Cleco W2119 series Installation and operating instructions

1

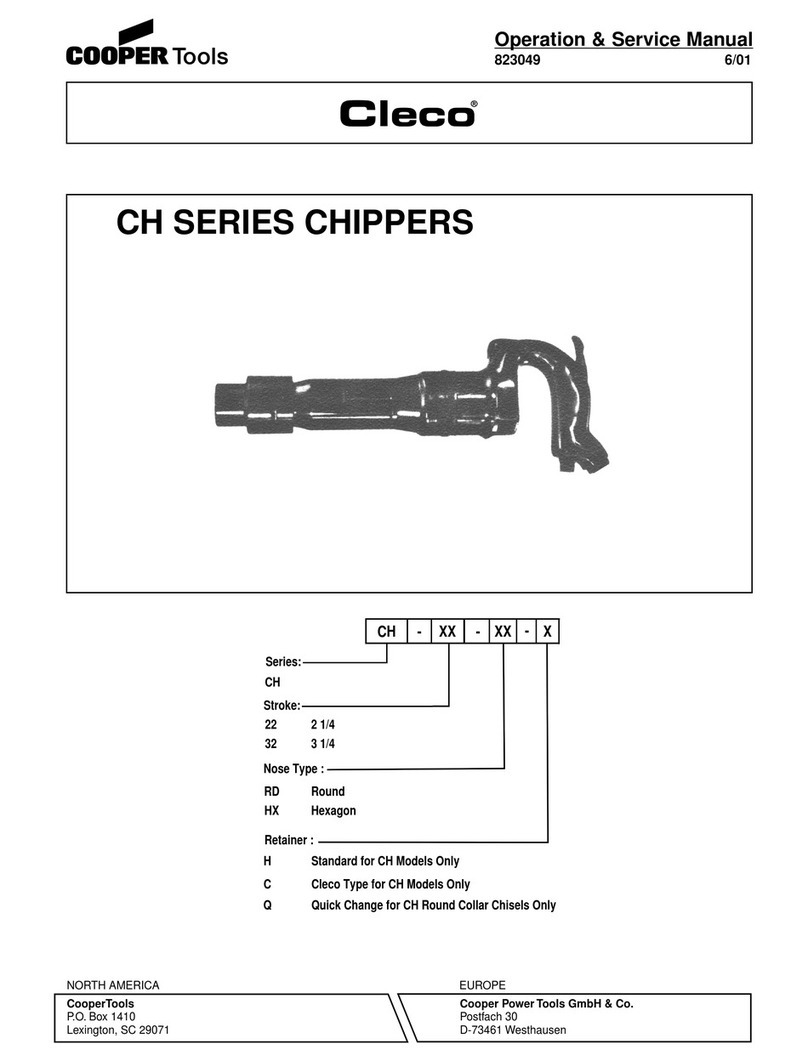

Operation & Service Manual

823036 2/01

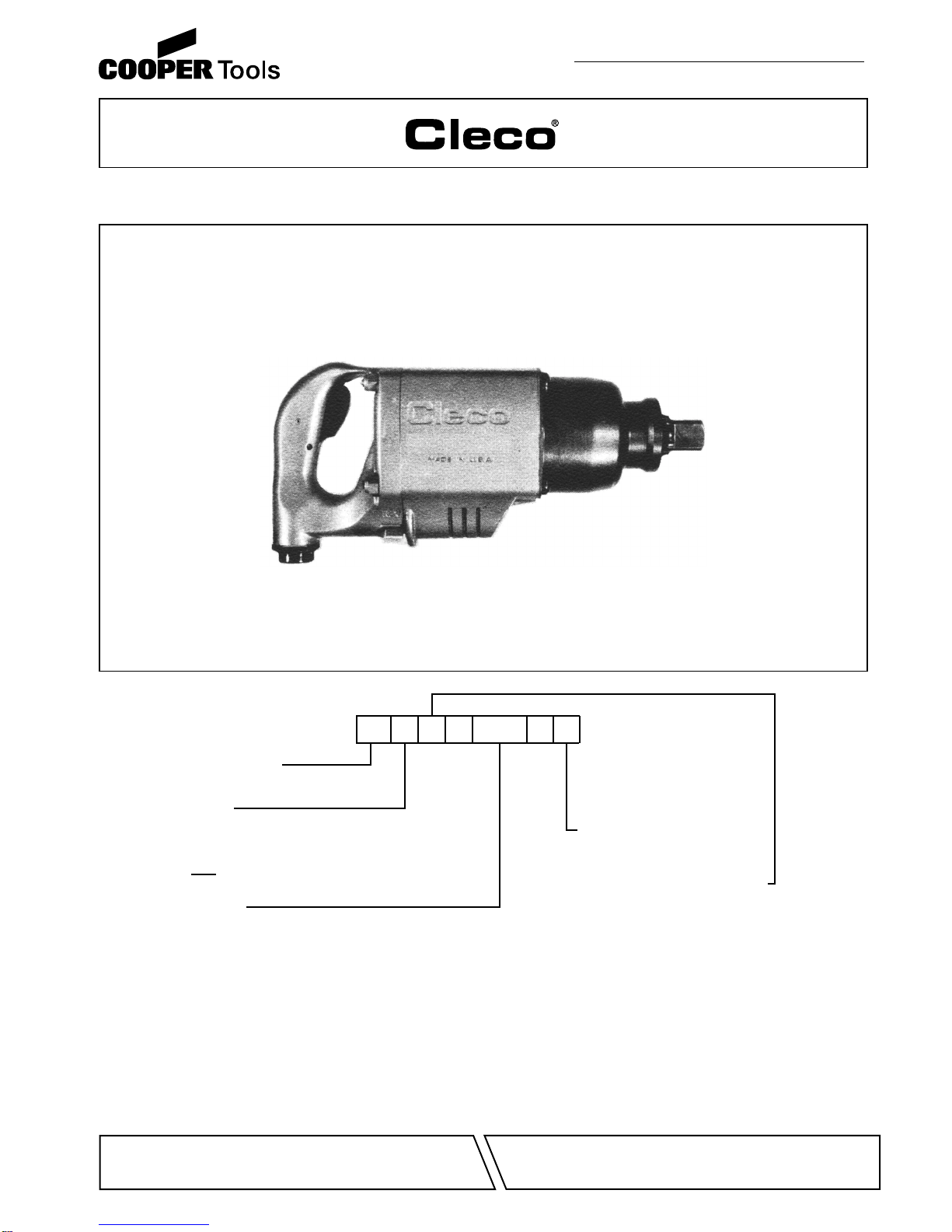

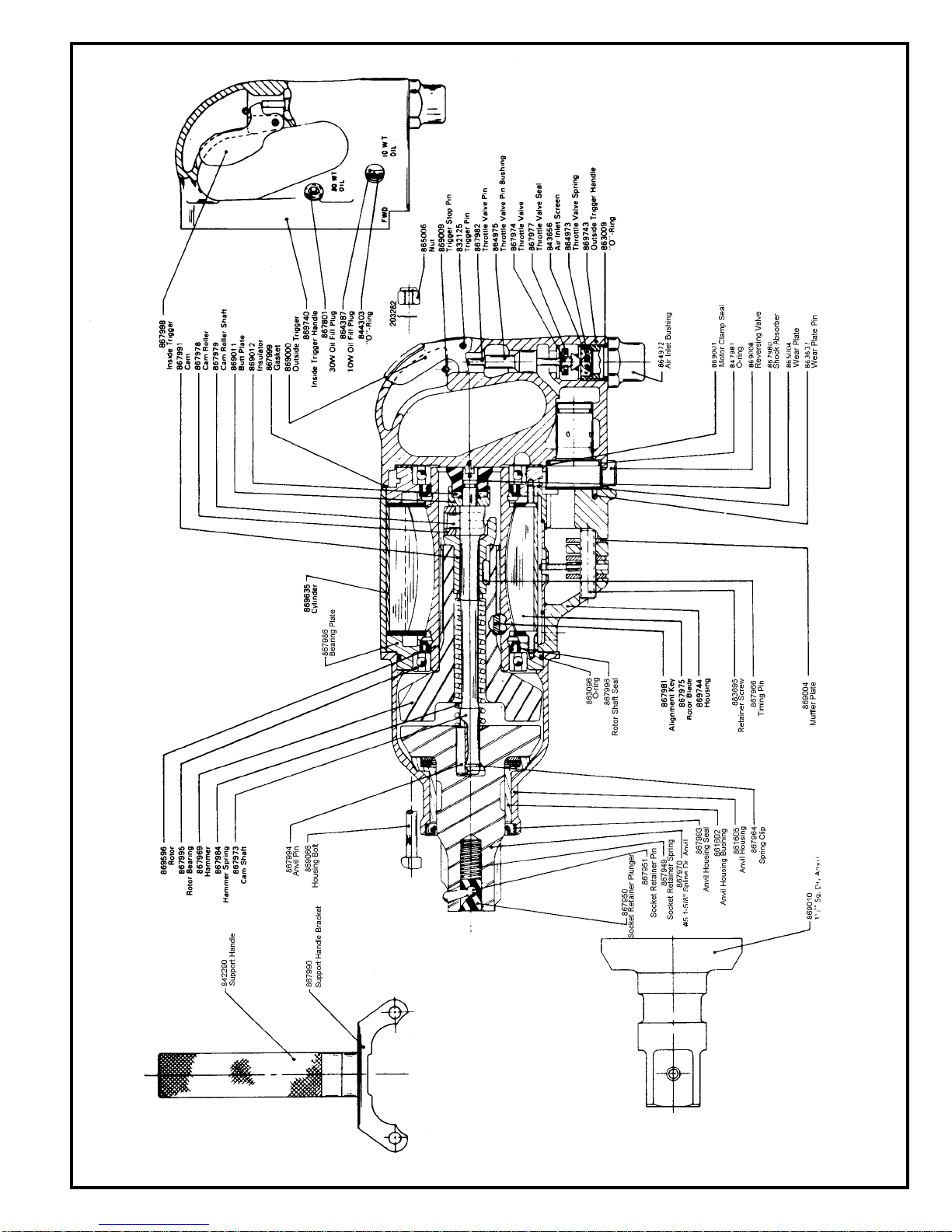

W2119 & W2120 SERIES IMPACTS

Tool Size:

2120

2119

Outside Trigger

W

Inside Trigger

Impact Wrench:

T

Handle:

-- XXXXXXX

Spline Drive (No. 5 Spline)

S

12 1 1/2"

Output Drive:

NORTH AMERICA EUROPE

CooperTools

P.O. Box 1410

Lexington, SC 29071

Cooper PowerTools GmbH & Co.

Postfach 30

D-73461 Westhausen

2

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

SafetyRecommendations

Neverusetheairhoseforsupporting,lifting,orloweringthetool.

Use a safety line or cable on the tool when working in elevated

areas.

Toolswith exposedthrottles shouldnot beusedwhere obstruc-

tionscan holdthethrottle inthe"on" position.Animpactwrench

operating in reverse will move backwards as a nut is removed

andcan trapan operator'shand, makingitdifficulttorelease an

outside trigger. Inside trigger or pistol grip tools are advised for

close quarter operation.

Onlyusesocketsdesignedforusewithimpactwrenches.Never

use a hand tool socket on an impact wrench. Hand tool sockets

can break, resulting in a hazard from flying pieces. Inspect

sockets,retainers,anddrivesregularlyforwearordamage,and

replaceasnecessary.Worn socketsreducepower,causedrive

wear, and increase the chance for breakage and should not be

used.

Impactwrenchesequippedwiththesplinedrivehaveanintegral

socketretainerpinwhichmaybedepressedbyascrewdriveror

similar tool when installing or removing a socket. Tools with

squaredrives 3/4" andlargeruse an aor- ringandpin for socket

retention.Retainers—either pin or integral—should beproperly

engaged to prevent dropping sockets into lower working levels.

Always use socket retainer components recommended by the

socket manufacturer. Never substitute wire, nails, or welding

rods for retaining pins because they are dangerous if thrown

from the tool at free speed, or if the protruding nail or wire is

accidently grasped by the operator.

Some individuals may be susceptible to disorders of the hands

and arms when performing tasks consisting of highly repetitive

motions and/or exposure to extended vibration. Cumulative

trauma disorders such as carpal tunnel syndrome and tendoni-

tis may be caused or aggravated by repetitious, forceful exer-

tions of the hands and arms. Vibration may contribute to a

condition called Raynaud's Syndrome. These disorders de-

velop gradually over periods of weeks, months, and years. It is

For your safety and the safety of others, read and understand

thesafetyrecommendationsbeforeoperatinganimpactwrench.

Always wear protective equipment and clothing.

For additional information on eye protection, refer to Federal

OSHA Regulations, 29 CFR, Section 1910.133, Eye and Face

Protection,andANSIZ87.1,OccupationalandEducationalEye

andFaceProtection. This standard is available from the Ameri-

can National Standards Institute, Inc., 11 West 42nd Street,

New York, NY 10036.

Hearing protection is recommended in high noise areas (above

85dBA). Close proximity ofadditional tools, reflective surfaces,

process noises, and resonant structures can substantially con-

tribute to the sound level experienced by the operator. Proper

hearing conservation measures, including annual audiograms

and training in the use and fit of hearing protection devices may

be necessary. For additional information on hearing protection,

refer to Federal OSHA Regulations, 29 CFR, Section 1910.95,

Occupational Noise Exposure, and American National Stan-

dards Institute, ANSI S12.6, Hearing Protectors.

• Gloves and other protective clothing should be worn as

required, unless they create a greater hazard.

• Do not wear loose fitting clothing, or clothing that may

restrict movement, become entangled or in any way

interfere with the safe operation of the impact.

Clecoimpact wrenches are designed to operate on90psig (6.2

bar) maximum air pressure. If the tool is properly sized and

applied, higher air pressure is unnecessary. Excessive air

pressure increases the loads and stresses on the tool parts,

sockets, and fasteners and may result in breakage. Installation

of a filter-regulator-lubricator in the air supply line ahead of the

tool is highly recommended.

Before the tool is connected to the air supply, check the throttle

for proper operation (i.e., throttle moves freely and returns to

closed position). Being careful not endanger adjacent person-

nel, clear air hose of accumulated dust and moisture. Before

removing a tool from service or changing sockets, make sure

theairlineisshutoff anddrained ofair. Thiswill preventthe tool

from operating if the throttle is accidently engaged.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

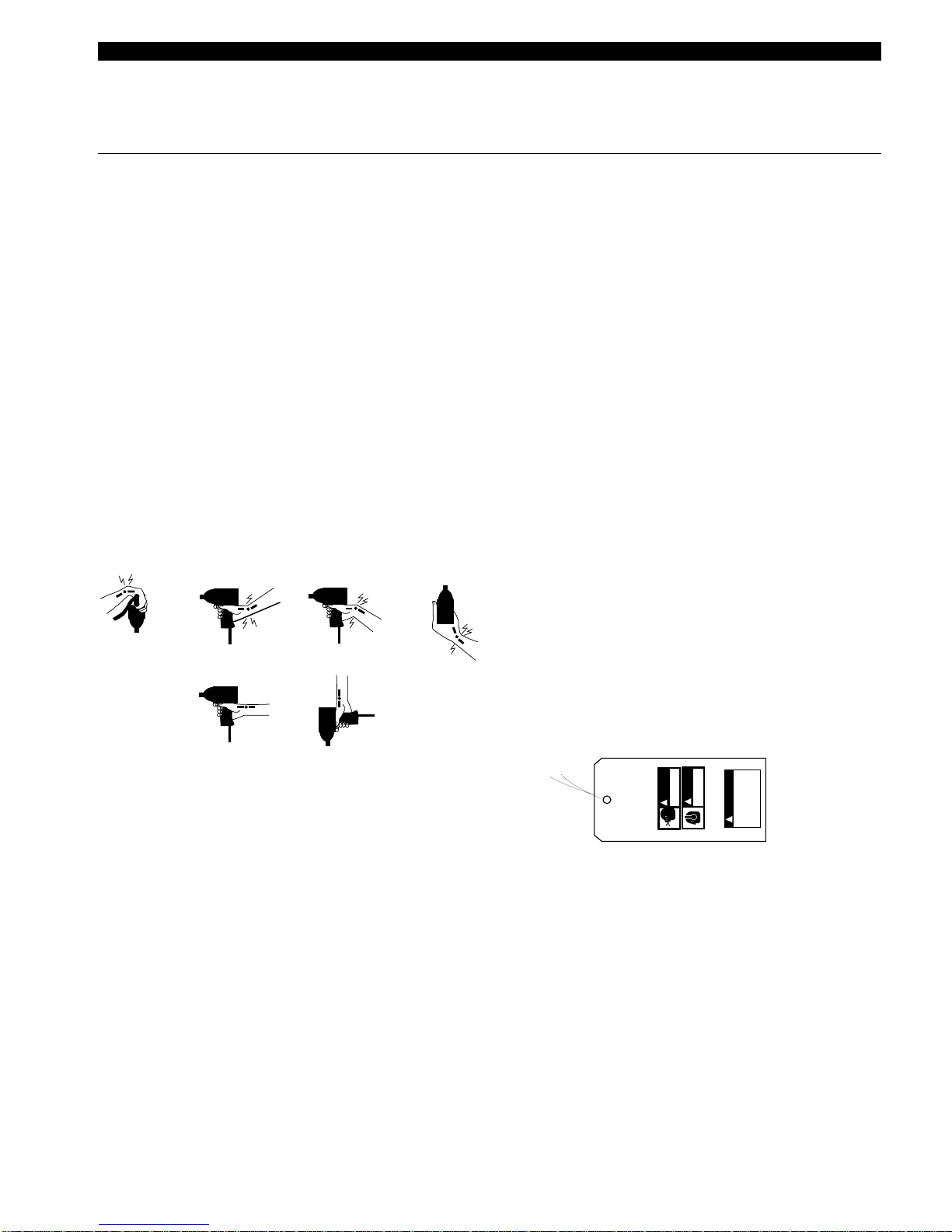

Outside Trigger Pistol Grip

Rev. Rev.

OKDO NOT USE!

Repetitive work motions and/or vibration

may cause injury to hands and arms.

Use minimum hand grip force consistent

with proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

WARNING

!

Avoid repeated bending of wrists and hands.

3

SafetyRecommendations

BAD POSTURE

GOOD POSTURE

OVER

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

Read Operating Instructions carefully. Follow

the Safety Recommendations for your safety

and the safety of others.

Hearing protection is recommended in high noise

areas (above 85 dBA). Close proximity of other

tools, reflective surfaces, process noises, and

resonant structures can substantially contribute

to the sound level experienced by the user.

WARNING

!

Repetitive work motions and/or vibration

can cause injury to hands and arms.

Use minimum hand grip force consistent with

proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

Avoid repeated bending of wrists and hands.

Do not remove this tag until

the operator of this tool has

read these safety precautions.

presently unknown to what extent exposure to vibrations or

repetitive motions may contribute to the disorders. Hereditary

factors, vasculatory or circulatory problems,exposure to cold

anddampness,diet,smokingandworkpracticesarethoughtto

contribute to the conditions.

Tool operators should be aware of the following warning signs

and symptoms so that a problem can be addressed before it

becomes a debilitating injury. Any user suffering prolonged

symptoms of tingling, numbness, blanching of fingers, clumsi-

nessor weakened grip, nocturnal pain in thehand,or any other

disorder of the shoulders, arms, wrists, or fingers is advised to

consultaphysician.Ifitisdeterminedthatthesymptomsarejob

related or aggravated by movements and postures dictated by

the job design, it may be necessary for the employer to take

steps to prevent further occurrences. These steps might in-

clude, but are not limited to, repositioning the workpiece or

redesigningthe workstation, reassigning workers to other jobs,

rotating jobs, changing work pace, and/or changing the type of

tool used so as to minimize stress on the operator. Some tasks

may require more than one type of tool to obtain the optimum

operator/tool/task relationship.

• Tasks should be performed in such a manner that the

wrists are maintained in a neutral position, which is not

flexed, hyperextended, or turned side to side.

• Stressful postures should be avoided. Select a tool

appropriate for the job and work location.

The following suggestions will help reduce or moderate the

effects of repetitive work motions and/or extended vibration

exposure.

•Use a minimum hand grip force consistent with proper

control and safe operation

•Keep body and hands warm and dry

•Avoid anything that inhibits blood circulation

—Smoking Tobacco

—Cold Temperatures

—Certain Drugs

•Keep wrists as straight as possible

•Avoid highly repetitive movements of hands and wrists,

and continuous vibration exposure

Work gloves with vibration reducing liners and wrist supports

are available from some manufacturers of industrial work

gloves.Thesegloves aredesignedtoreduceand moderatethe

effects of extended vibration exposure and repetitive wrist

trauma. Since they vary widely in design, material, vibration

reduction, and wrist support qualities, it is recommended that

the glove manufacturer be consulted for gloves designed for

your specific application. WARNING! Proper fit of gloves is

important. Improperly fitted gloves may restrict blood flow

to the fingers and can substantially reduce grip strength.

Also note that various tool wraps are available from a number

of different manufacturers. Like gloves, these wraps are also

intended to reduce and moderate the effects of extended

vibration exposure. They vary widely in design, material, thick-

ness, vibration reduction, effectiveness, and durability, so con-

sideration must be given to choosing the proper wrap for the

specific application.

This information is a compilation of general safety practices

obtained from various sources available at the date of produc-

tion. However, our company does not represent that every

acceptablesafetypractice isofferedherein, orthatabnormalor

unusual circumstances may not warrant or require additional

procedures. Your work may require additional specific safety

procedures. Follow these procedures as required by your

company.

Warnings

The warnings found on these tools are an essential part of the

product. Warnings should be checked periodically for ligibility.

Replacewarningswhenmissingorwhentheinformationcanno

longer be read. Replacements can be ordered as any spare

part.

869976

Formoreinformation,seethelatesteditionofANSIB186.1,

Safety Code for Portable Air Tools, available from the

American National Standards Institute, Inc., 11 West 42nd

Street, New York, NY 10036.

These operating instructions and service manual should

accompany tool if it is subsequently sold or ownership is

changed.

4

GENERAL INFORMATION

AIR SUPPLY

Thetoolisdesignedtooperateon90psig(6.2bar)airpressure

(measuredat the toolair inlet withthe tool running) using a

1/2"(12.7mm) hose up to 8' (2.4m)in length. An automatic

in-linefilter-lubricatoris highlyrecommendedto supplythe

tool with cleanlubricated air. This will keepthe tool in sus-

tained operation and increase its service life.

The air hose should be cleared of accumulated dirt and

moisture,thenone (1)teaspoon(5ml) of1 OWmachineoil

should be poured into the tool's air inlet before connection

the hose to the tool.

IMPORTANT: If a puick-disconnect coupling is used with

thetool,itshouldbeseparatedfromthetoolbyawhiphose.

All tools and hoses should be installed by trained, compe-

tent personnel. Hoses and fittings should be inspected

regularlyforwornordamagedareasandreplacedifneces-

sary.

LUBRICATION

An automatic in-line filter-lubricator is recommended as it

increases tool fif e and keeps the tool in sustained opera-

tion.Thein-linelubricator shouldberegularlychecked and

filled with a good grade of 1 OW machine oil. Proper

adjustment of the in-line lubricator is performed by placing

a sheet of paper next to the exhaust ports and holding the

throttle open approximately 30 seconds. The lubricator is

properly set when a light stain of oil collects on the paper.

Excessiveamountsofoilshouldbeavoided.Intheeventan

in-line lubricator is not used, the oil reservoir in the handle

should be utilized.

The oil reservoir marked "30W oil" should not require

attention until thetool istorn down for inspection purposes;

however, if the tool is on the application for an unduly long

periodoftime,theplugshouldberemovedandthereservoir

checked for the presence of oil. If oil is required, approxi-

mately1-1/4fluidounces(40ml)of30Woilshouldbeadded

to the oil reservoir.

STORAGE

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

shouldreceiveagenerousamountoflubricationatthattime

and again when returned to service. The tool should be

stored in a clean and dry environment.

MAINTINANCE - DISASSEMBLY

GENERAL - ALL MODELS

Disconnect the tool from the air supply and unscrew and

remove the four (4) nuts, No. 865006; then remove the

handleassembly,reversingvalve,No.869008,gasket,and

the motor clamp seal, No. 869001, from the rear of the

motor unit.

Drivethefour(4)housingbolts,No.869066,outthefrontof

themotorunit.Removingtheanvilhousing,No.861605,will

allow the complete impacting mechanism to slip out the

front of the motor unit. The anvil housing may need to be

rotated to clear the anvil and hammer lugs.

The impact wrench is now separated into four (4) basic

assemblies. See the following paragraphs for commplete

disassembly instructions on these assemblies

ANVIL HOUSING

For better performance, it is recommended that the anvil

housingseal, No. 867993, be replaced duringeach repair.

Thesealmayberemovedbypryingitoutwithascrewdriver.

Shouldtheanvilhousingbushing,No.861602,needreplac-

ing, the housing seal will have to be removed as outlined

abovePressthehousingbushingouttherearofthehousing

using a bushing driver 2-3/16" in diameter.

IMPACT MECHANISM

Clampthehammer,No867969,horizontallyinasoftjawed

viseanddrivetheanvil*awayfromthehammerusingasoft

hammerThiswillallowtheanvilpin,No867994,springclip,

No867964.andhammerspringNo.867984toberemoved

from the front of the cam shaft, No 867973

Remove the hammer from the vise and slip the cam shaft

and related components out of the rear of the cam, No.

867991. Remove the shock absorber, No. 867980, (slight

press fit) from the rear of the cam shaft. This will allow the

insulator, No. 869012, butt plate, No. 869011, cam roller,

No.869278,andcamrollershaft,No867979,toberemoved

from the cam shaft.

Slip the cam, No. 867991, out of the rear of the hammer,

being careful not to lose the timing pin, No. 867966.

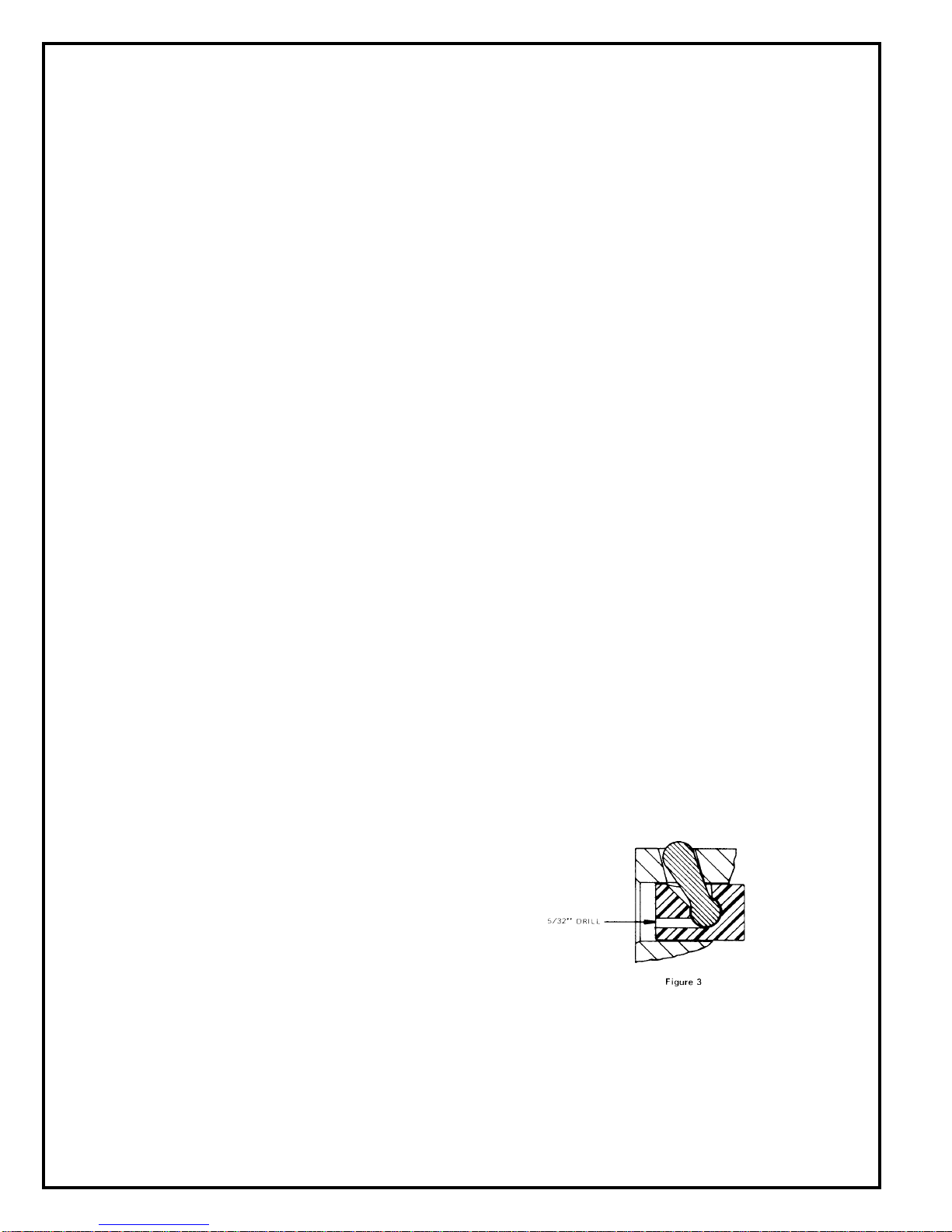

*NOTE:Onthesplinedriveanvils,shouldanyofthesocket

retainerpartsneedreplacing,a5/32"holeshouldbedrilled

in the socket retainer plunger, No. 867950, as shown in

Figure3.Insertapinpunchinthedrilledholeandlightlytap

thepunchunderthesocketretainerpin,No.867951.Pryon

the punch to pop the pin out of its pocket in the plunger.

MOTOR UNIT

Set the front of the housing, No. 869744, on a cylinder (4-

112''I.D.x5''long)andusingasuitabledriver(2-1/8"O.D.)

drivetherotoroutoftherearrotorbearing,No.867995.This

willremovethefrontbearingplate,No.867985,six(6)rotor

blades, No. 867975, and rotor from the housing. Invert the

housing on the fixture and use the rotor to drive the rear

bearing plate assembly from the housing. The cylinder

5

should not be removed from the housing unless replace-

mentisnecessary.Ifcylinderreplacementisnecessary,a4-

5/32" O.D. bushing driver (with a suitable relief for the

alignment key, No. 867981) should be used to press the

cylinder out of the housing.

Remove the rotor bearings, No. 867995, from the bearing

plates for inspection. For better performance, it is recom-

mendedthat the rotor shaftseals, No. 867996, bereplaced

during each repair.

NOTE: UNLESS THE "0" RINGS, NO. 844309, LOCATED

ONTHEO.D. OF THEBEARINGPLATE ARESEVERELY

DAMAGED, THEY SHOULD NOT BE REMOVED. IF RE-

PLACEMENTISNECESSARY,REPLACEMENT"0"RINGS

SHOULDBEINSTALLEDWITHAFASTCURECONTACT

ADHESIVE ("LOCTITE" 404).

For cleaning and inspection of the three (3) muffler plates,

No. 869004, unscrew the retainer screw, No. 883695.

HANDLEASSEMBLIES

Both the inside and outside trigger handle assemblies are

disassembled using the same procedure. Unscrewing the

air inlet bushing, No. 864972, will allow the "0"ring, No.

863009, air inlet screen, No. 843656, throttle valve spring,

No. 864973, throttle valve No. 867974, throttle valve seal,

No. 867977, and throttle valve pin, No. 867982, to be

removed from the handle.

If the throttle pin bushing, No. 864975, should need replac-

ing, tap. the I.D. of the bushing with a 114"-20 thread tap.

Inserta114-20 boltof the appropriatelength andclampthe

boltin the vise. Drivethe handle away fromthe vise using a

soft mallet.

Ifthetriggershouldneedreplacing,onlythetriggerpin(solid

pin), No. 832125, need be removed.

MAINTENANCE - REASSEMBLY

CLEANING AND INSPECTION

All parts should be cleaned in a solvent and inspected for

wearor damage.If rotor bladesmeasure lessthan 7116 on

either end, they should be replaced. Rotor bearings should

bereplaced if they feel rough after cleaning or show exces-

sive looseness.

HANDLE ASSEMBLY

Wheninstailingthetriggeruseapinslightlysmallerthanthe

hole in the handle to locate the trigger when driving the

trigger pin, No 832125. into the handle.

If the throttle valve bushing No 864975, was removed, the

newbushingshouldbepressedintoadepthof115/16"plus

or minus 1/64 from the bottom face of the handle.

Inspect the throttle valve seal, No, 867977, for wear or

deterioration. If replacement is necessary, the new seal

should be pushed (cupped face first) on the throttle valve,

No.867974,fromthetaperedend.Inspectthe"O"-ring,No.

863009,andreplace if necessary.Cleanthe threadsonthe

airinletbushing,No864972,andapply"LOCKTITE"No.271

to the threads.

Now install the throttle valve pin, No 867982, and throttle

valve assembly into the handle. Place the inlet air screen,

No.843656,aridthrottlevalvespring,No.864973,intheair

inlet bushing and screw the bushing into the handle. The

bushing should be torqued to 80 It lbs. minimum.

MOTOR UNIT

Insertthethree(3)mufflerplates.No.869004,andinstallthe

retaining screw, No. 883695.

During reassembly of the bearing plates, No. 867985, the

rotor shaft seals, No. 867996, should be installed with their

"lips'' facing out (visible after installation). When installing

therotorbearings,No.867995,pressonthebearing'souter

race. Lubricate both the seals and rotor bearings with 30W

oilbeforeassemblyintothemotorunit.Inspectthe"O"-ring,

No.863096,and replaceifnecessary. This"O"-ring isused

only on the front bearing plate (both bearing plates are

identical).

Ifthecylinderwasremoved,thenewcylinder(withalignment

key,No.867981,inplace)shouldbepressedinfromtherear

ofthemotorhousingtoadepth5/8"fromtherearfaceofthe

housing.

Lubricatethe"O"-ringsonthe O.D.oftherearbearing plate

assembly and press the assembly into the housing. When

installing either bearing plate assembly, be sure the "O"-

rings line up with the air ports in the housing. Invert the

housing and install the rotor with the end stamped ''REAR"

into the rear rotor bearing, No. 867995.

Insertthesix(6)rotorblades,No.867975,thenlubricatethe

"O''-ringsonthefront bearing plateassemblyandpress the

assembly into the housing. NOTE: Be sure '0--ring, No.

863096, is in place on the front bearing plate.

IMPACT MECHANISM

All parts should receive a thin coating of 30W oil before

assembly.

Insertthetimingpin,No.867966,intotherecesslocatedon

the small O.D. of the cam, No. 867991, and then install the

cam and pin into the rear of the hammer, No. 867969.

Installthecamrollershaft,No.867979,inthecamshaft,No.

867973. Put the cam roller, No. 867978, on the roller shaft

and slip the butt plate, No. 869011, insulator, No. 869012,

and shock absorber, No. 867980, onto the rear of the cam

shaft. Hold the cam shaft vertically on the work bench with

the shock absorber down and tap the end of the cam shaft

withasoftmallettoseatthecamshaftintheshockabsorber.

Slipthecamshaftandrelatedcomponentsthroughthecam

and hammer assembly. Install the hammer spring, No.

867984 spring clip, No. 867964, and anvil pin, No. 867994,

6

onto the front of the cam shaft and hammer assembly.

Rotatethe springclip toaccept theanvil pinand theninstall

theanvilontop oftheassembly (be suretheslot intheanvil

lines up with the anvil pin) and drive the anvil down until the

spring clip engages the recess in the anvil.

To install the socket retainer pin, No 867951, in the spline

drive anvil, insert socket retainer spring, No. 867949, and

socket retainer plunger, No. 867950 into the anvil and then

drive the socket retainer pin radially into the plunger.

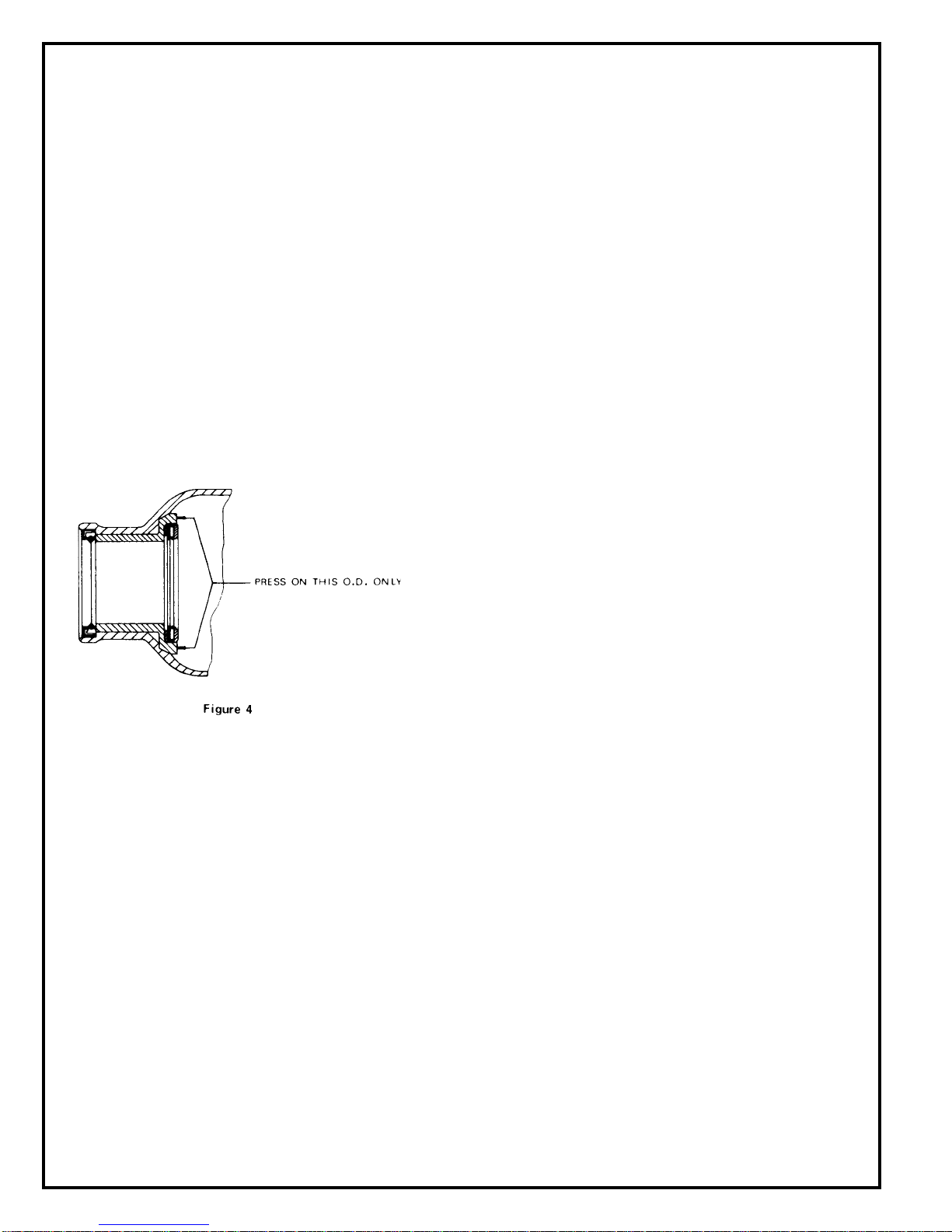

ANVIL HOUSING

If the anvil housing bushing, No 861602, is replaced, it

should be pressed in as shown in Fig. 4.

When replacing the anvil housing sea), No 867993, the

housing bore should be cleaned with a solvent and then

coatedwith''PERMATEX"AviationForm-A-GasketNo.3H,

andthenbeallowedtoairdryatleastfour(4)minutesbefore

pressingintheseal.Pressthesealinwithits"lip"towardthe

boreofthehousing(''Lip''shouldnotbevisibleafterassem-

bly.)

GENERAL- ALL MODELS

Coat the hammer and rotor splines with 30W oil and insert

theimpactmechanismintothefrontoftherotorLubricatethe

anvilhousingsealandbushingwith30Woilandinstallonthe

unitbeingsurethecontouroftheanvilhousingmatchesthat

of the motor housing The anvil and hammer lugs should be

in line with the recess in the make-up lip located in the anvil

housing.Installthedeadhandlebracket,No.867990,onthe

leftside ofthe tooland insertthe four(4) housing bolts. Tap

theboltswithahammeruntiltheanvilhousingseatsagainst

the motor housing.

ClarnpthetoolverticallyinaviseandinstallthegasketInsert

-0--ring,No.847981,intothereversingvalveboreandinstall

thereversingvalve,No.869008.Applyathincoatofgrease

to the motor clamp seal, No 869001, and place it into the

handle recess.

Put the handle on the tool and install the four (4) nuts, No.

865006. Torque these nuts to 20 ft. lbs. minimum.

Laythetoolonitsrightsideandremovethe30Woilfillplug,

No. 867801. Fill the reservoir with a good grade of 30W oil

up to the level of the fill indicator pin located in the reservoir

(approximately 1 - 1-1/4 fluid Ounces).

Place a couple of teaspoons of 10W machine oil in the air

inlet bushing before attaching the air hose to ensure imme-

diate lubrication of all motor parts.

SAFETY CHECK

Alltoolsshouldbetestedafterrepairorreplacementofparts

to assure that they are functioning properly.

7

8

PART NO.

842290

861602

861605

867949

867950

867951

867964

867966

867969

867970

867973

867976

867978

867979

867980

867983

PART NO.

867984

867987

867988

867990

867991

867993

867994

869010

869011

869012

869066

NAME OF PART

Support Handle

Anvil Housing Bushing (incl. 867976, 867983, 867987,

867988)

Anvil Housing (incl. 861602, 867993)

Socket Retainer Spring

Socket Retainer Plunger

Socket Retainer Pin

Spring Clip

Timing Pin

Hammer

#5 1-5/8" Spline Drive Anvil

Cam Shaft

Thrust Race

Cam Roller

Cam Roller Shaft

Shock Absorber

Cushion

NAME OF PART

Hammer Spring

Thrust Bearing

Thrust Race

Support Handle Bracket

Cam

Anvil Housing Seal

Anvil Pin

1-1/2" Sq. Dr. Anvil

Butt Plate

Insulator

Housing Bolt

QTY.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

QTY.

1

1

1

1

1

1

1

1

1

1

4

PARTS LIST — IMPACT MECHANISM

9

PART NO.

863096

863637

865004

867971

867975

867981

867985

867995

PART NO.

867996

869001

869004

869596

869635

869744

883695

NAME OF PART NAME OF PART

Rotor Shaft Seal

Motor Clamp Seal

Muffler Plate

Rotor

Cylinder (W-2119)

Housing (incl. 863637, 865004, 869004,883695)

Retainer Screw

QTY.

1

1

1

1

6

1

2

2

QTY.

1

1

1

1

1

PARTS LIST — MOTOR UNIT

O-ring 3-1/4" X 3-1/2"

Wear Plate Pin

Wear Plate

Cylinder (W-2120)

Rotor Blade

Alignment Key

Bearing Plate (incl. 844309)

Rotor Bearing

10

PART NO.

203282

832125

843656

844303

847981*

863009

864387

864972

864973

864975

865006*

PART NO.

867801

867974

867977

867982

567998

867999*

869000

869008*

869009

869740

869743

NAME OF PART

Washer

Trigger Pin

Air Inlet Screen

O-ring 3/16" X 5/16"

O-ring 1-3/8" X 1-1/2"

O-ring 3/4" X 7/8"

10W Oil Fill Plug

Air Inlet Bushing

Throttle Valve Spring

Throttle Valve Pin Bushing

Nut

NAME OF PART

30W Oil Fill Plug

throttle Valve

Throttle Valve Seal

Throttle Valve Pin

Inside Trigger

Gasket

Outside Trigger

Reversing Valve

Trigger Stop Pin

Inside Trigger Handle (incl. 864975)

Outside Trigger Handle (incl. 864975)

QTY.

2

1

1

1

1

1

1

1

1

1

4

QTY.

1

1

1

1

1

1

1

1

1

1

1

PARTS LIST — HANDLES

*Denotes parts not included in subassemblies listed below.

The complete handle can be ordered as a subassembly using the part numbers listed below.

Outside Trigger - 861867 Inside Trigger - 861863

11

NOTES

12

CooperTools

670 Industrial Drive

Lexington, SC 29072

Phone: (803) 359-1200

Fax: (803) 359-2013

www.cooperindustries.com

This manual suits for next models

1

Table of contents

Other Cleco Nail Gun manuals

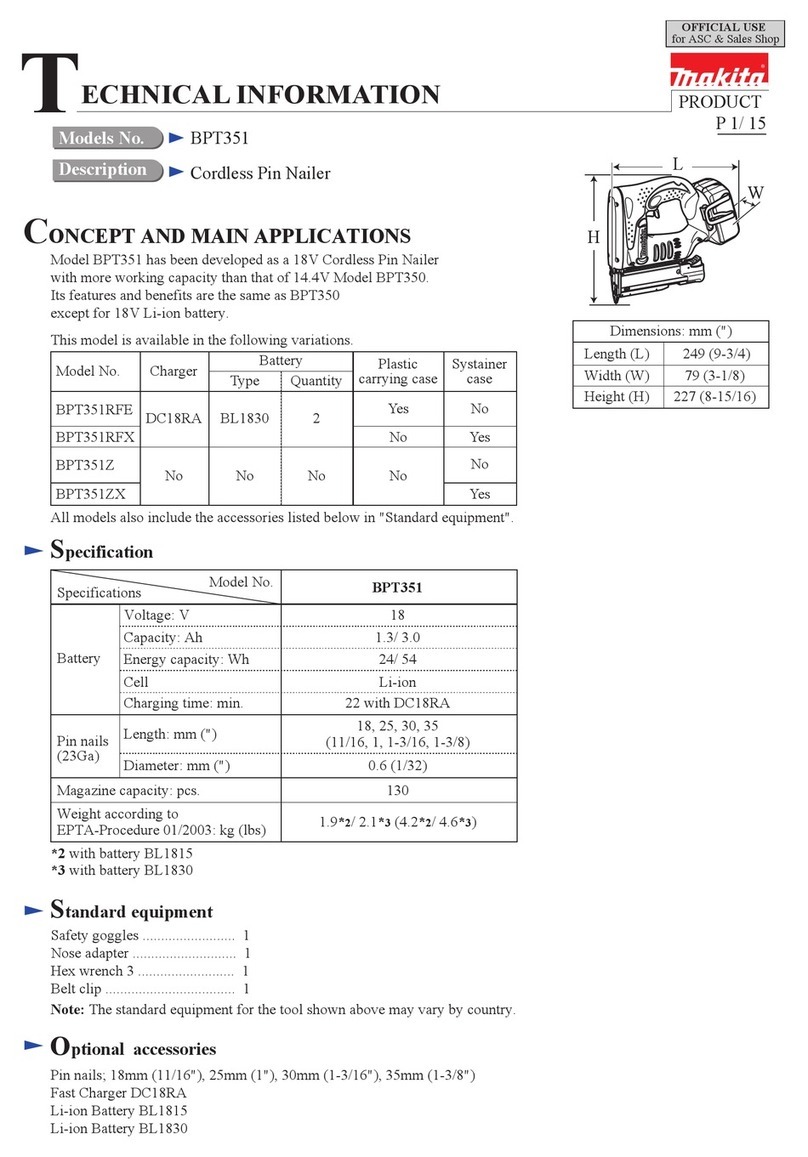

Popular Nail Gun manuals by other brands

Makita

Makita DPT353 instruction manual

BEA

BEA R 130 - 957E Operator's manual

Hitachi

Hitachi NR 90AA Handling instructions

Bostitch

Bostitch N89C Operating and maintenance manual

Milwaukee

Milwaukee 7150-21 Operator's manual

Hitachi

Hitachi NR90AD - Clipped Head to 3-1 Framing Nailer Instruction and safety manual