CLIVET CSRN-XHE2 Series User manual

CSRN-XHE2

49.4-110.4

R-410A

M07V40B13‐0711/20

MANUAL

FORINSTALLATION,

USEANDMAINTENANCE

2

The data contained in this manual is not binding and may be changed by the manufacturer without prior

notice. Reproduction, even partial, is FORBIDDEN. © Clivet S.p.A. - Feltre (BL) - Italia

Dear Customer,

We congratulate you on choosing these product

Clivet has been working for years to oer systems able to assure the maximum comfort for

a long time with highly-reliable, ecient, high-quality and safe solutions.

The target of the company is to oer advanced systems, that assure the best comfort and

reduce energy consumption as well as the installation and maintenance costs for the entire

life-cycle of the system.

With this manual, we want to give you information that are useful for all phases: from

reception, installation and use to disposal - so that such an advanced system can provide

the best performances during installation and use.

Best regards and have a good read.

CLIVET Spa

3

INDEX

Safety considerations 5

Configurations 7

Reception 10

Selecting the installation site 12

Water connections 17

Aeraulic connections 20

Electrical connections 21

Start-up 28

Control 36

Maintenance 60

Decommissioning 67

Residual risks 68

Technical information 70

4

SAFETY CONSIDERATIONS

Manual

The manual provides correct unit installation, use and

maintenance.

It is advisable to read it carefully so you will save time during

operations.

Follow the written indications so you will not cause damages to

things and injuries people.

Preliminaries

Only qualified personnel can operate on the unit, as required by

the regulation in force.

Risk situations

The unit has been designed and created to prevent injures to

people.

During designing it is not possible to plane and operate on all

risk situation.

Read carefully “Residual risk” section where all situation which

may cause damages to things and injuries to people are

reported.

Installation, starting, maintenance and repair required specific

knowledge; if they are carried out by inexperienced personnel,

they may cause damages to things and injuries people.

Intended use

Use the unit only:

civil air-conditioning

keep to the limits foreseen in the technical schedule and in

this manual

The manufacturer accepts no responsibility if the equipment is

used for any purpose other than the intended use.

Installation

Outdoor installation

The positioning, hydraulic system, refrigerating, electrics and the

ducting of the air must be determined by the system designer in

accordance with local regulations in force.

Follow local safety regulations.

Verify that the electrical line characteristics are in compliance

with data quotes on the unit serial number label.

Maintenance

Plan periodic inspection and maintenance in order to avoid or

reduce repairing costs.

Turn the unit off before any operation.

Pay particular attention to:

warnings / prohibitions / danger

indicating particularly important

operations or information, operations

that cannot be done, which compromise

the functionality of the unit or which

may cause damage to things or

persons.

5

Modification

All unit modifications will end the warranty coverage and the

manufacturer responsibility.

Breakdown/Malfunction

Disable the unit immediately in case of breakdown or malfunction.

Contact a certified service agent.

Use original spares parts only.

Using the unit in case of breakdown or malfunction:

voids the warranty

it may compromise the safety of the unit

it may increase time and repair costs

User training

The installer has to train the user on:

start-up/shutdown

set points change

standby mode

maintenance

what to do / what not to do in case of breakdown.

Data update

Continual product improvements may imply manual data changes.

Visit manufacturer web site for updated data.

Indications for the User

Keep this manual with the wiring diagram in an accessible place

for the operator.

Note the unit data label so you can provide them to the

assistance centre in case of intervention (see “Unit identification”

section).

Provide a unit notebook that allows any interventions carried out

on the unit to be noted and tracked making it easier to suitably

note the various interventions and aids the search for any

breakdowns.

In case of breakdown or malfunction

Immediately deactivate the unit

Contact a service centre authorized by the manufacturer

The installer must train the user, particularly on:

Start-up/shutdown

Set points change

Standby mode

Maintenance

What to do / what not to do in case of breakdown

6

Unit identification

The serial number label is positioned on the unit and allows to

indentify all the unit features.

The matriculation plate shows the indications foreseen by the

standards, in particular:

unit type

serial number (12 characters)

year of manufacture

wiring diagram number

electrical data

type of refrigerant

refrigerant charge

manufacturer logo and address

The matriculation plate must never be removed.

It contains fluorinated greenhouse gases.

Serial number

It identifies uniquely each unit.

Must be quoted when ordering spare parts.

Refrigerant

It contains fluorinated greenhouse gases

Type of refrigerant: R410A

Assistance request

Note data from the serial number label and write them in the

chart on side, so you will find them easily when needed.

Series

Size

Serial number

Year of manufacture

Number of electrical wiring diagram

7

R. Return air

S. Supply air

1. G4 efficiency filters + electronic filters (option)

or F7 filter (option)

2. Handling exchanger

3. Supply fan section

4. Hot gas reheating exchanger

5. Electric heaters.

6. Thermodynamic recovery on exhaust air

R. Return air

S. Supply air

FA. Fresh air

1. G4 efficiency filters + electronic filters (option)

or F7 filter (option)

2. Handling exchanger

3. Supply fan section

4. Hot gas reheating exchanger

5. Electric heaters.

6. Thermodynamic recovery on exhaust air

123

546

R

S

123

546

R

S

FA

123

546

R

S

CONFIGURATIONS

CAK configuration

Single fan section for full recirculation

CBK configuration

Single fan section for recirculation and fresh air

8

CCK configuration

Double fan section for recirculation, fresh air, exhaust, thermodynamic recovery

CCKP configuration

Double fan section with fresh air and THOR thermodynamic recovery

R. Return air

S. Supply air

FA. Fresh air

EX. Exhaust air

1. G4 efficiency filters + electronic filters (option)

or F7 filter (option)

2. Handling exchanger

3. Supply fan section

4. Hot gas reheating exchanger

5. Electric heaters.

6. Thermodynamic recovery on exhaust air

7. Exhaust damper

8. Exhaust fan section

9. Thermodynamic recovery on exhaust air

R. Return air

S. Supply air

FA. Fresh air

EX. Exhaust air

1. G4 efficiency filters + electronic filters (option)

or F7 filter (option)

2. Handling exchanger

3. Supply fan section

4. Hot gas reheating exchanger

5. Electric heaters.

6. Thermodynamic recovery on exhaust air

7. Exhaust damper

8. Exhaust fan section

9. Thermodynamic recovery on exhaust air

10. Thermodynamic recovery exchanger, THOR

123

546

R

S

FA

987

EX

123

546

R

S

FA

987

EX

10

9

Supply and return configuration

1° filtering stage - standard G4 ISO 16890 Coarse 60%

2° filtering stage - option F7 ISO 16890 ePM1 55%

2° filtering stage - option FES (electronic filters) ISO 16890 ePM1 90%

Filters nomenclature according to EN ISO 16890

Standard unit Option Option

Option Option Option

10

RECEPTION

Saftey

Operate in compliance with safety regulations in force.

For detailed information (dimensions, weight, technical

characteristics etc.) please refer to the TECHNICAL INFORMATION

section.

Use single protection devices: gloves, glasses etc.

Reception

You have to check before accepting the delivery:

That the unit hasn’t been damaged during transport

That the materials delivered correspond with that indicated on

the transport document comparing the data with the

identification label positioned on the packaging.

In case of damage or anomaly:

write down on the transport document the damage you found

and quote this sentence: “Conditional acceptance clear

evidence of deficiencies/damages during transport”

wontact by fax and registered mail with advice of receipt to

supplier and the carrier.

NOTE

Any disputes must be made within 8 days from the date of

the delivery. Complaints after this period are invalid .

Storage

Respect the indications on the outside of the pack.

In particolar:

minimum ambient temperature –15°C

(possible components damages)

maximum ambient temperature +49°C

(possible safety valve opening)

maximum relative humidity 95%

(possible damages to electrical components

NOTE

The unit may not be tilted more than 15° during transport.

NOTE

Removal of packaging

Be careful not to damage the unit.

Recycle and dispose of the packaging material in compliance with

local regulations.

11

A

B

Handling

Caution

Check that all handling equipment complies with local safety

regulations (cran, forklifts, ropes, hooks, etc.).

Provide personnel with personal protective equipment suitable

for the situation, such as helmet, gloves, accident-prevention

shoes, etc.

Observe all safety procedures in order to guarantee the

safety of the personnel present and the of material.

Verify unit weight and handling equipment lifting capacity.

Identify critical points during handling (disconnected routes,

flights, steps, doors).

Suitably protect the unit to prevent damage.

Lifting with balance (A)

Lifting with spacer bar (B)

Align the barycenter to the lifting point

Gradually bring the lifting belts under tension, making sure

they are positioned correctly.

Before starting the handling, make sure that the unit is

stable.

12

SELECTING THE INSTALLATION SITE

Positioning

Installation must be in accordance with local regulations. If

they do not exist, follow EN378

.

During positioning consider these elements:

customer approval

unit weight and bearing point capacity

safe accessible position

functional spaces

spaces for the air intake/exhaust

electrical connections

max. distance allowed by the electrical connections

water connections

Functional spaces

Functional spaces are designed to:

guarantee good unit operation

carry out maintenance operations

protect authorized operators and exposed people

Respect all functional spaces indicated in the TECHNICAL

INFORMATION section.

Positioning

Units are designed to be installed:

EXTERNAL

in fixed positions

Put the unit in a position where any leaking gas cannot enter

buildings or stagnate in closed areas. In the latter case,

observe the rules for machinery rooms (ventilation, leak

detection, etc.).

Installation standards:

install the unit raised from the ground

bearing points aligned and leveled

discharged condensation water must not cause harm/danger

to people and property

the accumulation of snow must not cause clogging of the

coils

avoid installations in places subject to flooding

Limit vibration transmission:

use anti-vibration devices or neoprene strips on the unit

support points

install flexible joints on the hydraulic and aeraulic connections

Protect the unit with suitable fence in order to avoid access to

unauthorised personnel (children, vandals, etc.)

A correct circulation of the air is mandatory to guarantee the

good unit operating..

The unit must be level.

Steel structure

Concrete floor

1 2 cm thick neoprene strips

2 concrete floor

3 floor

1 anti-vibration devices

2 steel structure

3 steel structure

13

Avoid therefore:

obstacles to the airflow

exchange difficulties

leaves or other foreign bodies that can obstruct the exchange

batteries

winds that hinder or favour the airflow

heat or pollution sources close to the unit (chimneys,

extractors etc)

stratification (cold air that stagnates at the bottom)

recirculation (expelled air that is sucked in again)

positioning below the level of the threshold, close to very high

walls, attics or in angles that could give rise to stratification

or recirculation phenomenons.

Ignoring the previous indications could:

energy efficiency decrease

alarm lockout due to HIGH PRESSURE (in summer) or LOW

PRESSURE (in winter)

CBK, CCK, CCKP configurations only

Avoid the accumulations of snow and ice in front of the exhaust

air outlet.

Pressure relief valve gas side

The installer is responsible for evaluating the opportunity of

installing drain pipes in compliance with the local regulations in

force (EN 378).

If ducted, the valves must be sized according to EN13136 .

Only if electronic filter is present

The most common contaminants for which the filter is designed,

are:

air pollution by PM10, PM 2,5 and PM1

Contaminants that can be filtered:

dry smokes

powder (up to 0,3 microns)

smoke electrostatically charged

Contaminants that can NOT be filtered:

water vapors also in low concentration

oil vapors

large amounts of dust

metal shavings,iron filing dusts and waste generally

Gas

Absolutely to avoid:

metal dusts also fine

fumes produced by combustion of organic and not materials

(wood, coal, gasoline, etc.)

only CBK, CCK, CCKP

Avoid snow accumulating

14

Gas heating module

Option

Burner with low pollutant emissions (NOx below 80 mg/kWh), in line with Class 5 of the EN 676 European

standard is supplied with a gas increase control for methane or LPG.

The heating module with burner includes:

hot air generator powered with methane

kit for transformation of power with liquefied petroleum gas (LPG)

kit of steel chimney for exhaust fumes

all the control and safety devices

The component requires gas supply (gas connections to be made by the Customer).

The location of the unit and the fume drain mode must comply with laws and standards in force in the

Country of use.

The Costumer may choose the flue chimney.

The Costumer is responsible for mounting the chimney kit during installation.

Based on the specific installation requirements, the length of the chimney can be increased with suitable

joints and fittings (not supplied by Clivet).

Gas connection

Read the gas heating module manual.

Connection must be carried out by qualified personnel.

use certified components and comply with the local standards in force

install on the gas connection: tap, large section filter and anti-vibration joint

check the supply pressure is correct and stable, in particular where more uses are inserted on the same

line.

System maintenance booklet

t must be kept in the place of installation of the unit

It must be filled-in upon commissioning

It must be updated with the results of the periodical checks, of the routine and extraordinary

maintenance interventions.

Gas cock

Gas filter (large section)

Anti-vibration joint

Gas filter (small section)

Safet gas solenoid vlave

Pressure stabiliser

Main gas burner solenoid valve

Pilot burner gas solenoid valve

15

1 remove the unit supply flange closing.

2 approach the unit to the Gas Module.

3 match the supply flanges by means of the supplied terminals.

4 tighten screws

5 guarantee the absence of air bypass.

A. Apply the flat adhesive gasket15x5 on the Gas Module flange perimeter to guarantee the absence

of air bypass.

B. Fix with screws the flue supporting bracket to the GM frontal panel

C. Fix the extensions with clamps to the flue supporting bracket

D. Fix the suction terminals in ambient and the fuel components (curves, extensions, terminals) by the

corresponding gaskets

16

Gas use features

Connections performed by costumer

A. rooftop

B. supply fan

C. gas module

D. connecting cables

E. electrical panel - terminal XG

17

P

H

S

T

A

WATER CONNECTIONS

Condensate drain

The condensate must be disposed in order to avoid damages to

people and things.

Unit discharge fitting: the connection must not transmit

mechanical stresses and must be performed taking care not to

damage the unit discharge fitting.

Provide a siphon that, eliminating the negative pressure caused

by the fan, prevents the air intake from the discharge duct.

The connection between the attachment and the siphon must

be hermetically sealed (A)

The piping must have adequate slope to allow out flow.

Anchor the ducting with an adequate number of supports..

Otherwise are generated duct failures and air locks that

prevent the runoff.

Insulate the duct and the siphon to avoid the condensate

drippings.

Connect the condensate discharge to a sewerage drainage

network.

DO NOT use white water or drainage networks to avoid the

aspiration of odours in the case of evaporation of water

contained in the siphon.

Check at the end of the work, the regular condensate runoff

pouring some water in the tray.

Siphon height calculation

T = 2P

S = T/2

P is the pressure determined by the fan in correspondence of the

condense collection bowl (approx. 1 mm = 9.81 Pa)

Example :

P = 300 Pa = 30 mm

T = 2P = 60 mm

S = T/2 = 30 mm

Condensation in winter operation

When a heat pump is running it produces a considerable amount

of water due to the defrosting cycles of the external coil.

The condensate must be disposed in order to avoid damages to

people and things.

Risk of freezing

Prevent the risk of freeze if the unit, drain or plumbing

connections can be subject to temperatures close to 0°C.

isolate the piping

protect the piping with heating cables laid underneath the

insulation

18

Immersed electrode humidifier

Option

Connexion humidificateur: 1” F

Supply water

The humidifier must be supplied with mains water having the following features:

pressure between 0.1 and 0.8 Mpa (1 – 8 bar)

temperature between 1 and 40°C

Do not use:

water treated with softeners: it can corrode the electrodes and form foam with possible faults/

malfunctionings

pit, industrial or potentially polluted (chemically or bacteriologically) water

disinfectants or anti-corrosive substances mixed with water, as potentially irritating

Supplying the humidifier with water treated with reverse osmosis filtering system gives the following

advantages:

reduces limescale deposits

reduces energy consumptions

reduces maintenance costs

increases humidifier duration

Check that the filter guarantees a water flow rate higher than the flow rate of the installed humidifier.

Limit values for the supply water

Respect the limits indicated in the table

No relation can be demonstrated between water hardness and conductivity.

Limit values for the supply

water

conductivity medium-low medium-high

min max min max

Hydrogen ions pH 7 8,5 7 8,5

Specific conductivity at 20°C μS/cm 125 500 300 1250

Total dissolved solids TDS mg/l (1) (1)(1) (1)

Dry residue at 180°C R 180 mg/l (1) (1)(1) (1)

Total hardness TH mg/l CaCO350

(2) 250 100

(2) 400

Temporary hardness mg/l CaCO330

(3) 150 60

(3) 300

Iron + Manganese mg/l Fe+Mn 0 0,2 0 0,2

Chloridesppm Cl 0 20 0 30

Silica mg/l SIO20 20 0 20

Residual chlorine mg/l Cl-0 0,2 0 0,2

Calcium sulphate mg/l CaSO40 60 0 100

Metallic impurities mg/l 0 0 0 0

Solvents, diluents, soaps,

lubricants

mg/l 0 0 0 0

(2) not lower than 200% of the chloride

content in mg/l of Cl-

(3) not lower than 300% of the chloride

content in mg/l of Cl-

(1) Values depending on specific conductivity;

in general:

Drainage water

It can reach a temperature of 100°C.

It contains the same substances of the supply water but in higher concentration.

As it is not toxic, it can be disposed of with white waters.

19

Heating coil

Option

Max. operating pressure = 10 bar

A drain cock

B vent valve

Provided by the costumer:

1 anti-vibration devices

2 piping supports

3 Shut-off valves

13

A

B

2

20

AERAULIC CONNECTIONS

The dimensioning and correct execution of the aeraulic

connections are fundamental to guarantee good unit operation

and adequate level of silence in the room.

When designing and manufacturing the ducting, consider LOAD

LOSSES, AIR FLOW AND SPEED that must be consistent with the

unit features.

Particularly consider that load losses higher than the unit useful

prevalence, lead to reduction in flow rate, with consequent unit

blocks.

the weight of the channels must not burden on the connection

flanges

place anti-vibration joints between channels and unit

connection to the flanges and between the various sections of

the channels must guarantee air seal, avoiding dispersions

penalising the overall efficiency of the system

limit the load losses by optimising the path, the type and

number of bends and junctions

use wide bends evaluating the opportunity of equipping them

with deflectors (in particular with high air speed or bends with

reduced radius)

Treated air channelling

The internal surface of the channel must be smooth, enable its

washing and must not contaminate the air.

Thermally isolate the channels and the flanges to avoid energy

losses and forming of condensation.

DIFFUSERS INLETS GRILLES

A correct diffusion of the air in the room is determining for the

level of comfort.

When choosing and positioning the grilles, inlets and diffusers,

avoid:

excessive air speed

forming of stagnant and stratification areas

cold air delivery in room

forming of localised currents (also due to uneven distribution

of air)

excessive room temperature variations, vertically and

horizontally

short circuits of the supply air towards the return air

For sound comfort, consider that:

the air diffusers must be chosen verifying the sound power

generated at nominal flow rate conditions

the cut-off to diffusers must be carried out with flexible

elements

the return grilles must be widely dimensioned

Isolate the channels

Isolate the flanges

Other manuals for CSRN-XHE2 Series

1

Table of contents

Other CLIVET Air Handler manuals

Popular Air Handler manuals by other brands

Juwent

Juwent OptiMax-10 Original instruction manual

Gree

Gree U-match Series Service manual

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren Freshbox 100 WiFi user manual

Euroclima

Euroclima ZHK NANO instruction manual

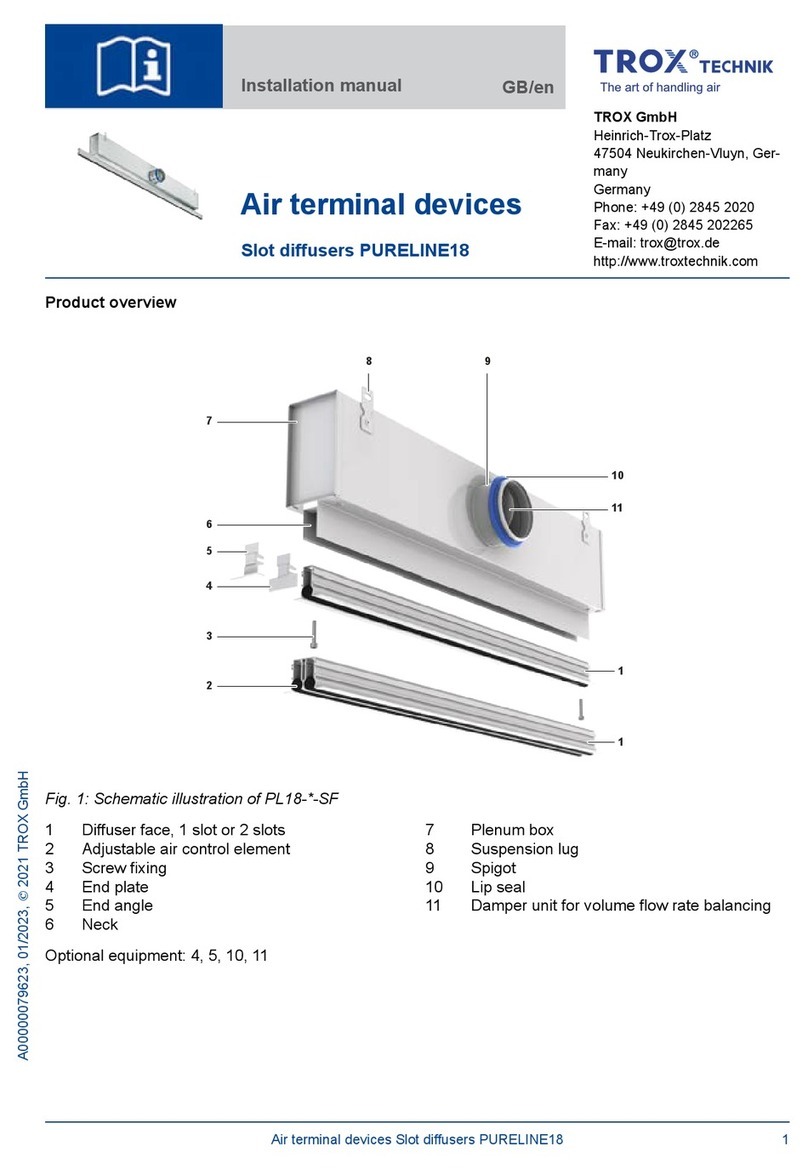

Trox Technik

Trox Technik PURELINE18 installation manual

Mars

Mars TGRX Series Installation and maintenance instructions