Cleco 15ML-1.6B- 837 Troubleshooting guide

1

Printed in U.S.A. 12-1-97

OPERATING INSTRUCTIONS

AND

SERVICE MANUAL

15ML-1.6B- 837

FIXTURIZED NUTRUNNER

®

COMPLETE TOOL

MODEL NO. CODE NO.

15ML-1.6B-837 230837

READ SAFETY RECOMMENDATIONS BEFORE OPERATING TOOL

2

CAUTION!

Personal hearing protection is

recommended when operating

or working near this tool.

Safety Recommendations

Foryoursafetyandthesafetyofothers,readandunder-

standthesafetyrecommendationsandoperatinginstruc-

tions before operating any tool.

Always wear protective equipment:

For additional information on eye protection and face

protection,refer to FederalOSHA Regulations, 29Code

ofFederalRegulations,Section1910.133.,EyeandFace

Protection, and American National Standards Institute,

ANSIZ87.1,OccupationalandEducationalEyeandFace

Protection.Z87.1isavailablefromtheAmericanNational

StandardsInstitute,Inc.,11West42ndStreetNewYork,

NY. 10036.

Hearing protection is recommended in high noise areas

85 dBA or greater. The operation of other tools and

equipmentinthearea,reflectivesurfaces,processnoises

and resonant structures can substantially contribute to,

and increase the noise level in the area. Excessive air

pressureabove90PSIGor wornmotorcomponentscan

also increase sound level emitted by tool. For additional

informationonhearingprotection,refertoFederalRegu-

lations,Section 1910.95, Occupational NoiseExposure,

andAmericanNationalStandardsInstitute,ANSI S12.6,

Hearing Protectors.

Cleco tools are designed to operate on 90 psig (6.2 bar)

maximum air pressure. If the tool is properly sized and

applied, higher air pressure is unnecessary. Excessive

airpressureincreases theloadsandstresseson thetool

parts,sockets,andfastenersandmayresultinbreakage.

Installationofafilter-regulator-lubricator intheairsupply

line ahead of the tool is recommended.

Before the tool is connected to the air supply, check the

throttle for proper operation (i. e., throttle moves freely

and returns to closed position). Being careful not to

endangeradjacent personnel,cleartheairhoseofaccu-

mulated dust and moisture. Before removing a tool from

serviceorchangingsockets,makesuretheairlineisshut

off and drained of air. This will prevent the tool from

operating if the throttle is accidently engaged.

Some individuals may be susceptible to disorders of the

hands and arms when performing tasks consisting of

highly repetitive motions and/or exposure to extended

vibration. Cumulative trauma disorders such as carpal

tunnelsyndrome andtendonitiscanbecausedoraggra-

vated by repetitious, forceful exertions of the hands and

arms. Vibration may contribute to a condition called

Raynaud's Syndrome. These disorders develop gradu-

ally over periods of weeks, months, and years. It is

presentlyunknownto whatextentexposuretovibrations

or repetitive motions may contribute to the disorders.

Hereditary factors, vasculatory or circulatory problems,

exposuretocoldanddampness, diet, smoking and work

practices are thought to contribute to the conditions.

Anytool operator should beawareof the following warn-

ing signs and symptoms so that a problem can be

addressedbeforeitbecomesadebilitatinginjury.Anytool

operator should be aware of the following warning signs

and symptoms so that a problem can be addressed

beforeitbecomesadebilitatinginjury.Anyusersuffering

prolongedsymptomsoftingling,numbness,blanchingof

fingers, clumsiness or weakened grip, nocturnal pain in

the hand, or any other disorder of the shoulders, arms,

wrists, or fingers is advised to consult a physician. If it is

determined that the symptoms are job related or aggra-

vated by movements and postures dictated by the job

design,itmaybenecessaryfortheemployertotakesteps

to prevent further occurrences. These steps might in-

clude, but are not limited to, repositioning the workpiece

or redesigning the workstation, reassigning workers to

other jobs, rotating jobs, changing work pace, and/or

changingthetypeoftoolusedsoastominimizestresson

theoperator.Sometasksmayrequiremorethanonetype

of tool to obtain the optimum operator/tool/task relation-

ship.

WARNING!

Impact resistant eye protection

must be worn while operating

or working near this tool.

Repetitive work motions and/or vibration

can cause injury to hands and arms.

Use minimum hand grip force consistent

with proper control and safe operation.

Keep body and hands warm and dry.

Avoid anything that inhibits blood circulation.

Avoid continuous vibration exposure.

Keep wrists straight.

WARNING

!

Avoid repeated bending of wrists and hands.

3

Safety Recommendations

The following suggestions will help reduce or moderate

the effects of repetitive work motions and/or extended

vibration exposure:

•Use a minimum hand grip force consistent with

proper control and safe operation

•Keep body and hands warm and dry (cold

weather is reported to be a major factor contrib

uting to Raynaud's

Syndrome)

•Avoid anything that inhibits blood circulation

—Smoking Tobacco (another contributing

factor)

—Cold Temperatures

—Certain Drugs

•Tasks should be performed in such a manner

that the wrists are maintained in a neutral posi-

tion, which is not flexed, hyperextended, or

turned side to side.

•Stressful postures should be avoided —select

a tool appropriate for the job and work location

•Avoid highly repetitive movements of hands

and wrists, and continuous vibration exposure

(after each period of operation, exercise to

increase blood circulation)

•Keep tool well maintained and replace worn

parts

Work gloves with vibration reducing liners and wrist sup-

portsareavailablefromsomemanufacturersofindustrial

workgloves.Toolwrapsandgripsarealsoavailablefrom

anumberofdifferentmanufacturers.Thesegloves,wraps,

and wrist supports are designed to reduce and moderate

the effects of extended vibration exposure and repetitive

wrist trauma. Since they vary widely in design, material,

thickness,vibrationreduction,andwristsupportqualities,

it is recommended that the glove, tool wrap, or wrist

support manufacturerbeconsultedforitemsdesignedfor

yourspecificapplication.WARNING!Properfitofgloves

is important. Improperly fitted gloves may restrict

bloodflowtothefingersandcansubstantiallyreduce

grip strength.

Abooklet,AssemblyToolErgonomics,isavailablefreeof

charge by writing the following address:

Industrial Tool Division

P. O. Box 40430

Houston, Texas 77240 USA

713/462-4521

Please request Form No. 60669.

Formoreinformationonthesafeuse ofportableairtools,

see the latest edition of ANSI B186.1, Safety Code for

Portable Air Tools, available from the American National

Standards Institute, Inc. 11 West 42nd Street New York,

NY. 10036.

Warning Labels

The warning labels found on these tools are an essential

partofthisproduct.Labelsshouldnotberemoved.Labels

shouldbecheckedperiodicallyforligibility.Replacewarn-

ing labels when missing or when the information can no

longer be read. Replacement labels can be ordered as

any spare part.

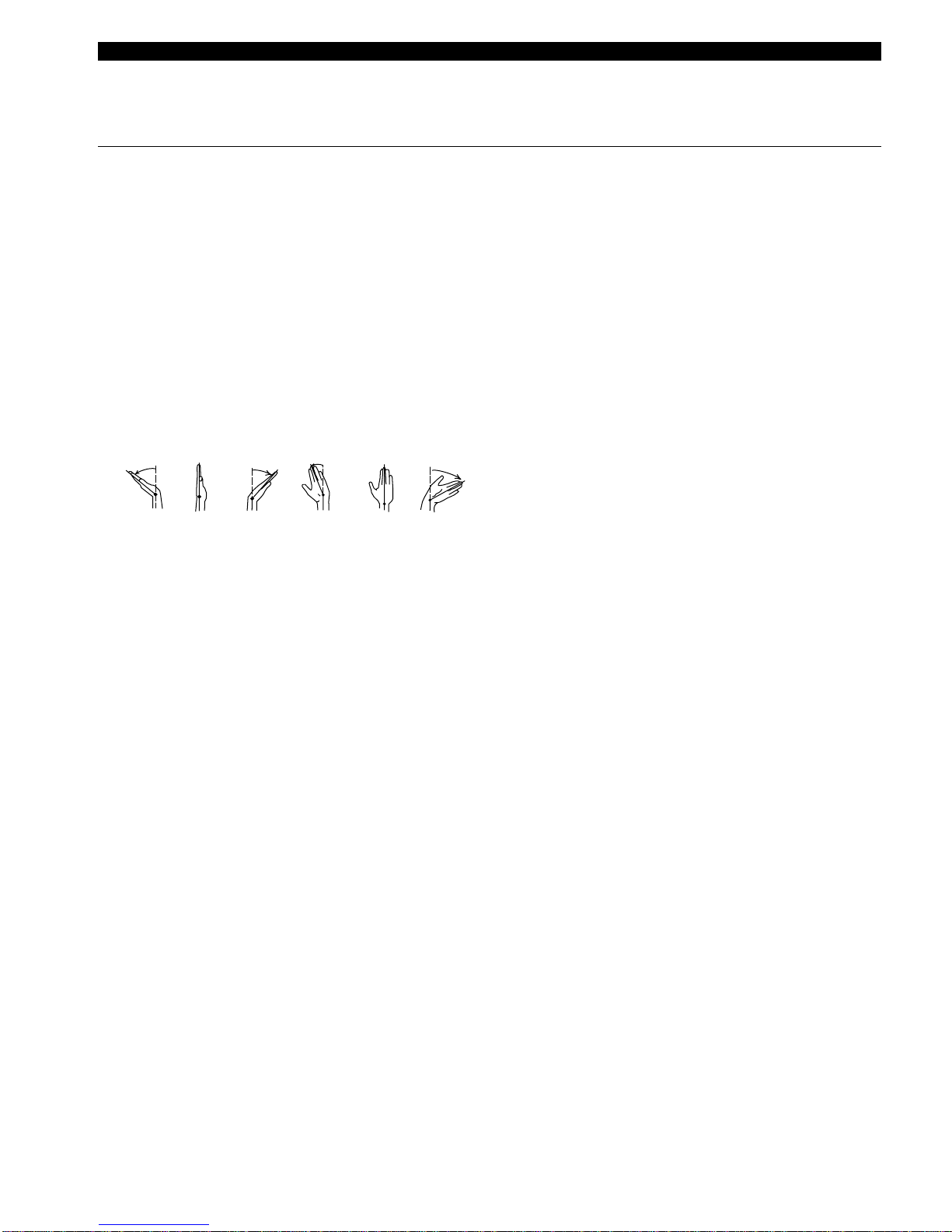

Extension Neutral Flexion Radial Deviation Neutral Ulnar Deviation

Avoid Avoid Avoid

OK Avoid OK

4

OPERATION

The tools are designed to operate on 90 PSIG (6.2 bar) air

pressure. The 15ML series requires a 3/8" hose.

The 15ML series is started by depressing the lever and

stopped by releasing the lever.

LUBRICATION

An automatic in-line filter-lubricator is recommended as it

increasestoollifeandkeepsthetoolinsustainedoperation.

Thein-line lubricator shouldbe regularly checked and filled

withagoodgradeof10Wmachineoil.Properadjustmentof

thein-linelubricatorisperformedbyplacingasheetofpaper

next to the exhaust ports and holding the throttle open

approximately 30 seconds. The lubricator is properly set

when a light stain of oil collects on the paper. Excessive

amounts of oil should be avoided.

In the event that it becomes necessary to store the tool for

an extended period of time (overnight, weekend, etc.), it

shouldreceivea generousamountof lubricationatthattime

and again when returned to service. The tool should be

stored in a clean and dry environment.

Allothergearsandopenbearingsshouldreceiveagenerous

amountofShell#65115Maleuscompoundduringassembly.

After completing assembly of the gear case, and prior to

assembling it with the motor and motor housing, additional

Shell lubricant must be added until the gear case cavity is

approximately 2/3 full. Do not overfill.

FOR YOUR SAFETY AND THE SAFETY OF OTHERS READ AND UNDERSTAND THE SAFETY

RECOMMENDATIONS BEFORE OPERATING TOOL.

OPERATING INSTRUCTIONS

5

SERVICE INSTRUCTIONS

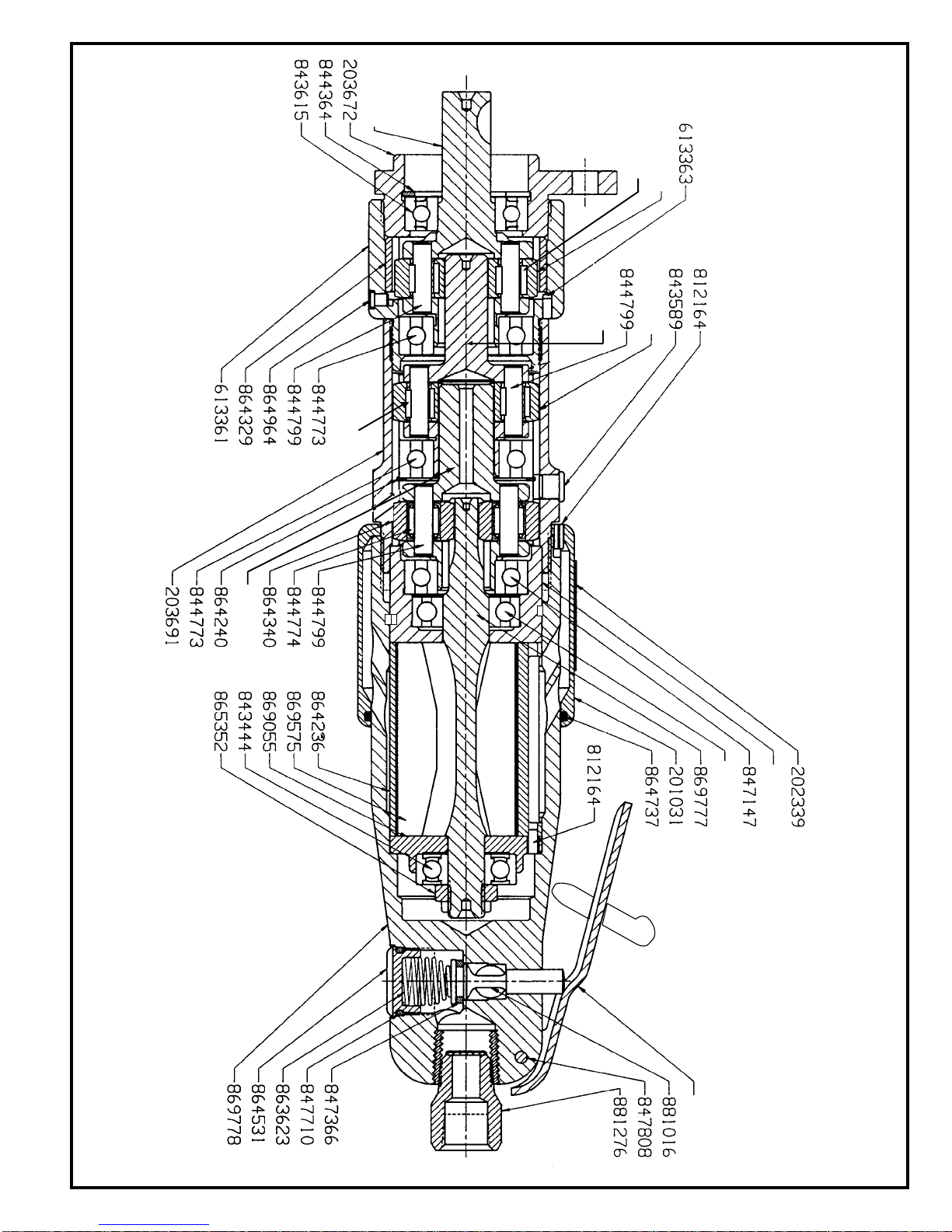

DISASSEMBLY

Thetool should beclamped in the visewith the geartrain in

a vertical position. Using a suitable wrench, unscrew the

gear case and slip the motor out of the motor housing.

NOTE: On the double reduction tools, the first reduction

spider will remain with the motor and should be removed at

this time. This completes the disassembly of the tool into

three (3) major subassemblies (Gear Case, Motor, and

MotorHousing). Seethefollowingparagraphsforcomplete

disassembly instruction.

GEARCASE:HoldingthesecondgearcaseNo.613361,in

the vise, unscrew bearing retainer No. 203672. Drive third

reductiongearspiderNo.204623,outofbearingNo.843615.

Unscrew second gear case No. 613361, from gear case.

Thesecondreduction spiderassemblymaybepressedout

therearofthegearcase,No.203691,aftertheretainerring,

No. 864240, is removed from the inside of the gear case.

After the spider bearings have been removed, using a

suitable bearing puller, the idler gears may be removed for

inspection by driving the idler gear pins out the rear of the

spiders.

MOTOR:Usingasoft-facedmallet,drivetherotoroutofthe

front rotor bearing, No. 619991. This will allow the removal

ofthefrontbearingplate,No.865344,cylinder,No.864236,

and rotor blades, No. 869575. After removing the rotor lock

nut, No. 865352, from the rear rotor shaft, the rotor may be

driven out of the rear rotor bearing, No. 843444.

MOTORHOUSING:Thethrottlevalve,No.869350,usedin

the pistol grip handle may be removed for inspection by

unscrewing the inlet bushing, No. 833471. The lever back-

head throttle valve seal, No. 847366, may be removed by

unscrewing the throttle valve cap, No. 864531.

Unscrew the inlet bushing, No. 881276, for inspection and

cleaning of the air screen on the lever backhead.

REASSEMBLY

The tool is reassembled in the reverse of disassembly. All

parts should be thoroughly cleaned and inspected for wear

beforereassembly.Replaceallbearingswhichfeelroughor

haveexcessiveendplay.ThesealsonbearingNo.619991

andNo.843615shouldbecheckedclosely andthebearing

shouldbereplaced if visibledamageisevidenttothe seals.

All other gears and open bearings should receive a gener-

ous amount of Shell #65115 Maleus compound during

assembly.Aftercompleting assemblyofthegearcase, and

prior to assembling it with the motor and motor housing,

additionalShelllubricant must be added untilthegear case

cavity is approximately 2/3 full. Do not overfill.

Toassemblethemotor,installtherearrotorbearingintothe

rearbearingplate.Makesuretheouterbearingraceisfirmly

seatedinthebearingplate.Clamptherotorbodylightlyinthe

visewiththethreadedendupandsliptherearbearingplate

assemblyontotherotorshaftfarenoughfortherotorlocknut

to start. Tighten the lock nut until there is approximately

.0015" (.038mm) clearance between the rotor and bearing

plate.Theouterbearingraceshouldbefirmlyseatedandthe

rotor bumped forward when checking this clearance.

Itisrecommendedthatnewrotorbladesbeinstalledateach

repaircycle.Ifnotreplaced,theusedones must measure a

minimum of 7/32" (5.5mm) at both ends.

The front motor bearing is sealed, so it cannot be packed

withgreased. The rearrotor bearing shouldbe packed with

a good grade of NLGI 2-EP grease after assembly of the

motor unit.

During assembly of the gear case to the motor and motor

housing, be sure that the teeth of the rotor mesh with the

teeth of the idler gears. Rotate the gear train by hand to be

sure the teeth are properly meshed before air is applied.

FOR YOUR SAFETY AND THE SAFETY OF OTHERS READ AND UNDERSTAND THE SAFETY

RECOMMENDATIONS BEFORE SERVICING TOOL.

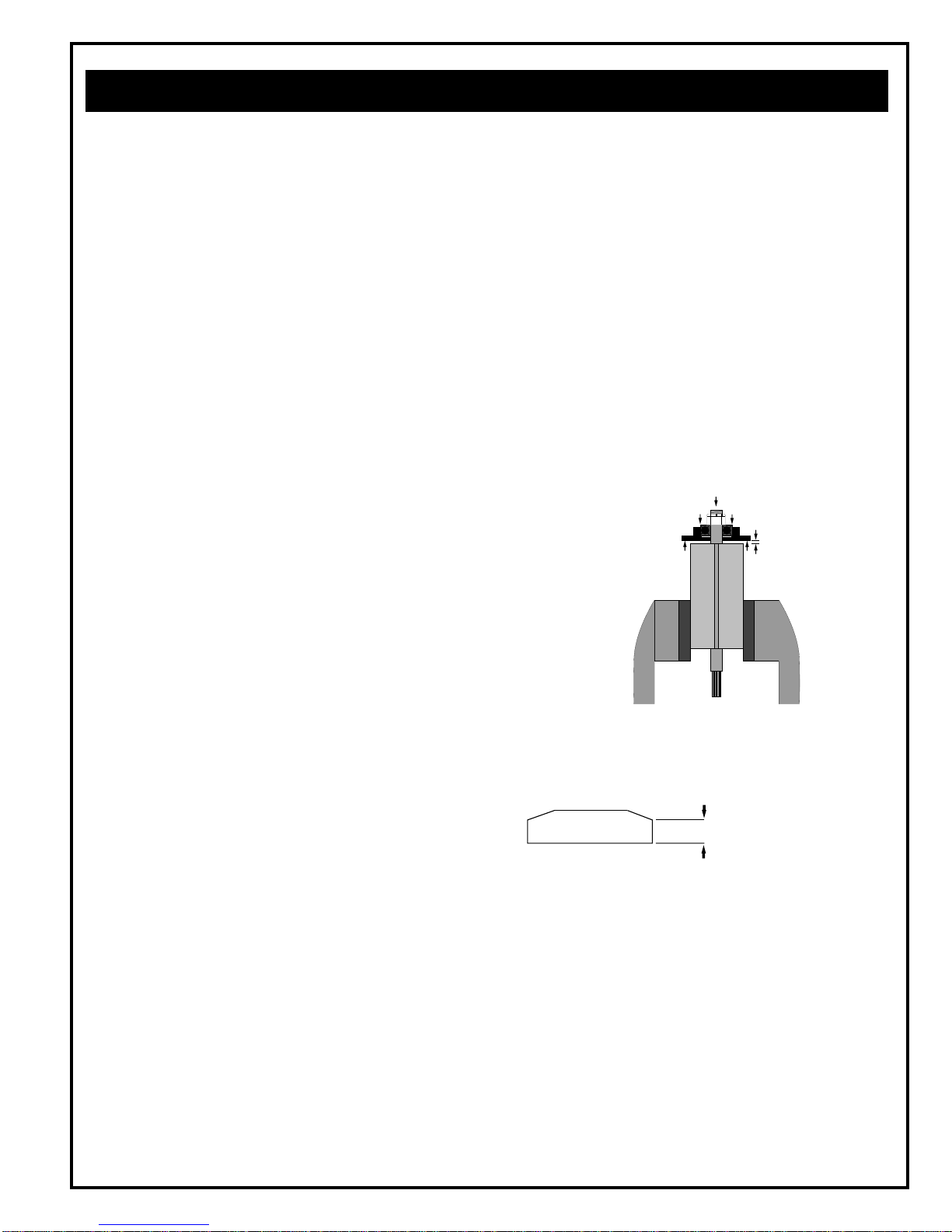

SOFT

JAWED

VISE

.0015"

Clearance

Must be replaced if

7/32" (5.5mm) or less

at either end.

6

201031-2

202339-8

203672-1

203691-1

204623-3

204631-6 *

204632-4 †

613361-5

613363-4

619991-3

812164-2

843444-1

843615-6

844364-0

844773-2

844774-0 * †

844799-7 * †

847147-6

847366-2

847710-1

847808-3

861992-6

863623-5

864236-5

864240-7

864323-1 *

864329-8

864340-5 †

864531-9

864737-2

864964-2

865344-6

865352-9

869055-4

869575-1

869777-3

869778-1

881016-0

881276-0

1s

1

1

1

1

1

1

1

1

1

1

1

1

1

2

6

6

1

1

1

1

1

1

1

1

4

1

2

1

1

1

1

1

1

4

1

1

1

1

EXHAUST DEFLECTOR

SAFETY LABEL

BEARING RETAINER

GEAR CASE

3RD RED. SPIDER

2ND. RED. SPIDER (14T)

1ST. RED. SPIDER (14T)

GEAR CASE

PIN, DOWEL

BEARING, BALL

PIN, ROLL

BEARING, BALL

BEARING, BALL

RETAINER RING

BEARING, BALL

IDLER GEAR BEARING

PIN

BEARING, BALL

THROTTLE VALVE SEAL

"O"RING

PIN, GROOVE

LOCK-OFF LEVER

SPRING, THROTTLE VALVE

CYLINDER

BEARING RETAINER

2ND. & 3RD. RED. IDLER GEAR (16T)

GEAR, RING

1ST. RED. IDLER GEAR (18T)

CAP

"O"-RING

GREASE FITTING

FRONT BEARING PLATE

NUT, LOCK

REAR BEARING PLATE

ROTOR BLADE

ROTOR

BACKHEAD

VALVE, THROTTLE

BUSHING

PARTNO. NAME OF PARTS QTY.

* PARTS INCLUDED IN 2ND. RED. SPIDER SUBASSEMBLY — 201767

† PARTS INCLUDED IN 1ST. RED. SPIDER SUBASSEMBLY — 201766

7

865344

619991

204632

864323

204631

864323

204623

861992

844774

844774

This manual suits for next models

1

Table of contents

Other Cleco Nail Gun manuals