CLIVET KJRP-75A Operating instructions

PEMF00001

IA19M012ML-00

INSTALLATION

& OWNER’S MANUAL

In-built controller KJRP-75A

Thank you very much for purchasing our product.

Before using your unit, please read this manual carefully and keep it for future reference.

This manual gives detailed description of the precautions

that should be brought to your attention during operation.

In order to ensure correct service of the wired controller

please read this manual carefully before using the unit.

For convenience of future reference, keep this manual after

reading it.

CONTENTS

1 OPERATION

1.1 Operation precautions 01

1.2 Operation conditions 02

1.3 Main functions 02

1.4 User interface 03

1.5 Instructions for use 04

1.6 Further details 06

2 INSTALLATION

2.1 Safety precautions 09

2.2 Installation accessories 10

2.3 Installation dimensions 11

2.4 Installation method 12

2.5 Schematic drawing of installation 19

Means improper handling may lead to personal death

or severe injury.

CAUTION

Means improper handling may lead to personal injury

or property loss.

1 OPERATION

1.1 Operation precautions

Read the safety precautions carefully before installing, and

must be obeyed.

WARNING

This manual uses the following icons:

Prohibit Follow the guide lines

Please entrust the distributor or professionals to install the unit.

Before cleaning or maintenance, please cut off the power, and

prohibit to use water for washing, to prevent electrical shock.

01

Do not operate by wet hand, to prevent electrical shock.

Do not use pesticide, disinfectant and flammability spray

materials to spray directly, otherwise will cause fire or

deformation.

Do not peel off the button and the cover by hand, to prevent

electrical shock.

1.2 Operation conditions

Voltage input DC 12V

Operating ambient temperature range

-10~43°C

Operating ambient humidity range ≤ RH90%

1.3 Main functions

1. Connected to IDU main control board via 5-core shielded

cable;

2. Setting IDU operating status by tapping touch keys;

3. LED display.

02

1.4 User interface

Cooling Heating Dry Auto

Follow Me

Display Area Of the

Wired Controller

Automatic Fan Speed

Mode Button

Running Indicator

Remote Signal

Receiving Area

Temperature

Fan Speed

Fan Speed

Button

Temp. Setting

Button

Backlight Button On/Off Button

03

1.5 Instructions for use

1.5.1 Basic setting

1 2 3 4 5

1 Tap Mode button

The operating mode changes in the

following order:

Heating

Dry

Auto

2 Adjust temperature

Temperature range 17°C~30°C

3 Tap Fan Speed button

Seven fan speeds and Auto available.

4 Tap On/Off button

To start the unit and send all the configured

parameters.

5 Tap Backlight button

Backlight is on by default. Tap Backlight button

to turn it off.

04

CAUTION

If the wired controller is placed in a box, it may not

accurately detect the ambient temperature !

1.5 Instructions for use

1.5.2 "Follow Me" Operation Process

The Follow Me function is disabled by default.

After active the Follow Me function, controller

will showing the room temp which detect by

the controller self, and send the value to

fancoil every 3 mins, to replace the value

which detect by the room temp sensor of

fancoil sensor.

Start or exit Follow Me

Long press the Up button + Down button for

2s to start (or to exit) the Follow Me function.

The Follow Me function icon is turn on (or turn

off) .

05

CAUTION

Do not peel off the buttons and liquid crystal cover, to

prevent electric shock!

1.6 Further details

1.6.1 Supplementary instructions

Fan Speed button :

Fan speed cannot be set in Dry/Auto mode (Auto displayed).

Backlight mode:

1

)

Steady On: means backlight is normally on.

Tapping to start the unit can enter the backlight steady

on mode.

If backlight is off, tapping can switch to steady on mode.

2

)

Auto Off: means backlight is automatically off after 4s.

If backlight is off, tapping any button (except backlight and

On/Off) can switch to Auto Off mode.

CAUTION

06

No.

1

Error

Error

Name

E2PROM

communication error

Remarks

Unit stopped; unrecoverable

Fault

Code

E7

2 Error

Wired controller

temperature sensor

port abnormal

The wired controller can

operate normally after the

wired controller temperature

sensor fails.

There are two cases:

(1)

When the Follow Me

function is enabled,

the E0 code is displayed E0

(not displayed during

operation), and the main

board is controlled by

the temperature of the air

return port.

(2)

The E0 code is not

displayed when the

Follow Me function is disabled.

3 Error

4 Error

Room temperature

(air return port)

sensor port abnormal

Coil sensor (T2C)

port abnormal

Unit stopped; automatic

recovery after clearing E2

Unit stopped; automatic

recovery after clearing

07

E3

No.

Error

Name

Remarks Fault

Code

5

Error Coil sensor (T2H)

port abnormal

Unit stopped; automatic

recovery after clearing

E4

6

Error

DC motor stall fault

Unit stopped; unrecoverable

E8

7

Error

Main board and wired

controller communication

error

Unit stopped; automatic

recovery after clearing

E9

8

Protection

Water level exceeding

warning line

Automatic recovery after

clearing

EE

9

Protection

Model protection not set

(model DIP switch not

listed in the model table)

Power-on recovery after a

model is selected

PF

10

Protection

Water temperature

protection

Automatic recovery after

clearing

P1

11

Protection

Anti-freezing protection Automatic recovery after

clearing

P0

12

Protection

Remote shutdown

The running indicator and

fault indicator act, the buzzer

does not, and the protection

code is output.

P2

08

2 INSTALLATION

2.1 Safety precautions

Read the safety precautions carefully before installing the

unit.

Stated below are important safety issues that must be

obeyed.

WARNING

Please entrust the distributor or professionals to

install the unit, do not install the unit by the user.

Do not uninstall the unit randomly.

The wiring should adapt to the wired controller

current.

The specified cables shall be applied in the wiring.

No external force may be applied to the terminal.

The circuit of wire controller is low voltage circuit,

do not contact to the high voltage circuit, and can

not be arranged in the same wiring pipe with the

high circuit, the distance between the wiring pipes

should at least more than 300~500mm.

09

2.2 Installation accessories

Please confirm that all the following parts have been

supplied.

No. Name

Qty

Remarks

1 Wire controller 1 Used to control the IDU main unit.

2 M4×20 Philips head screw

4 Used to install the wired controller onto

the wall.

3 Installation and operation

manual 1 Used to guide the operation and

installation of wired controller.

4 Plastic bolt 4 Used to install the wired controller onto

the wall.

5

Connection cable set

1 Used to connect the IDU main control

board and the wired controller.

Do not connect transition or extended connection

in the middle of the wirings of the wire controller.

10

Please install the following accessories in the filed.

NO. Name

Qty

Remarks

1 Shielded 5-core cable 1

RVVP-0.5 mm2×5, embedded into the wall

2 Wiring tubes (insulation

suite) 1

Embedded into the wall; maximum wiring

length: 15 m

3 Big Phillips screwdriver 1

Used to install cross recessed head screws

4 Small slotted screwdriver 1

Used to remove the bottom cover of

wired controller

2.3 Installation dimensions

Before installation, refer to the mounting dimensions and the

size of product below (unit: mm).

75 15

11

102

60

2.4 Installation method

2.4.1 Non-wall-mounted

1. Wiring requirements

The two ends of the connection cable set are different. That

with the larger 5-core plug is defined as terminal A, while

that with the smaller 5-core plug is defined as terminal B.

Terminal A Terminal B

12

30 41

Connect terminal A to the 5-core socket of the IDU main

control board (See the figure below).

Supplied connection cable set

of IDU main control board IDU Main control board

Terminal A

2. Insert a slotted-head screwdriver into the bottom slot of the

wired controller, and rotate in the direction indicated to remove

the rear cover of the wired controller.

Screwdriver

rotation direction

Slotted

screwdriver

13

The wired controller can be installed on the left or right

side of FCU, depending on the circumstances.

3. Take terminal B out of the FCU electric control box and pass

it through the wiring hole in the rear cover of the wired

controller. Connect terminal B to the 5-core socket on the PCB

of wired controller. Then, restore the rear cover of wired

controller and install the wired controller into the FCU electric

control box with the display panel face-up, as shown below.

Terminal B

Rear cover of

wired controller Wired Controller

CAUTION

14

2.4.2. Wall-mounted

1. Wiring requirements

Cut the connection cable set in the middle (unsheathed

place). The section that includes terminal A is section A,

while the section that includes terminal B is section B.

Connect terminal A to the 5-core socket of the IDU main

control board (See the figure below).

Supplied connection cable set of IDU main control board

Section A

5-core shielded cable embedded

into the wall

IDU Main

control board

Connect the cut end of section A (the end opposite to

terminal A) to the 5-core shielded cable embedded in wall

reliably, as shown in the above figure.

Connect the cut end of section B (the end opposite to

terminal B) to the 5-core shielded cable embedded in wall

reliably, as shown in the figure below.

15

5-core shielded cable

embedded in the wall

Section B

Make sure that the five wiring terminals of the wired

controller (A/B/X2/Y2/E) correspond to those of the

connection cable set (accessory) one by one.

The shielded layer of 5-core shielded cable must be grounded.

The longest wiring length of the system is 50 m.

2. Insert a slotted-head screwdriver into the bottom slot of the

wired controller and rotate in the direction indicated to remove

the rear cover of the wired controller, as shown in the figure below.

Screwdriver

rotation direction

Slotted

screwdriver

16

This manual suits for next models

1

Table of contents

Other CLIVET Controllers manuals

Popular Controllers manuals by other brands

Lynxspring

Lynxspring ONYXX LX BZ424-LX Installation and wiring guide

oventrop

oventrop Regtronic BS/2-B Installation and operating instructions

Danfoss

Danfoss AK-SC255 installation guide

Klutch

Klutch 57392 owner's manual

RTMOTION

RTMOTION MK3.x Series user guide

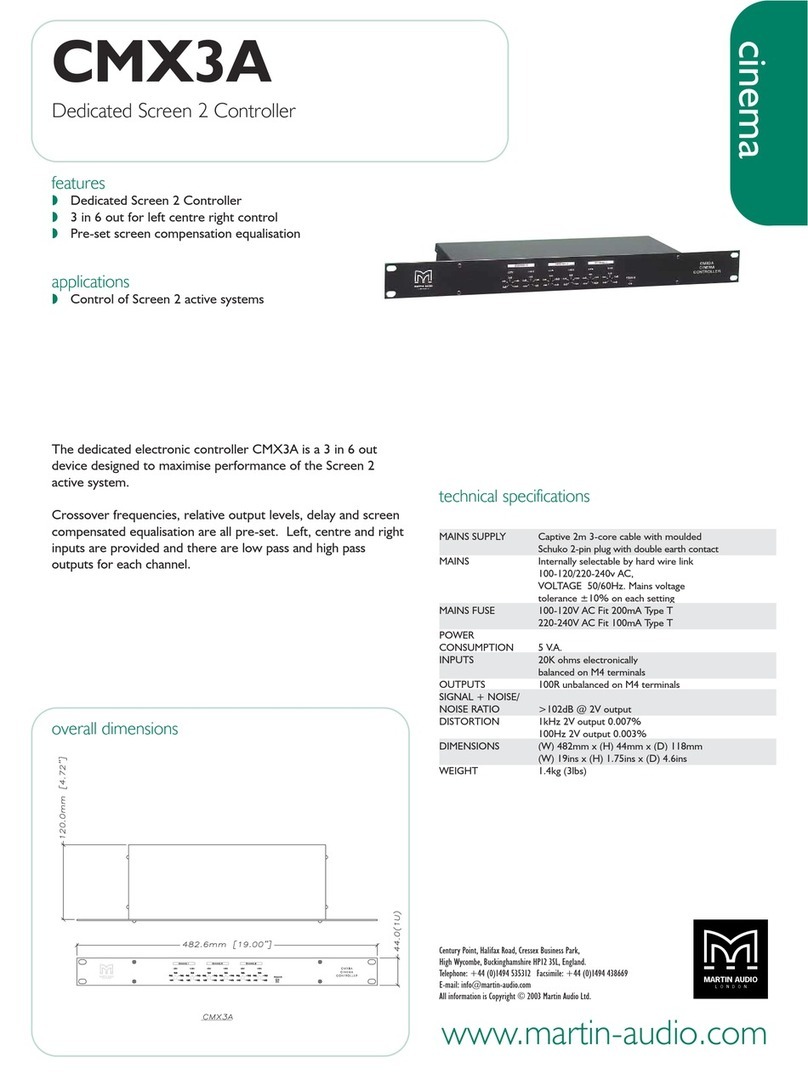

Martin Audio

Martin Audio Dedicated Screen 2 Controller CMX3A Specifications