CMC Rescue ENFORCER User manual

INSTRUCTIONS FOR USE

CMC Rescue, Inc.

6740 Cortona Drive

Goleta, CA 93117 USA

800 235 5741 |805 562 9120

email |info@cmcpro.com

cmcpro.com

ENFORCER

Load Cell Kit

nFAILURE TO FOLLOW THESE INSTRUCTIONS, OR IMPROPER

USE OF THIS EQUIPMENT COULD RESULT IN SERIOUS INJURY

OR DEATH.

nTHIS EQUIPMENT HAS BEEN DESIGNED AND MANUFACTURED

FOR USE BY EXPERIENCED PROFESSIONALS ONLY.

nDO NOT ATTEMPT TO USE THIS EQUIPMENT WITHOUT PROPER

TRAINING.

nUSE, INSPECT, AND REPAIR ONLY IN ACCORDANCE WITH

THE MANUFACTURER’S INSTRUCTIONS.

WARNING!

IMPORTANT INFORMATION, PLEASE READ AND SAVE.

ISO 9001 Certified

©2018 CMC Rescue, Inc.

300750.01.012418

5F04

CARRYING, MAINTENANCE & STORAGE

Do not store for long periods with the batteries installed as they may leak and corrode the

interior of the device.

REPAIR

SAMPLE LOG

The sample log suggests records that should be maintained by the purchaser or user of

life safety equipment.

Equipment Inspection and Maintenance Log

Item # Date in Service

Brand / Model Strength

Date How Used or Maintained Comments Name

MEETS THE AUXILIARY EQUIPMENT REQUIREMENTS

OF NFPA 1983, STANDARD ON LIFE SAFETY ROPE AND EQUIPMENT

FOR EMERGENCY SERVICES, 2017 EDITION.

EMERGENCY SERVICES AUXILIARY EQUIPMENT

IN ACCORDANCE WITH NFPA 1983-2017.

300750 GENERAL USE (G) MBS 42 kN (9,441 lbf)

Structural parts manufactured in the USA using domestic and foreign materials.

Assembled in the USA using domestic and foreign electronic subassemblies.

Clean and dry this equipment after each use to remove any dust, debris and moisture.

During use, carrying and storage keep the equipment away from acids, alkalis, rust and

strong chemicals. Do not expose the equipment to flame or high temperatures. Store in a

cool, dry location. Do not store where the equipment may be exposed to moist air,

particularly where dissimilar metals are stored together.

All repair work shall be performed by the manufacturer. All other work or modifications void

the warranty and releases CMC from all liability and responsibility as the manufacturer.

USER INFORMATION

User Information shall be provided to the user of the product.

NFPA Standard 1983 recommends separating the User Information from the equipment and

retaining the information in a permanent record. The standard also recommends making a

copy of the User Information to keep with the equipment and that the information should be

referred to before and after each use.

Additional information regar ding auxiliary equipm ent can be found in NFPA 1500, Standard

on Fire Department Occupational Safety and Health Programs and NFPA 1983, Standard

on Life Safety Rope and Equipment for Emergency Services.

INSPECTION

The service life of equipment used for rescue depends greatly on the type of use and the

environment of use. Because these factors vary greatly, a precise service life of the equipment

cannot be provided. Moisture, ice, salt, sand, snow, chemicals and other factors can prevent

proper operation or can greatly accelerate wear and may damage the electronics.

Inspect the equipment for cracks, dents, elongation of the swivels, corrosion or excessive

wear. Verify that the swivels rotate freely and that the axle bolts have not loosened. If any

significant damage is observed, the equipment should be removed from service. Minor

nicks or sharp spots may be smoothed with emery paper.

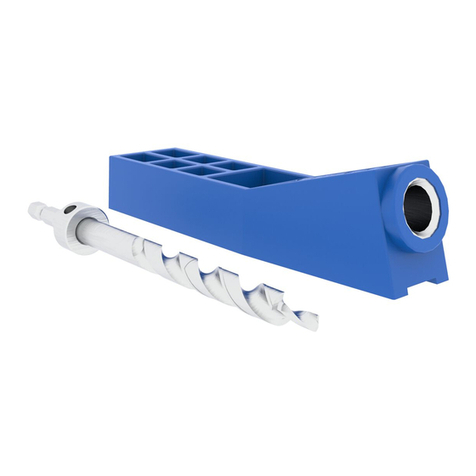

USING THE ENFORCER

To measure the force applied to a rope system at a given point, connect the Enforcer

between two components of the system. An example would be for monitoring the tension

in the trackline of a highline system.

Ensure the Enforcer is free to align with the load (Figure 1) and does not bind or lever

against connectors (Figure 2) or terrain/obstructions (Figure 3). Verify compatibility

with other components of your system. Incompatible connections can cause detachment,

breakage, etc. Do not use with steel cable having a twisted construction.

The Enforcer is rated to 42 kN (9,442 lbf), but the electronics may be damaged at loads

over 20 kN (4,496 lbf) and at loads over 20 kN the display will permanently indicate

OVERLOADED. In this case the Enforcer should not be used in life safety applications.

It is recommended that you establish your own Working Load Limit (WLL) depending

on your use.

Refer to the Quick Reference Guide provided for instructions on how to operate each

of the Load Cell functions, including Bluetooth connectivity to a mobile device. For

the most current version of the reference card, please visit cmcpro.com/enforcer

or call Customer Support at 800 235 5741.

Structural components of the Enforcer are very rugged, and the electronics are durable,

but it can be damaged by dropping. The electronics are resistant to light moisture, but not

waterproof. The unit should be protected from rain or other direct water exposure. If it must

be used in such conditions wrap it in clear plastic, making sure it dries out completely

later. If you use the Enforcer in drop or strength testing, protect it from hitting something

if breakage will occur.

Figure 1 OK Figure 2 NO Figure 3 NO

If the equipment is dropped or impact loaded, it should be inspected by a qualified

inspector prior to being returned to service. Based on the history of the incident, if there is

any doubt regarding the safety of the equipment, it should be removed from service and

retired. You should occasionally apply a known force to verify the Enforcer is accurate. Be

aware during use; stop and check if forces don’t seem reasonable. The Enforcer unit should

be returned to the manufacturer for calibration when needed. Contact Customer Support at

800 235 5741 for more information.

Inspect the equipment according to your department's policy for inspecting life safety

equipment. Inspect the equipment prior to entry into service, after each use, and at least

once every 12 months. The equipment should be thoroughly inspected by an inspector

that meets your department's training standard for inspection of life safety equipment.

Keep a record of the date, person performing the inspection and results, as well as the

date of first use, name of users and any other pertinent information necessary to keep

accurate track of the equipment’s usage history in the equipment log or on a tag that

attaches to the equipment. Each user should be trained in equipment inspection and

should inspect the equipment before each use.

This manual suits for next models

1