CI-154 User’s Manual

Page 4

Counts may be displayed and printed in a variety of formats, including Total Count,

Differential Count, Concentration per Cubic Foot, Concentration per Cubic Liter, and

Concentration per Cubic Meter. Alarm settings are available for each particle

channel, including a Beep On Count setting that is useful in filter scanning

applications. In addition to the particle channel alarms, alarms can be set for the

sample flow rate.

Up to 3,000 samples can be stored in the internal memory, and can be transferred

as a comma delimited ASCII file through the RS-232 serial port or Ethernet port to a

computer. They can be easily transferred to common spreadsheets. All samples are

date and time stamped. Once the data is taken, the user can view or print a variety

of reports, such as Alarm Violations, Averages, ISO 14644-1, GMP, or Federal

Standard 209E.

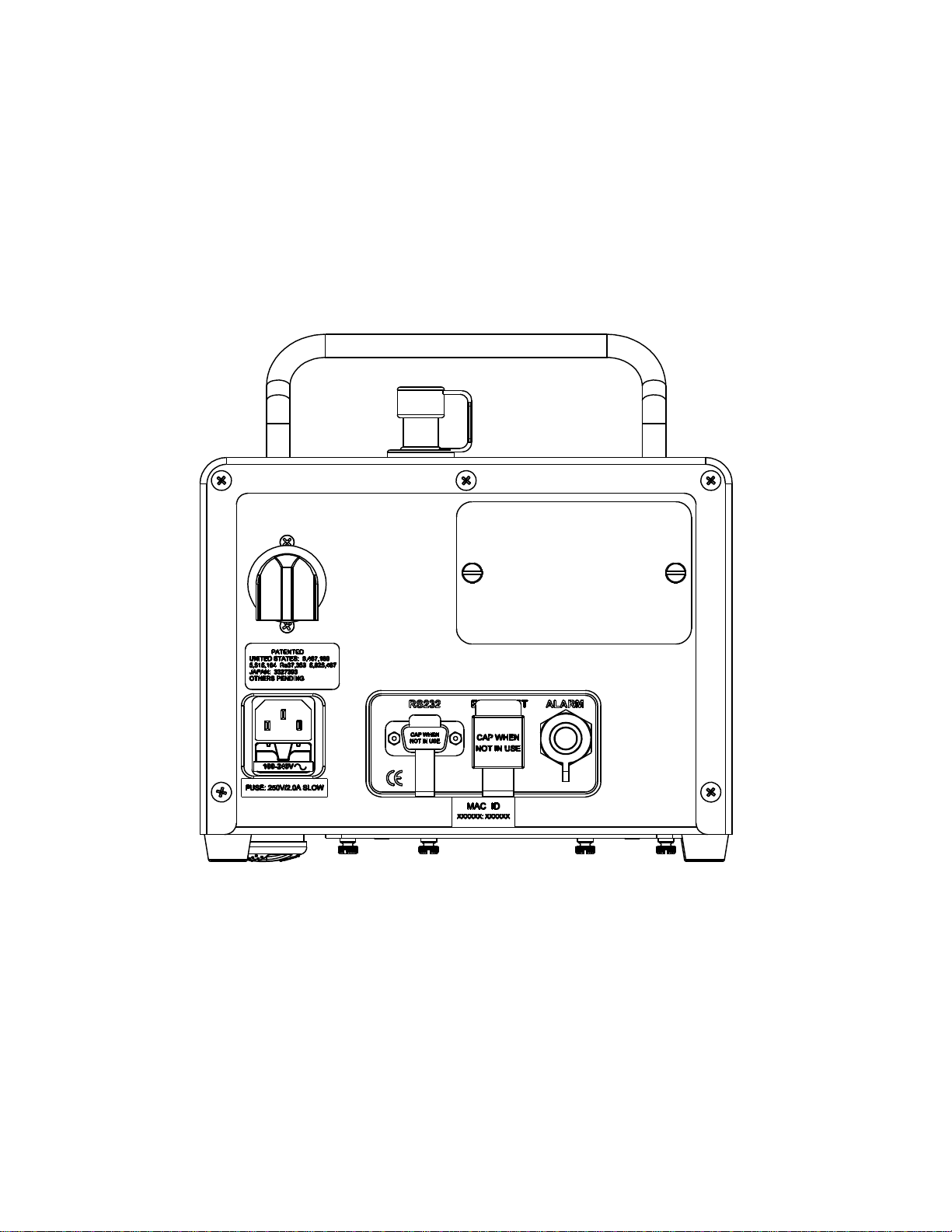

A USB port is available on the front panel for connecting a USB jump drive. The

samples stored in the internal memory can be copied to a file on the drive. The data

in the file is comma separated text with a check code at the end for verifying data

integrity. User programs containing location ID’s and settings can also be read out

and written to the drive. The USB clone feature enables settings to be duplicated

from one unit to another. The USB menu system appears when the drive is inserted.

An alphanumeric keypad is provided on the touch screen for entering location IDs.

Each sample may be assigned to a location ID when it is acquired. A numeric keypad

is provided on the touch screen for entering sample volumes, delays, alarms, and

other numerically set parameters. A distinct initial delay may be set independent of

subsequent delays between samples. This feature gives the operator extra time to

clear the area before the particle counter begins sampling. Other sample settings

program the CI-154 to take a certain number of samples, then stop, or to take

samples once every given time period. Averages can be automatically printed at the

end of a given number of samples. The blower (pump) is turned off during long

delays to conserve battery power.

Once all of the settings are determined, they may be saved as a program using a

name determined by the user. Up to 100 location IDs are also saved with the

program. This enables the user to recall a set of locations and sample settings for a

given test situation. Up to 30 programs with 100 IDs each may be saved in the

internal memory. Reports are grouped by program names. Therefore, the user can

assign programs named for certain areas for which separate reports are required.

The CI-154 has a user authentication and password protection feature that can be

enabled. This feature allows certain permissions to be granted users depending on

their access level. User names are printed on all reports and records when this

feature is enabled. Users are authenticated by their personal private passwords. A

supervisor level is provided for administering users. Up to 20 users may be defined

with one of four access levels. Access levels are applied to the USB functions as well.

A user definable unit ID is also provided that likewise prints on all records and

reports when this feature is enabled.

The patented particle sensor used in the CI-154 operates on the light scattering

principle. It uses a laser diode as the light source, and an elliptical mirror collection

system. The light scattered by particles and collected by the elliptical mirror is

focused onto a solid-state photo detector, which converts the light energy into

electrical current. The highly efficient optical system and detection electronics

provide the means for this instrument to correctly size and count particles, based on

NIST traceable standards.