Location

Choosing the proper location is an important step before you assemble the structure. The following

suggestions and precautions will help determine whether your selected location is the best location.

• Never erect the structure under power lines.

• Identify whether underground cables and pipes are present before preparing the site or

anchoring the structure.

• Location should be away from structures that could cause snow to drift on or around the

building.

• Do not position the building in a place where large loads such as snow and ice, large tree

branches, or other overhead obstacles could fall.

Site

After choosing a location, proper preparation of the site is essential. The following site characteristics

will help ensure the integrity of the structure.

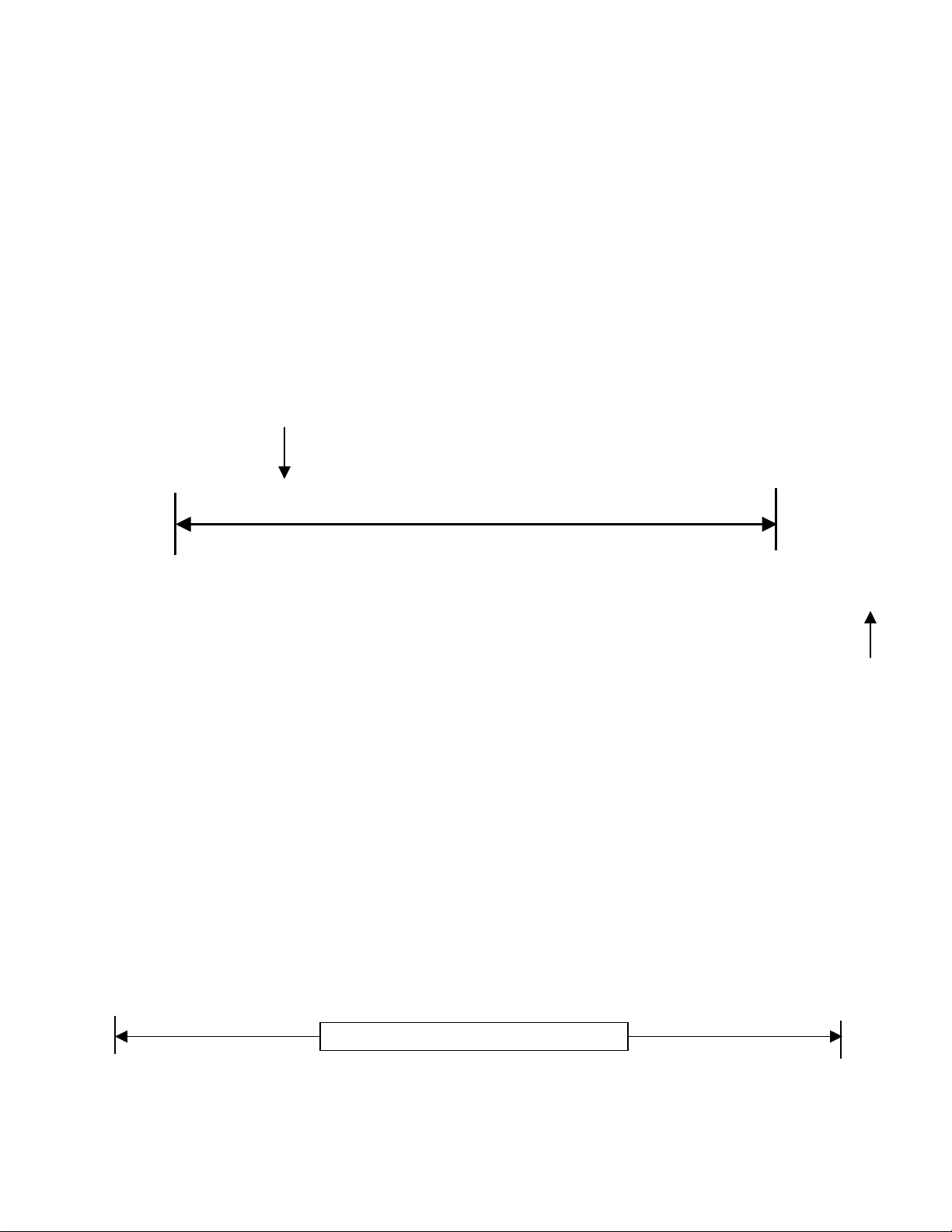

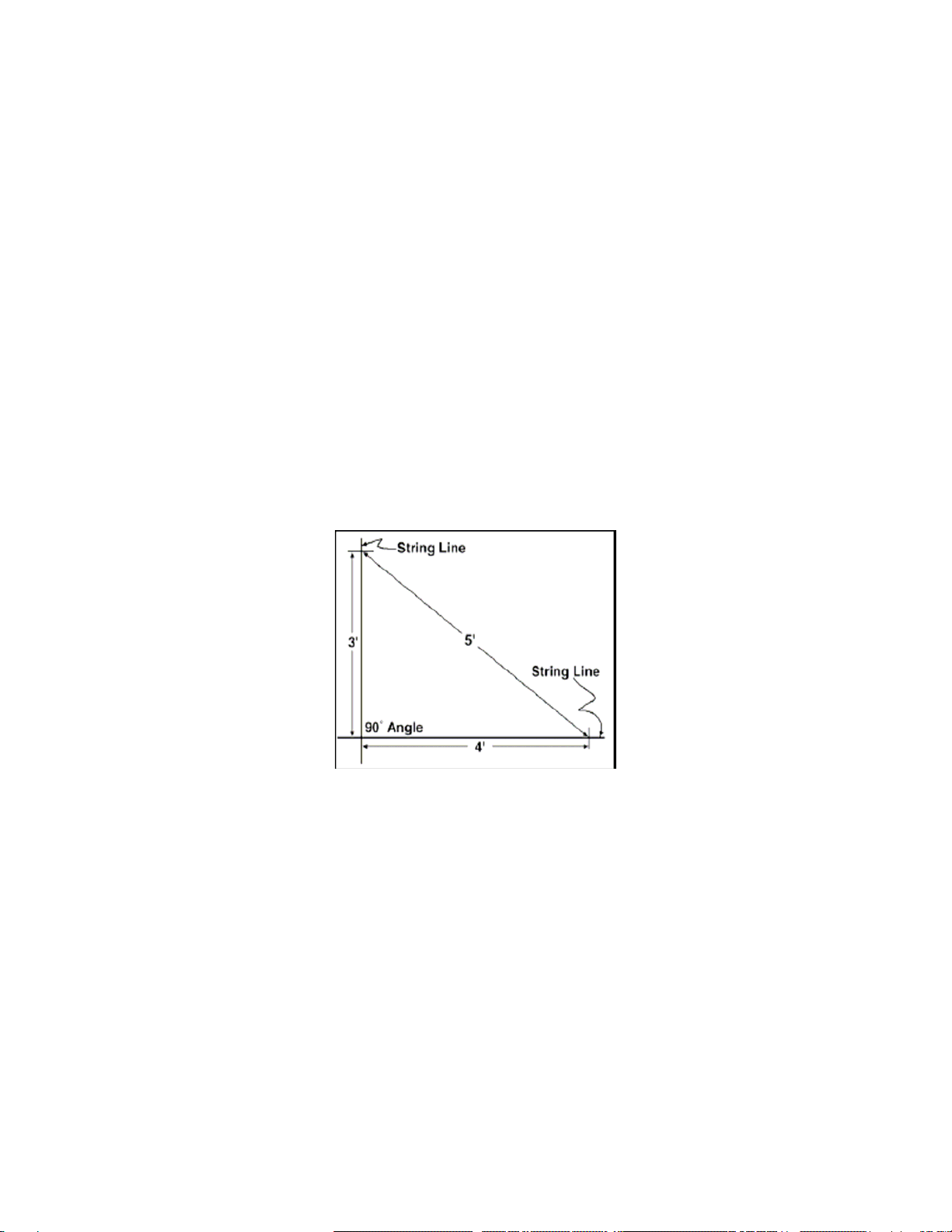

• The site must be level to properly and safely erect and anchor the structure.

• If the site is not level, use footings to provide a secure base for the structure. Pre-cast concrete

blocks, pressure-treated wood posts, or poured footings are all acceptable when properly

used.

• Drainage: Water draining off the structure and from areas surrounding the site must drain away

from the site to prevent damage to the site, the structure, and contents of the structure.

ATTENTION: The individuals assembling this structure are responsible for designing and furnishing

all temporary bracing, shoring and support needed during the assembly process. For safety reasons,

those who are not familiar with recognized construction methods and techniques must seek the help

of a qualified contractor.

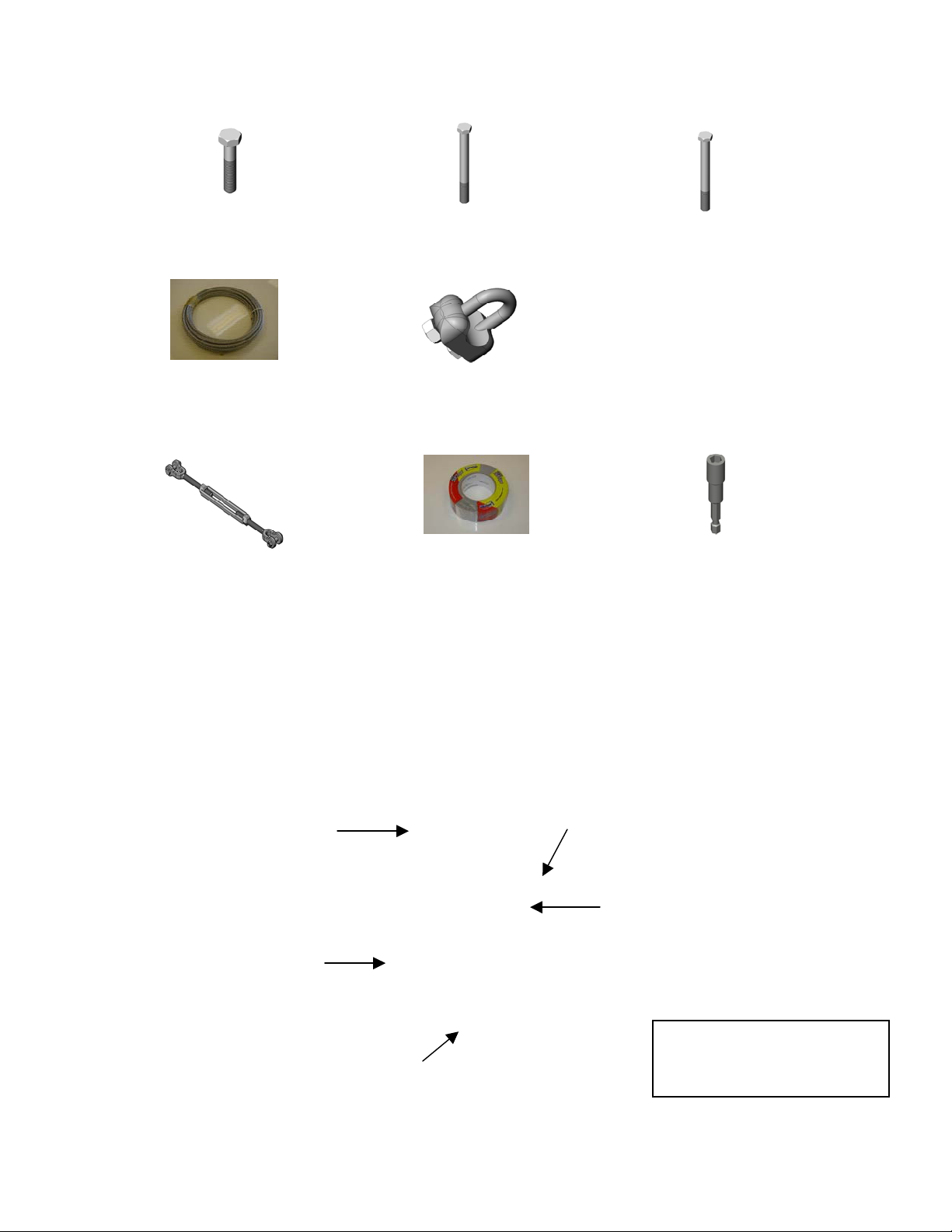

Unpack and Identify the Parts

The following steps will ensure that you have all the necessary parts before you assemble the

structure.

1. Unpack the contents of the box and place them where you can easily inventory the shipment.

Refer to the Bill of Material.

2. Verify that all parts listed on the Bill of Material are present. If anything is missing, contact

customer service.

NOTE: At this time, you do not need to open the plastic bags containing the fasteners.

Visit www.ClearSpan.com for additional products and customer assistance.