·Cleveland Controls

Di-".ision~of

UniControl Inc.

Model·

RFS-4150

/

AIR PRESSURE SENSING SWITCH WITH ADJUSTABLESET POINT

APPLICATION

•'

Model RFS-4150 is a general purpose prov-

ing switch designed for HVAC and Energy

Management-applicatipns. This switch can

be used to sense positive, negative,

or

dif-

ferential air pressure.

GENERAL DESCRIPTION &

OPERATION

The

plated

hotJsiog_contains_a__dlapbLagm~<L~

__

-------,

calibration spring, and a snap-acting switch.

The sample line connections located on

each side

of

the diaphragm accept

o/is",

W',

and

7'\s"

flexible tubing. Various electrical

connections are available.

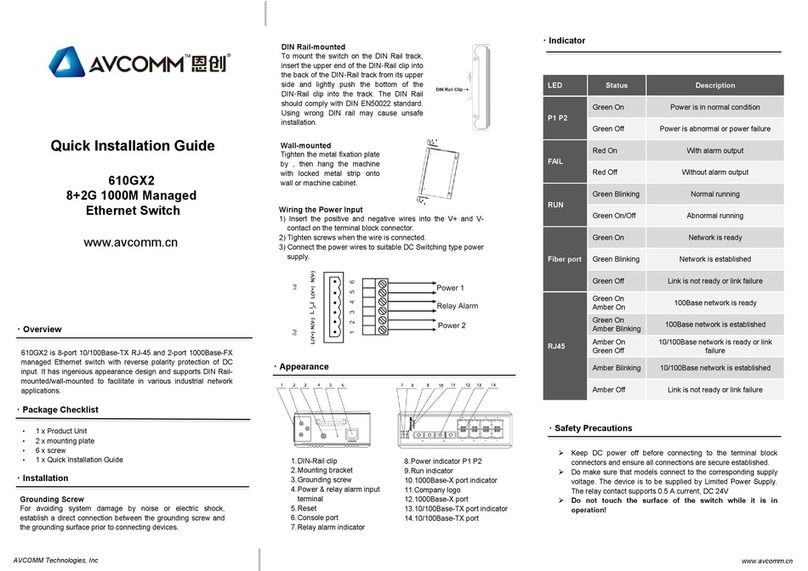

MOUNTING {FIG. 1)

Select a mounting location which is free

from vibration. The Model RFS-4150 must

be mounted with the diaphragm

in

any verti-

cal plane

in

order to maintain the specified

operating set point. Avoid mounting with the

sample line connections

in

the "up" position.

The standard model

is

surface~mounted

via

th~

two round holes (0.14" dia.) ortwo

of

the

fourslots

(o/is"

wide) on the zinc-plated strap

bracket.The mounting holes and slots are

3-Va"

apart. Custom mounting configurations

are available.

Figure

1:

Mount with the diaphragm

in

any

vertical plane.

-

-~,-~

·~

\1)

AIR SAMPLING CONNECTION

{FIG. 2)

Tri-barbed sample line connectors suitable

to

accept flexible tubing are situated on either

side

of

the diaphragm as shown

in

Figure

2.

The tri-barbed connectors accept

·o/is",

Y..",

and

o/;s"

ID

flexible tubing. For sample

lines up to 10 feet

in

length,

11s"

ID

tubing

is

acceptable. For lines up to 20 feet, use

Y.."

ID tubing.

Locate the sampling probe a minimum

of

Figure 2

INLET

Positive Only

LowerNegative

HigherPositive

NLETL

Negative Only

HigherNegative

LowerPositive

--

-1;5-ductl:liameters-downstreamiromth.::.-.:H.·--+t=lctu.r:e

~---

---

------+

source. Install the sampling probe as close

to the center

of

the airstream as possible.

Refer to Figure 2 to identify the high pres-

sure inlet (H)

and

the low pressure inlet

(L).

Selectone ofthe five application options

listed below, and connect the sample lines

as recommended.

HIGH

PRESSURE

LOW

PRESSURE

0

N.C.

N.O.