www.cbsscientific.com Tel# 858-755-4959

3

FRANÇAIS INFORMATION IMPORTANTE À L'USAGE DES UTILISATEURS

Le présent manuel d'utilisation explique la manière de se servir efficacement du produit en conditions

de sécurité. Il est recommandé de soigneusement lire la totalité du manuel, avec ses consignes

et ses instructions.

Le triangle avec point d'exclamation est un symbole destiné à avertir l'utilisateur du produit de

l'importance de certaines exigences relatives au fonctionnement, à l'entretien et/ou à la

garantie.

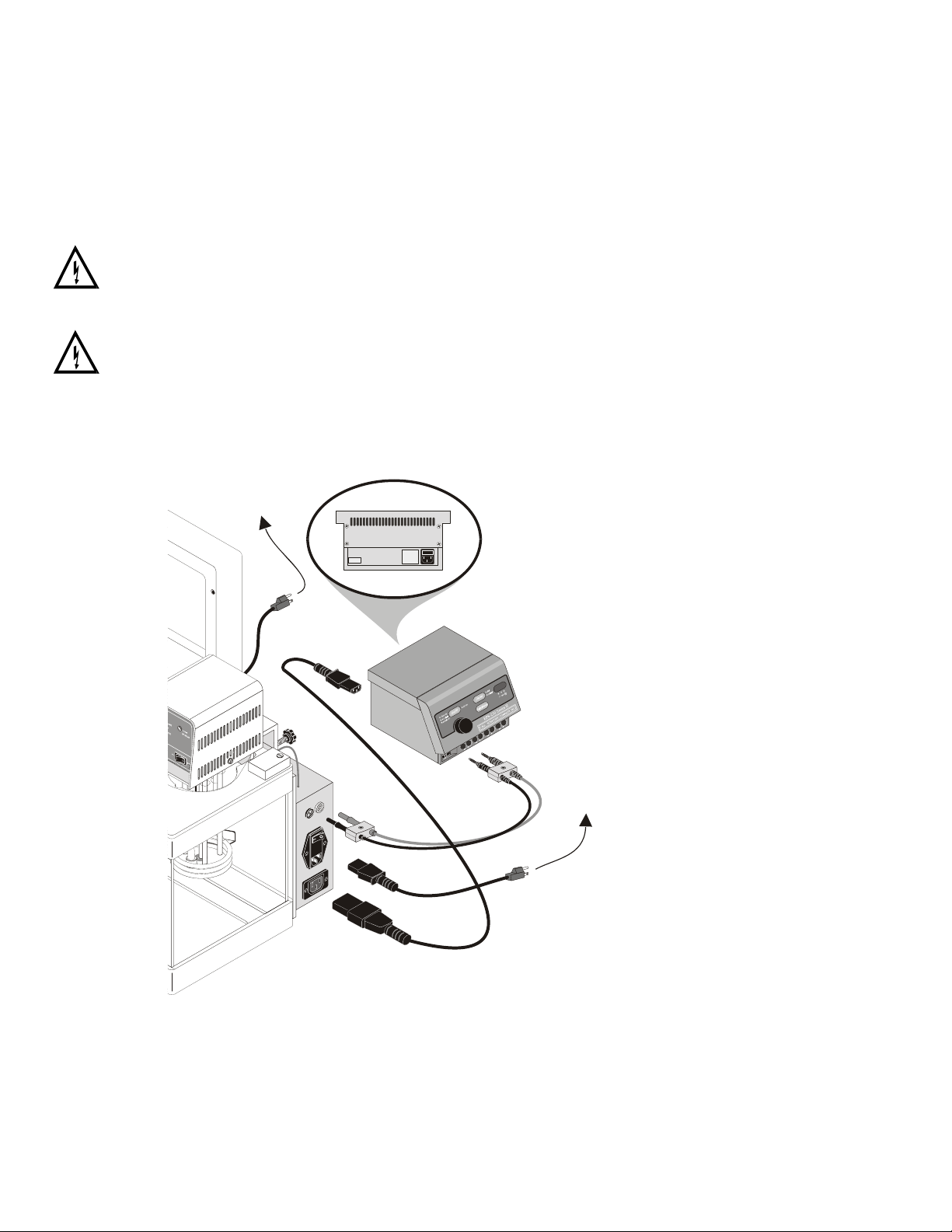

Le triangle avec flèche en zigzag est un symbole destiné à avertir l'utilisateur du produit de la

possibilité d'exposition à des décharges avec danger de secousses électriques.

Tout manquement à l'observation des consignes et des instructions peut exposer les personnes

et les biens à des dommages corporels et/ou matériels et peut annuler toute garantie. Il faut toujours

interrompre l'alimentation de courant continu avant de déconnecter les cordons d'alimentation du

produit. Déconnecter d'abord les cordons d'alimentation branchés sur la source de tension

(alimentation de secteur) puis ceux branchés sur le produit. Pour une sécurité maximum, il faut toujours

faire fonctionner ce système dans un lieu isolé, peu fréquenté, où le personnel non autorisé n'a pas

accès. Ne jamais faire fonctionner un matériel endommagé ou affecté par des fuites.

GARANTIE ET RESPONSABILITÉ

Le produit a été fabriqué conformément aux normes applicables les plus exigentes en matière de

matériaux, de main d'oeuvre, de conception et d'ingéniérie. C.B.S. Scientific garantit que le produit a

subi des essais et que ses performances rempliront les conditions des spécifications publiées ou leur

seront même supérieures. La présente garantie n'est valide que si le produit a fonctionné et a été

entretenu conformément aux consignes et instructions fournies.

C.B.S. Scientific garantit que le produit sera dépourvu de vices de matériaux et de main d'oeuvre, en

conditions de service normales, pendant un an à compter de la date d'expédition. Au cas où le produit

s'avérerait défectueux pendant cette période de garantie, C.B.S. Scientific réparera ou remplacera le

produit, à sa discrétion et gratuitement, si le produit lui est retourné port payé d'avance. La garantie ne

couvre pas les dommages de transport; les dommages causés par l'imprudence, le manque de soins,

l'abus ou la négligence; l'usure normale résultant d'une utilisation fréquente; les dommages causés par

la corrosion des solvants; et les dommages causés par la manipulation inadéquate ou des

changements apportés par l'utilisateur. La garantie ne couvre pas non plus les performances non

satisfaisantes résultant de conditions hors du contrôle de C.B.S. Scientific. C.B.S. Scientific ne pourra

en aucun cas être tenue responsable de dommages indirects, y compris, de manière non limitative, la

perte de bénéfices, le manque à gagner, la perte d'occasions d'affaires, l'impossibilité d'usage ou tous

autres dommages associés, quelle qu'en soit la cause, ni de dommages résultant de l'usage incorrect

du produit.

ESPAÑOL INFORMACIÓN IMPORTANTE PARA EL USUARIO

El presente instructivo explica la manera de usar este producto en forma segura y efectiva. Sírvase

leerlo en su totalidad y seguir detenidamente las indicaciones que contiene.

El símbolo del triángulo con exclamación llama la atención del usuario a requisitos

importantes para el uso y mantenimiento del producto, así como para la validez de la

garantía.

El símbolo del triángulo con rayo llama la atención del usuario a la posibilidad de

riesgos eléctricos.

El incumplimiento de las instrucciones aquí señaladas podría dar lugar a riesgos a la persona, al

laboratorio o a ambos y podría anular toda garantía. Siempre apague la fuente de corriente continua

antes de desenchufar los cables eléctricos del producto. Primero desconecte los cables de la fuente

de energía y después del producto. Para mayor seguridad, siempre use este sistema en un área

aislada, de poco movimiento de personas e inaccesible a personal no autorizado. Jamás use equipo

que presenta algún daño o fuga.

GARANTÍA Y RESPONSABILIDAD

Este producto fue fabricado de acuerdo con las normas más estrictas que sean factibles en cuanto a

materiales, mano de obra y diseño. C.B.S Scientific garantiza que se sometió el producto a pruebas y

que cumplirá o excederá las especificaciones publicadas. Esta garantía será válida únicamente si se

usa y se da servicio de mantenimiento al producto de acuerdo con las instrucciones señaladas.

C.B.S. Scientific garantiza que este producto se encontrará libre de defectos de materiales y mano de

obra por un período de servicio normal de un año a partir de la fecha de embarque. Si el producto

resulta defectuoso durante este período, C.B.S. Scientific lo reparará o lo repondrá, a criterio de C.B.S.,

libre de cargos, si se devuelve el producto a C.B.S. porte pagado. Esta garantía no cubre daños

sufridos en tránsito, daños provocados por descuido, mal uso o negligencia, desgaste normal como

consecuencia del uso excesivo, daños atribuibles a corrosión provocada por solventes, daños

causados por el uso indebido o alteraciones realizadas por el usuario ni rendimiento insatisfactorio

atribuible a circunstancias fuera del control de C.B.S. Scientific. C.B.S. Scientific en ningún caso

asumirá responsabilidad por daños incidentales o subsecuentes, incluyendo, en forma no limitativa, la

pérdida de utilidades, de ingresos, de oportunidades comerciales o del uso del producto y otros daños

afines, fuere cual fuere su origen, ni por daños derivados del uso incorrecto del producto.

DEUTSCH WICHTIGE INFORMATION FÜR DEN BENUTZER

Diese Bedienungsanleitung beschreibt wie man dieses Produkt sicher und wirksam benutzt. Bitte lesen

und befolgen Sie alle Anweisungen in dieser Anleitung.

Das Dreieck mit Ausrufezeichen weist den Benutzer des Produktes darauf hin, daß

wichtige Bedienungs-, Wartungs- und/oder Garantievorschriften zu beachten sind.

Das Dreieck mit Zickzackblitz warnt den Benutzer des Produktes vor möglichen

Gefahren durch elektrische Spannungen.

Nichtbeachtung dieser Anweisungen kann zu persönlichen und/oder labortechnischen Schäden

führen und gleichzeitig alle Garantien als nichtig erklären. Die DC Stromzufuhr muß immer, vor dem

Entfernen der Stromkabel vom Produkt, abgeschaltet werden. Die Stromzufuhrkabel müssen zuerst

von der Steckdose und erst dann vom Produkt entfernt werden. Um höchste Sicherheit zu

gewährleisten sollte dieses System in einem abgesonderten und besonders ruhigen Bereich eingesetzt

werden und vor Unbefugten sicher sein.

GARANTIE UND HAFTUNG

Dieses Produkt wurde unter Anwendung von Produkten mit höchster Qualität und aus Materialien mit

bester Verarbeitung und modernstem Design hergestellt. C.B.S Scientific garantiert, daß das Produkt

getestet wurde und alle publizierten Spezifikationen übertrifft. Diese Garantie ist jedoch nur gültig,

wenn das Produkt nach der beigefügten Bedienungsanleitung bedient und gewartet wurde.

C.B.S. Scientific garantiert, daß dieses Produkt bei normaler Bedienung aus fehlerfreiem Material

besteht und fehlerfrei in der Ausführung ist. Diese Garantie gilt für ein Jahr ab Lieferdatum. Sollte das

Produkt in diesem Zeiraum fehlerhaft werden, bietet C.B.S. Scientific eine kostenlose Reparatur bzw.

Kostenlosen Ersatz, einschließlich freiem Rückporto. Diese Garantie schließt folgendes aus:

Transportschaden, Schaden durch Nachlässigkeit, Mißbrauch oder Vernachlässigung, normale

Abnützung durch regelmäßigen Gebrauch, Schaden durch Säureangriff, Schaden durch falsche

Handhabung, Veränderung des Produktes durch den Benutzer, oder unzureichende Leistungen die sich

nicht im Verantwortungsbereich von C.B.S. Scientific befinden. C.B.S. Scientific kommt unter keinen

Umständen für folgende Schäden auf: Sachschadensverlust, Einkommensverlust, Verlust von

Geschäftsmöglichkeiten, Verlust der Anwendung und andere damit verbundene Schäden die auf irgend

eine Art und Weise entstanden sind, oder Schäden die aus falscher Anwendung des Produktes

entstanden sind.

ITALIANO INFORMAZIONI IMPORTANTI PER L’UTENTE

Questo manuale spiega come utilizzare questo prodotto in maniera sicura ed efficiente. Si pregai di

leggere e seguire con cautela le istruzioni di ogni parte di questo manuale.

Il triangolo contenete il simbolo di un punto esclamativo avverte l’utente di importanti

requisiti relativi al funzionamento, manutenzione e/o garanzia del prodotto.

Il triangolo contenete il simbolo di un lampo avverte l’utente del prodotto della

possibilità di pericoli dovuti a corrente elettrica.

La mancata osservanza delle istruzioni può essere causa di pericolo alla propria persona ed al

laboratorio, oltre a poter annullare la garanzia. Prima di distaccare il cordone d’alimentazione dal

prodotto, spegnere sempre la sorgente di corrente continua. Distaccare i cordoni d’alimentazione

prima dal lato della sorgente di tensione e poi dal lato del prodotto. Per maggior sicurezza, mettere

sempre in funzione il prodotto in un’area isolata con poco traffico che non sia accessibile al personale

non autorizzato. Non mettere mai in funzione un’apparecchiatura che sia danneggiata o abbia perdite.

GARANZIA E RESPONSABILITÀ

Questo prodotto è stato fabbricato seguendo gli standard più elevati per i materiali, la manodopera e la

progettazione. La C.B.S. Scientific garantisce il prodotto è stato sottoposto a prova e raggiunge o

supera i valori pubblicati per i dati tecnici. Questa garanzia è valida solo se il prodotto è messo in

esercizio e soggetto a manutenzione secondo le istruzioni fornite.

La C.B.S. Scientific garantisce che questo prodotto è libero di difetti di materiali e manodopera, in

normali condizioni d’esercizio, per la durata di un anno dalla data di spedizione. Se, in questo periodo, il

prodotto si dimostrerà difettoso, la C.B.S. Scientific, a suo giudizio, lo riparerà o sostituirà. Questa

garanzia non copre danni in transito, danni causati da negligenza, uso improprio, trascuratezza,

normale consumo derivante da uso frequente, o danni causati da solventi corrosivi, danni causati da

maltrattamento o da modifiche apportate dall’utente e non copre prestazioni insoddisfacenti che siano il

risultato di condizioni al di fuori del controllo del fabbricante. La C.B.S. Scientific non sarà in ogni caso

responsabile per danni incidentali o consequenziali, incluso, senza limitazioni, perdite di profitto, perdita

di entrate, perdita di opportunità d’affari e altri danni relativi, comunque causati, e per danni risultati da

uso incorretto del prodotto.