Page 4 of 13

Intended Use

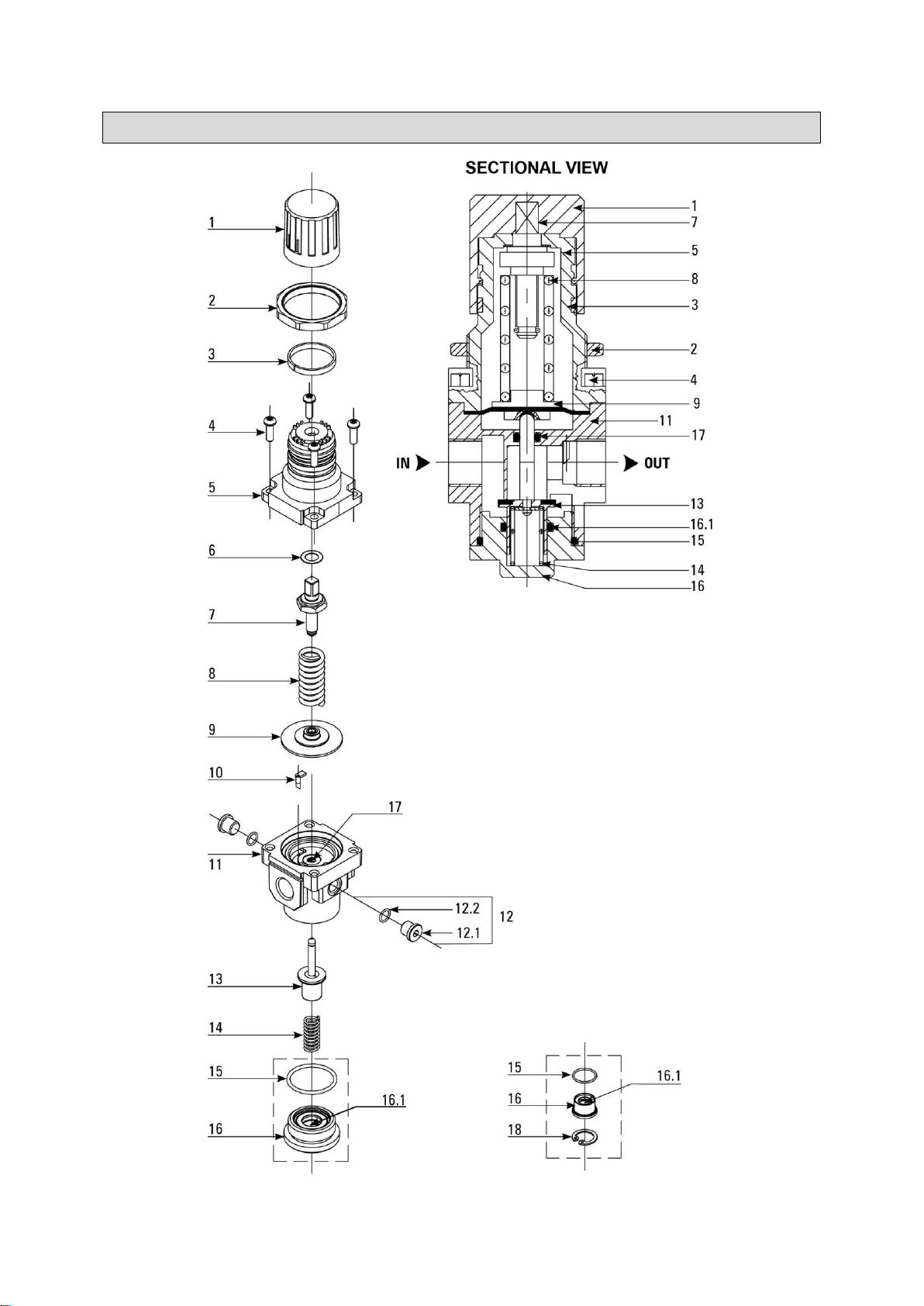

One of the most commonly used air line accessories, regulators are used to maintain a steady outlet

pressure, unaffected by variations/fluctuations in the inlet pressure. Regulators step down the air line

pressure and can be set at any desired pressure below the inlet air pressure. With an aluminum die

cast body, these are designed with a non-raising “press to lock” adjusting knob for locking at any set

pressure. Regulators work on a diaphragm operated, relieving mechanism with pressure

compensated by a balanced poppet. These can be installed in any position.

WHY USE A REGULATOR?

Air regulators are used to provide a controlled and consistent air supply as required by different

pneumatic equipment. The knob can be used to adjust the air supply thus resulting in increasing or

decreasing the air pressure.

WETTED COMPONENTS

Aluminum, Brass, Steel, Acetal, Stainless Steel, and Nitrile

STANDARD CONFIGURATION

Pressure adjustment range of 7 - 145 PSI (0.5 - 10 BAR)

OPTIONAL CONFIGURATION

Custom built includes the following pressure adjustment ranges:

3 - 28 PSI (0.2 - 2 BAR)

3 - 58 PSI (0.2 - 4 BAR)

8 - 100 PSI (0.5 - 7 BAR)

Technical Specifications

Important Safety Information

Read and understand all instructions. Failure to follow all instructions may result in serious injury

or property damage.

The warnings, cautions, and instructions in this manual cannot cover all possible conditions or

situations that could occur. Exercise common sense and caution when using this tool. Always be

aware of the environment and ensure that the tool is used in a safe and responsible manner.

Do not allow persons to operate or assemble the product until they have read this manual and

have developed a thorough understanding of how it works.

Do not modify this product in any way. Unauthorized modification may impair the function and/or

safety and could affect the life of the product. There are specific applications for which the product

was designed.

Use the right tool for the job. DO NOT attempt to force small equipment to do the work of larger

industrial equipment. There are certain applications for which this equipment was designed. It will

be a safer experience and do the job better at the capacity for which it was intended. DO NOT use