end of its long working life, dispose of the materials itcontains (especially oils, batteries and electronic

components)in an appropriate manner, taking into account that the machine itself was constructed using 100%recyclablematerials.

•The batteries must be removed from the machine before its disposal. The batteries must be disposed of in a safe manner, fully observing the laws and

regulations inforce.

•Keepchildren andanimals away from the poweredmotor, as itheats up and may cause burns and injuries (bothdirectly and via the machines which it moves).

•Learn how to switch themotor off quickly, and how to use all the controls.Never entrust the motor to people who haven't had the appropriate training.

10

MACHINE PREPARATION

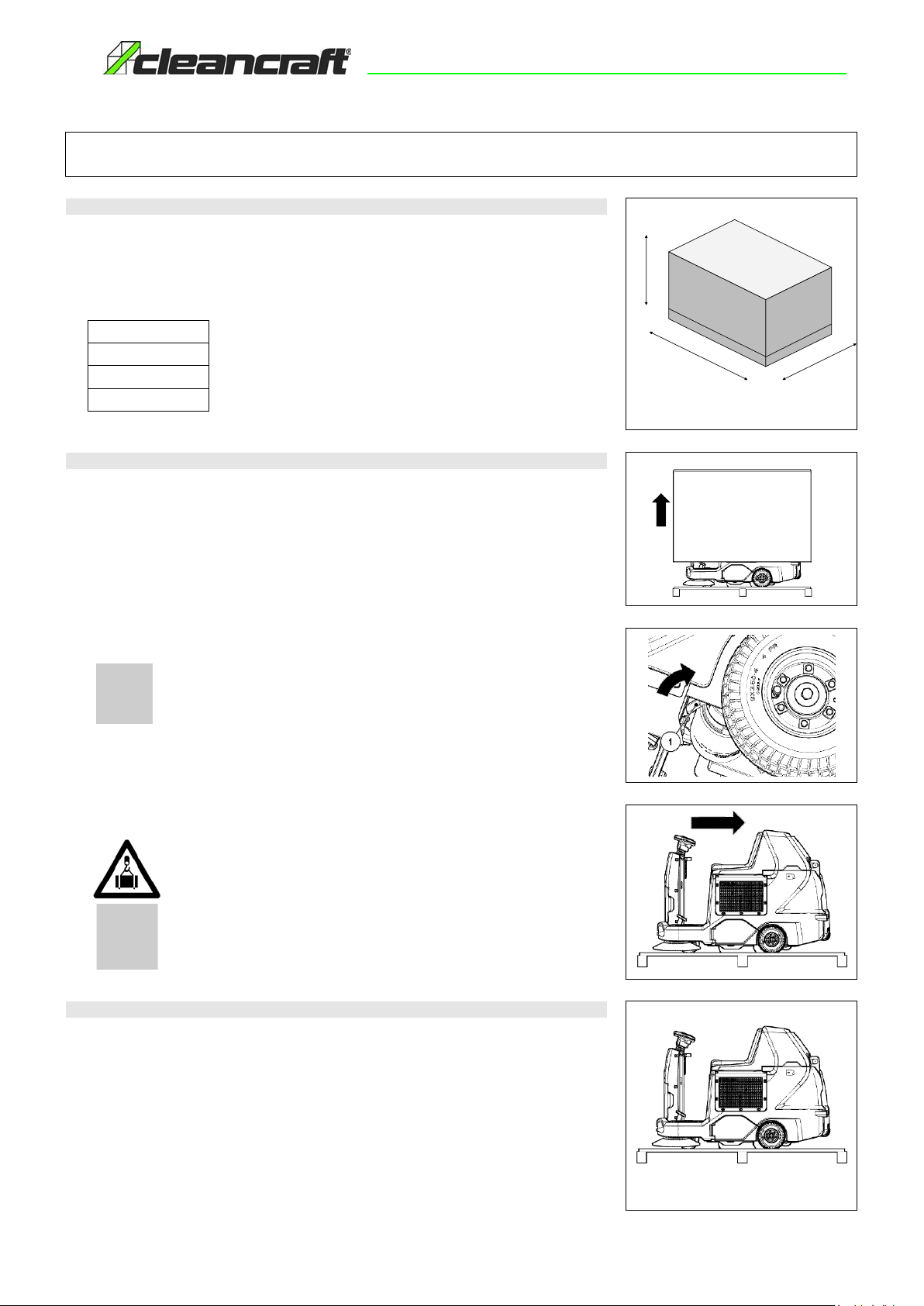

1. HANDLING OF THE PACKED MACHINE

The machine iscontained in specific packaging with a pallet for the handling with fork trucks. The

packages cannot be placed on top of eachother.

The total weight of the machine with its packaging is210 kg

The dimensions ofthe packaging are as follows:

A : 1270 mm

B : 1020 mm

C : 1760 mm

A

CB

2. HOW TO UNPACK THE MACHINE

1. Remove the outer package.

2. Disengage theelectronic brake,turnthe lever (1) (onthe rear right-handsideof themachine)clockwise.

3. The machine is fixed to the pallet with wedges which block the wheels.Remove the wedges.

4. Use a chute to get themachine down from the pallet, pushing it backwards.

ATTENTION: Duringtransportation, the electrical brake should not be engaged, the

machine will in any event, if the critical speed threshold iscrossed, activate the

internal brakingsystem ofthe chopper circuit board and will emit a warning noise.

5. Keep the pallet for any future transport needs

WARNING: If the product is delivered in cardboard containers, handle the packed

product withsuitable lifting means thatcomply with the legal requirements

WARNING: During this operation, check there are no people or objects near the

machine

3. HOW TO MOVE THE MACHINE

1. Check that the central brush is lifted from the ground, otherwise lift it by moving the lever onthe rear

of the steering column.

2. Check that the side brush/es is/are lifted from the ground, otherwise lift it/them by moving the lever

on the rear of the steering column.

3. Place it on a pallet using a chute.

4. Check the main switch is in the “0” position, if this is not the case, turn the key by a quarter of a turn

to the left.

5. Remove the keyfrom the main switch.

6. Secure the machine to the pallet using wooden wedges.

7. Engage the electronic brake.

11

MACHINE PREPARATION

4. HANDLEBAR CONTROL COMPONENTS

The handlebar control components are identified as follows:

1. Level indicator for battery/hour meter.

2. Filter shaker control button.

3. Horn button.

4. Reverse button.

5. Vacuum motor "STOP" button.

5. STEERING COLUMN COMPONENTS

The steering column components are identified as follows:

1. Central brush lifting lever.

2. Lever for raising the side brush (1SL version) or brushes (2SL version).

3. Main key switch.

4. Emergency button.

6.FOOTBOARD COMPONENTS

The footboard components are identified as follows:

1. Drive pedal, accelerator pedal

2. Front flaplifting pedal

12

MACHINE PREPARATION

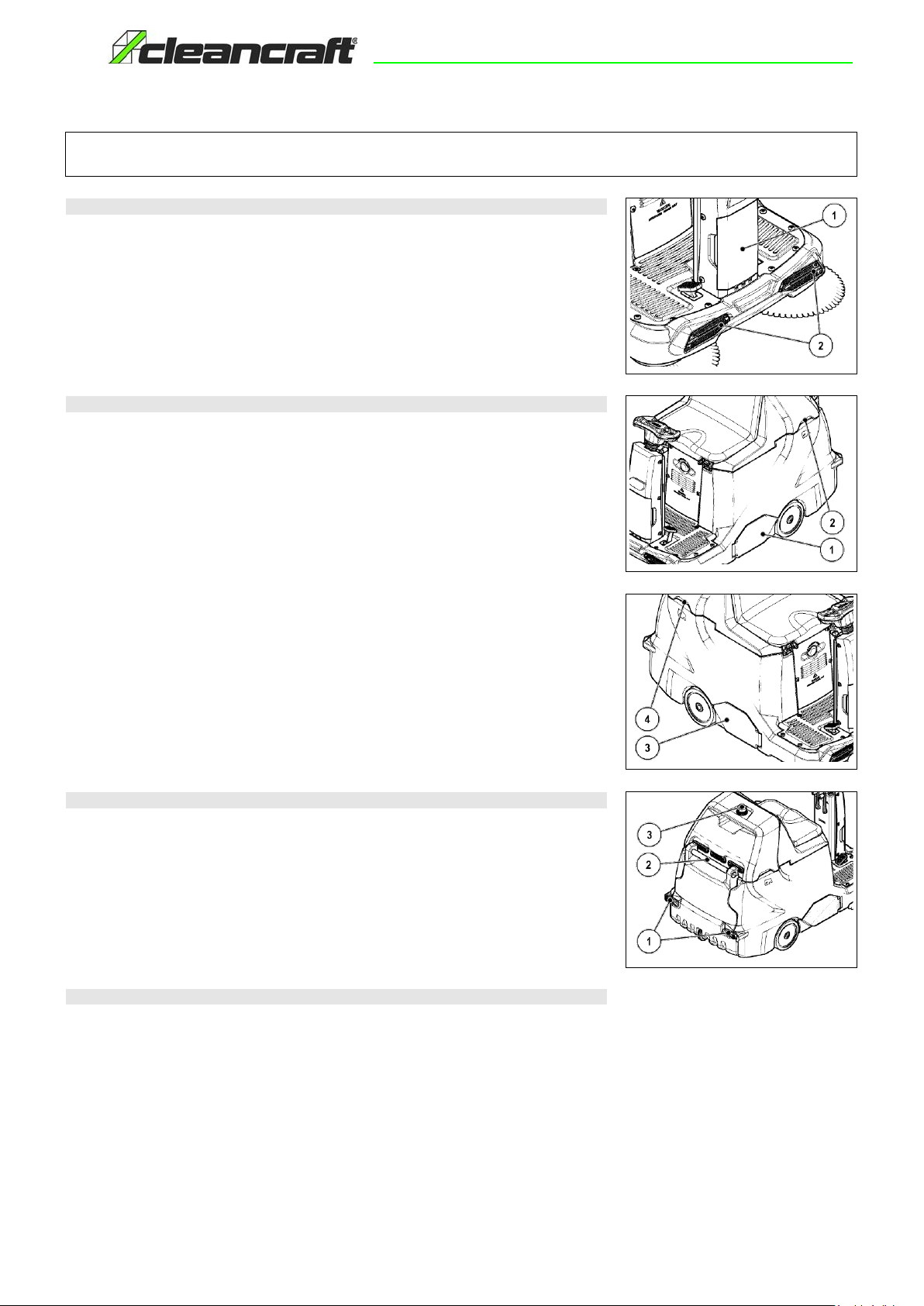

7.FRONT COMPONENTS

The front components ofthe machine are identified as follows:

1. Storage compartment.

2. Headlights.

8.SIDE COMPONENTS

The components on the side of the machine are identified as follows:

1. Left side panel central brush engage/adjustment.

2. Seat unit lifting handle.

3. Right side panel central brush maintenance.

4. Seat unit lifting handle.

9.REAR COMPONENTS OFTHE MACHINE

The rear components ofthe machine are identified asfollows:

1. Debris hopper retainer.

2. Debris hopper handle.

3. Blinking light (optional).

10. BATTERY TYPE

Power tothe machine must besupplied by sealed traction batteries withgas recombination or gel

technology. OTHER TYPES MUST NOT BE USED.

The batteries must meet the requirements laid out inthe norms: CEI EN60254-1:2005-12 (CEI 21-5) +

CEI EN60254-2:2008-06 (CEI 21-7)

The battery compartmentcan housetwo 12V batteries

For a good operating performance, we suggest the use of 105 Ah C5 batteries

13

MACHINE PREPARATION

11. BATTERY MAINTENANCE AND DISPOSAL

For informationabout battery maintenance, refer to the instructions provided by the battery manufacturer.

When the battery reaches the end of its working life, itmust be disconnected by expert, trained personnel,

then lifted (using the grips and suitable lifting devices) to remove it from the battery compartment.

EXHAUSTED BATTERIES ARE CLASSIFIED AS DANGEROUS WASTE ANDMUST BE

CONSIGNED TO THE AUTHORISEDBODIES FOR CORRECT DISPOSAL.

WARNING: you are advised to always wear protective gloves, to avoid the risk

of serious injury to your hands.

WARNING: You are advised to only lift and move the batteries with lifting and

transportation means suitable for the specific weight and size

12. FITTING THE BATTERIES INTO THE MACHINE

The batteries must be housed inthe appropriate compartment beneath the seat unit. They should be

handled using lifting equipment that issuitablein terms ofboth weight andcoupling system. They must

alsosatisfy the requirements of Standard CEI 21-5. The dimensions ofthebattery compartment are:

340 x174xH310 mm.

WARNING: For battery maintenance and daily recharging, you must carefully follow

the instructions provided by the manufacturer or retailer. All installation and

maintenance operations must be carried out by specialised personnel.

WARNING: Ensure that you comply with the accident prevention regulations inforce in

the country where you work or with DIN EN 50272-3 and DIN EN 50110-1, before any

handling of the batteries.

WARNING: To prevent an accidental short circuit use insulated tools to connect the

batteries, and do not place or drop metal objects on the battery. Remove rings,

watches and any clothing with metal parts that may come into contact with the battery

terminals.

To insert the batteries into the compartment proceed as follows:

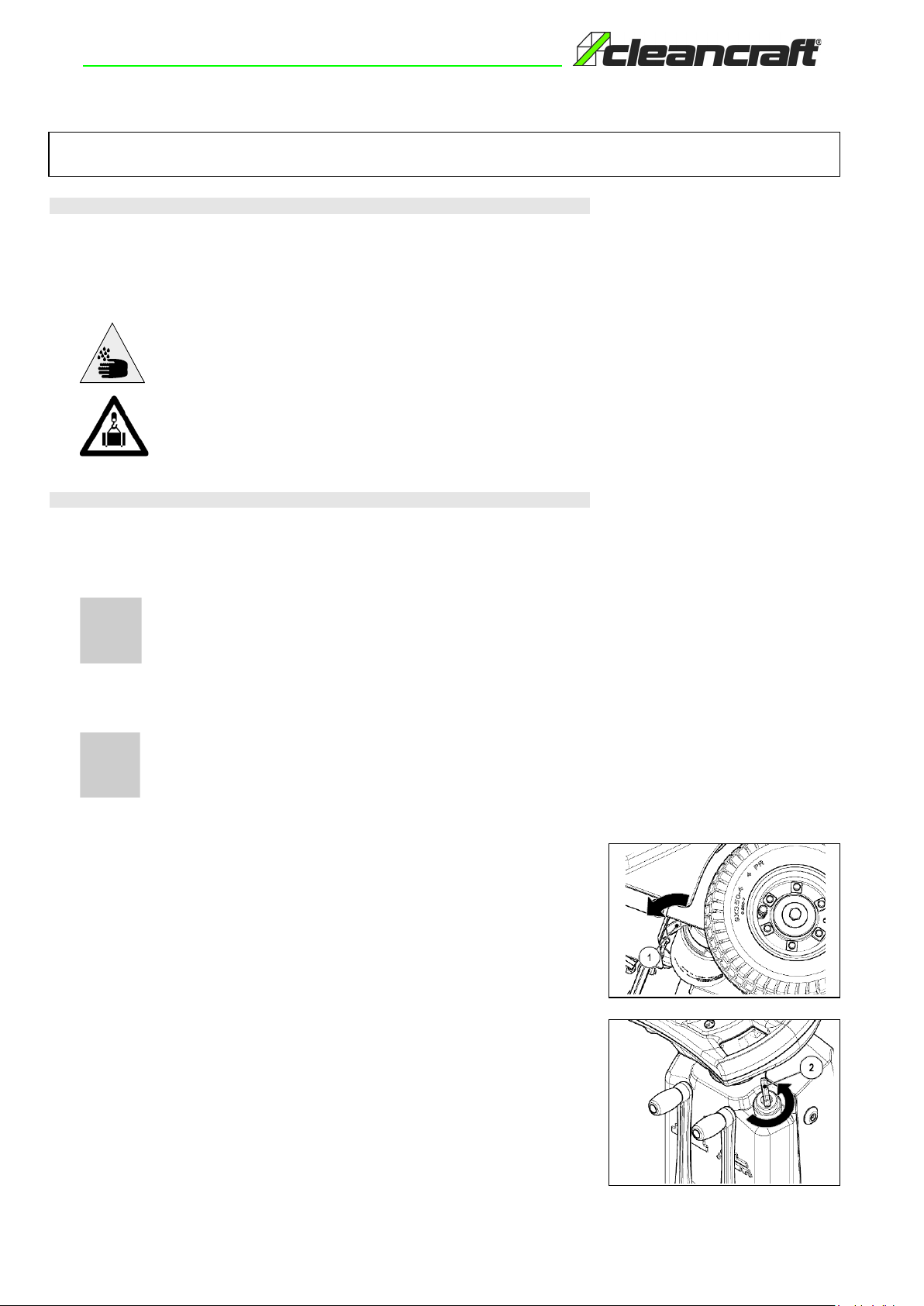

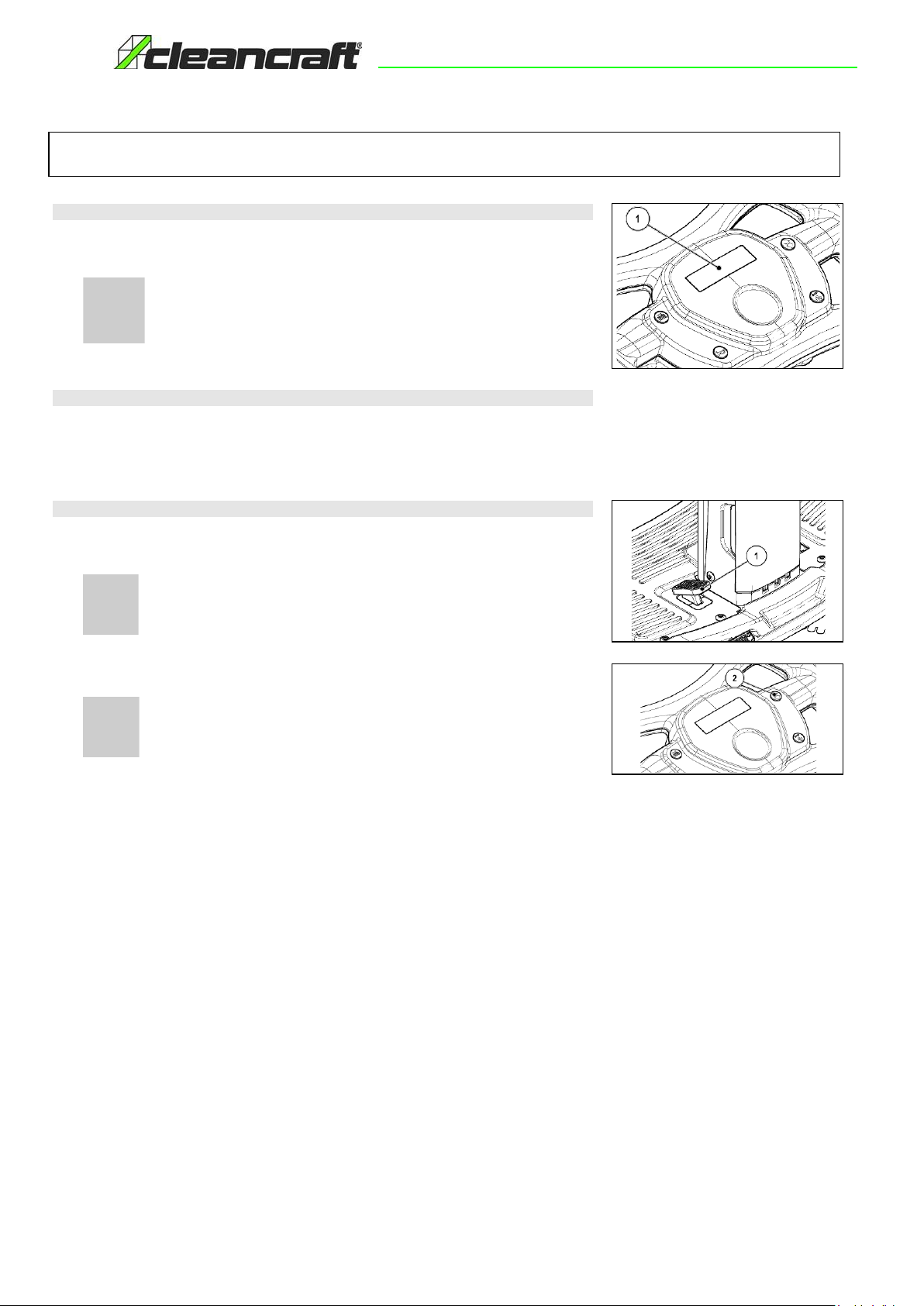

1. Makesure the electric brake is engaged, otherwise engage it using the lever (1) located at the left

rear of the machine (working direction).

2. Check the main switch (2) is in the “0” position, if this is not the case, turn the key by a quarter of a

turn tothe left, and remove the key from the instrument panel.

14

MACHINE PREPARATION

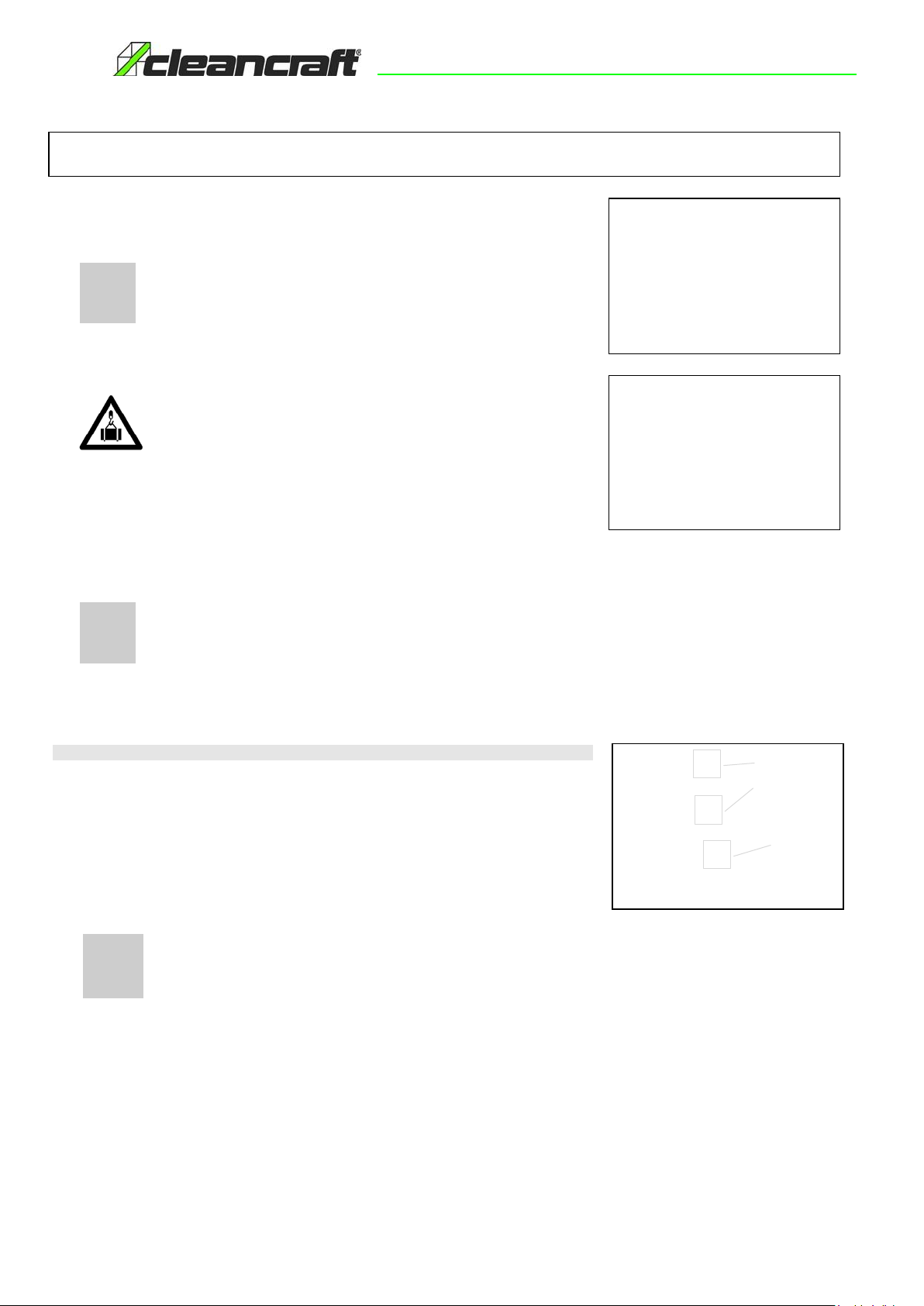

3. Grasp the handle located on the side of the operatorseat unit.

4. Lift the operator seat unit until the safety clamp (3) is hooked.

WARNING: Before installing the battery,clean the battery compartment with a damp

cloth. Check that the connectors on the cables supplied are functioning correctly.

WARNING: Check thatthe characteristics of the battery that you are lookingto use are

appropriate for the type of work to be performed. Check the battery charge and the

condition of the contacts on the battery.

WARNING: You are advised toonly lift and move the batteries with lifting and

transportation means suitable for the specific weight and size.

WARNING: The lifting hooks must not damage the blocks, connectors or cables.

5. House the batteries in the compartment, positioningthe poles “+” and“-“ opposite each other.

WARNING: Before inserting the batteries into the machine, remember tocover the

terminals witha little grease to protect them against external corrosion.

WARNING: You are advised to use airtight batteries only, to avoidthe leakage of acids!

WARNING: You are advised to always wear protective gloves, to avoid the risk of

serious injury to your hands.

15

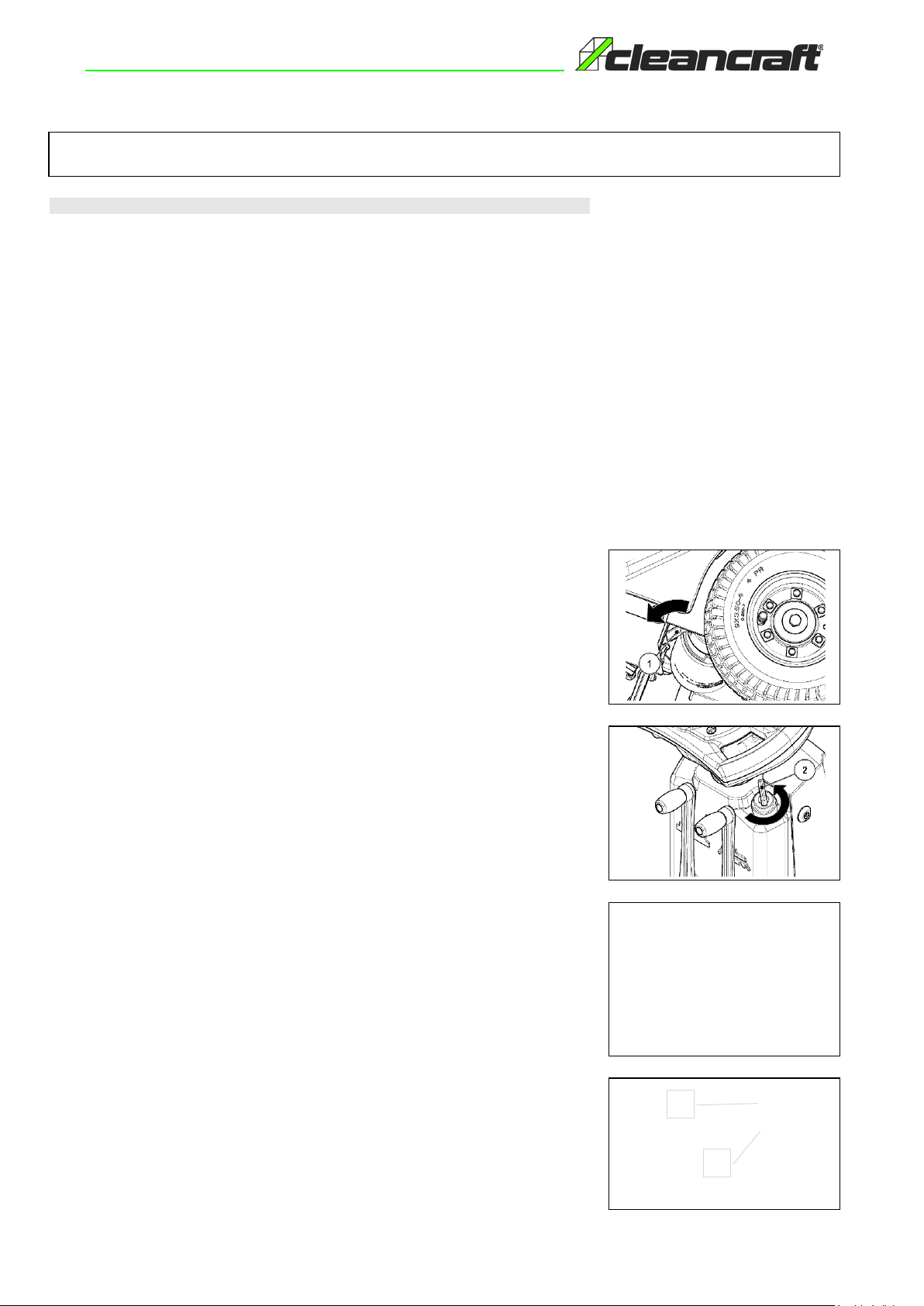

13. CONNECTING THE BATTERIES AND BATTERY CONNECTOR

To connect the batteries proceed as follows:

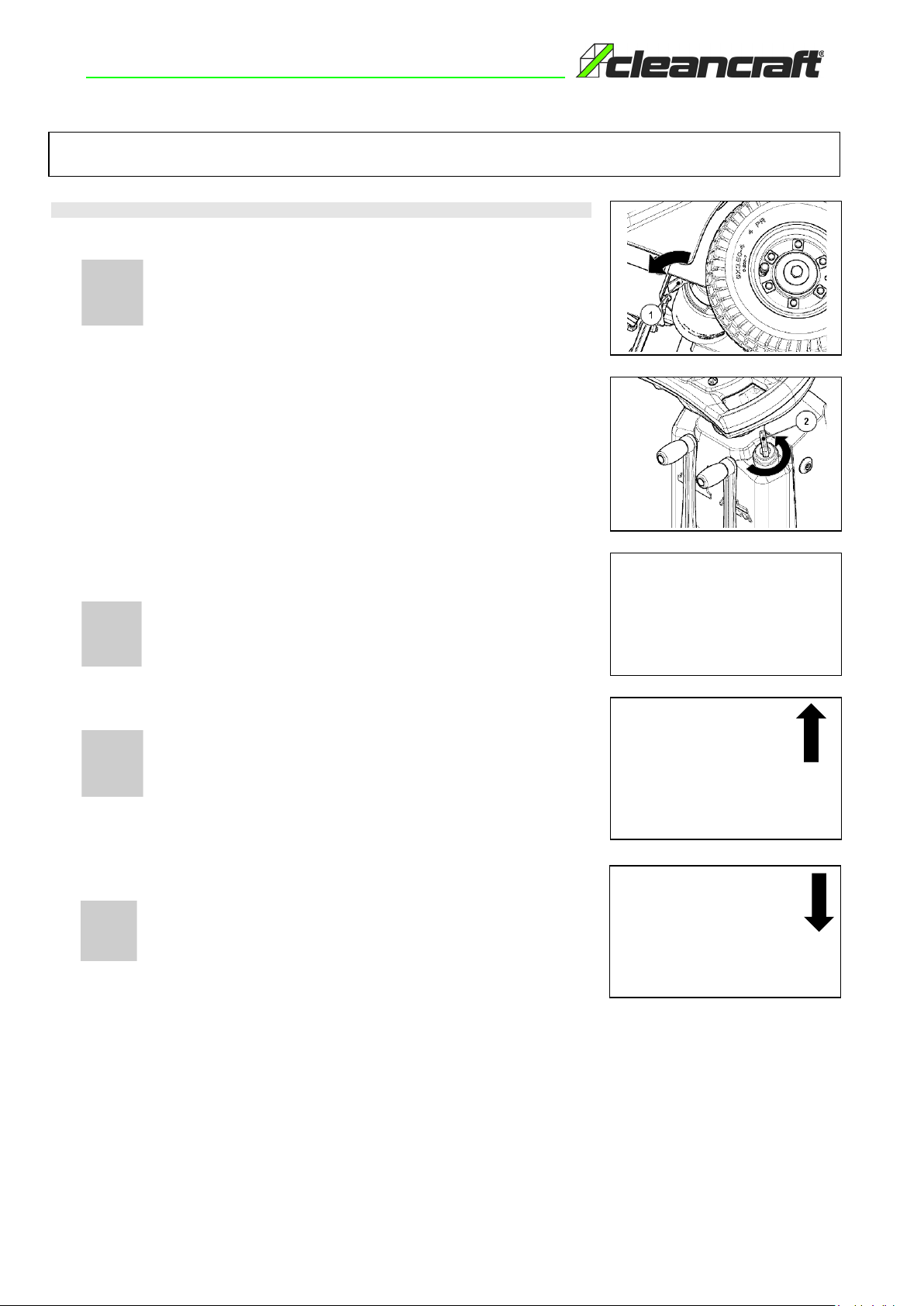

1. Connect the batteries in series to the "+" and "-" poles using the supplied jumper cable (1).

2. Connect the battery connector cable to the "+" and "-" poles in order to obtain theterminal voltage

of 24V.

3. Connect the electric system connector (3) to the battery connector (2).

WARNING: All installation andmaintenanceoperations must becarried out by expert

personnel, trained atthe specialised assistance centre.

WARNING: you are advised to always wear protective gloves, to avoid the risk of

serious injury to your hands.

2

1

3

MACHINE PREPARATION

14. BATTERY CHARGER CONNECTION

In order not tocause permanent damage to the batteries, itisessential to avoid their complete discharge:

arrange the recharge within a few minutes of the switchingon of the "discharged batteries" blinkinglight.

WARNING: Never leave the batteries completely discharged, even if the machine is not

being used. Check the battery charger is suitable for the batteries installed, in terms of

both capacity and type.

To connect the battery charger you must:

1. Movethe machine to theplaceused for maintenance or recharging the batteries.

2. Make sure the electric brake is engaged, otherwise engage it using the lever (1) located at the left

rear of the machine (working direction).

3. Check the main switch (2) is in the “0” position, if this is not the case, turn the key by a quarter of a

turn tothe left, and remove the key from the instrument panel.

4. Grasp the handle located on the side of the operatorseat unit.

5. Lift the operatorseat unit until thesafety clamp (3) is hooked.

WARNING: Park the machine in an place protected from the weather andwith suitable

ventilation, and on aflat and levelsurface; near the machine there must be no objects

that could either damage it, or be damaged through contact with it.

6. Disconnect the electric system connector (4) from the battery connector (5).

ATTENTION: this process must becarried out by qualified personnel. An incorrect

connection of the connector may cause problems with machine functioning.

16

7. Connect the battery charger cable (6) to the battery connector (5).

WARNING: Keep the seat unit open for the duration of the battery recharging cycle to

allow gas fumes to escape.

WARNING: The room used to recharge the batteries must be adequately ventilated to

prevent the accumulation of gases that leak from batteries.

The coupling connector of the battery charger is supplied insidethe bag containingthis instruction

booklet, and must be fitted tothe battery charger cables asshown inthe instructions.

MACHINE PREPARATION

8. Connect the recently wired cable to the external battery charger.

WARNING: Carefully read the use and maintenance instructions of the battery charger

that is used for charging.

WARNING: Danger of gas exhalation and leakage of corrosive liquids.

WARNING: Danger of fire: donot go near with free flames

9. When the recharge cycle is complete, disconnect the battery charger connector from theexternal

battery charger.

10. Disconnect the battery charger cable (6) from the battery connector (5).

11. Connect the battery connector (5) to the electricsystemconnector (4).

12. Grasp of the handle locatedon the side of the operator seat unit and lower the seat unit until it is in

the working position.

15. BATTERY CHARGER CONNECTION

In order not tocause permanent damage to the batteries, itisessential to avoid their complete discharge:

arrange the recharge within a few minutes of the switchingon of the "discharged batteries" blinkinglight.

WARNING: Never leave the batteries completely discharged, even if the machine is

not beingused. Check the battery charger is suitable for the batteries installed, in

terms of both capacity and type.

17

MACHINE PREPARATION

To connect the battery charger you must:

1. Movethe machine to theplaceused for maintenance or recharging the batteries.

2. Makesure the electric brake is engaged, otherwise engage it using the lever (1) located at the left

rear of the machine (working direction).

3. Check the main switch (2) is in the “0” position, if this is not the case, turn the key by a quarter of a

turn tothe left, and remove the key from the instrument panel.

4. Grasp the handle located on the side of the operator seat unit.

5. Lift the operatorseat unit until thesafety clamp (3) is hooked.

WARNING: Park the machine in an place protected from the weather andwith suitable

ventilation, and on aflat and levelsurface; near the machine there must be no objects

that could either damage it, or be damaged through contact with it.

6. Remove the battery charger cover (4).

7. Connect the battery charger power cable connector tothe socket on the charger itself.Before

inserting the power cable into the socket of the charger, verify that there isno condensate or other

forms of liquids.

8. Plug the battery charger powercable into the mains socket.

WARNING: Carefully read the use and maintenance manual of thecharger that is

delivered inside the bagcontaining this instruction booklet.

WARNING: Keep the seat unit open for the duration of the battery recharging cycle to

allow gas fumes to escape.

WARNING: The room used to recharge the batteries must be adequately ventilated to

prevent the accumulation of gases that leak from batteries.

9. When the recharge cycle is complete, disconnect the battery charger cable from the mains.

10. Disconnect the battery charger power cable connector from the socket on the charger itself.

11. Replace the battery charger cover (4).

12. Grasp of the handle locatedon the side of the operator seat unit and lower the seat unit until it is in

the working position.

WARNING: if the machine's electric system is accidentally powered (by turningthe

main switch to "I"), the commands display will show “BATTERY-CHARGER” and no

steering wheel command will function.

WARNING: Always make sure the green LED of the battery charger is on before using

the machine again.

4

4

18

MACHINE PREPARATION

16. BATTERY CHARGELEVEL INDICATOR

On the instrument panel of themachine thereis a monitor (1) indicating(amongst other things) the battery

charge status. If the lower linecontains ten light indicators, the battery charge level is 100%. If the battery

charge percentage is at 00% and flashing, this means thebatteries are discharged.

WARNING: After a fewseconds that the battery charge has reached 20%,the central

brush motor, the side brush/es motor, and the vacuum motor will turn off

automatically.With theremainingcharge, it is still possible, however, to move the

machine to the location designated for rechargingthe batteries.

17.HOUR METER

On the machine's instrument panel there is a display (1) indicating the total machine usage time. The top

line shows the hoursandminutes offunctioning. Theflashing “:” symbol Indicates that the hour meter is

countingthe machine functioning time.

18.WORKING FORWARD SPEED

This machine is equipped withelectronic traction control. To move the machine, after having turned the

key in the "I" position, push the drive pedal (1) adjusting thespeed by pressing and releasing the pedal.

The machine will then start moving.

ATTENTION! The machine will not start to move (eitherforwards or backwards) if the

electrical brake is not engaged. In this case, you will see"ELECTRICAL BRAKE?" on

the command display.

To move the machine backwards, press the button (2) on the instrument panel, then immediately press

the pedal (1). Adjust the speed by altering the degree of pressure onthe pedal.

WARNING! The reverse speed is lower than the forward speed to comply with current

health and safety standards.

19

19.BLINKING LIGHT (OPTIONAL)

The machinecan be equipped with ablinking light that turns onautomatically when the key inthe main

switch is turned on.

20. HEADLIGHTS

The machine has headlights that turn on automatically when the main switch is turned to "I" or "II".

PREPARING TO WORK

21. PREPARING TOWORK

Before beginning to work, itisnecessary to:

1. Ensure that the debris hopper is empty, otherwise empty it completely (see paragraph "EMPTYING

THE DEBIT HOPPER").

2. Check that the condition of the central brush is suitable for the work, otherwise arrange for its

maintenance (see paragraph "CLEANING THE BRUSH CENTRAL" or "CENTRAL BRUSH

REPLACEMENT").

3. Check that the condition of the side brush (version 1SL or brushes version 2SL) is suitable for the

work, otherwise arrange for their maintenance (see paragraph "CLEANING THE SIDE BRUSH" or

"SIDEBRUSHREPLACEMENT").

4. Makesure the electric brake is engaged, otherwise engage it using the lever (1)located at the left

rear of the machine (working direction).

5. Check the main switch (2) is in the “0” position, if this is not the case, turn the key by a quarter of a

turn tothe left, and remove the key from the instrument panel.

6. Makesure the emergency switch is in the OFF position.

7. Grasp the handle located on the side of the operatorseat unit.

8. Lift the operatorseat unit until thesafety clamp (3) is hooked.

9. Connect the machine connector (4) to the battery connector (5).

10. Grasp of the handle locatedon the side of the operator seat unit and lower the seat unit until it is in

the working position.

4

5

20

This manual suits for next models

1

Table of contents

Other CleanCraft Blower manuals