Click 'N Carve 8403 User manual

Index

Chapter 1 Introduction ............................................................................1-1

Chapter 2 Safety Instructions ................................................................2-1

2-1 Safety Regulation and Notice ..........................................................2-1

2-2 Electrical Requrements ...................................................................2-3

2-3 Wiring Diagram ...............................................................................2-4

2-4 Extension Cords ..............................................................................2-5

2-5 Grounding Instructions ....................................................................2-6

Chapter 3 Hardware Features ...............................................................3-1

Chapter 4 Item Included with the Engraver ..........................................4-1

Chapter 5 Software Installation .............................................................5-1

5-1 Change User Account Control settings ...........................................5-1

5-2 EDIT Installation ..............................................................................5-3

5-3 CNC Installation ..............................................................................5-7

Chapter 6 EDIT Application Instructions .............................................6-1

6-1 Knowing the Work Region ...............................................................6-2

6-1-1 Menu Introduction ..................................................................6-2

6-1-2 EDIT Tool List .........................................................................6-4

6-1-3 Working Area .........................................................................6-5

6-1-4 Output Setting Area ...............................................................6-5

1. Output Setting ..................................................................6-5

2. 3D View ............................................................................6-9

3. G-Code Transfer ...............................................................6-9

4. Recorder List .....................................................................6-9

6-1-5 Document Information ..............................................................6-9

6-2 Description of File Format .............................................................6-10

6-2-1 File Formats can be Opened and Saved ...............................6-11

6-2-2 Resolution ..............................................................................6-11

6-2-3 Denition of Color Tone .......................................................... 6-12

6-3 Denition of Tool ............................................................................ 6-13

6-3-1 System Preset Tool ................................................................ 6-13

6-3-2 Tool added by User ................................................................ 6-14

6-3-3 Characteristics of Each Type of Tool ......................................6-18

6-4 Examples ......................................................................................6-19

6-4-1 Application : Photo engraved on White Plastic Material

(acrylic) ..............................................................6-19

6-4-2 Application : Photo engraved on Semi-transparent Dark

Color Plastic Materials (acrylic) .........................6-22

6-4-3 Application : Carving a Human Face on Wood Material ........6-25

6-4-4 Frame .....................................................................................6-31

6-5 Software Error Messages and Troubleshooting ............................6-34

6-6 Frequently Asked Questions (FAQ) ...............................................6-35

Important: You should turn off "sleep", "hibernate" and “hybrid sleep" mode in

your computer before engraving, or this will affect engraving

operation.

CNC software can supported the le format that created by Vectric,

ArtCAM, Bmp software. Please save the le in G-Code(mm),

G-Code(inch), G-Code Arcs(mm) or G-Code Arcs(inch) format.

EDIT and CNC software require a PC that runs Windows XP,

Windows 7 or Windows Vista.

Chapter 7 Positioning and Connecting the Engraver .........................7-1

7-1 Placing the Engraver .......................................................................7-1

7-2 Connecting the Power Cord ............................................................7-3

7-3 Connecting the Engraver to the Computer ......................................7-3

Chapter 8 Knowing the CNC Work Region ..........................................8-1

8-1 Menu Introduction ............................................................................8-2

A. Menu Listing ..................................................................................8-2

B. Displays the G-Code Fields ...........................................................8-4

C. Main Function Area .......................................................................8-4

D. Information Fields ..........................................................................8-5

E. Coordinates ...................................................................................8-5

F . Manual Control Area ......................................................................8-5

G. Preview Window ............................................................................8-6

H. Spindle Speed ..............................................................................8-7

I . Feed Rate Speed .........................................................................8-7

8-2 Software Error and Warning Messages and Troubleshooting .........8-8

Chapter 9 Engraver Operation Guide ....................................................9-1

9-1 Environment Settings ......................................................................9-1

9-2 Controller and Hotkey Settings ........................................................9-3

9-2-1 Controller Functions .................................................................9-3

9-2-2 Controller and Hotkey Environment Settings ...........................9-3

9-3 Holding the Engraving Workpiece ....................................................9-7

9-3-1 Wood Material ..........................................................................9-7

9-3-2 Acrylic Material .........................................................................9-8

How to use Silicone Mat ..........................................................9-8

9-3-3 Other Material Stick on Support Board ....................................9-9

9-4 Use of Clamps ..............................................................................9-10

9-5 Tool Installation Procedure .............................................................9-12

9-6 Engraving Path Conrmation .........................................................9-13

9-7 Starting Point Set-up .....................................................................9-18

9-8 Engraving Debris Removal Steps .................................................9-19

9-9 Feed Rate Speed Adjustment Instructions ....................................9-20

Chapter 10 Application .........................................................................10-1

10-1 Photo Engraved ..........................................................................10-1

10-2 GO TO Z Application ....................................................................10-3

10-3 OFFSET Application ...................................................................10-5

Chapter 11 Maintenance and Cares ....................................................11-1

Chapter 12 Q & A ...................................................................................12-1

Chapter 13 Exploded Diagram and Parts List

...................................13-1

13-1 Exploded Diagram .......................................................................13-1

13-2 Parts List ....................................................................................13-2

13-3 Spare Parts ..................................................................................13-3

Chapter 14 Specification ......................................................................14-1

1

This Engraver is a computer controlled engraver which contents an user-

friendly software package and easy-to-operate engraver. This engraver is

ideal for novice who wants to learn CNC or school for education material or

hobbyist and artist for small production of their project. The only thing you

need is a computer and a digital photo that you want engraved on wood or

acrylic and that’s it!!!! Follow by step by step instruction and you can finish

your project with no sweat!

Please read and follow all Safety Regulation and Operating Instructions

before turning on this engraver. If you do not understand any statement,

please contact the authorized dealer or service center.

The data and information in this manual may be subject to change without any

prior notice.

Please keep the carton and packaging for further servicing.

Chapter 1 Introduction

2-1

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE REFERENCE.

Warning Label

The warning label as below will put on the engraver which indicate hazard

and understand the graphic on it. DO NOT remove this warning label from the

engraver.

Machine safety symbol is to remind operator to pay attention on it.

About Warning and Danger symbol

● Warning: a warning symbol means the presence of a hazard that has the

potential of causing moderate or minor personal injury.

● Danger: a danger symbol means the presence of a hazard that has the

potential of causing death or serious personal injury.

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with

grounded surface. For example: pipes, radiators, refrigerator enclosures.

3. WEAR EYE PROTECTION. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

4. WEAR FACE OR DUST MASK. Cutting dust may scatter, causing bodily

injury.

5. WEAR EAR PROTECTION. Prevent permanent hearing loss by wearing

ear protection. Power tools can generate high levels of noise.

6. SECURE WORK. Use clamps or a vise to hold work when practical. It’s

safer than using your hand.

7. WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties,

rings, bracelets, or other jewelry which may get caught in moving parts.

No slip footwear is recommended. Wear protective hair covering to contain

long hair.

8. CONSIDER WORK AREA ENVIRONMENTS. Remove materials or debris

that may get turned by sparks. Don’t use in damp or wet locations, or in the

presence of explosive atmospheres (gaseous dust, fumes, or flammable

materials) Keep work area well lighted, don’t expose power tools in rain.

Please operate under temperature at 5°C~40 °C (41~104 °F) and within a

humidity of 35~80%

9. DON’T USE IN STORM OR LIGHTNING. Doing so might get an electric

shock or cause severe injury.

Chapter 2 Safety Instructions

2-1 Safety Regulation and Notice

2-2

10.AIR VENTILATED THE WORK AREA. Do not cover the air inlet by cloth or

paper or stack up items nearby the power tool.

11.KEEP CHILDREN AND VISITORS AT SAFE DISTANCE. To avoid

accident, keep all children and visitors should be kept safe distance from

the power tool.

12.CHILDREN OPERATES WITH ADULT SUPERVISION. Failure to do so

may result in injury.

13.MAKE WORKSHOP KID PROOF with padlocks, master switches, or by

removing starter keys.

14.STORE IDLE TOOLS. When not in use, tools should be stored in dry and

high or lock in a place that out of reach of children.

15.STALL ON A STABLE SURFACE. Failure to do so may result in falling of

the tool and leading to injury.

16.DON’T OVERREACH. Keep proper footing and balance at all times.

Engraved area cannot bigger than its capacity.

17.REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking

to see that keys and adjusting wrenches are removed from tool before

turning it on.

18.DISCONNECT TOOLS FROM OUTLET. When it is not in use, before

changing accessories, or performing recommended maintenance,

disconnect tools from outlet.

19.DON’T FORCE TOOL. It will do the job better and safer at the rate for

which it was designed.

20.USE RIGHT TOOL. Don’t force small tool for attachment to do the job of a

heavy-duty tool. Don’t use tool for purpose not intended to.

21.CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine

that it will operate properly and perform its intended function – check for

alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or

other parts that is damaged should be properly repaired or replaced.

22.STOP OPERATING WHILE IN AN ABNORMAL PHENOMENON (smoke,

burning odor, unusual sounds..etc). If above happened, please stop

operating immediately and contact your authorized dealer or service

center.

23.AVOID LEAVE A RUNNING TOOL UNATTENDED. Never leave the tool

until it comes to a complete stop.

24.AVOID UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

25.USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for

recommended accessories. The use of improper accessories may cause

risk of injury to persons.

26.DO NOT HOLD OR STRESS THE SPINDLE DURING OPERATION.

Doing so will accelerate wear and cause premature failure.

27.MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best

and safest performance. Follow instructions for lubricating and changing

accessories. Inspect tool cords and extension cords periodically and if

damaged, please contact authorized dealer or service center and have it

repaired by them.

2-3

28.USE THE PROPER EXTENSION CORD. Only use the extension cord in

good condition. Never use more then one extension cord. Do not use the

extension cord with other electric products. Read “2-4 EXTENSION CORD”

section for more information.

29.DO NOT UNPLUG THE POWERCORD PLUG WITH WET HANDS. Doing

so may result in electrical shock.

30.DO NOT DISASSEMBLE, REPAIR, OR MODIFY. Doing so may lead to fire

or abnormal operation resulting in injury.

31.ONLY USE ATTACHED POWERCORD. Failure to do so may lead to fire or

electrical shock.

32.POWECORD MUST GROUNDED. Failure to do so may lead to fire or

electrocution.

33.DON’T ABUSE CORD. Never yank the cord to disconnect it from

receptacle, disconnect it from receptacle by hands. Keep cord away from

heat, oil and sharp edges. Do not destroy, modify, bend, twist, pull, binding

or pinching it nor place any object of weight on it .Inspect cords regularly

and repair or replace if damaged.

34.STAY ALERT Watch what you are doing. Use common sense. Do not

operate tool when you are tired.

35.DO NOT OPERATE ANY POWER TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY MEDICATION AFFECTING

ALTERNESS.

36.The usage of emergency stop: If there is any problem during engraving

and need to stop immediately, please press the emergency stop button to

stop the machine and motor to protect the operator.

● CONNECTING TOOL TO POWER SOURCE OUTLET. This machine

source must be

grounded while in use to protect the operator from electrical shock.

● In the event of a malfunction or breakdown, grounding provides a path of

least resistance for electrical current to reduce the risk of electrical shock.

This tool is equipped with an electric cord having equipment grounding

conductor and a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

● Do not modify the plug provided if it will not fit the outlet. Have the proper

outlet installed by a qualified electrician.

● Improper connection of the equipment-grounding conductor can result in a

risk of electric shock. The conductor with insulation having an outer surface

that is green (with or without yellow stripes) is the equipment-grounding

conductor. If repair or replacement of the electric cord or plug in necessary,

do not connect the equipment – grounding conductor to a live terminal.

● Check with a qualified electrician or service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether the

tool is properly grounded.

● Use only 3-wire extension cords that have 3-prong grounding plugs and

3-pole receptacles that accept the tool’s plug.

● Repair or replace damaged or worn cord immediately.

● Only UL Listed extension cords should be used with this product.

2-2 Electrical Requrements

2-4

● Improper use of extension cords may cause inefficient operation of your

tool, which can result in overheating. Be sure your extension cord is rated

to allow sufficient current flow to the motor. For the proper gauge for your

tool, see EXTENSION CORDS section below.

● Do not let your fingers touch the terminals of plug when installing or

removing the plug to or from the outlet.

● If not properly grounded, this power tool can incur the potential hazard of

electrical shock particularly when used in damp locations or in proximity to

plumbing.

2-3 Wiring Diagram

.

o

2-5

2-4 Extension Cords

WARNING:

To avoid permanent motor damage you must use the correct extension cord.

Never use more than one extension cord at a time.

Use proper extension cord and make sure your extension cord is in good

condition. When using an extension cord, make sure all cords are no smaller

than a #18 gauge and equipped with 3 prong plugs. Use of anything smaller

may result in the overheating or burn out of the motor. It is recommended to

have an electrician check the incoming voltage prior to usage to ensure safe

and efficient use. The smaller the gauge numbers the heavier the cord.

1. Use only extension cords that are intended for outdoor use. These

extension cords are identified by a marking "Acceptable for use with

outdoor appliances; store indoors while not in use." Use only extension

cords having an electrical rating not less than the rating of the product.

Do not use damaged extension cords. Examine extension cord before

using and replace if damaged. Do not abuse extension cords and do not

yank on any cord to disconnect. Keep cord away from heat and sharp

edges. Always disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

2. WARNING - To reduce the risk of electrocution, keep all connections dry

and off the ground. Do not touch plug with wet hands.

3. Ground Fault Circuit Interrupter (GFCI) protection should be provided

on the circuit(s) or outlet(s) to be used for the tile saw. Receptacles

are available having built-in GFCI protection and may be used for this

measure of safety.

2-6

2-5 Grounding Instructions

This tool is equipped with an electric cord having an equipment-grounding

conductor and grounding plug. The plus must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided-if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result

in a risk of electric shock. The conductor with insulation having an outer

surface that is green with or without yellow stripes is the equipment-

grounding conductor. If repair or replacement of the electric cord or plug

is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether the

tool is properly grounded.

Repair or replace damaged or worn cord immediately.

B. Grounded, cord-connected tools intended for use on a supply circuit

having a nominal rating less than 150volts; This tool is intended for use

on a circuit that has on outlet that looks like the one shown in figure A in

illustration 2. A temporary adapter, which looks like the adapter shown

in figure B in illustration 2, may be used to connect this plug to a 2-pole

receptacle as shown in figure B in illustration 2 if a properly grounded

outlet is not available. The temporary adapter should be used only until

a properly grounded outlet can be installed by a qualified electrician. The

green-colored rigid ear, lug, and the like, extending from the adapter must

be connected to a permanent ground such as properly grounded outlet

box.

A. All grounded, cord-

connected tools:

In the event of

a malfunction or

breakdown, grounding

provides a path of least

resistance for electric

current to reduce the risk

of electric shock.

3-1

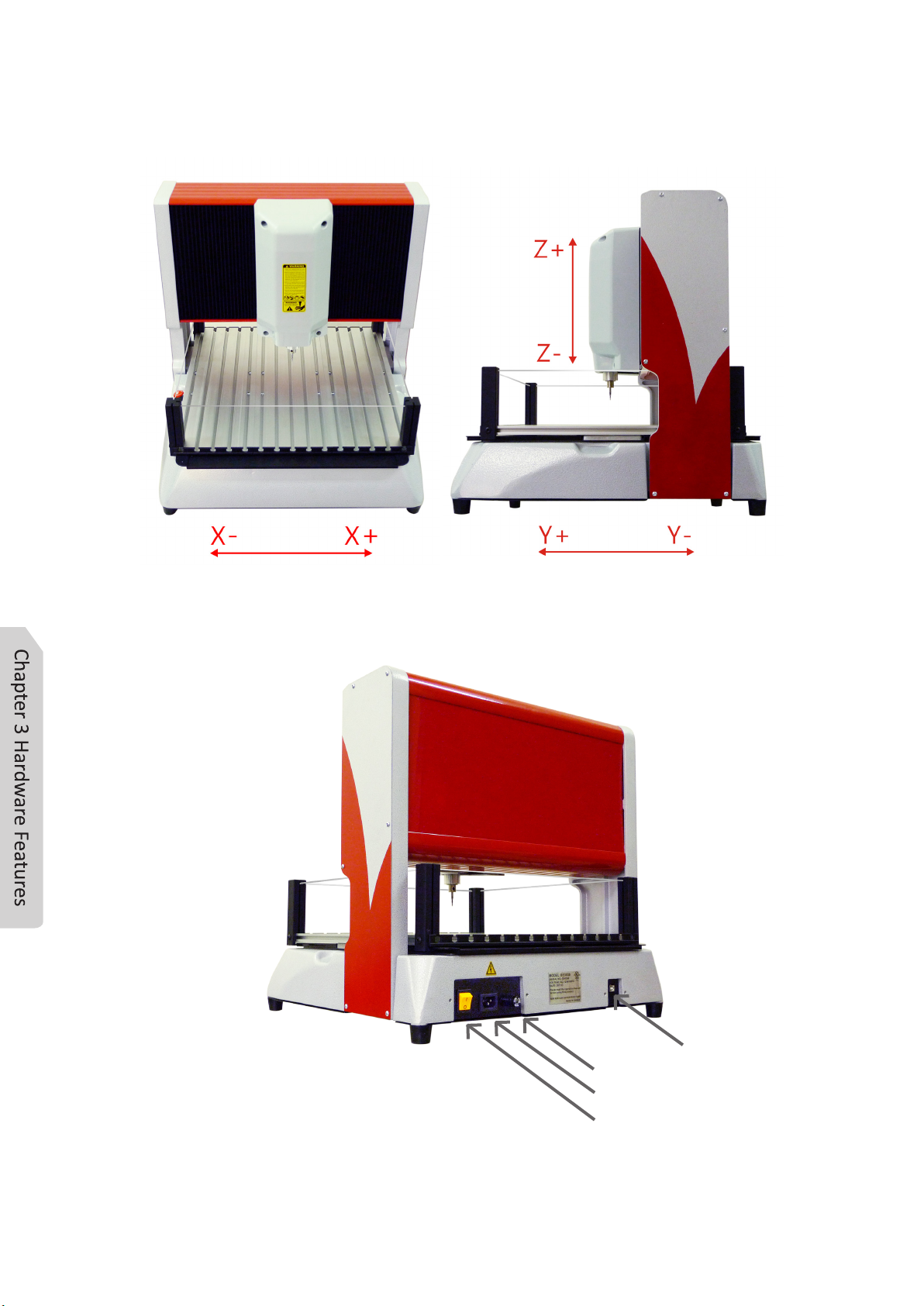

Chapter 3 Hardware Features

Front View:

Spindle Cover

Cutting Tool

Working Table

Emergency Stop

3-2

X, Y, Z axis direction:

Rear View:

Fuse

AC Power Supply

Switch

USB Port

3-3

Air Outlet:

Bottom Air Outlet

!

AIR VENTILATED THE WORK AREA.

Do not cover the air inlet by cloth or paper or stack up items nearby the

machine.

4-1

Chapter 4 Item Included with the Engraver

Power Cord × 1 USB Cable × 1 Controller × 1

Allen Key_2.5mm × 1 Silicone Mat × 1

Support Board × 1 Thin Paper × 1

( for Starting Point set-up)

BravoProdigy Software

Installation Disc × 1

Operating Instructions × 1 Engraving Material

Tungsten Carbide Tool × 2

Clamp Set

Small ×2 Big ×2

5-1

Chapter 5 Software Installation

5-1 Change User Account Control Settings :

If you are WINDOWS 7 or WINDOWS VISTA user, please modify the Setting

in UAC (User Account Control) when you install this software. The simple

procedure is as follow: [Start] -> [Control Panel] -> [[User Accounts] ->

[Change User Account Control settings] -> Adjust the slider to [Never notify] -

> [OK].

The detailed modify method is as follows:

1. Left click the Start button.

2. Open the Control Panel.

3. Click [User Accounts]

5-2

4. Click the [Change User Account Control settings]

5. WIN 7 user : Adjust the slider to [Never notify], then click .

Please reboot computer to complete this modification.

VISTA user : Uncheck the box for “ Use User Account Control (UAC)” and

then click .

Please reboot computer to complete this modification.

Note:For more information on how to change user account control setting,

please refer to your Laptop / Computer instruction manual.

5-3

5-2 EDIT Installation :

5-2-1 System Requirement for BravoProdigy EDIT:

5-2-2 EDIT Installation:

1. Place the BravoProdigy Installation Disc in the CD-ROM driver.

After inserting Installation Disc, the below image will pop up automatically.

If the installation program did not run automatically, please do as following:

Step1: Please open Windows Explorer or click Start-> (My) Computer, and

click “BravoProdigy Software” under “Devices with Removable

Storage” and right mouse click.

Step2: Choose “open” and double click “autorun.exe” to install.

The minimum requirement of computer is Pentium 4 2.6GHz RAM 1 GB.

Intel Pentium Duo-Core 3.0GHz RAM 2GB or better is recommended.

It is highly recommend not to using other software during engraving operation.

2.Click , set up by BravoProdigy Software

Setup Wizard. Please follow the instruction to install. If the software

wizard doesn’t appear automatically, then install by double-clicking

Software Disc.

5-4

4. Follow by BravoProdigy EDIT Software Setup Wizard. See image as below.

Press to process.

3. Please select the language and then click .

5-5

5. Copyright Agreement dialog will appear. Please read the Copyright

Agreement and fully understand. If you accept this Copyright Agreement,

please check “I accept the agreement” and press to continue.

6. Now, it will show the program location in the dialog. If you would like not to

select a different folder, please press after confirmation.

5-6

Note: If you want to change the location, press to change the

location of this software.

7. Press to install the software.

Table of contents