CLIVET WSAN-XSC3 MF Series User manual

This manual suits for next models

10

Other CLIVET Heat Pump manuals

CLIVET

CLIVET WSAN-YMi 21 R32 Reference manual

CLIVET

CLIVET WSAN-YSi R32 User manual

CLIVET

CLIVET WSAN-XSC 352 Guide

CLIVET

CLIVET MV6R-XMi Reference manual

CLIVET

CLIVET WSAN-XIN MF 18.2 User manual

CLIVET

CLIVET WSAN-XIN 21 User manual

CLIVET

CLIVET WSAN-EE 17 Guide

CLIVET

CLIVET WSAT-YSI User manual

CLIVET

CLIVET WSAN-XSC3 90.4 User manual

CLIVET

CLIVET CKN-XHE2i 10.1 User manual

CLIVET

CLIVET WSAN-XPR Series Guide

CLIVET

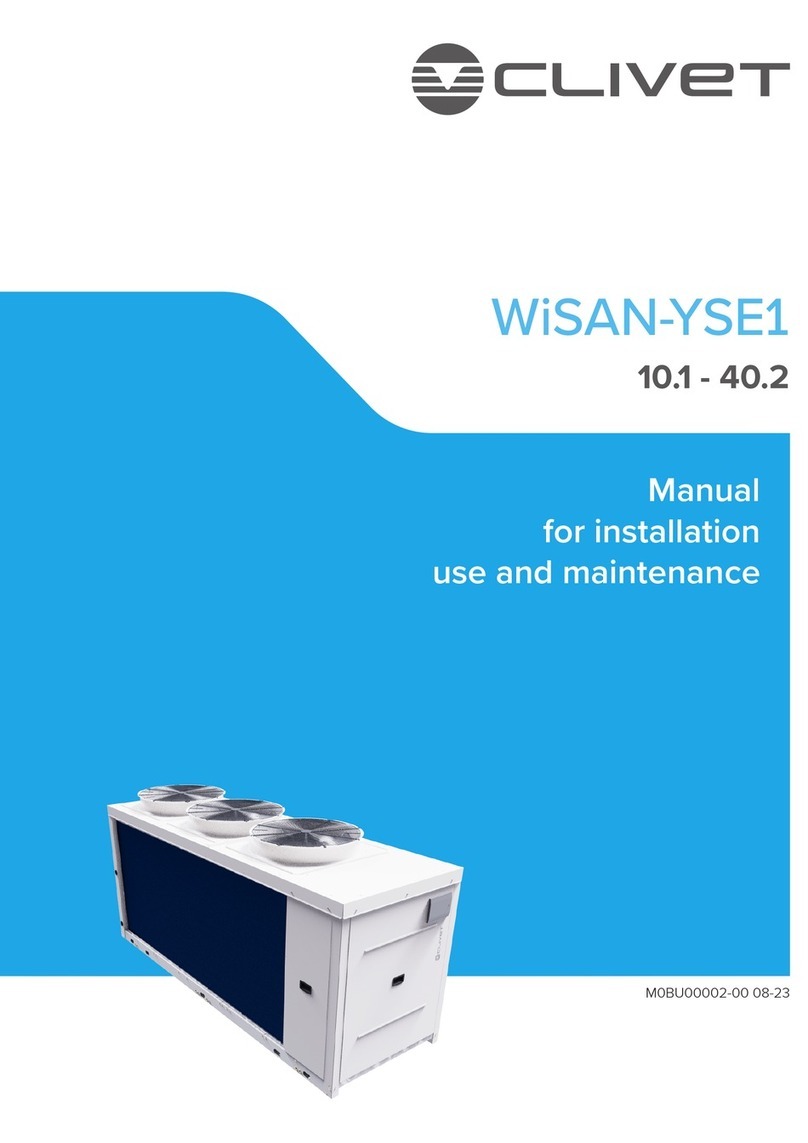

CLIVET WiSAN-YSE1 10.1 User manual

CLIVET

CLIVET Ceiling & Floor-SM2 IF2 53M Series Reference manual

CLIVET

CLIVET MSRN-XSC3 + CEV-XN User manual

CLIVET

CLIVET G3K0GB-1 User manual

CLIVET

CLIVET WSN-XIN Series User manual

CLIVET

CLIVET MSAT-XEE 8.2 User manual

CLIVET

CLIVET WSAN-XEE Series Guide

CLIVET

CLIVET WiSAN-YME 1 S 2.1 Reference manual

CLIVET

CLIVET WSAR-MT-E User manual

Popular Heat Pump manuals by other brands

Samsung

Samsung Max Heat DVM S2 Technical data book

Nibe

Nibe FIGHTER 1240 Installation and maintenance instructions

Ameristar

Ameristar M4MHW2209A installation instructions

Panasonic

Panasonic WH-SHF09D3E5 Service manual

Mitsubishi Electric

Mitsubishi Electric SUZ-SWM VA Series installation manual

Carrier

Carrier 50TFQ008-012 Installation, Start-Up and Service Instructions