Climer ECOHEAT TD EH500TD User manual

INSTALLATION AND USER MANUAL

ECOHEAT TD

EH500TD

INSTALLATION AND USER MANUAL

ECOHEAT TD

V1REV5EN1222

INSTALLATION AND USER MANUAL

ECOHEAT TD

V1REV5EN1222

1. INTRODUCTION ............................................................................................................1

2. GENERAL INDICATIONS...............................................................................................1

3. TECHNICAL INFORMATION..........................................................................................2

4. INSTALLATION STEPS.................................................................................................. 6

5. THERMODYNAMIC SOLAR PANEL INSTALLATION ....................................................7

6. PLACING ECOHEAT...................................................................................................... 9

7. CONNECTION BETWEEN ECOHEAT TD AND PANELS............................................ 10

8. HYDRAULIC CONNECTION ........................................................................................ 14

9. ELECTRICAL CONNECTION....................................................................................... 15

10. COMISSIONING. CONTROLLER.................................................................................16

11. WARRANTY CONDITIONS..........................................................................................26

INSTALLATION AND USER MANUAL

ECOHEAT TD

V1REV5EN1222

INSTALLATION AND USER MANUAL

ECOHEAT TD

1V1REV5EN1222

1. INTRODUCTION

This product has been manufactured according to the European Quality Standards,

incorporates prime grade materials and its correct working has been tested before it leaves our

facilities.

Through this Installation and User Manual, you will be guide towards the correct and safety

installation of the product. It is necessary to carefully read this manual before making any

handling to avoid problems arising from the misuse of the product.

The company reserves the right to modify the information included in this document at any

time without prior notice.

2. GENERAL INDICATIONS

2.1. Safety notes

The incorrect or inappropriate use of this product could lead to hazardous situations, causing

damage or injuries to the user, third parties or even to the product itself or material goods.

-The installer has the responsibility to install the minimum safety devices (hydraulic and

electrical) set out in this Manual. In case of failure, the lack of any device may cause

burns or other injuries.

-The installer has the responsibility to inform the user about the function and placement

of the safety devices installed into the device and the installation.

-The water outlet temperature could reach 62 degrees. Do not touch the pipes while

the system is working to avoid any risk of burns.

2.2. Installer’s qualification

Since the installation of the ECOHEAT TD involves handling coolant as well as carry out

welding work, it is needed the technical staff have the official certification that accredits them

as authorized to handle coolants.

The installer must explain the user the application of the product and the use and

management of the unit, and he should provide the user all the documentation supplied

with the equipment.

INSTALLATION AND USER MANUAL

ECOHEAT TD

2V1REV5EN1222

2.3. Package contents

The ECOHEAT system comprises the following components:

-ECOHEAT TD

-Thermodynamic panels

-Liquid distributors

-Anchoring elements

-Silent-Blocks

-User Manual

2.4. Indications about transport and unpacking the unit

The unit is supplied packed into a wooden pallet properly secured to prevent damage

during transport.

The materials used to the packing are recyclables, so dispose it in an appropriate container.

Use a forklift or hand pallet truck to transport the unit to the installation site, always

introducing the forks into the bottom of the pallet being careful not to damage the unit.

In case you identify any damage at the time of the reception of the unit, it is mandatory to

register it in the reception note of the transport company, and then, submit the complaint.

For this reason, it is recommended to make a thorough visual inspection of the goods before

signing the reception note.

3. TECHNICAL INFORMATION

3.1. Operating Principle

INSTALLATION AND USER MANUAL

ECOHEAT TD

3V1REV5EN1222

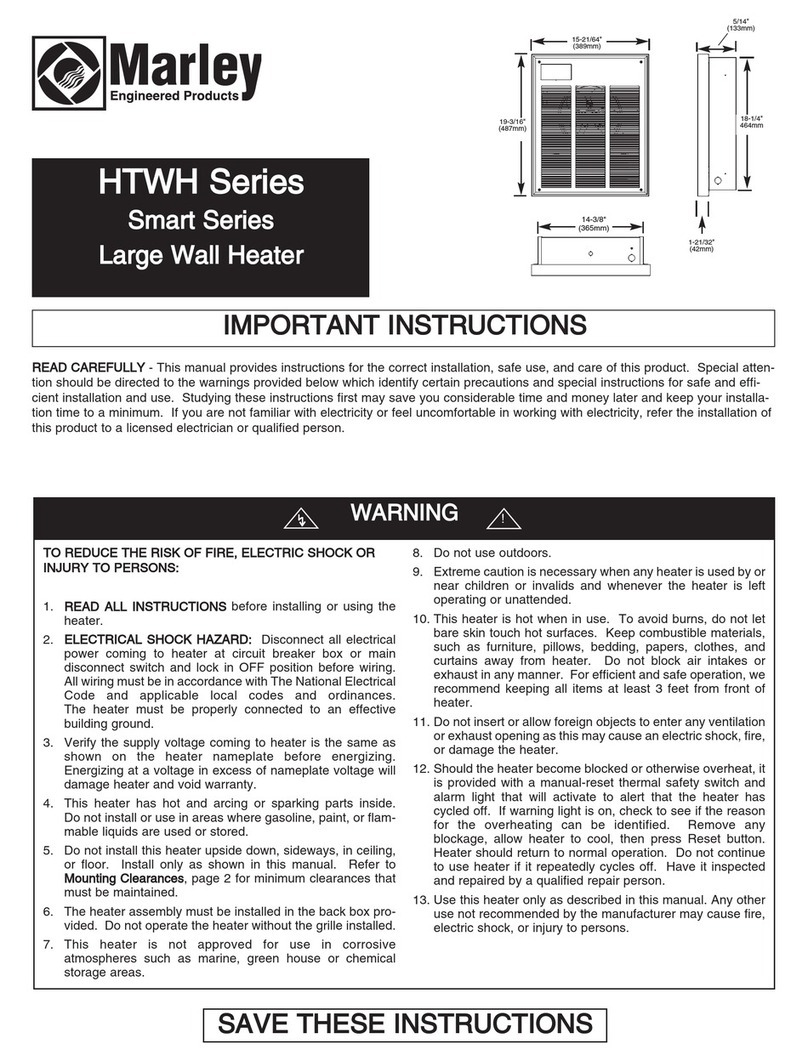

3.2. Dimension drawings

It is possible to remove the side and front casing access easily to any part of the system.

INSTALLATION AND USER MANUAL

ECOHEAT TD

4V1REV5EN1222

Dimensions, mm

EH500TD

A

702

B

785

C

2066

D

1326

E

191

F

250

Back connections

Front connections

F

Refrigerant inlet (gas), 1/2‘’

J

Hot water outlet, 1‘’

G

Refrigerant outlet (liquid), 3/8”

K

Recirculation connection, 1’’

H

Power supply 230 V/1PH/50 Hz

L

Electrical heater / Temperature probe

I

Cold water inlet, 1’’

INSTALLATION AND USER MANUAL

ECOHEAT TD

5V1REV5EN1222

3.3. Technical data

*Depends on ambient temperature and solar radiation

Thermodynamic panel dimensions:

INSTALLATION AND USER MANUAL

ECOHEAT TD

6V1REV5EN1222

4. INSTALLATION STEPS

Before starting the installation, check the availability of all the necessary components and tools:

-Copper tee for gas line: 2 inlets 3/8 - 1 outlet 1/2

-Liquid distributor (supplied): 1 inlet 3/8 - 2 outlets 1/4

-High- and low-pressure manometers

-Vacuum pump

-Scales

-Nitrogen bottle

-Refrigerant quality copper pipe

-Pipe-cutter

-Tube bender

-Pipe expander

-Welder

-Copper Rods (40% Silver)

-Insulating hose

-Drill

-Screwdriver

-Hydraulic installation components

-Electric installation components

Once it has been checked that it is available all the necessary components and tools, the

installer should follow the next steps:

1. Placing and anchoring panels

2. Joining and welding the refrigerant pipes

3. Placing the ECOHEAT TD

4. Joining and welding liquid and suction line between ECOHEAT TD and panel

5. Nitrogen pressure test (maximum 10 bar)

6. Vacuum

7. Filling refrigerant installation

8. Hydraulic installation

9. Electric installation

INSTALLATION AND USER MANUAL

ECOHEAT TD

7V1REV5EN1222

10. Commissioning

11. Adjustment of refrigerant load

5. THERMODYNAMIC SOLAR PANEL INSTALLATION

5.1. Site selection

The choice of the installation site of the thermodynamic panel is a key factor in the final

performance of the unit. For this reason, we recommend following the indications to achieve

the best performance:

-South orientation is indeed the best to take the maximum advantage of solar radiation.

Panel may also have other orientations, but northerly orientation is the worst to receive

solar radiation.

-Inclination: The minimum inclination of the panel is 45º to ensure the correct

evaporation of the coolant. It is recommended to install the panel with an inclination

between 45º and 90º. The minimum inclination of the panel must be 5º to ensure the

correct evaporation of the fluid.

-Direction: The panel can be installed in a vertical or horizontal position. In the case of

horizontal installation, the refrigerant inlet will be made through the lower part of the

panel.

-Distance to the equipment: The maximum distance allowed from the panels to the

equipment is 15 meters (sum of the distances L1 + L2 + L3 + L4 in the following figure).

INSTALLATION AND USER MANUAL

ECOHEAT TD

8V1REV5EN1222

5.2. Anchoring panel

Beside the panel, it is supplied a bag with anchoring elements that contains the following

pieces:

When the panel is installed in vertical

position, always the inlet and outlet

connection has been at the bottom.

(It is not allowed to install the reverse)

If the panel is installed at

horizontal position, refrigerant

inlet pipe should be connected

into the bottom connection.

Ref.

Qty.

Panel

1

1

Aluminium support

(L shape)

2

6

Screw M5

3

6

Nut M5

5

6

Washer 5

4

12

Sheet metal screw

6

6

Block M6

7

6

INSTALLATION AND USER MANUAL

ECOHEAT TD

9V1REV5EN1222

Anchor the panels using the lateral and front holes to the suitable surface.

6. PLACING ECOHEAT

The place where the system will be installed should allow an easy access to make maintenance

work or inspection.

Air outlet of ECOHEAT is around 5-10 degrees below inlet temperature, so in case that the

exhaust air would not be ducted, the room temperature will be considerably reduced.

Beside these factors, it is important to consider the following indications regards the installation

site:

-The system has been designed and manufactured for it indoors utilization. Install the

system in a dry, frost-free room at a minimum temperature of 5ºC.

-Installer must install the supplied Silent blocks to avoid the transmission of vibration.

INSTALLATION AND USER MANUAL

ECOHEAT TD

10 V1REV5EN1222

7. CONNECTION BETWEEN ECOHEAT TD AND PANELS

a. Pipeline installation

First, measure the distance between Ecoheat and Panels and cut the appropriate copper

pipe length. The diameter for each line is:

-Liquid line: 3/8 inch

-Gas line: ½ inch

b. Distributor/ collector installation

Install a cooper tee to distribute and collect the refrigerant to/from the panels.

Its function is to ensure the homogeneous refrigerant flow in the whole panel installation.

The installer must weld the following accessories:

-Gas line: T connection with 2 connections of 3/8 inch (Panels) and 1 connection of

½ inch (Ecoheat)

-Liquid line: Liquid distributor with 2 connections of ¼ inch (Panels) and 1

connection of 3/8 inch (Ecoheat)

Install the distributor vertically, face upwards according to the picture:

IMPORTANT: To ensure the same flow of refrigerant in every panel and consequently take

advantage of the evaporation surface entirely; you should install the same tube length from

the distributor to each panel. If a pipe is too long for the length require, it must be rolled

up.

INSTALLATION AND USER MANUAL

ECOHEAT TD

11 V1REV5EN1222

IMPORTANT: It is recommended to weld pipelines by oxyacetylene welding.

Welding is a critical step in the installation and to do it well ensures that the system will run

properly along its useful life.

Only expert staff should make this step by using proper tools and high-quality materials.

INSTALLATION AND USER MANUAL

ECOHEAT TD

12 V1REV5EN1222

c. Join refrigerant pipes to the Panels and Ecoheat

Panels are supplied with two nuts for the inlet and outlet connection. The inlet to each panel

is 1/2 inch diameter. The installer has to insert the nut into the copper pipe, flare the pipe

and then use the nut to fit it.

Repeat the procedure with the outlet connection using 3/4 inch copper pipe.

Then, join the suction line that comes from the panel to the coolant inlet of ECOHEAT, and

the liquid line to the coolant outlet. The connections are threaded, if welding is needed,

weld by oxyacetylene welding.

INSTALLATION AND USER MANUAL

ECOHEAT TD

13 V1REV5EN1222

IMPORTANT (Only when welding is needed):

It is recommended to weld pipelines by oxyacetylene welding.

Welding is a critical step in the installation and to do it well ensures that the system will run

properly along its useful life.

Only expert staff should make this step by using proper tools and high-quality materials.

d. Nitrogen test and cleaning procedure

To check the tightness, introduce nitrogen by using the pressure gauge already installed

into load ports.

CAUTION: Never exceed a nitrogen load greater than 10 bars.

Use leaking detector fluid at every welding and even in panel’s connections to verify the

absence of leaks.

e. Vacuum

Connect the vacuum pipe to the pressure gauge to carry out a vacuum of the whole

installation.

f. Coolant filling

Open the load ports to fill the circuit with the refrigerant loaded into the system.

INSTALLATION AND USER MANUAL

ECOHEAT TD

14 V1REV5EN1222

8. HYDRAULIC CONNECTION

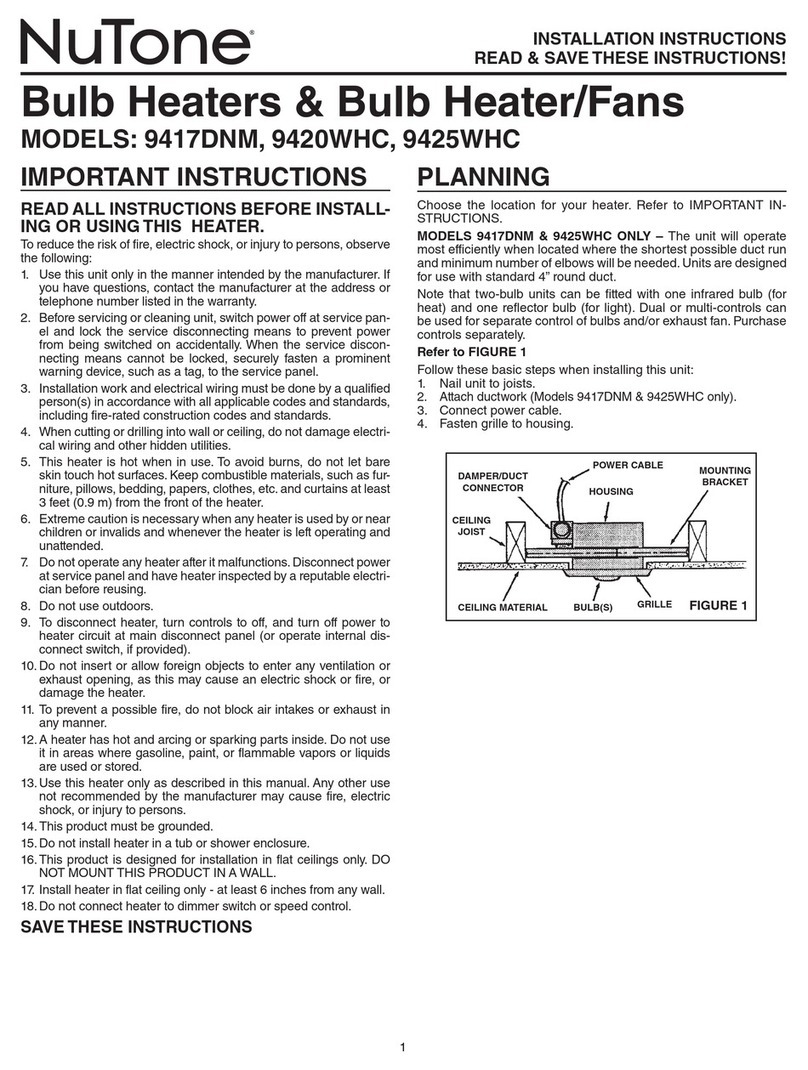

The hydraulic connections are shown in the following scheme:

The installer must install the following components of the hydraulic circuit shown in the scheme.

-Cold water inlet (1)

-Ball valves (2)

-Pressure reducing valve (3)

-Non- return valve (4)

-Lined Filter Strainer (Y Type) (5)

-Drain (6)

-Safety valve (7)

-Expansion vessel (8)

-Check valve (9)

-Recirculation pump (10)

-DHW (11)

Once the hydraulic connections are made, vent the circuit to avoid the air inside the installation.

INSTALLATION AND USER MANUAL

ECOHEAT TD

15 V1REV5EN1222

9. ELECTRICAL CONNECTION

The power supply of the system is 230 V/1/50 Hz. The power supply line must be protected

with a 16 A circuit breaker. The electrical scheme is shown in the picture below:

PV: Photovoltaic connection

LPS: Low pressure switch

HPS: High pressure switch

NTC1: Water temperature probe

D: Display

R: Electrical heater

K: Compressor

230 VAC: Power supply

A1-A2: Relay

INSTALLATION AND USER MANUAL

ECOHEAT TD

16 V1REV5EN1222

10. COMISSIONING. CONTROLLER.

10.1. User interface connection D ESC R IPT I

Symbol

Meaning when it lights

Compressor switched on

Alarm active

Compressor working hours exceeded

Unit in ºC

Unit in ºF

Electric heater switched on

Stand-by

Table of contents

Other Climer Heater manuals

Popular Heater manuals by other brands

LVI

LVI YALI COMFORT Installation and operating manual

GET

GET G4HAL instructions

NuTone

NuTone 9417DNM installation instructions

Kampmann

Kampmann Katherm QK nano Assembly and installation instructions

Atlantic

Atlantic SOKIO quick start guide

Twin-Star International

Twin-Star International Duraflame 10HM9275-M323 manual