3

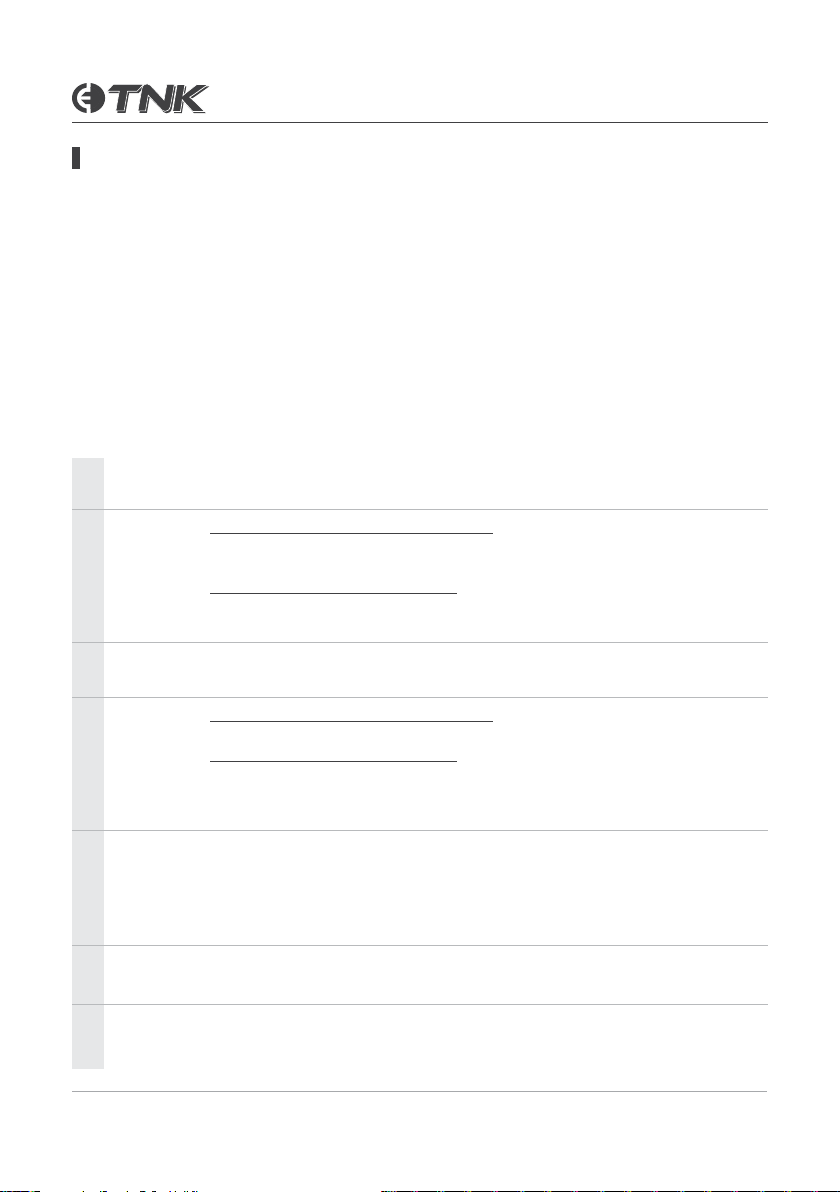

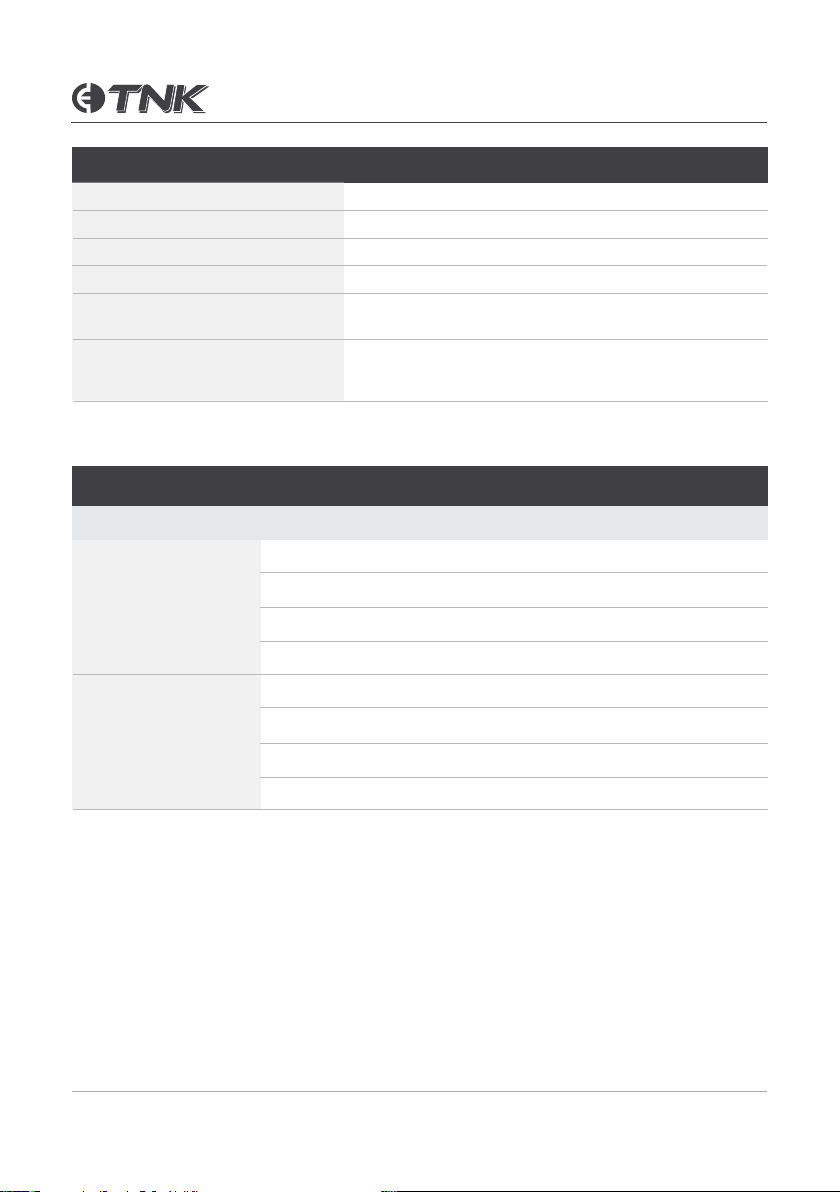

User Manual / TNK-10000LV-A1

Statement of Law

TNK is an energy storage solution designed in Australia and manufactured by Xiamen Well Energy

Technology Co., Ltd. Clenergy Technologies is the majority shareholder in this joint venture – Xiamen

Well Energy.

Xiamen Well Energy Technology Co., Ltd. owns the copyright of the document.

No part of this document may be excerpted, reproduced, translated, annotated or duplicated in any

form or by any means without the prior written permission of Xiamen Well Energy Technology Co.,

Ltd.

This product complies with the design requirements of environmental protection and personal safe-

ty. The storage, use and disposal of this product should be in accordance with the product manual,

relevant contract or relevant laws and regulations.

Customers can check for product or technology updates on Xiamen Well Energy Technology Co.,

Ltd.’s website.

The product may be subject to modification without prior notice to the user.

Safety Precautions

To prevent accidental fires or explosions, do not immerse the battery in water or expose it to exces-

sive heat.

Please connect wires correctly during installation. Do not reverse the polarity.

Do not connect the positive (+) or negative (–) terminals to any conductive material such as a wire to

prevent short circuits.

Do not subject the battery to any damage, such as piercing it with sharp objects, striking it with

heavy objects or trampling it.

Turn off the power completely when removing any device from the system or rewiring the system to

reduce the risk of electric shock.

In the unlikely event of fire danger on the battery, use a dry powder fire extinguisher. Using a liquid

fire extinguisher may lead to an explosion.

For your safety, please do not arbitrarily dismantle or disassemble any component. The maintenance

must be performed by authorised technical personnel or our company’s technical support team.

Failure to do so will result in malfunction and will void the warranty.

Do not dispose of the battery in household waste. To reduce environmental impacts, bring your

battery to a certified recycling depot at the end of its life.

Warning

- Statement of Law / Safety Precautions -