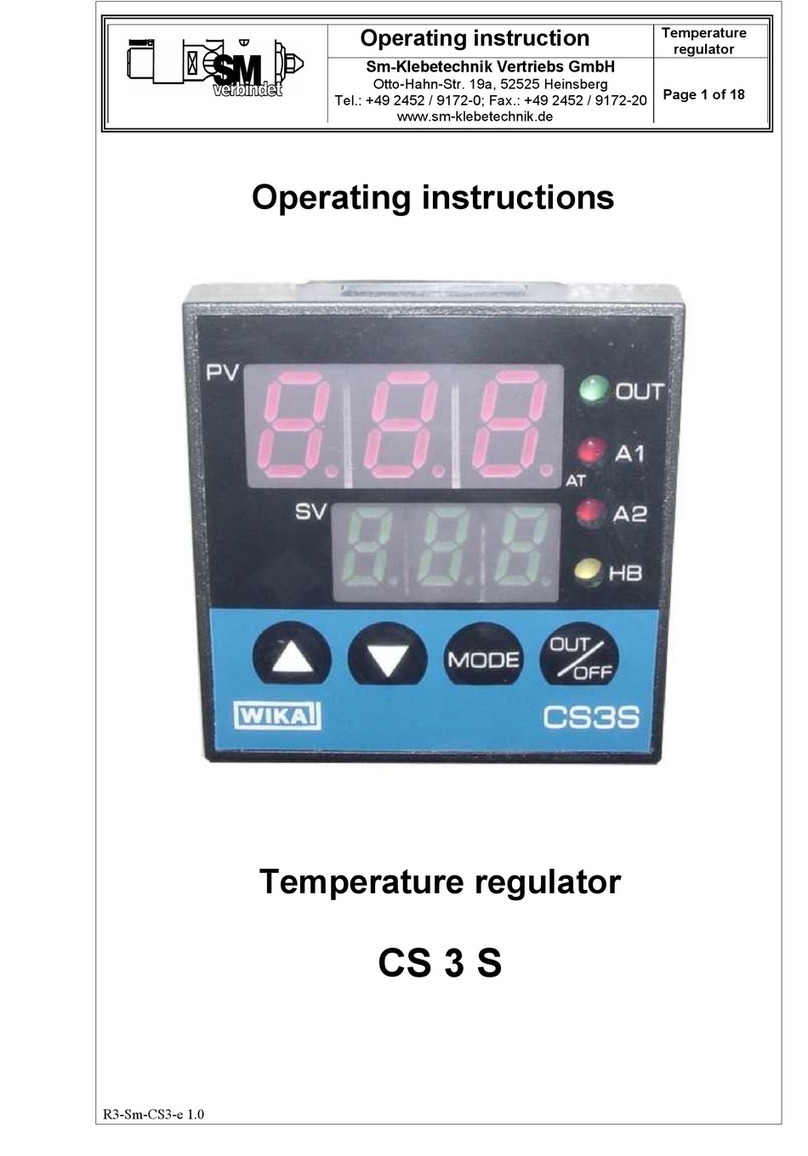

Operating Instructions Temperature Indicating Controller CS4H / CS4L

V1.1 •05/2006 - 4 -

List of contents

1. Model informations

1.1 Model name ····················································································································· 6

1.2 Rated input ······················································································································· 7

2. Name and functions of the sections ········································································ 8

3. Mounting to control panel

3.1 Site selection ·················································································································· 10

3.2 External dimension ········································································································· 10

3.3 Panel cutout ····················································································································11

3.4 CT (current transformer) external dimension ···································································11

3.5 Mounting ························································································································ 12

4. Wiring connection

4.1 Terminal arrangement ···································································································· 13

4.2 Wiring connection example ···························································································· 14

5. Setup

5.1 Setup flow chart ············································································································· 17

5.2 Main setting mode

SV1 ································································································································· 19

SV2 ································································································································· 19

5.3 Sub setting mode

AT setting/Auto-reset setting ··························································································· 19

OUT1 proportional band setting ······················································································ 19

OUT2 proportional band setting ······················································································ 19

Integral time setting ········································································································· 20

Derivative time setting ····································································································· 20

ARW (Anti-reset windup) setting ····················································································· 20

OUT1 proportional cycle setting ······················································································ 20

OUT2 proportional cycle setting ······················································································ 20

A1 setting ························································································································ 20

A2 setting ························································································································ 20

HB (Heater burnout alarm) setting ··················································································· 21

LA (Loop break alarm) action time setting ······································································· 21

LA (Loop break alarm) action span setting ······································································ 21

5.4 Auxiliary function setting mode 1

Setting value lock selection ····························································································· 22

SV high limit setting ········································································································· 22

SV low limit setting ·········································································································· 22

Sensor correction setting ································································································· 22

Communication protocol selection ··················································································· 22

Instrument number setting ······························································································· 22

Data transfer rate selection ····························································································· 23

Parity selection ················································································································ 23

Stop bit selection ············································································································· 23

5.5 Auxiliary function setting mode 2

Sensor selection ·············································································································· 24

Scaling high limit setting ·································································································· 24

Scaling low limit setting ··································································································· 24

Decimal point place selection ·························································································· 25

PV filter time constant setting ·························································································· 25

OUT1 high limit setting ···································································································· 25

OUT1 low limit setting ····································································································· 25

OUT1 ON/OFF action hysteresis setting ········································································· 25

OUT2 action mode selection ··························································································· 25

OUT2 high limit setting ···································································································· 25

OUT2 low limit setting ····································································································· 25

Overlap band/Dead band setting ····················································································· 26

OUT2 ON/OFF action hysteresis setting ········································································· 26

A1 action selection ·········································································································· 26