INTRODUCTION

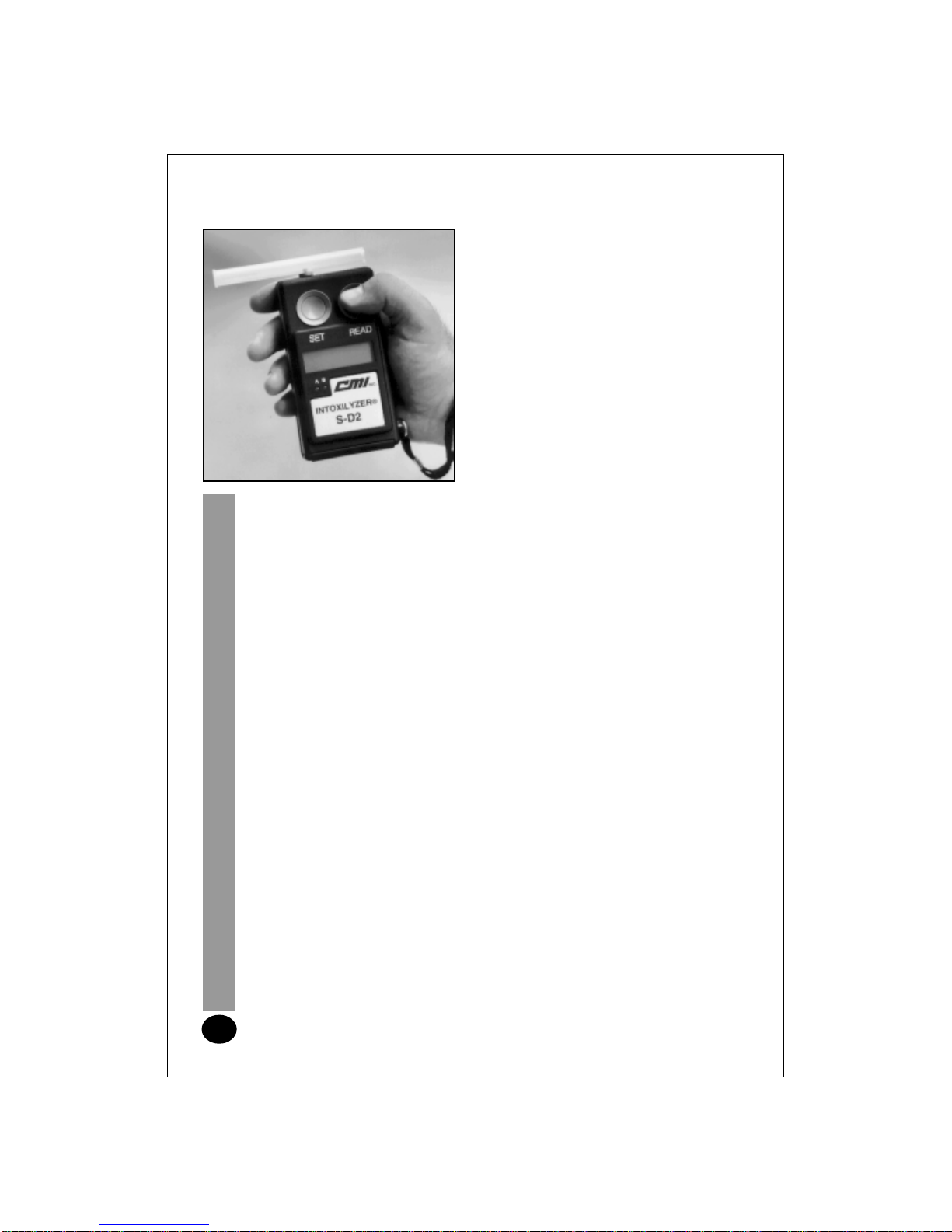

The Intoxilyzer®S-D2

representsa wellestablished

conceptinbreathalcohol

testing analysis. It is used

worldwideinlawenforce-

ment,transportationand

workplace safety applications. The S-D2 is just

oneof the range of instruments manufactured by

CMI, Inc. for these purposes.

TheIntoxilyzer®S-D2isaccurate and reliable,

allowinga complete breath test procedureto be

conducted in about one minute.

Thismanualdescribes the operation,

maintenance,calibrationcheck,and calibration

adjustment of the S-D2. This manual should be

readcompletelyandfullyunderstoodbyeach

operator prior to testing a subject. It is further

recommendedthatoperatorspractice the breath

testing process before giving an actual “in the

field” test.

The information contained in this manual concerning operational

procedures, protocols, accuracy verification schedules and

techniques is presented solely for the purpose of establishing a

general knowledge of the instrument and its operation. CMI

recognizes that many law enforcement customers have

agencies responsible for specifying instrument procedures,

protocols and techniques based upon their individual needs,

current laws and pre-existing administrative rules. Therefore, if

any such procedure, protocol, schedule or technique described

in this manual conflicts with the rules set forth by a recognized

governing agency, CMI defers to those authorized entities.

1

INTOXILYZER®S-D2 Operator’s Manual