HEXAGON 07.2019 en 2

Index

Page

1Preface...................................................................................................................................3

2EC Declaration of Conformity...............................................................................................4

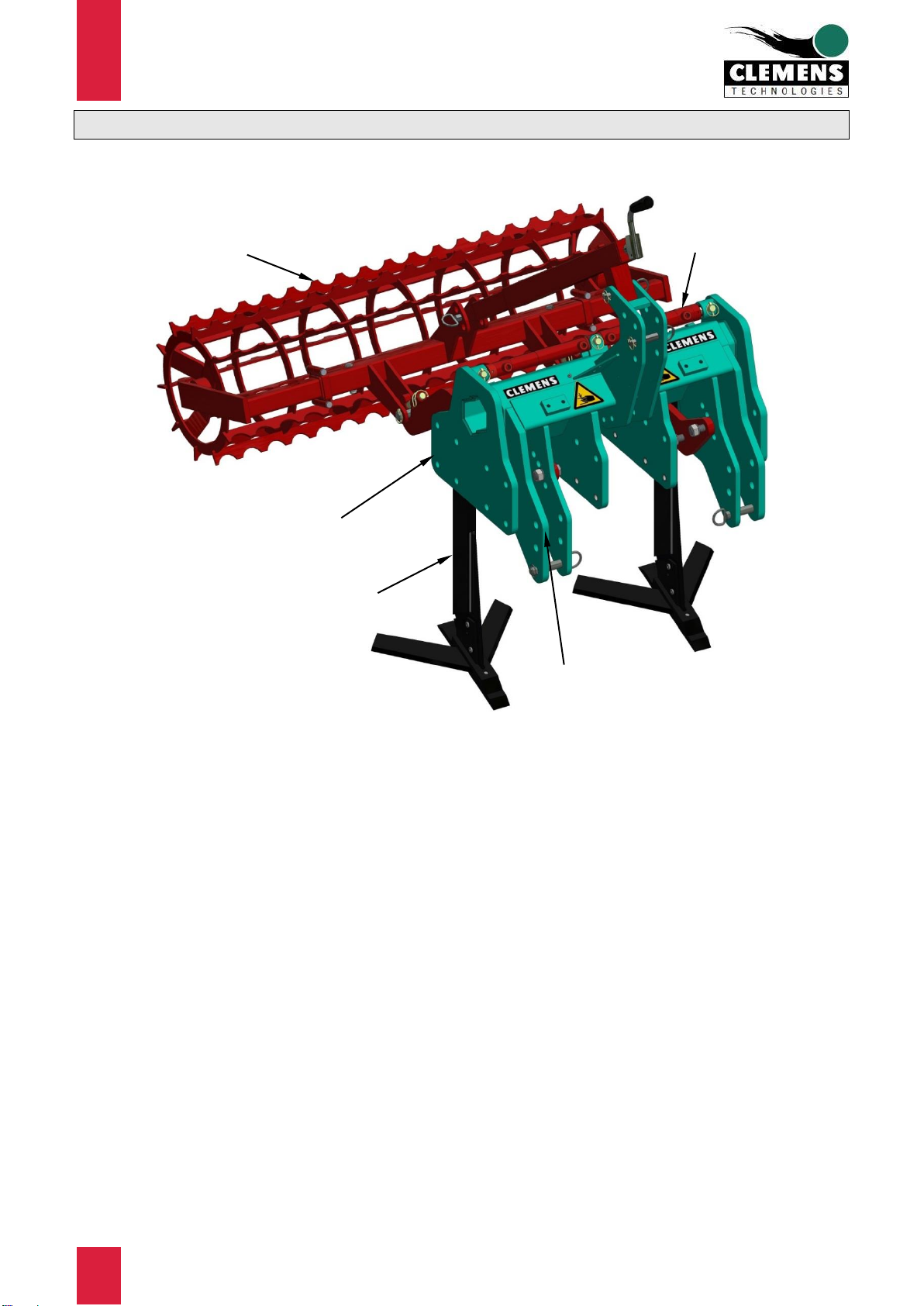

3Machine description: HEXAGON cultivator.........................................................................5

4Commissioning and working with the HEXAGON...............................................................6

4.1 Before initial commissioning ............................................................................................6

4.2 Attachment to tractor .......................................................................................................6

4.3 Working with the HEXAGON cultivator ............................................................................6

4.4 Mounting option C.DRIVE................................................................................................8

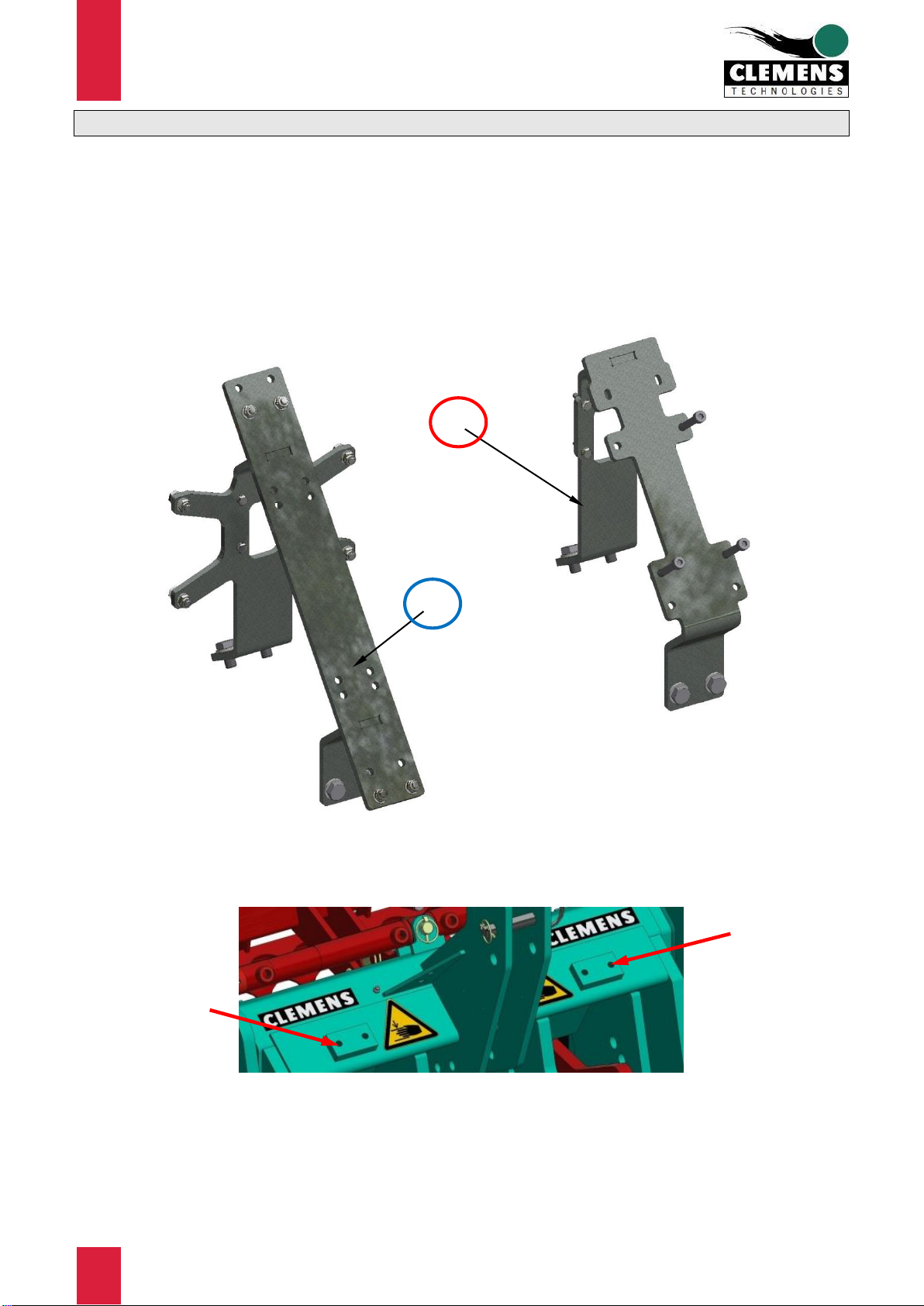

4.4.1 Mounting brackets for C.DRIVE components..........................................................................8

4.4.2 Application of the brackets to the HEXAGON cultivator..........................................................9

5Maintenance and care.........................................................................................................10

6Notes on safety....................................................................................................................11

7Technical data: HEXAGON cultivator.................................................................................12

8Spare parts list ....................................................................................................................13

8.1 Fixing points and hydraulic hoses (all models)...............................................................13

8.2 Basic frame with sliding units and hydraulic width adjustment (all models) ....................14

8.3 Master and slave cylinder for HEXAGON 729................................................................16

8.4 Master and slave cylinder for HEXAGON 723................................................................17

8.5 Master and slave cylinder for HEXAGON 724................................................................18

8.6 Extensions, guard rails, lower link extension..................................................................19

8.7 Disk harrow with mounting frame...................................................................................20

8.8 Accessories for disk harrow...........................................................................................21

8.9 Mounting plates for: RADIUS, central tool, chisel body..................................................22

8.10 Cultivator tine C-shaped with clamp...............................................................................23

8.11 Tine 80x25 complete .....................................................................................................24

8.12 Clamp for pivoting disc colter on tine 80x25...................................................................25

8.13 Set of Bison tines for ripping..........................................................................................26

8.14 Frame for land roller with spindle adjustment.................................................................28

8.15 Land roller Ø400 mm (16“) for open soil ........................................................................29

8.16 Cage rollers Ø400 mm (16“) for green cover..................................................................29

8.17 Support, lower link, support wheel mount ......................................................................30

8.18 Steel support wheel.......................................................................................................31

8.19 Support wheel, pneumatic .............................................................................................32

8.20 Oscillating support wheel, pneumatic.............................................................................34

9List of illustrations ..............................................................................................................36