7

In this chapter you will go through the easy steps to engrave a coffee mug. A piece has been supplied

for you to experiment on. Don’t be disappointed if the first cup you create does not come out

perfect. With just a couple of attempts you will master the simple process and techniques and be

well on your way to getting the most out of your cylindrical engraver.

Step 1.

You must turn off limits when you start to use the Vision Cylindrical Engraver. To do this, hit “F2”

then the “Goto Home” key on the controller. Using this sequence, the controller toggles between

using limit switches and not using limit switches. This sequence is used repeatecly when you have a

Phoenix/Vision Cylindrical Combo system because the Phoenix has limit switches, but the Vision

Cylindrical does not.

NOTE: If you are using the Phoenix and want to change to the Vision Cylindrical Engraver, hit

“F2” then “Goto Home” before you change the A/B switch to the Vision Cylindrical En-

graver. If you are using the Vision Cylindrical Engraver and want to switch to the Phoenix, hit

“F2” then “Goto Home” before you change the A/B switch to the Phoenix.

Step 2.

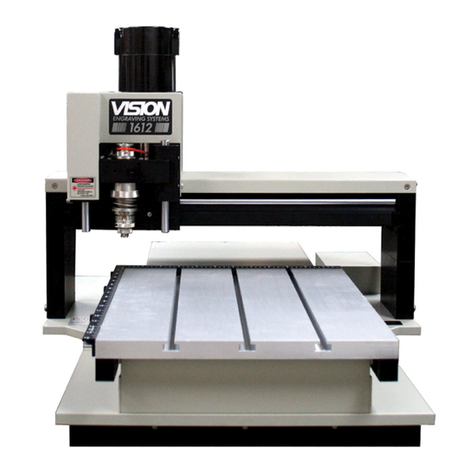

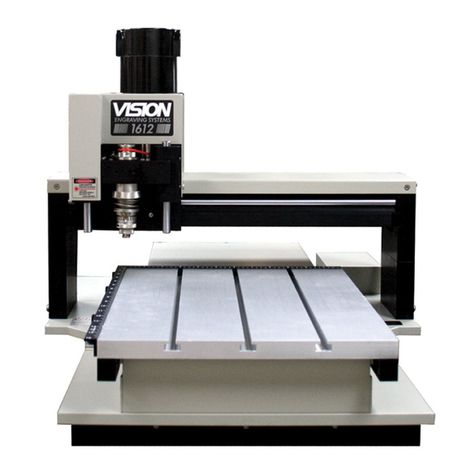

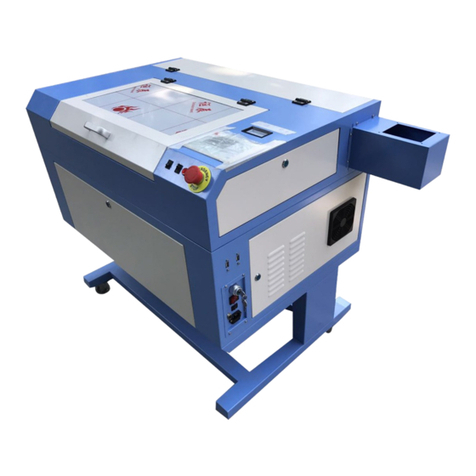

Refer to figure 2.1. By turning the black carriage adjustment knob located on the left side in the rear

of the unit, you can move the carriage out of the way to insert the coffee mug. You can

also move the carriage out of the way by using the controller jog keys, however, once

jogged from the controller, the knobs are then locked and you must continue to use

the jog keys from that point on.

Step 3.

Insert the mug as shown in figure 2.1 (top of the mug to the right), and move the tail stock over

until the mug is held in place. This is done by lifting the metal bar out of the grooved slots and

replacing in the grooves farther to the left. Rotate the tail stock handle to tighten or loosen to get a

secure hold on the mug. Care must be taken to center the cup in the tailstock and headstock.

NOTE: Do not over tighten. The friction of the rubber surfaced head and tailstock is generally

sufficient to hold most items in place. Lightly tighten. Over time you will become experienced with

the feeling of a secure mug or glass.

To ensure that the mug handle is not going to interfere with the engraving head,

simply rotate the secured mug until the handle is facing you as shown in figure

2.1.

CHAPTER 2 Quick Start to Cylindrical Engraving

The UP/DOWN Jog Keys will move the

carriage

The LEFT/RIGHT Jog Keys will rotate the head/

tailstock