Cloos GL 302 User manual

Operating Instructions /

Spare parts list

GL 302

Portable Inverter

GT-D - 03.09.13 - Rev.0

PLEASE KEEP SAFELY FOR FUTURE REFERENCE

CARL CLOOS Schweißtechnik GmbH

Industriestrasse

D-35708 Haiger

Tel.(+49) 2773/85-0

Fax.(+49) 2773/85-275

mail: [email protected]

www.cloos.de

Document: QIGL302DC Month/Year 01/13

EC-Declaration of Conformity

in accordance with EC Directives 2006/95/EG (low voltage) and 2004/108/EG (EMV)

Designation of machine des Gerätes: TIG welding machine

Type: QINEO GL 302 DC

Serial number: see type plate (on the rear of the machine)

The following EC Directives have been applied:

- EC Low voltage directives (2006/95/EG)

- EC Directives on Electromagnetic compatibility (2004/108/EG)

- EC Directives RoHS (2011/65/EU)

The following harmonised standards have been applied:

- EN 60974-1: Arc welding equipment

Part 1: Welding power sources

- EN 60974-3 Arc welding equipment

Part 3: Arc striking and stabilizing devices

- EN 60974-10: Arc welding equipment

Part 10: Electromagnetic compatibility (EMC) requirements

Manufacturer's signature: Dipl.-Kfm. Ralf Pulverich

Information on the signatory: Managing Director

We herewith certify that the welding machine mentioned below has been developed, designed and

Any significant modifications or extensions on the machine which are not carried out by the above

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

3/28

1INTRODUCTION .....................................................................4

2FRONT PANEL .......................................................................4

3REAR PANEL .........................................................................5

4INSTALLATION ......................................................................5

4.1 CONNECTIONS TO THE ELECTRICAL MAINS NETWORK.5

4.2 PREPARING FOR MMA WELDING........................................5

4.3 PREPARING FOR TIG WELDING..........................................6

5USER INTERFACE .................................................................8

6UNIT POWER-UP ...................................................................9

7RESET (LOAD FACTORY SETTINGS)..................................9

7.1 PARTIAL RESET.....................................................................9

7.2 TOTAL RESET......................................................................10

8SET-UP (INITIAL SET-UP OF THE WELDING POWER

SOURCE) ..............................................................................10

8.1 TORCH LOADING.................................................................12

9ALARMS MANAGEMENT ....................................................12

THERMAL ALARM! ..........................................................................12

COOLING DEVICE ALARM..............................................................12

10 WELDING PARAMETERS ...................................................13

Welding current.................................................................................13

Max welding current..........................................................................13

Hot-start ............................................................................................13

Arc-force ...........................................................................................13

VRD ..................................................................................................13

Long arc voltage ...............................................................................13

Remote control..................................................................................13

Dynamic arc......................................................................................13

Second current Bi-level.....................................................................13

Base current......................................................................................13

Peak time..........................................................................................14

Base time..........................................................................................14

Pulse frequency ................................................................................14

Slope down .......................................................................................14

Final current......................................................................................14

Post-gas............................................................................................14

Pre-gas .............................................................................................14

Start current ......................................................................................14

Slope up............................................................................................14

Spot TIG time....................................................................................14

HF arc start .......................................................................................14

Minimum pedal current .....................................................................14

Q-start...............................................................................................14

Multi-tack...........................................................................................14

10.1 PARAMETERS ACTIVATION ...............................................15

11 WELDING SETTINGS...........................................................16

11.1 ELECTRODE WELDING (MMA)...........................................16

11.1.1 MMA PARAMETERS SETTING (1ST LEVEL).................................16

11.1.2 MMA PARAMETERS SETTING (2ND LEVEL) ................................16

11.1.3 MMA SPECIAL FUNCTIONS ...........................................................16

11.2 DC TIG WELDING.................................................................17

11.2.1 DC TIG PARAMETERS SETTING (1ST LEVEL).............................17

11.2.2 DC TIG PARAMETERS SETTING (2ND LEVEL) ............................17

11.2.3 DC TIG SPECIAL FUNCTIONS MENU............................................18

12 JOBS MANAGEMENT..........................................................19

12.1 SAVING A JOB......................................................................19

12.2 LOADING A USER JOB OF FACTORY SET JOB................19

12.3 DELETING A JOB .................................................................19

13 TORCH TRIGGER MODES ..................................................20

13.1 2T LIFT-ARC WELDING .......................................................20

13.2 2T HF WELDING...................................................................20

13.3 4T LIFT-ARC WELDING .......................................................20

13.4 4T HF WELDING...................................................................21

13.5 BI-LEVEL LIFT WELDING.....................................................21

13.6 BI-LEVEL HF WELDING .......................................................21

13.7 2T SPOT WELDING..............................................................21

13.8 2T SPOT HF WELDING........................................................22

13.9 PILOT ARC WELDING..........................................................22

14 TECHNICAL DATA...............................................................23

15 SPARE PARTS.....................................................................24

16 ELECTRICAL DIAGRAM .....................................................26

16.1 GL 302 DC ............................................................................26

16.2 TORCH CONNECTOR .........................................................27

16.3 REMOTE CONTROLLER CONNECTOR .............................27

Cod.006.

0

03/06/201

ENG

L

4/28

1

T

Rea

d

The

m

If t

h

mand

a

§

GL 30

2

all the

f

arc ch

a

The so

compa

n

This u

n

pipelin

e

The pa

weldin

g

The cu

The si

m

with 5

0

The wi

d

the co

m

possibl

0

001.1442

3 v2.1

L

ISH

INTROD

U

T

his handboo

k

installati

o

d

the "Genera

l

separatel

y

fr

o

m

eanin

g

of th

e

precautionar

y

h

e "General p

r

a

tor

y

to reque

s

Retain thes

e

This symbol i

d

result of a pre

v

This s

y

mbol i

d

a different se

c

information.

This s

y

mbol i

d

This s

y

mbol a

the execution

2

DC is an inve

r

f

unctions requi

r

a

racteristics.

lidit

y

of the co

m

n

ion for works

h

n

it is ideal for

m

e

s and chemic

a

rameters pres

e

g

b

y

re

g

ulation

rrent is ad

j

usta

m

pl

y

and intuiti

v

0

storable pro

g

r

d

e ran

g

e of ad

j

m

plementar

y

p

a

e to weld in sl

o

U

CTION

IM

P

k

must be con

s

o

n and commi

s

l

prescription

s

o

m this handb

o

commissioni

n

e

s

y

mbols in t

h

y

information

a

prescription

s

r

escriptions f

o

s

t a replacem

e

or from

y

o

u

e

documents

f

KE

Y

d

entifies an acti

v

ious action.

d

entifies additio

c

tion of the ma

n

d

entifies a refer

ccompanies i

m

of the relevant

r

ter-based wel

d

r

ed for DC TIG

m

ponents of thi

s

h

op and outdoo

m

aintenance, fo

o

a

l plants.

e

t in the DC TI

G

exclusivel

y

of t

ble also from t

h

v

e interface all

o

ams.

ustable pulsed

a

rameters

(

bas

e

o

w and fast pul

s

P

ORTA

s

i

g

ned to the

u

s

sionin

g

of th

e

s

for use" han

d

o

ok before ins

ng

the unit.

h

is manual an

d

a

re

g

iven in th

e

s

for use”.

o

r use" are no

t

e

nt cop

y

from

t

u

r dealer.

f

or future con

s

Y

on that occurs

nal information

n

ual containin

g

ence to a chap

t

m

portant inform

a

operations.

d

in

g

power sou

r

and MMA wel

d

s

unit makes it

a

r applications.

o

d industr

y

, h

yd

G

pulsed s

y

ner

g

he current.

h

e Up-Down to

r

o

ws hi

g

h precis

frequenc

y

in c

o

e

current and d

s

ed mode.

NT!

u

ser prior to

e

unit.

d

book supplie

tallin

g

and

d

the associat

e

e

"General

t

present, it is

t

he manufact

u

s

ultation.

automaticall

y

a

or a reference

the associated

t

er of the man

u

a

tion concernin

g

r

ce complete

w

d

in

g

with excell

e

a

reliable worki

d

raulics, oil

g

ic curve simpli

f

r

ch.

ion ad

j

ustment

s

o

mbination wit

h

ut

y

c

y

cle

)

mak

e

d

e

d

u

rer

a

s a

to

u

al.

g

w

ith

e

nt

n

g

fy

s

h

e

s it

The

w

the ta

b

A

cces

−m

a

c

u

−fo

o

a

d

−U

P

−liq

2

1: N

e

2: P

o

3: C

o

4: C

o

p

o

w

eldin

g

modes

a

b

le.

MODE

MMA

TIG

CONTINUOUS

TIG PULSED

SYNERGIC

TIG

sories that can

a

nual remote c

o

u

rrent.

o

t-pedal remot

e

dj

ustment of w

e

P

/DOWN torch

uid cooler for

T

FRONT

P

1

eg

ative pole w

e

o

sitive pole wel

d

o

nnector for lo

g

o

nnector for

g

a

s

o

wer source J

a

nd procedure

s

+

++

+

+

+

be connected

o

ntroller for re

m

e

controller for

T

e

ldin

g

current.

or torch with p

o

T

IG torches.

P

ANEL

4

e

ldin

g

socket.

d

in

g

socket.

g

ic si

g

nals of TI

s

feed hose:

torch

s

available are

t

PROCEDU

R

2

2T

2 STE

P

2 STE

4 STE

P

4 STE

4 STEP BI-

L

4 STEP BI-LE

V

to the unit:

m

ote ad

j

ustme

n

T

IG torch arc s

t

o

tentiometer.

3

G torch.

GL 302

t

hose indicated

R

E

2

T SPOT

SPOT + HF

P

LIFT-ARC (2T)

P + HF (2T HF)

P

LIFT-ARC (4T)

P + HF (4T HF)

L

EVEL (4T B-LEV

E

V

EL + HF (4T B-L

E

HF)

n

t of the weldin

g

t

rikin

g

and rem

2

DC

in

E

L)

E

VEL

g

ote

GL

0

3

1:

2:

3:

4:

Tota

l

(incl

u

Num

Typ

e

5:

Volt

a

Curr

e

IP pr

If

t

4

4.1

The

sha

l

pa

ge

The

volt

a

Co

n

off.

302 DC

REAR

P

2

4

Weldin

g

powe

r

Remote contro

Connector for

g

cylinder Jpo

w

Power cable.

l

length

u

ding internal part)

ber and cross sect

e

of plug supplied

Cooler power

f

a

ge

e

nt output

otection rating

t

he socket is n

o

pr

e

INSTA

L

Read the war

n

CONNEC

T

NETWO

R

characteristic

s

l

l be connecte

d

e

23.

machine can

b

ag

e is stabilise

d

n

nect/disconne

c

P

ANEL

3

r

source ON/O

F

ller connector.

g

as feed hose:

w

er source

ion of wires

f

eedin

g

connec

t

o

t connected t

o

e

sence of haza

L

LATION

L

i

n

in

g

s hi

g

hli

g

hte

“General pr

e

T

IONS TO T

H

R

K

s

of the mains

p

d

are

g

iven in t

h

b

e connected t

o

d

.

c

t the various d

5

F

F switch.

4

N

t

or.

IP

2

IP

6

WARNIN

G

Hi

g

h volt

a

o

an

y

devices a

l

rdous volta

g

e l

e

WARNIN

G

i

ftin

g

and pos

i

d b

y

the followi

e

scriptions for

u

H

E ELECTRI

C

p

ower suppl

y

to

h

e section entitl

e

o

motor

g

enerat

o

evices with the

1

2.5 m

4

x 1.5 mm

2

N

ot supplied

230 V~

1.35 A

2

0 (cap open)

6

6 (cap closed)

G

!

ag

e!

l

wa

y

s close th

e

e

vels!

G

!

i

tionin

g

n

g

s

y

mbols in

t

u

se”.

C

AL MAINS

which the equ

i

e

d “technical d

a

o

rs provided th

machine switc

e

cap:

t

he

i

pment

a

ta” on

eir

hed

4.

2

1.

2.

3.

4.

5.

6.

7.

8.

9.

S

10

.

W

Th

e

2

PREPA

R

Set the weldi

n

energized).

Plu

g

the pow

e

Choose the el

of the workpi

e

Insert the ele

c

Connect the

e

socket: Positi

v

Connect the

e

Ne

g

ative pole

Connect the

e

Read the wa

r

Set the weldi

n

powered).

S

elect the follo

w

Set the requir

e

W

hen the rem

o

lockin

g

screw

the remote co

e

s

y

stem is rea

R

ING FOR M

M

ng

power sourc

e

e

r cable plu

g

in

t

ectrode based

e

ce to be welde

c

trode in the el

e

e

lectrode holde

r

v

e pole weldin

g

e

arth clamp plu

g

weldin

g

socke

t

e

arth clamp to t

h

r

nin

g

s hi

g

hli

g

ht

e

“General pre

s

ng

power sourc

e

w

in

g

weldin

g

m

e

d weldin

g

par

a

o

te controller [

R

is ti

g

htened, w

ntroller.

d

y

to start wel

d

M

A WELDIN

G

e

ON/OFF swit

c

t

o a mains soc

k

on the t

y

pe of

m

d.

e

ctrode holder.

r

clamp plu

g

to

g

socket.

g

to the followi

n

t.

h

e workpiece

b

WARN

Electric sho

c

e

d b

y

the follo

w

s

criptions for u

s

e

ON/OFF swit

c

ode on the us

e

a

meter values

o

R

C] is connecte

eldin

g

current

c

d

in

g

.

Cod.006.

0

03/06

/

EN

G

G

c

h to “O”

(

unit

d

k

et outlet.

m

aterial and th

the followin

g

w

ng

weldin

g

soc

k

b

ein

g

processe

d

ING!

c

k hazard!

w

in

g

s

y

mbols in

s

e”.

c

h to “I”

(

unit

e

r interface: M

M

o

n the user int

e

d

and the relati

c

an be ad

j

uste

d

0

001.1442

/

2013 v2.1

G

LISH

5/28

d

e-

ickness

w

eldin

g

k

et:

d

.

the

M

A

e

rface.

ve

d

usin

g

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH GL 302 DC

6/28

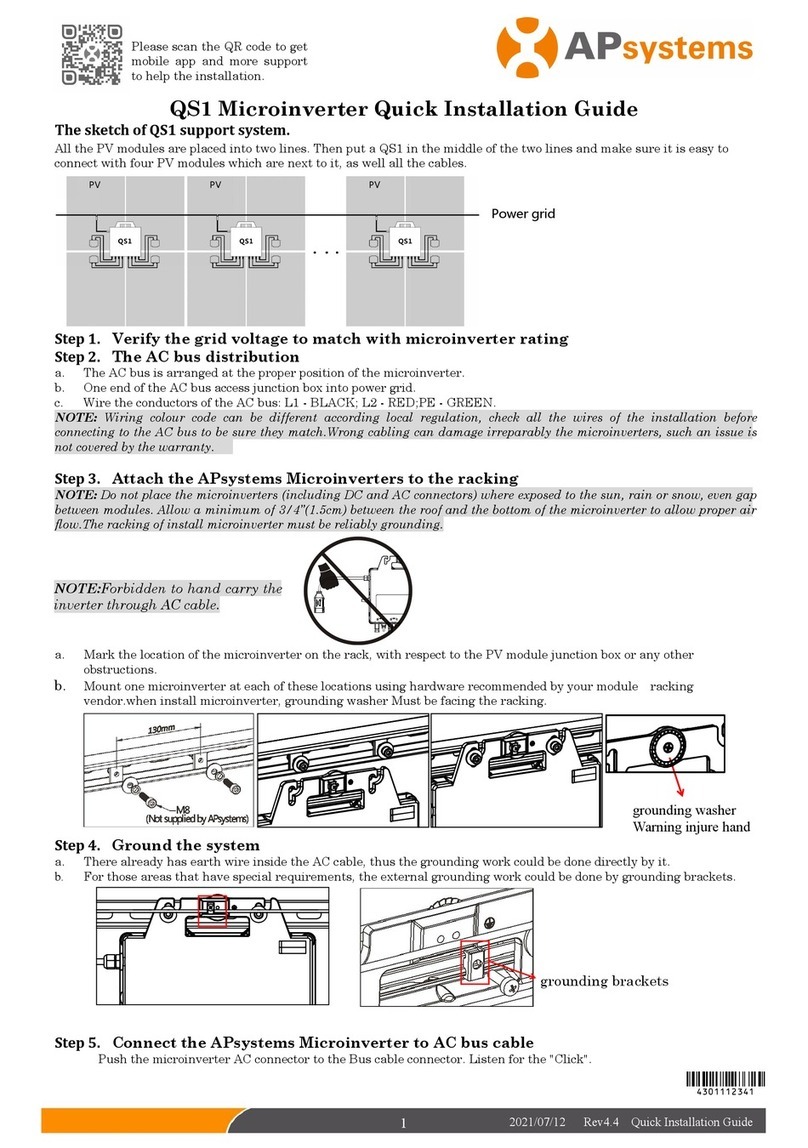

4.3 PREPARING FOR TIG WELDING

Installation with cooling unit

1. Set the welding power source ON/OFF switch to “O” (unit de-

energized).

2. Remove the screws from the power source cabinet.

3. Loosen the screws of the upper brackets of the cooler and open

out the brackets slightly.

4. Place the power source on top of the cooler.

5. Secure the cooler brackets to the power source using the

previously removed screws.

6. Connect the plug of the cooler power cable to the cooler power

socket on the rear panel of the welding power source.

7. Set the cooler ON/OFF switch to “I” (unit powered).

8. Plug the power cable plug into a mains socket outlet.

9. Connect the gas hose from the welding gas cylinder to the rear

gas socket.

10. Open the cylinder gas valve.

11. Connect the gas hose from the welding torch to the front gas

socket.

12. Connect the torch plug to the following welding socket: Negative

pole welding socket.

13. Choose the electrode based on the type of material and thickness

of the workpiece to be welded.

14. Insert the electrode in the TIG torch.

15. Connect the torch plug to the following welding socket: Positive

pole welding socket.

16. Connect the earth clamp to the workpiece being processed.

17. Set the welding power source ON/OFF switch to “I” (unit

powered).

18. Select the following welding mode on the user interface: DC TIG

19. Press the torch trigger with the torch well clear of any metal parts.

This serves to open the gas solenoid valve without striking the

welding arc.

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

7/28

20. Use the flow control valve to adjust the flow of gas as required

while the gas is flowing out.

21. Set the required welding parameter values on the user interface.

When the remote control pedal is connected and the relative

locking screw is tightened the welding current will vary in relation

to the pressure exerted on the pedal.

The system is ready to start welding.

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH GL 302 DC

8/28

5USER INTERFACE

CODE SYMBOL DESCRIPTION

L1 Illumination shows that the following function has been activated: Q-START

L2 Illumination shows that the following function has been activated: DYNAMIC ARC

L3 Illumination shows that the following function has been activated: MULTI TACK

L4 This LED illuminates to confirm the presence of power on the output sockets.

L5 This LED illuminates to show an anomaly in the operating conditions.

See “ALARMS MANAGEMENT”(§ 9 page 12).

L6 Illumination shows that the following function has been activated: 2 times Spot procedure

§ 13.7 page 22 / § 13.8 page 22

L7

When this LED illuminates the following parameter can be set: TIG SYNERGIC PULSE

When this is on, it means that the synergic mode is active and that the operator can set just the welding current while the other parameters are

automatically regulated by the machine. The synergy is optimised by angle welding.

L8 Illumination shows that the following function has been activated: High frequency arc strike (HF)

L9 This LED indicates that the current reference setting is imposed by the remote controller.

L10 Illumination shows that the following function has been activated: 2 times procedure

§ 13.1 page 20 / § 13.2 page 20

L11 Illumination shows that the following function has been activated: 4 times procedure

§ 13.3 page 20 / § 13.4 page 21

L12 Illumination shows that the following function has been activated: 4 times Bi-level procedure

§ 13.5 page 21 / § 13.6 page 21

L13 This LED illuminates to show that the following welding mode is selected: MMA

L14 This LED illuminates to show that the following welding mode is selected: TIG CONTINUOUS

L15 This LED illuminates to show that the following welding mode is selected: TIG PULSED

D1

Parameters/functions setting: 1st level menu: The displays show the value of the following parameter: WELDING CURRENT

Parameters/functions setting: 2nd level menu: The displays show “L.2“.

Welding: The displays show the value of the following parameter: WELDING CURRENT

D2

Parameters/functions setting: The displays show the selected parameter and its value.

Welding: The displays show the average instantaneous voltage value.

HOLD function: The displays show the average voltage value of the last weld executed.

The "HOLD" value is cleared when a new weld is started, or when any action is performed on the user interface.

S1

DC TIG mode: Press the button to select the parameter to be set. Possible choices:

-Q-START

-DYNAMIC ARC

-MULTI-TACK

S2 Press the button once to open the JOB upload menu.

Hold down the button for 3 seconds to gain access to the JOB save/delete menu.

S3 Press the button once to select the parameters of the first level menu.

GL

0

C

6

Set

Fir

s

Su

b

7

The

The

−

−

7.1

The

−

−

−

Set

S3

Exi

t

Exi

t

S3

302 DC

C

ODE S

Y

S4

S5

E1

UNIT P

O

the weldin

g

po

w

300T

Fx.x

x.x=

s

t powe

r

-up or

The weldin

g

p

b

sequent pow

e

The weldin

g

p

RESET

reset procedu

r

reset procedu

r

Too man

y

cha

n

Unidentified s

o

PARTIAL

reset procedu

r

settin

g

s of the

saved JOBS

set language

the weldin

g

po

w

S5

H

S

R

t

without conf

i

Press an

y

This acti

o

t

with confirm

a

Press th

e

This acti

o

Wait for t

Y

MBOL

Ho

Ho

D

C

Th

i

Pa

W

e

O

WER-UP

w

er source O

N

The messa

ge

software vers

powe

r

-ups fo

p

ower source

s

er

-ups

p

ower source

s

(

LOAD F

A

r

e involves co

m

r

e is useful in t

h

ng

es made to t

h

o

ftware proble

m

RESET

r

e involves res

t

SETUP menu

w

er source O

N

H

old down both

et the weldin

g

R

ECALL PART

I

i

rmation

y

button

(

exce

p

o

n will automati

a

tion

e

button.

o

n will automati

he memor

y

cle

ld down the button

ld down the button

C

TIG mode: This

b

§ 13 page 20

i

s button selects th

rameters/functio

n

e

lding: The encod

e

N

/OFF switch to

e

appears on th

e

ion

llowin

g

a RES

s

ets up for weld

s

ets up for weld

A

CTORY S

m

plete restorati

o

h

e followin

g

ca

s

h

e weldin

g

par

a

m

s that prevent

t

t

oration of the

p

N

/OFF switch to

buttons simult

a

power source

O

I

AL SETUP ?

p

t S2

)

.

call

y

close the

call

y

close the

ar procedure t

o

for 3 seconds to g

at the time of pow

b

utton selects the t

o

e welding mode.

n

s setting: The en

c

e

r allows the weldi

n

“I” to switch o

n

e

followin

g

dis

p

ET procedure

in

g

with the fa

c

in

g

in the lates

t

ETTINGS

)

o

n of the defau

l

s

es:

a

meters so us

e

t

he weldin

g

po

w

p

arameter valu

e

“O” to switch t

h

a

neousl

y

.

O

N/OFF switch

The messa

g

menu.

menu.

o

terminate.

ain access to the

s

er-on to gain acce

s

o

rch trigger proced

c

oder provides the

n

g current to be m

o

n

the unit.

p

la

y

s: D2

c

tor

y

presets.

t

stable weldin

g

l

t values, para

m

e

r finds it difficu

l

w

er source fro

m

e

s and settin

g

s

,

h

e unit off.

to “I” to switch

g

e appears on

t

DESCRIPTI

O

s

econd level menu.

s

s to the SETUP

m

ure.

facility to alter the

o

dified.

g

confi

g

uration

t

m

eters and me

m

l

t to restore de

f

m

functionin

g

c

o

,

except the foll

on the unit.

t

he followin

g

di

s

O

N

m

enu.

selected paramet

e

t

hat was active

m

or

y

settin

g

s s

e

f

aults.

o

rrectl

y

.

owin

g

settin

g

s:

SIMULT

A

s

pla

y

s: D2

e

r.

at the time of

p

e

t in the factor

y

:

A

NEOUS ACTION

S

Cod.006.

0

03/06

/

EN

G

p

ower-off.

y

.

S

0

001.1442

/

2013 v2.1

G

LISH

9/28

Cod.006.

0

03/06/201

ENG

L

10/28

7.2

The re

s

A

ll me

m

Set th

e

S3

Exit w

i

Exit w

i

S3

8

Set th

e

S3

S3

E1

*1: Th

e

*2: Thi

*3: Thi

0

001.1442

3 v2.1

L

ISH

TOTAL RES

s

et procedure i

n

m

or

y

locations

w

e

weldin

g

powe

r

S5

Hold

Set

t

RE

C

E1

Sele

RE

C

i

thout confirm

Press an

y

b

u

This action

w

i

th confirmati

o

Press the b

u

MEMORY

R

This action

w

Wait for the

SET-UP

(I

e

weldin

g

powe

r

Hold down t

h

Set the weldi

SET UP T

h

SELECT LA

N

Use this butt

o

Usin

g

the en

c

Press an

y

k

e

e

value of this

p

s settin

g

enabl

e

s settin

g

enabl

e

ET

n

volves compl

e

w

ill be reset an

r

source ON/O

F

down both bu

t

t

he weldin

g

po

w

C

ALL PARTIA

L

ct the followin

g

C

ALL FACTOR

Y

ation

u

tton

(

except

S

w

ill automatical

o

n

u

tton.

R

ESETTING N

O

w

ill automatical

memor

y

clear

p

I

NITIAL S

E

r

source ON/O

F

h

e button.

n

g

power sour

c

h

e messa

g

e a

p

N

GUAGE:

o

n to scroll the

c

oder, edit the

ey

(

except S3

)

t

p

arameter can

b

e

s slow pulsed

e

s fast pulsed

m

e

te restoration

o

d hence all

y

o

u

F

F switch to “O

t

tons simultane

o

w

er source ON

/

L

SETUP ?

settin

g

with th

e

Y

SETUP ?

S

2

)

.

l

y

close the m

e

O

W........ T

h

l

y

close the m

e

p

rocedure to te

E

T-UP OF

T

F

F switch to “O

c

e ON/OFF sw

i

p

pears for a fe

w

The

m

settin

g

s to edi

t

value of the se

t

o save the sett

SETTING

SELECT LANG

U

COOLER ACTIV

A

START CURR

E

FINAL CURR

E

CURRENT

H

KIND OF PU

L

PILOT AR

C

b

e set as a per

c

mode.

m

ode.

o

f the default v

a

u

r personal wel

d

” to switch the

u

o

usl

y

.

/

OFF switch to

Th

e

e

encoder:

e

nu.

h

e messa

g

e ap

p

e

nu.

rminate.

T

HE WEL

D

” to switch the

u

i

tch to “I” to sw

i

w

seconds on th

m

essa

g

e appe

a

t

.

lected settin

g

.

in

g

and quit th

e

Tab.

1

MIN

U

AGE:

A

TION OFF

E

NT %

E

NT %

H

F 20 A

L

SE SLOW (*

2

C

OFF

c

enta

g

e of the

a

lues, paramet

e

d

in

g

settin

g

s w

i

u

nit off.

“I” to switch on

e

messa

g

e app

p

ears on the f

o

D

ING PO

W

u

nit off.

i

tch on the unit

.

e followin

g

dis

p

a

rs on the follo

w

e

menu.

1

- Setup setti

n

DEFAULT

A

UT

A

A

SYN

2

) SLOW

OFF

weldin

g

curren

t

e

rs and memo

r

i

ll be lost!

the unit.

ears on the foll

llowin

g

displa

ys

W

ER SOU

R

SIM

U

p

la

y

s: D2

w

in

g

displa

y

s:

D

ngs

MAX

P

ON

A

*1

A

*1

300 A

FAST (*3)

ON

t

or as an abso

ry

settin

g

s set i

n

SIMULTANE

O

owin

g

displa

y

s

s

: D2

R

CE

)

U

LTANEOUS ACTI

O

D

2

ITALIANO

ENGLISH

FRANÇAIS

DEUTSCH

ESPAÑOL

DUTCH

P

ORTUGUES

SUOMI

CESKY

POLSKI

lute value expr

e

n

the factor

y

.

O

US ACTIONS

: D2

O

NS

e

ssed in Ampe

GL 302

res.

DC

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

11/28

Cooler activation

−ON= The cooler is always running when the power source is switched on. This mode is preferable for heavy duty and automatic welding

procedures.

−OFF= The cooler is always disabled because an air-cooled torch is in use.

−AUT= When the unit is switched on the cooler is switched on for 16 s. During welding procedures the cooler runs constantly. When welding is

terminated the cooler continues to run for 90 s + a number of seconds equivalent to the average current value shown using the HOLD

function.

Current HF

This parameter establishes the current value during HF discharge. The value of this parameter can be set as an absolute value or in SYN.

With SYN setting the HF current value is calculated automatically on the basis of the preset welding current value.

Consequences of a higher value:

−Arc striking is facilitated, even on very dirty workpieces.

−Risk of piercing excessively thin gauge workpieces.

Pilot arc

The function enables the output of a low current between the 1st and 2nd times of the torch trigger to shield the mask in advance and avoid the

risk of blinding flashback caused by the welding current.

Cod.006.

0

03/06/201

ENG

L

12/28

8.1

Ma

k

pre

v

If a to

r

Power

-

A

chec

If the c

o

If the c

o

C

(any

)

Power

-

O

W

Torch

Press

a

T

9

T

A

MESS

A

THERM

A

ALARM!

COOLIN

DEVICE

ALARM

0

001.1442

3 v2.1

L

ISH

TORCH LO

A

k

e sure the tor

c

v

ents the risk o

f

r

ch is installed

-

up with oper

a

k is performed

o

olant circuit is

o

olant circuit is

OOLING DEVI

)

Pres

s

If the

-

up with oper

a

O

peration of the

W

eldin

g

is perfo

chan

g

e-over

w

a

nd release th

e

his serves to s

t

ALARMS

his LED illumin

n alarm messa

A

GE

A

L

Overheating

Indicates trip

p

source therm

Leave the un

overheated c

possible.

When the un

i

power sourc

e

G

Cooler alar

m

Indicates ins

u

liquid cooling

A

DING

c

h in use is cor

r

f

burns to whic

h

or replaced wh

to t

h

a

tion of the co

o

automaticall

y

o

full, the power

not full, all fun

c

CE ALARM

s

the button or

t

problem persi

s

a

tion of the co

o

cooler and the

rmed without li

q

w

ith operation

e

torch tri

gg

er.

t

art the cooler f

o

MANAGE

M

ates if an incor

r

g

e appears on

MEANING

alarm

p

ing of the welding

al protection.

it running so that t

h

omponents cool a

s

i

t has cooled, the

w

e

will reset automa

t

m

u

fficient pressure i

n

circuit.

r

ectl

y

sized in r

e

h

the operator i

s

ile the unit is r

u

h

e torch in the

c

o

ler set to "O

N

o

f the presence

source sets u

p

c

tions are inhib

The messa

g

t

orch tri

gg

er to

s

ts rectif

y

the c

a

o

ler set to "O

F

cooler alarm

a

q

uid coolin

g

of

of the cooler

s

o

r 15 seconds

t

M

ENT

r

ect operatin

g

c

the followin

g

d

power

h

e

s

rapidly as

w

elding

t

ically.

A

ll fun

c

Excep

t

-c

o

-c

o

n

the torch

A

ll fun

c

Excep

t

-c

o

The al

a

perfor

m

Coole

r

the co

o

Coole

r

circum

Coole

r

runnin

g

persis

t

e

lation to the

w

s

potentiall

y

ex

u

nnin

g

, the circ

u

c

ase of hi

g

h vol

N

" or "AUT" m

of liquid in the

p

in the most re

c

ited and there

w

g

e appears on

t

repeat the che

c

a

use of the ala

r

F

F"

a

re disabled.

the torch.

s

et to "ON"

t

o fill the torch

c

c

ondition occur

s

ispla

y

: D2

Tab. 2

c

tions disabled.

t

ions:

o

oling fan.

o

oler (if switched o

n

c

tions disabled.

t

ions:

o

oling fan.

a

rm message pers

m

ed on the user in

t

r

ON: the alarm is

s

o

ler presence sign

a

r

OFF: the alarm i

s

stances.

r

AUT: the alarm i

s

g

; the alarm signal

t

s.

WA

R

w

eldin

g

current

r

posed, potenti

a

u

it of the newl

y

ta

g

e arc strike

s

ode

coolin

g

circuit

a

c

ent stable wel

w

ill be no outp

u

t

he followin

g

di

s

c

kin

g

procedur

e

r

m.

c

oolin

g

circuit.

s

.

- Alarm mess

a

EVENT

n

).

ists on the display

t

erface.

s

ignalled as long a

s

a

l persists.

s

never signalled, ir

s

signalled at the ti

m

occurs as long as

R

NING!

r

equired and f

o

a

l faults, and ir

r

installed must

s

without an

y

li

q

a

nd the cooler

i

din

g

confi

g

urat

u

t power prese

n

s

pla

y

s: D2

e

for an additio

n

ag

e

s

until the first opera

s

the unit alarm is

a

respective of the

m

es in which the u

n

t

he unit presence

s

o

r the available

r

eversible dam

a

be filled with c

o

q

uid in the circ

u

i

s switched on

f

ion.

n

t.

n

al 15 seconds

-M

a

w

e

rat

-C

h

co

m

da

t

-C

h

cir

c

tion is

a

ctive and

n

it is

s

ignal

-C

h

co

r

-C

h

illu

-C

h

-C

h

no

t

co

n

and selected c

o

ag

e to the torc

h

o

olant to avoid

u

it.

f

or 15 seconds

s

.

CHE

C

a

ke sure that the p

o

e

lding process is lo

w

ed power output.

h

eck that the opera

t

m

pliance with the

w

t

a plate specificati

o

h

eck for the presen

c

c

ulation around th

e

h

eck that the conn

e

r

rect.

h

eck that the O/I s

w

minates when the

h

eck that the coole

r

h

eck that the coolin

t

ably the torch hos

e

n

nections of the c

o

GL 302

o

olin

g

t

y

pe. Th

i

and the s

y

ste

m

the risk of dam

.

C

KS

o

wer required by t

h

w

er than the maxi

m

t

ing conditions are

w

elding power sou

r

o

ns.

c

e of adequate air

e

welding power so

e

ction to the cooler

w

itch is set to I and

pump is running.

r

is filled with coola

g

circuit is liquid ti

g

e

s and the internal

o

oler.

DC

i

s

m

.

a

g

e

h

e

m

um

in

r

ce

urce.

is

that it

nt.

g

ht,

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

13/28

10 WELDING PARAMETERS

For a better understanding of the parameter functions described in the table, refer to the following diagram.

(I1) TIG WELDING CURRENT

(I2) BASE CURRENT

(I3) FINAL CURRENT

(I4) STARTING CURRENT

(t1) UP SLOPE TIME

(t2) PEAK TIME

(t3) BASE TIME

(t4) DOWN SLOPE TIME

(1/t2+t3) PULSED CURRENT FREQUENCY

Welding current

Output current value during welding.

Max welding current

Maximum output current value that can be achieved with remote

controller external reference.

Hot-start

This parameter aids electrode melting at the time of arc striking.

Consequences of a higher value:

−Easier arc strike.

−Increased spatter at welding start.

−Increase of strike area.

Consequences of a lower value:

−More difficult arc strike.

−Less spatter at welding start.

−Smaller strike area.

Arc-force

This parameter helps to avoid electrode sticking during welding.

Consequences of a higher value:

−Fluidity during welding.

−Welding arc stability.

−Greater electrode fusion in workpiece.

−More welding spatter.

Consequences of a lower value:

−The arc is extinguished more easily.

−Less welding spatter.

VRD

This parameter reduces the potential across the welding sockets

when welding is not in progress.

The arc strike procedure is as follows:

−Touch the workpiece with the electrode tip.

−Raise the electrode.

Power is released for several seconds.

−Touch the workpiece with the electrode tip.

The welding arc will strike.

Long arc voltage

This parameter inhibits power output when the potential between

electrode and workpiece exceeds the preset threshold level.

Consequences of a higher value:

−The welding arc persits even with a significant distance between

the electrode and the workspiece.

Consequences of a lower value:

−Faster exit from weld.

Remote control

This parameter enables the unit to receive the current reference

signal from a remote control.

Dynamic arc

Welding power remains constant even when the distance between

electrode and workpiece changes.

Consequences of a higher value:

−The welding arc concentration remains unchanged.

−Prevents electrode sticking.

−Thin workpieces may become deformed more easily.

Second current Bi-level

With a rapid press and release (less than 0.5 seconds) of the torch

trigger during welding, the output current value switches to the value

set by means of the “bi-level second current” parameter.

In DC TIG welding, the parameter is useful when welding different

gauge workpieces during the same pass; when moving between

different gauges the output current can be changed simply by

pressing the torch trigger.

In AC TIG welding the parameter is useful to change the heat output

during welding; when the workpiece heats up to the point at which

there is a risk of deformation, the current value (= heat) can be

reduced simply by pressing the torch trigger.

Base current

Pulsed wave minimum current.

Consequences of a higher value:

−Faster creation of weld pool.

−Increase of heat-affected zone.

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH GL 302 DC

14/28

Peak time

Time for which the current pulse is at the maximum value.

Consequences of a higher value:

−Greater weld penetration.

−Facility to make deeper cuts.

Consequences of a lower value:

−Reduction of heat-affected zone.

−Difficult to create a weld pool.

Base time

Time during which current output is at the base value.

Consequences of a higher value:

−The filler material is spread more evenly.

−Increase of heat-affected zone.

Pulse frequency

Consequences of a higher value:

−Slower melt speed.

−Reduction of heat-affected zone.

Slope down

Time during which the current changes from the welding value to the

end value by means of a slope.

Final current

During electrode welding the parameter makes it possible to obtain a

uniform deposit of filler material from the start to the end of the

welding process, closing the deposition crater with a current such as

to deposit a final droplet of filler material.

By keeping the torch trigger pressed during the 3rd time, the crater

filler current is maintained thereby ensuring optimal crater filling, until

the POST GAS time is started by releasing the torch trigger (4Th

time).

Post-gas

Time of post gas delivery when the welding arc is extinguished.

Consequences of a higher value:

−More effective pickling (improved appearance of workpiece at the

end of the welding pass).

−Higher gas consumption.

Consequences of a lower value:

−Lower gas consumption.

−Oxidation of electrode tip (more difficult arc strike).

Pre-gas

Time of gas delivery before the arc strike.

Consequences of a higher value:

−This parameter allows a shielded environment to be created,

thereby eliminating contaminants at the start of the welding pass.

Start current

Unit current output value immediately after the arc strike.

Slope up

Time during which the current changes from the starting value to the

welding value by means of a slope.

Spot TIG time

When the torch trigger is pressed the welding arc persists for the time

set in the parameter.

Press the torch trigger again to resume the welding process.

The arc strike procedure is as follows:

Positioning of the torch with the electrode on the workpiece.

Press the torch trigger and keep it pressed.

Lift the torch slightly.

As soon as the electrode is lifted then the HF ignition starts.

The arc ignites for few hundredths of a second (time can be set up).

The result of this is a very precise, not oxidized welding spot without

any plastic deformation of the sheet.

HF arc start

This parameter enables the arc strike in the TIG welding procedure by

means of a high frequency (HF) current discharge.

The parameter prevents the inclusion of impurities at the start of the

weld pass.

This parameter can harm electronic boards when welding is

performed on equipment that incorporates such devices.

Minimum pedal current

Minimum output current value with foot pedal controller external

reference.

The current is set as a percentage with respect to the "maximum foot

pedal current" parameter.

Q-start

This parameter allows the unit to start in synergic pulsed TIG mode

for the preset time interval, before switching automatically to the

welding procedure selected on the interface panel.

The parameter creates a weld pool faster with respect to the standard

starting procedure.

This parameter is useful when spot welding thin gauge sheet.

Multi-tack

This parameter allows thin gauge sheet to be welded without

deformation.

Consequences of a higher value:

−Welding of thinner gauge sheet without deformation.

−Less melting of material, slower welding process.

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

15/28

10.1 PARAMETERS ACTIVATION

The welding parameters are available in accordance with the selected welding mode and procedure.

Certain parameters are available only after other parameters or functions of the unit have been enabled or set.

The table shows the settings required to enable each parameter.

9: always available 1: Available with the user interface reference

active

2: Available with "REMOTE CONTROL"= ON

and remote controller connected

3: Available when "HF ARC START" parameter

=ON 4: Not available with "MULTI TACK" active 5: Available with "KIND OF PULSE"= SLOW

6: Available with "KIND OF PULSE"= FAST

MENU MODE x

zPROCEDURE x

PARAMETER z

1° WELDING CURRENT 1 1 1 1 1 1 1 1 1 1 1 1 1

1° MAX WELDING CURRENT 2 2 2 2 2 2 2

1° HOT-START

9

1° ARC-FORCE

9

1° PRE-GAS 3 3 3 3 3 3 3 3 3 3 3 3

1° START CURRENT

999999999999

1° SLOPE UP 4 4 4 4 4 4 4 4 4 4 4 4

1° SECOND CURRENT BI-LEVEL 999

1° BASE CURRENT

99999999

1° PEAK TIME

DUTY CYCLE 99999999

1° PULSE FREQUENCY 6 6 6 6 6 6 6 6

1° BASE TIME 5 5 5 5 5 5 5 5

1° SLOPE DOWN 4 4 4 4 4 4 4 4 4 4 4 4

1° POST-GAS

999999999999

2° VRD

9

2° LONG ARC VOLTAGE 9

2° REMOTE CONTROL

9999999999999

2° FINAL CURRENT 4 4 4 4 4 4 4 4 4 4 4 4

2° SPOT TIG TIME 9

9

9

2° MINIMUM PEDAL CURRENT 2 2 2 2 2 2

2° HF ARC START 999999999999

SPECIAL Q-START 3 + 4 3 + 4 3 + 4 3 + 4 3 + 4 3 + 4

SPECIAL DYNAMIC ARC 94 4 4 4

SPECIAL MULTI-TACK 3 3 3 3 3 3

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH GL 302 DC

16/28

11 WELDING SETTINGS

11.1 ELECTRODE WELDING (MMA)

S5 This button serves to select the following welding mode:

MMA

11.1.1 MMA PARAMETERS SETTING (1ST LEVEL)

S3 Press this button to scroll the list of settings to edit.

The selected parameter and its value are shown on the following displays: D2

E1 Using the encoder, edit the value of the selected setting.

The value is saved automatically.

Press any key (except S3) to save the setting and quit the menu.

Tab. 3 - Parameters of the 1st level menu in MMA mode

PARAMETE

R

MIN DEFAULT MAX

WELDING CURRENT 10 A 80 A 300 A

MAX WELDING CURRENT 5 A 80 A 300 A

HOT-START 0 % 50 % 100 % *1

A

RC-FORCE 0 % 30 % 100 % *1

*1: This parameter is set as a percentage referred to the value of the following parameter: WELDING CURRENT

11.1.2 MMA PARAMETERS SETTING (2ND LEVEL)

S3 Hold down the button for 3 seconds to gain access to the 2nd level menu.

L.2 The message appears on the following displays: D1

L.2= LEVEL.2= 2ND LEVEL MENU

The selected parameter and its value are shown on the following displays: D2

S3 Press this button to scroll the list of settings to edit.

E1 Using the encoder, edit the value of the selected setting.

The value is saved automatically.

Press any key (except S3) to save the setting and quit the menu.

Tab. 4 - Parameters of the 2nd level menu in MMA mode

PARAMETE

R

MIN DEFAULT MAX

VRD OFF OFF ON *3

LONG ARC VOLTAGE 37 SYN 65 *4

REMOTE CONTROL OFF OFF ON *2

*2: The activation is suitable for the following welding modes:

−MMA

−DC TIG

−AC TIG

Compatible remote control types:

−manual remote controller.

*3: The activation is suitable for the following welding modes:

−MMA

*4: SYN: This code indicates that parameters control is synergic. The optimal value of this parameter is set automatically by the microprocessor

on the basis of the preset welding current value. This value can be displayed but it is not user-adjustable.

11.1.3 MMA SPECIAL FUNCTIONS

S1 Press this button to scroll the list of settings to edit.

The selected parameter and its value are shown on the following displays: D2

E1 Using the encoder, edit the value of the selected setting.

The value is saved automatically.

Press any key (except S1) to save the setting and quit the menu.

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

17/28

Tab. 5 - Special functions in MMA mode

PARAMETE

R

MIN DEFAULT MAX

DYNAMIC ARC OFF OFF ON

11.2 DC TIG WELDING

S5 Use this button to select one of the following welding modes:

DC TIG PULSED DC TIG SYNERGIC TIG

S4 Use this button to select one of the following torch trigger procedures:

2 STEP 2T SPOT 4 STEP 4 STEP BI-LEVEL

11.2.1 DC TIG PARAMETERS SETTING (1ST LEVEL)

S3 Press this button to scroll the list of settings to edit.

The selected parameter and its value are shown on the following displays: D2

E1 Using the encoder, edit the value of the selected setting.

The value is saved automatically.

Press any key (except S3) to save the setting and quit the menu.

Tab. 6 - 1st level menu parameters in DC TIG mode

PARAMETE

R

MIN DEFAULT MAX

WELDING CURRENT 5 A 80 A 300 A

MAX WELDING CURRENT 5 A 80 A 300 A

SECOND CURRENT BI-LEVEL 10 % 50 % 200 % *1

BASE CURRENT 1 % 40 % 200 %

SYN SYN SYN *3

PEAK TIME 0.1 s 5.0 s 5.0 s *5

DUTY CYCLE 1 % 50 % 99 % *4

SYN SYN SYN *3

BASE TIME 0.1 s 5.0 s 5.0 s *5

PULSE FREQUENCY

0.1 Hz 100 Hz 2.5 kHz *4

0.1 Hz 5.0 Hz 5.0 Hz *5

SYN SYN SYN *3

SLOPE DOWN 0.0 s 0.0 s 25.0 s

FINAL CURRENT 5 % 5 % 80 % *2

5 A 5 A 300 A *2

POST-GAS 0.0 s 10.0 s 25.0 s

PRE-GAS 0.0 s 0.1 s 10.0 s

START CURRENT 2 % 50 % 200 %

5 A 50 A 300 A

SLOPE UP 0.0 s 0.0 s 25.0 s

*1: This parameter is set as a percentage referred to the value of the following parameter: WELDING CURRENT

*2: The value of this parameter can be set as a percentage of the welding current or as an absolute value expressed in Amperes.

*3: SYN: This code indicates that parameters control is synergic. The optimal value of this parameter is set automatically by the microprocessor

on the basis of the preset welding current value. This value can be displayed but it is not user-adjustable.

*4: Available when "KIND OF PULSE" parameter= FAST

*5: Available when "KIND OF PULSE" parameter= SLOW

11.2.2 DC TIG PARAMETERS SETTING (2ND LEVEL)

S3 Access the 2nd level menu by holding the button down for 3 seconds.

L.2 The message appears on the following displays: D1

L.2= LEVEL.2= 2ND LEVEL MENU

S3 Press this button to scroll the list of settings to edit.

The selected parameter and its value are shown on the following displays: D2

E1 Using the encoder, edit the value of the selected setting.

The value is saved automatically.

Press any key (except S3) to save the setting and quit the menu.

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH GL 302 DC

18/28

Tab. 7 - 2nd level menu parameters in DC TIG mode

PARAMETE

R

MIN DEFAULT MAX

SPOT TIG TIME 0.01 s 0.1 s 10.0 s

HF ARC START ON ON OFF

REMOTE CONTROL OFF OFF ON *1

MINIMUM PEDAL CURRENT 1 % 50 % 90 % *2

*1: The activation is suitable for the following welding modes:

−MMA

−DC TIG

−AC TIG

Compatible remote control types:

−manual remote controller.

−UP/DOWN or potentiometer TIG torch.

−foot pedal controller.

The maximum and minimum TIG welding current values can be set with the foot pedal controller.

The up slope and down slope cannot be controlled via the foot pedal.

The following welding procedures can be selected with the foot pedal: + +

2T LIFT-ARC 2T HF 2T SPOT 2T SPOT + HF

If both remote controllers are connected, the foot pedal assumes priority over the UP/DOWN or potentiometer TIG torch.

When this function is active welding is performed without the following parameters:

−SLOPE UP

−SLOPE DOWN

−All special functions

*2: This parameter is set as a percentage referred to the value of the following parameter: WELDING CURRENT

11.2.3 DC TIG SPECIAL FUNCTIONS MENU

S1 Press this button to scroll the list of settings to edit.

The selected parameter and its value are shown on the following displays: D2

E1 Using the encoder, edit the value of the selected setting.

The value is saved automatically.

Press any key (except S1) to save the setting and quit the menu.

Tab. 8 - Special functions in DC TIG

PARAMETE

R

MIN DEFAULT MAX

DYNAMIC ARC OFF OFF ON *3

Q-START 0.1 s OFF 10.0 s *3

MULTI-TACK 0.5 Hz OFF 6.0 Hz *2 *3

*2: When this function is active welding is performed without the following parameters:

−SLOPE UP

−SLOPE DOWN

−START CURRENT

−FINAL CURRENT

−DYNAMIC ARC

−Q-START

*3: When "REMOTE CONTROL"= ON and a foot pedal is connected the functions are all inhibited.

GL 302 DC

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH

0

19/28

12 JOBS MANAGEMENT

Personalised welding settings, or JOBs, can be saved in memory locations and subsequently uploaded.

Up to 50 jobs can be saved (j01-j50).

The settings of the SETUP menu are not saved.

12.1 SAVING A JOB

This function is available when welding mode is not active.

S5 Hold down the button for 3 seconds.

JOB STORAGE SELECTION The message appears on the following displays: D2

S5 Press the button to confirm.

STORE JOB N.xx The message appears on the following displays: D2

xx= number of the first free job.

JOB MEMORY FULL When there are no free memory locations the message appears on the following displays: D2

E1 Use the encoder to select the required job number.

On selecting a currently occupied memory location, the job number flashes.

If you confirm at this point, the new job will overwrite the previously saved settings.

Exit without confirmation

Press any button (except S2).

This action will automatically close the menu.

Exit with confirmation

S2 Press the button.

This action will automatically close the menu.

12.2 LOADING A USER JOB OF FACTORY SET JOB

This function is available when welding mode is not active.

S2 Press and release the button.

LOAD JOB N.xx Only when the jobs have been uploaded, the message is shown on the following displays: D2

xx= number of the latest job used.

NO JOB LOADED If there are no jobs in the memory the message is shown on the following displays: D2

E1 Use the encoder to select the number of the job to be uploaded.

Exit without confirmation

Press any button (except S2).

This action will automatically close the menu.

Exit with confirmation

S2 Press the button.

LOADED JOB N.xx The message appears on the following displays: D2

This action will automatically close the menu.

When a job is loaded and an UP/DOWN torch is installed, press the torch triggers to select the saved jobs.

12.3 DELETING A JOB

This function is available when welding mode is not active.

S2 Hold down the button for 3 seconds.

JOB STORAGE SELECTION The message appears on the following displays: D2

E1 Select the following setting with the encoder:

JOB ERASURE SELECTION The message appears only if there are saved JOBS, on the following displays: D2

S2 Press the button to confirm.

ERASE JOB N.xx The message appears on the following displays: D2

xx= number of the latest job used.

Cod.006.0001.1442

03/06/2013 v2.1

ENGLISH GL 302 DC

20/28

NO STORED JOB The message appears only if there are saved JOBS, on the following displays: D2

E1 Use the encoder to select the number of the job to be deleted.

Exit without confirmation

Press any button (except S2).

This action will automatically close the menu.

Exit with confirmation

S2 Press the button.

This action will automatically close the menu.

13 TORCH TRIGGER MODES

13.1 2T LIFT-ARC WELDING

1. Touch the workpiece with the torch electrode.

2. Press (1T) and keep the torch trigger pressed.

3. Slowly lift the torch to strike the arc.

The welding current reaches the preset value, by way of a up slope time, if programmed.

4. Release (2T) the trigger to start the weld completion procedure.

The current reaches the end current value in the time set in the down slope time parameter.

The arc is extinguished.

Gas delivery continues for the time set in the post gas parameter.

13.2 2T HF WELDING

1. Bring the torch up to the work until the electrode tip is approximately 2 or 3 mm away.

2. Press (1T) and keep the torch trigger pressed.

The arc strikes without contact with the workpiece and the voltage discharges (HF) cease automatically.

The welding current reaches the preset value, by way of a up slope time, if programmed.

3. Release (2T) the trigger to start the weld completion procedure.

The current reaches the end current value in the time set in the down slope time parameter.

The arc is extinguished.

Gas delivery continues for the time set in the post gas parameter.

13.3 4T LIFT-ARC WELDING

1. Touch the workpiece with the torch electrode.

2. Press (1T) and release (2T) the torch trigger.

3. Slowly lift the torch to strike the arc.

The welding current reaches the preset value, by way of a up slope time, if programmed.

4. Press (3T) the trigger and keep it pressed to start the weld completion procedure.

The current reaches the end current value in the time set in the down slope time parameter.

The arc continues and the current output will be the value set in the end current. parameter.

In these conditions the weld pool can be closed (crater filler current).

5. Release (4T) the trigger to extinguish the arc.

Gas delivery continues for the time set in the post gas parameter.

Table of contents

Other Cloos Inverter manuals

Popular Inverter manuals by other brands

Generac Power Systems

Generac Power Systems 009600-5, 009734-5 owner's manual

Platinum

Platinum 7000 R3 Installation and user guide

KEHUA TECH

KEHUA TECH SPI-B2 Series user manual

Power Electronics

Power Electronics SD700FL Series Hardware and installation manual

Westerbeke

Westerbeke 8 BCDT-614 Specifications

Hyundai

Hyundai HY12000LE-3 instruction manual

EG4

EG4 6000EX-48 user manual

Steca

Steca coolcept StecaGrid 1500 Installation and operating instruction

Wagan

Wagan Smart AC 100 USB user manual

Power Products

Power Products LIMITED 2000I Instructions for use

Afore

Afore Anybuild BNT KTL Series user manual

Champion

Champion 100238 Owner's manual & operating instructions