Climate Wizard CW-H10 User manual

CW-H10, CW-H15 MOTOR

INSTALL GUIDE

1

CW-H10, CW-H15

862798-D AU US 1604

The motor frame is held in place by metal stops. Whilst

pulling on the inlet cone, carefully slide the motor frame

forwards and then up to clear the framework.

If required, a large flat head screwdriver may be inserted

between the motor frame and cooler body to gain

additional leverage.

Pull the motor out of the frame and clear of the cooler far

enough to gain access to the motor cable connections at

the back of the motor.

Remove the motor connection cover at the back of the

motor. Disconnect the motor cables (using a small flat

head screwdriver) and remove from the motor frame.

Move the old fan/motor assembly away from the cooler.

WARNING - ELECTRICAL WORK MUST ALWAYS BE

CARRIED OUT BY A QUALIFIED ELECTRICAL

WORKER !

Isolate the Cooler at the switchboard ensuring that the

circuit breaker or fuse cannot be turned on or re-installed

whilst work is being carried out on the cooler.

Step 1: Air Filter or Safety Grille Removal

Depending upon the options fitted, either the air

filter/cowling assemblies or inlet air safety grille will need

to be removed to allow access the motor front plate. Refer

to the installation, operation and maintenance manual for

instructions.

Before the existing motor can be removed, the excess

length of the motor power and control cables needs to be

fed into the inlet transition.

Remove the small side service door (control box side).

Identify and release the 2x cable glands fitted to the inlet

transition side wall as shown in Fig 1. Push all excess

length of these cables through the glands. There is no

need to remove the cables from the control enclosure.

Step 2: Release Excess Cable

1

Step 3: Remove Old Fan/Motor

Remove and discard the qty. 12 M6x16mm socket head

cap screws and flat washers (4 on side, 8 on face) from

the motor face plate as shown in Fig 2.

2

Step 4: Connect the New Motor

Motor Connection Schematics

Remove the new motor assembly from the crate. As items

may have moved in transit, check the fan/motor assembly

rotates freely and has even clearance between the inlet

cone and impeller.

Check the rating label on the NEW replacement motor and

confirm the motor model number is one of the following;

R3G560-RB32-01

(3~, 380-480V, 50/60Hz)

R3G560-RA25-21

(1~, 200-277V, 50/60Hz)

R3G560-AG31-11

(3~, 200-240V, 50/60Hz)

CW-H10, CW-H15 MOTOR

INSTALL GUIDE

3

2

CW-H10, CW-H15

862798-D AU US 1604

5

Step 4: Connect the New Motor cont.

Place the new fan/motor assembly near the cooler so that

the motor power and control cables can be connected.

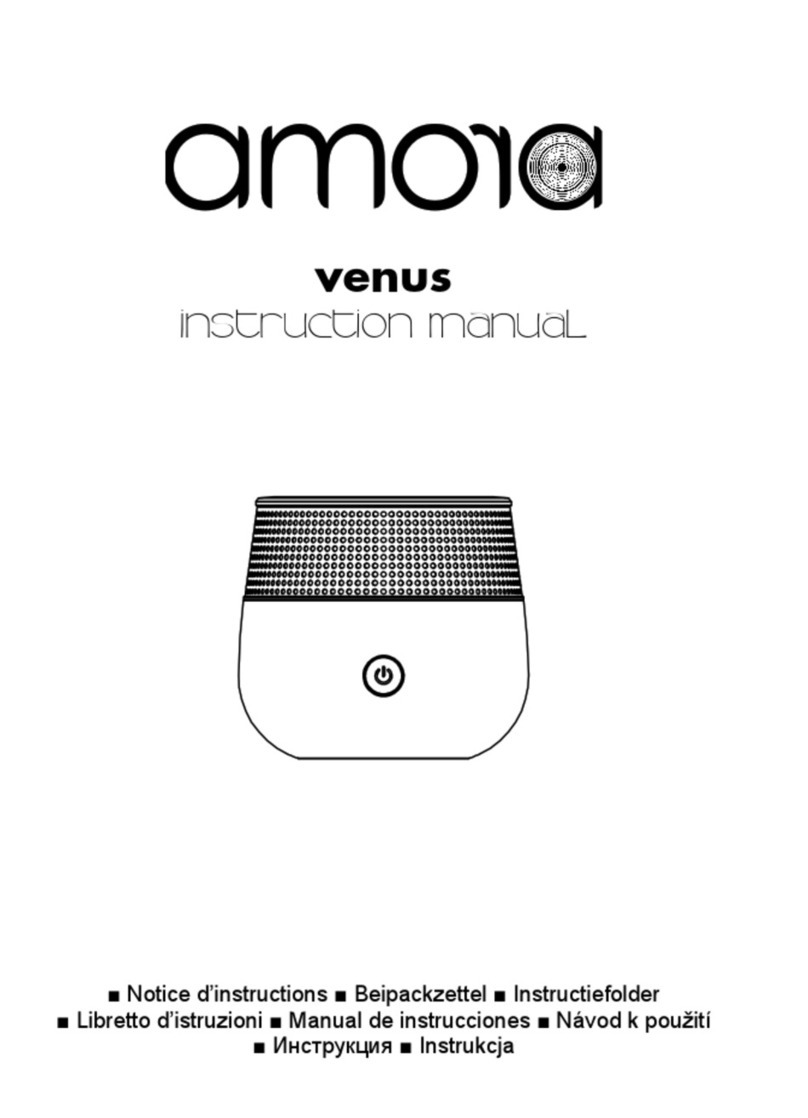

Pass both cables through the large rubber grommet in the

motor frame as shown in Fig 3.

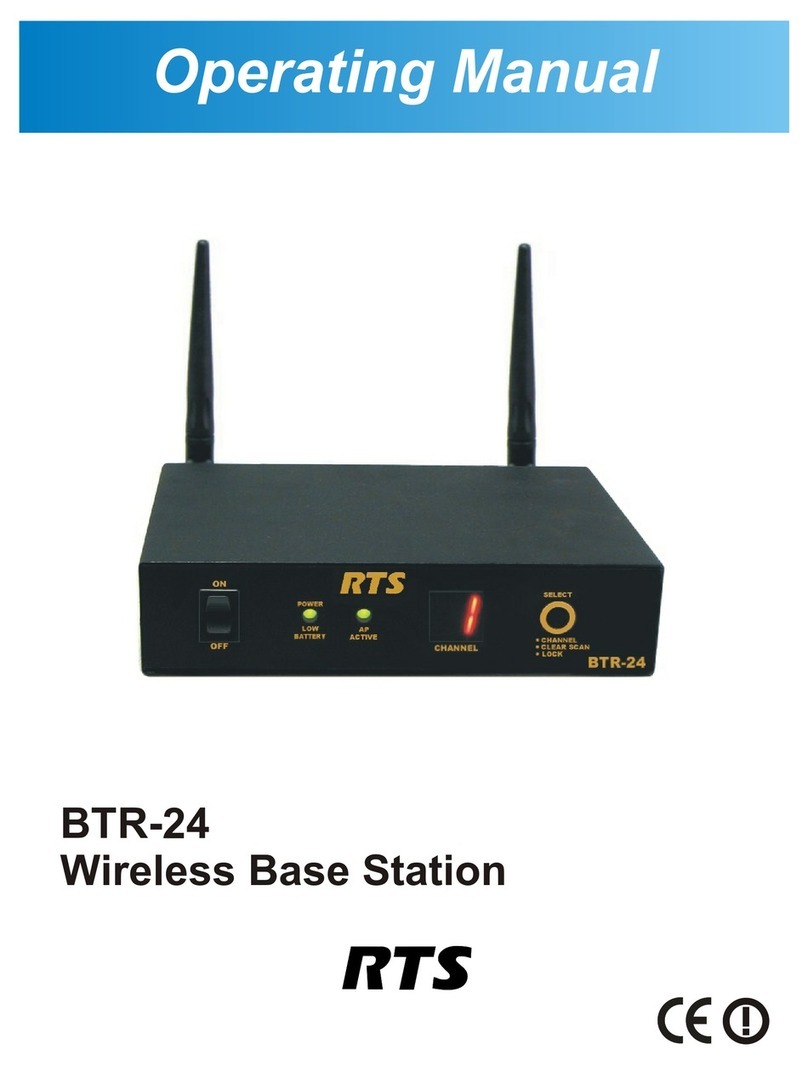

Remove the motor connection cover at the back of the

motor. Pass the motor power cable through the right hand

cable gland and the motor control cable through the left

hand cable gland. The middle cable gland is not used.

Wire the motor to the following schematic.

Ensure the cable glands are secure against the power

and control cables. Ensure the central connection has the

blanking plug fitted (refer Fig 4). Replace the connection

cover, applying a tightening torque of 3.5Nm to the

screws.

4

Zip-tie the cables to the motor frame where they pass

through the large grommet, leaving sufficient length of

cable to avoid any strain on the motor connection plate

glands.

Step 5: Fit the New Motor Assembly

Whilst taking care not to trap the motor power and control

cables, lift the motor/fan assembly into the cooler. As the

assembly is pushed fully back, slowly pull all excess cable

length through the 2x inlet transition glands.

Secure the motor/fan assembly with new Qty.12

M6x16mm Socket Head Cap Screws and Flat Washers,

applying a tightening torque of 5Nm.

Tighten the 2x cable glands in the inlet transition side wall.

Bundle and zip-tie all excess cable length inside the cooler

as shown in Fig 1.

Replace the small side service door, applying a coating of

anti-seize paste to the fasteners and a tightening torque of

3Nm.

Step 6: PCBA Replacement

Your motor replacement kit may contain a new PCBA.

This is required in instances where the replacement motor

is a newer model than the old motor. If no new PCBA has

been supplied, proceed to Step 7, otherwise complete this

step first.

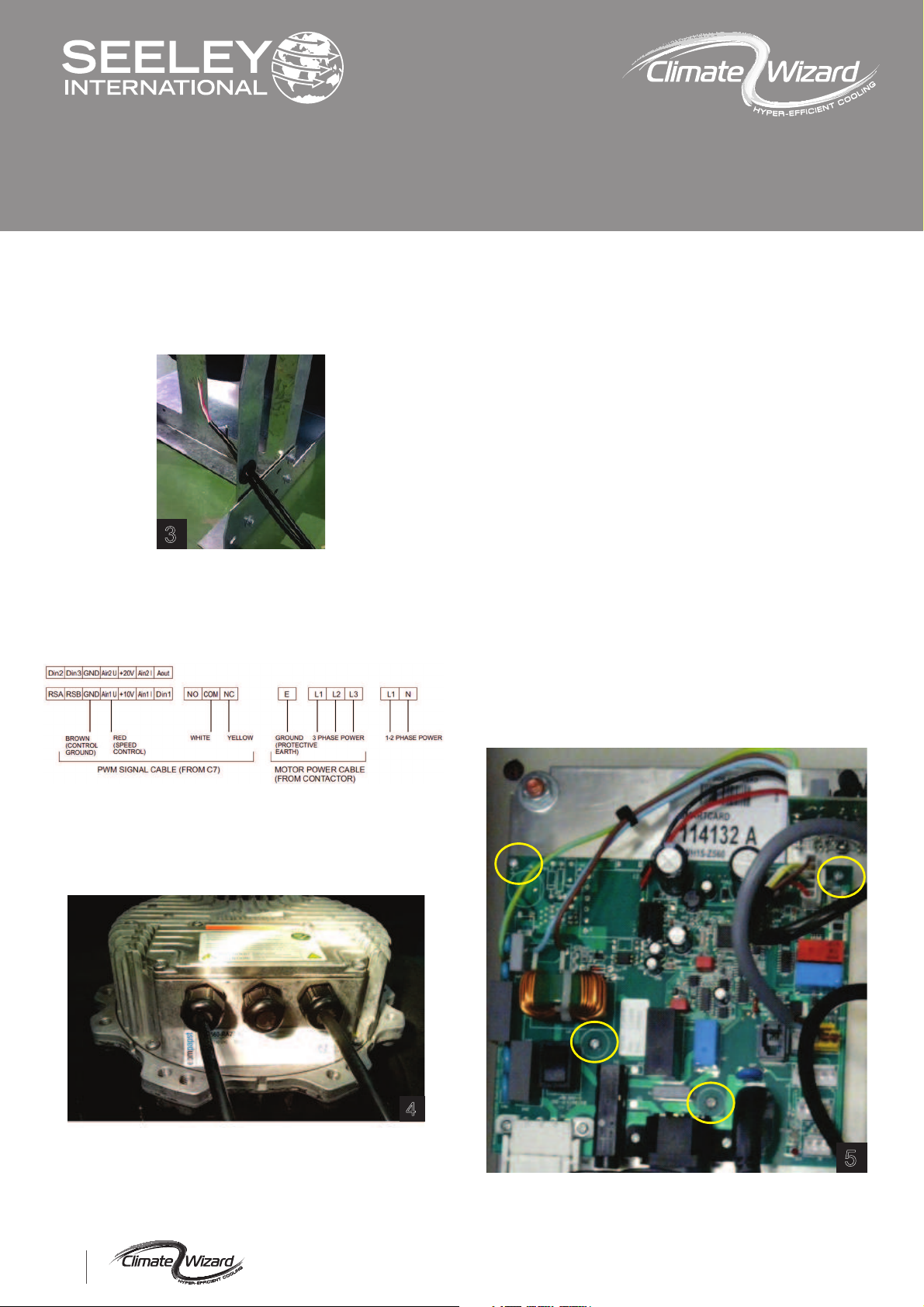

Open the control enclosure and disconnect all cables from

the old PCBA. The PCBA is the larger of the two circuit

boards. Release the PCBA by removing the Qty. 4 M3x3

Pan Head Screw and Star Washers shown in Fig 5.

5

Fit the new PCBA, apply a tightening torque of 1Nm.

Reconnect all the previously removed cables.

CW-H10, CW-H15 MOTOR

INSTALL GUIDE

3

CW-H10, CW-H15

862798-D AU US 1604

Step 7: Smart Card Replacement

Your motor replacement kit will contain a new Smart Card.

Insert the new Smart Card into the PCBA with label facing

out as shown in Fig 5.

The new smart card contains the data required for the

new motor to function correctly and needs to be used

whether the PCBA has been replaced or not.

Step 8: Motor Ground Bond Test

WARNING –The ground bond test is an important

safety check. It confirms that the motor is well

connected to the cooler's ground pin.

As shown in Figures 6 and 7, connect an ohmmeter to the

cooler as follows;

Connect the first test lead to the controls enclosure cable

earth pin.

Confirm the measured resistance is 0.1 Ohms

(1000 Milliohms) or lower.

6

7

Connect the second test lead to the head of an inlet cone

fastener.

Step 8: Functional Test

WARNING –DO NOT OPERATE THE FAN WITHOUT A

SUITABLE GUARD. REFIT THE AIR FILTER FRAME OR

INLET AIR SAFETY GRILLE PRIOR TO STARTING

MOTOR.

Start the cooler in vent mode. Confirm that the fan starts,

rotates in a clockwise direction and the speed changes as

it is adjusted using the wall control.

Confirm there is no excessive vibration or unusual noise.

Step 9: Air Discharge Damper Setup

If removed in Step 1, fully re-fit the air filters and cowling

assemblies. Refer to the Installation, Operation and

Maintenance Manual for instructions.

In instances where the replacement motor is a newer

model than the old motor, it is likely that the new fan/motor

may have slightly different air flow performance. It is

strongly recommended that the airflow balancing

procedure found in the Commissioning Section of the

Installation, Operation and Maintenance Manual be

repeated using the following Pressure Settings appropriate

to your Climate Wizard Model;

CW-H10: 155 Pa (0.62 in wg static)

CW-H15: 190 Pa (0.76 in wg static)

CW-H15S: 120 Pa (0.48 in wg static)

CW-H15S (Winery): 165 Pa (0.66 in wg static)

Where different from the Installation, Operation and

Maintenance Manual, the Pressure Settings in this

installation guide takes precedence. This will ensure the

setup of the cooler is optimised for best cooling

performance.

CW-H10, CW-H15 MOTOR

INSTALL GUIDE

4

CW-H10, CW-H15

862798-D AU US 1604

AUSTRALIA

1300 650 399

1300 367 437

1300 650 644

Seeley International Technical Support

Seeley Spare Parts Distributors

Authorised Service Agents

(All regions outside Australia: For any inquiries, please contact your local Breezair

distributor)

- Failure to install and commission the product in compliance with these

instructions, or failure to do the job properly and competently, may void the

customer’s warranty. Further, it could expose the Installer and/or the Retailer to

serious liability.

WARNING

It is the policy of Seeley International to introduce continual product improvement.

Accordingly, specifications on this document are subject to change without notice.

Whilst every care has been taken to ensure data accuracy, Seeley International Pty

Ltd does not assume liability for any errors and or omissions.

Notes

Other manuals for CW-H10

2

This manual suits for next models

1

Popular Accessories manuals by other brands

Jupiter Avionics

Jupiter Avionics JA72-006 Installation and operating manual

Mr Safe

Mr Safe KB-350 user manual

LU-VE

LU-VE F31HC Series Installation, Operation, Service and Maintenance Instructions

Philips

Philips HF3519 user manual

Tripp Lite

Tripp Lite UPB-20K0-2U1C owner's manual

Sentera Controls

Sentera Controls FCMFFB-R Mounting and operating instructions