STERRAD®100S Installation Guide 3

Contents

Chapter 1. Installation Overview..............................................................................5

Introduction........................................................................................................6

Installation Forms ......................................................................................................6

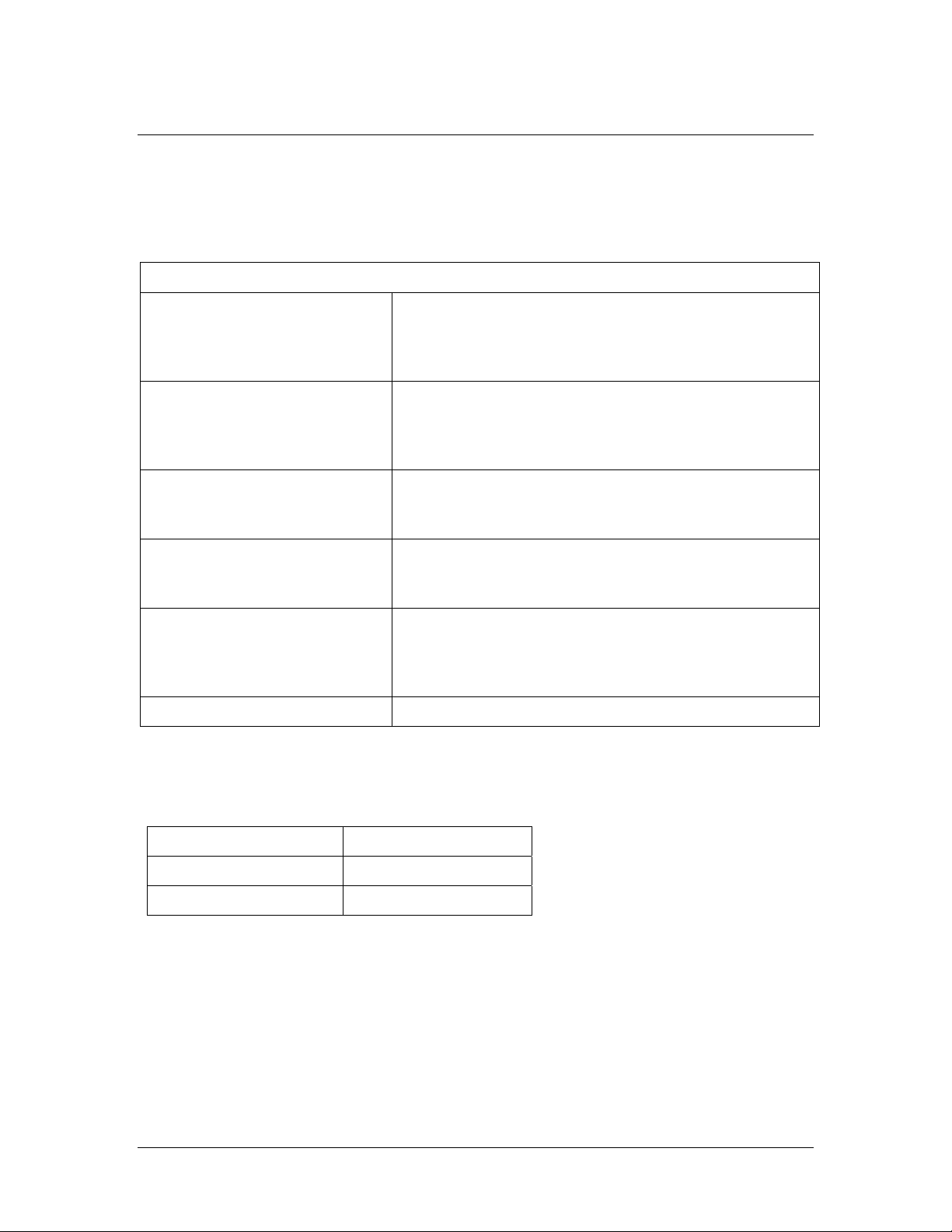

Physical Specifications ......................................................................................7

Environmental Conditions..................................................................................8

Electrical Requirements.....................................................................................9

Heater Impedance .............................................................................................9

Thermocouples..................................................................................................10

Standards ..........................................................................................................10

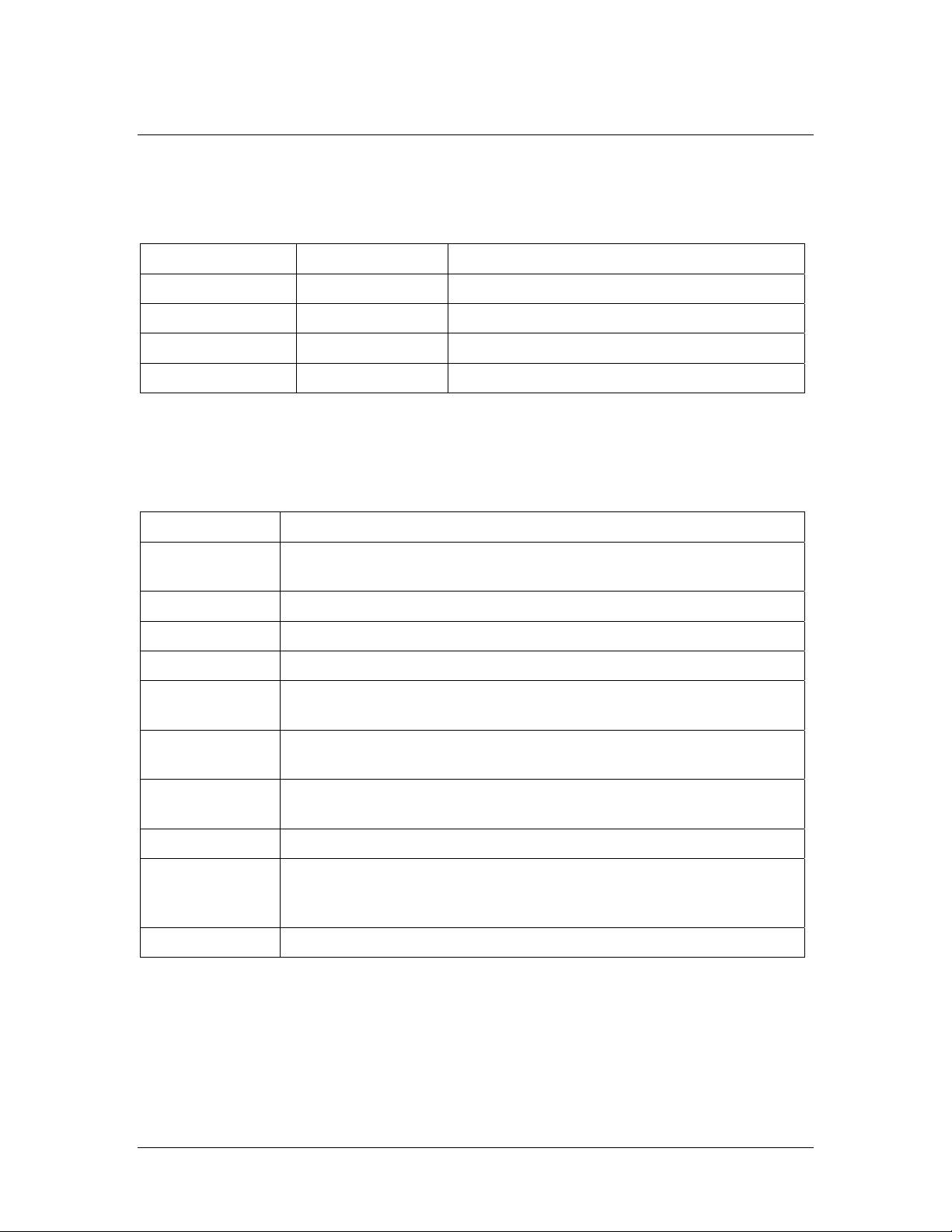

System Configuration ........................................................................................11

STERRAD100S Sterilizer Configuration Kit – USA.............................................11

STERRAD100S Sterilizer Configuration Kit - International .................................11

Tools and Test Equipment.................................................................................13

Chapter 2. For Your Safety.......................................................................................15

Overview............................................................................................................16

Personal Safety and First Aid ............................................................................ 16

Safe Maintenance..............................................................................................17

Cassette Handling .............................................................................................18

Device Safety.....................................................................................................19

Chapter 3. Installation...............................................................................................21

Pre-Installation...................................................................................................22

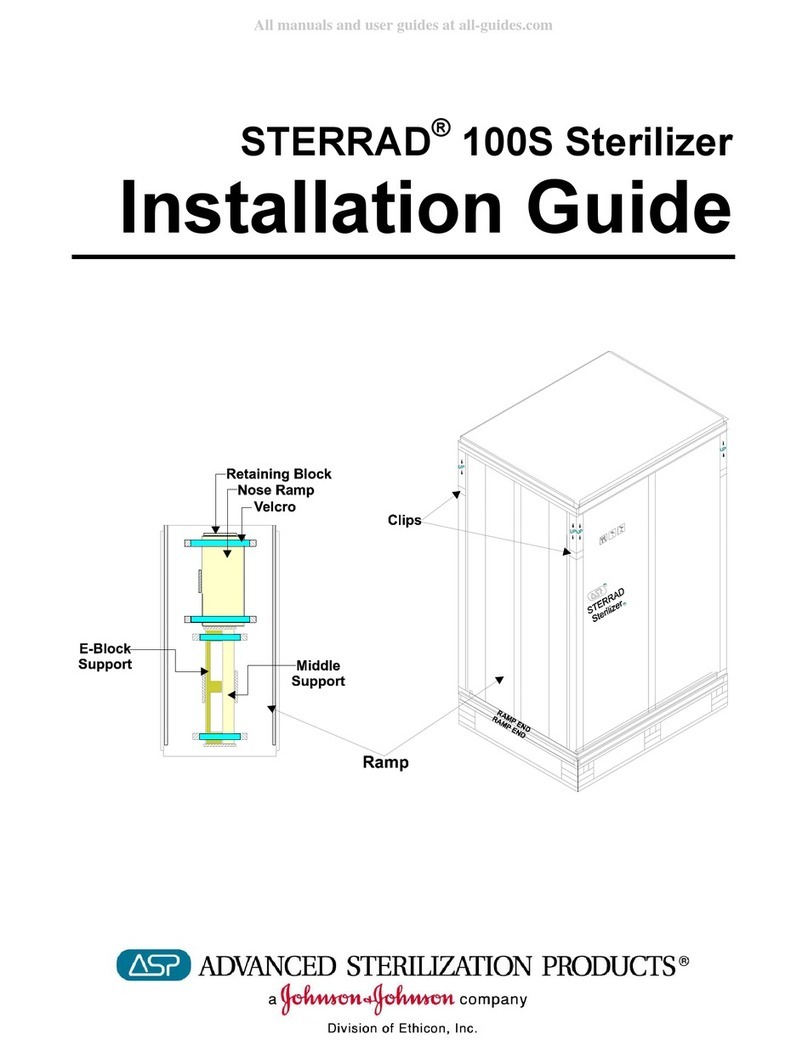

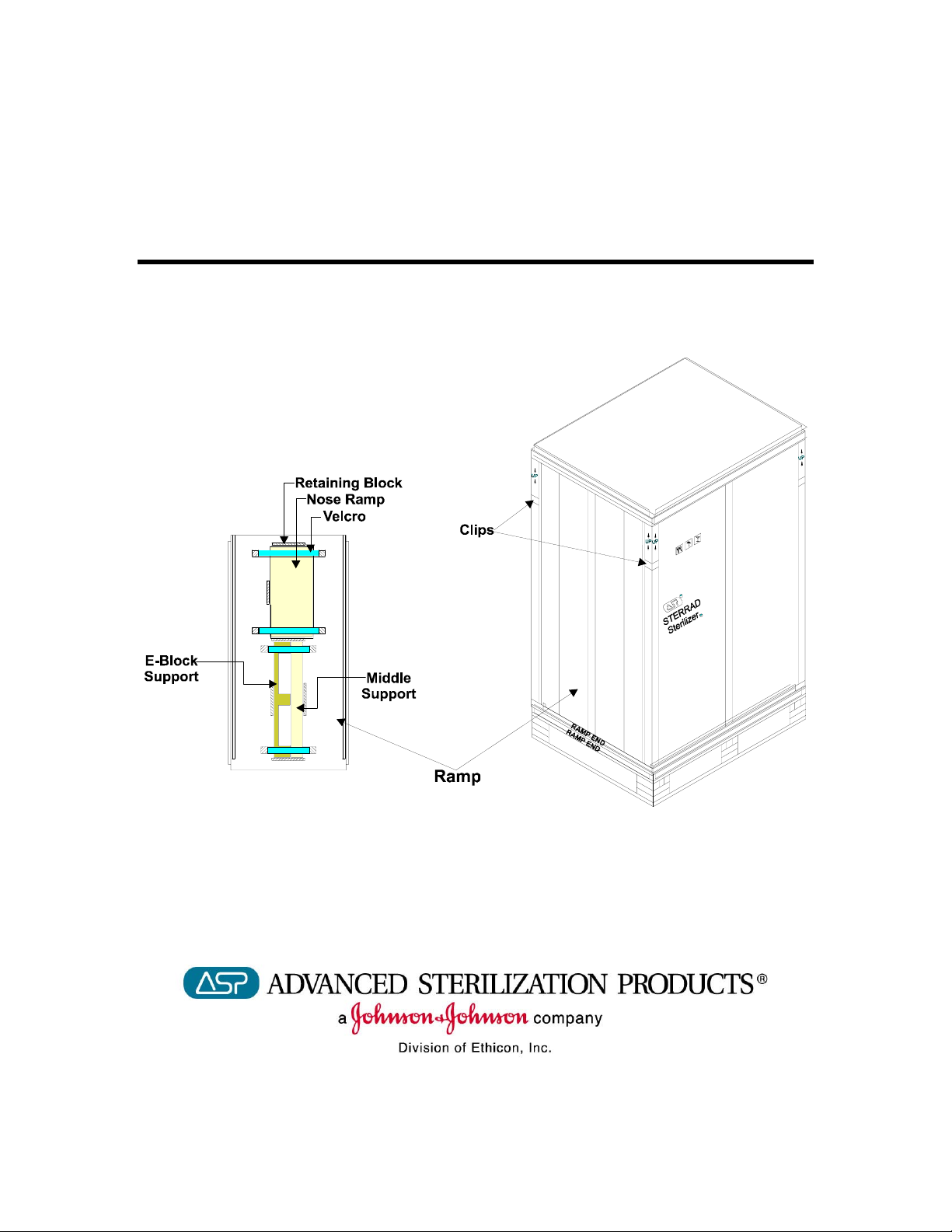

Uncrating the System ........................................................................................24

Installing the Seismic Restraints........................................................................27

Pre-Installation Procedure-To Be Done by the Customer .........................................28

Installing the Brackets ...............................................................................................30

Vacuum Subsystem Assembly ..........................................................................31

System Configurations.......................................................................................33

Attach Machine Label................................................................................................33

Thermal Overload Relay............................................................................................34

Power Plug.................................................................................................................35