INSTRUCTIONMANUAL

MODEL8128

POWERCLAMPSENSOR

Series

POWERCLAMPSENSOR

KYORITSUELECTRICALINSTRUMENTS

WORKS,LTD.

1.Safetywarnings

○Thisinstrumenthas been designed, manufactured and

tested according to IEC 61010: Safety requirements for

ElectronicMeasuringapparatus,anddelivered inthe

bestcondition after passing quality controltests.This

instructionmanual contains warnings and safety rules

whichhave to be observed by the user to ensure safe

operationof theinstrumentand tomaintainit insafe

condition.Therefore,readthroughtheseoperating

instructionsbeforeusingtheinstrument.

WARNING

●Readthroughandunderstandinstructionscontained

inthismanualbeforeusingtheinstrument.

●Keepthemanualathandto enablequickreference

whenevernecessary.

●Theinstrument istobeusedonly initsintended

applications.

Theoperating instructions described in themanual

mustbeobserved.

●Understandandfollowallthesafetyinstructions

containedinthemanual.Itisessentialthattheabove

instructionsareadheredto.Failuretofollowthe

above instructions may cause injury and or

instrumentdamage.

○The symbol indicated on the instrument, means that

theusermustrefertotherelatedpartsinthemanualfor

safeoperation of the instrument. It is essential to read

the instructions wherever the symbol appears in the

manual.

DANGER is reserved for conditions and actions

thatarelikelytocauseseriousorfatal

injury.

WARNING is reserved for conditions and actions

thatcancauseseriousorfatalInjury.

CAUTION is reserved for conditions and actions

that can cause minor injury or

instrumentdamage.

F

〜

Refertotheinstructionsinthemanual.

IndicatesaInstrumentwithdoubleorreinforced

insulation

Indicatesthatthisinstrumentcanclamponbare

conductors.

IndicatesAC

Safetysymbols

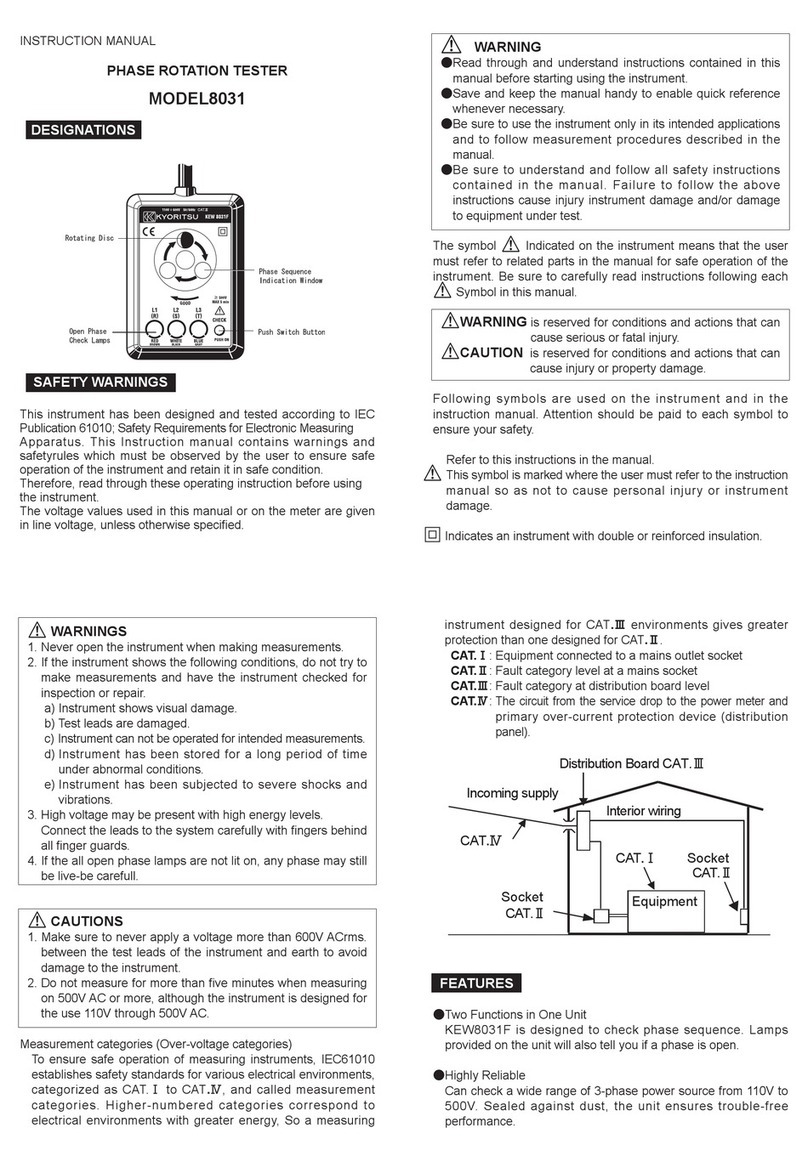

○Measurementcategories(Over-voltagecategories)

Toensuresafeoperationofmeasuringinstruments,IEC

61010establishessafetystandardsforvariouselectrical

environments,categorizedasCATⅠtoCATⅣ,and

calledmeasurementcategories.

Higher-numberedcategoriescorrespondtoelectrical

environmentswithgreatermomentaryenergy,soa

measuringinstrumentdesignedforCATⅢ environments

canenduregreatermomentaryenergythanone

designedforCATⅡ.

CAT.Ⅰ:SecondaryelectricalcircuitsconnectedtoanAC

electricaloutlet throughatransformer orsimilar

device.

CAT.Ⅱ:Primary electrical circuits of equipment

connectedtoanACelectricaloutletbyapower

cord.

CAT.Ⅲ:Primaryelectricalcircuitsoftheequipment

connecteddirectly tothe distributionpanel,and

feedersfromthedistributionpaneltooutlets.

CAT.Ⅳ:Thecircuitfrom the service drop to the service

entrance,and to the power meter andprimary

overcurrentprotectiondevice(distribution

panel).

Incoming wire

CAT.IV

Interior wiring

Transformer

CAT.I

CAT.II

CAT.III

t

2.Features

●ThisisaclampsensorforourPowermeter.

●Designedtointernationalsafetystandard

IEC 61010-2-032

CAT.Ⅲ 300V(PollutionDegree2)

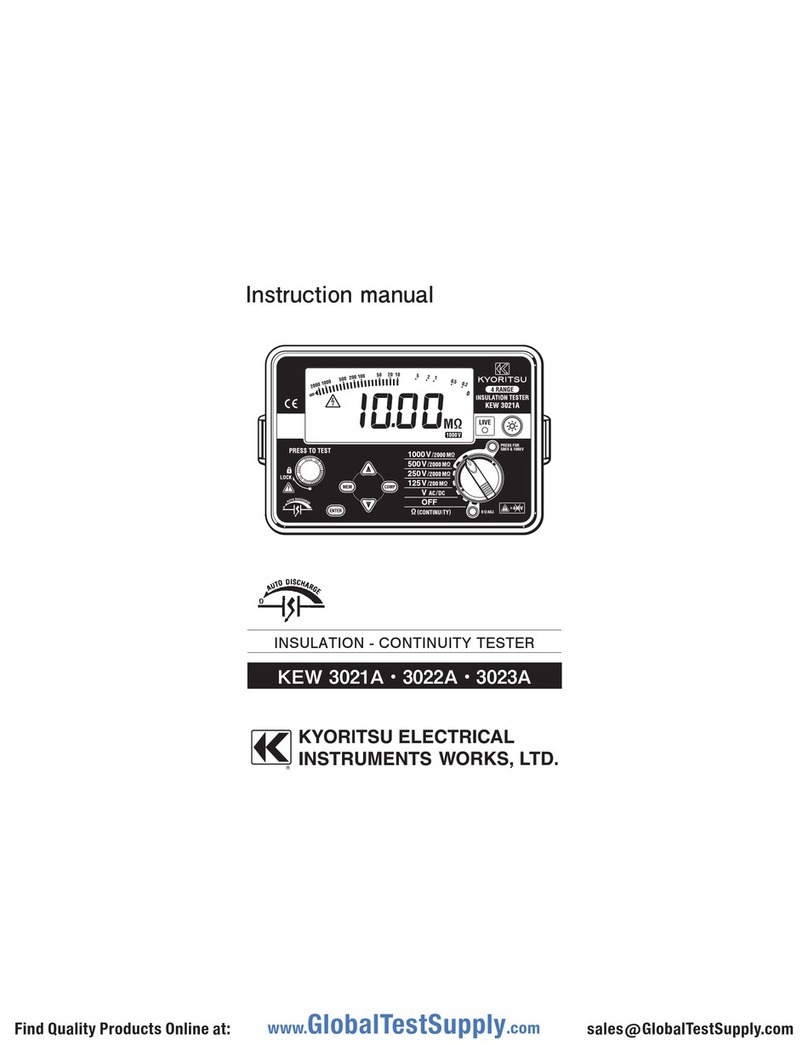

3.Instrumentlayout

4.Dinplugpinassignment

3:GNDpin

5:Outputsignalpin

6:Sensorsignalpin

(Resistancebetween3Pin

and6Pin:91kΩ)

1,2and4:Nouse

*Above figureshows the pin assignment seeing the Clamp

sensorfrom outputconnectorpart. The figureofthe pin

assignment of connection terminal is symmetrical to above

figure.

TransformJaws

Barrier

Trigger

Cable

Outputconnector

5

3

12

4

6

DISTRIBUTOR

Kyoritsu reserves the rights to change specifications or designs

describedinthismanualwithoutnoticeandwithoutobligations.

Approx.19Ω

Model

Ratedvoltage

Outputvoltage

Measuringrange

Accuracy

(Input:sinewave)

Phase

characteristics

Temperature&humidityrange

(Guaranteedaccuracy)

Operatingtemperaturerange

Storagetemperaturerange

Maximumpermissibleinput

Output

impedance

Locationforuse

Applicable

standards

Withstand

voltage

Insulation

resistance

ConductorSize

Dimension

Cablelength

Outputterminal

Weight

Accessories

Accessories

23±5℃,relativehumidity:85%orless(nocondensation)

0〜50℃,relativehumidity:85%orless(nocondensation)

-20〜60℃,relativehumidity:85%orless(nocondensation)

IEC61010-1,IEC61010-2-032

MeasurementCAT.III(300Vrms)

Pollutiondegree2

IEC61326

AC3540Vrms(50/60Hz)for5sec.

betweenJawandenclosure

betweenenclosureandoutputterminal

betweenJawandoutputterminal

50MΩ orgreaterat1000V

betweenJawandenclosure

betweenenclosureandoutputterminal

betweenJawandoutputterminal

5.Specifications

Approx.3m

MINIDIN6PIN

8128

AC5A

10mV/A(AC50mV/AC5A)

(AC500mV/AC50A)

AC0〜50Arms(70.7Apeak)

±0.5%rdg±0.1mV

(50/60Hz)

±1.0%rdg±0.2mV

(40〜1kHz)

±2degwithin(at0.5〜50A/45〜65Hz)

AC50Armscontinuous(50/60Hz)

Altitudeupto2000m,Indoors

Approx.24mmindiameter(max.)

100x60x26mm

Approx.160g

Cablemarker

Instructionmanual

MODEL7146(BananaF4adjusterplug)

MODEL7185(Extensioncable)

Conductor

Load

Currentdirection

arrow

Power

source

6-1Measurementprocedures

(1)Connectthe Output connector to theInput terminal of

themeasuringinstrument.

(2)Pressthe Triggertoopenthe transformer jawsand

clampontooneconductor.Inthiscase,themeasured

conductorshallbeatthecenterofthejaws.

Whenconnecting a sensorwitha Power meter(our

Powermeter,MODEL6300,etc.)matchthearrowmark

(Powersourcetoload),whichisindicatedonthe

transformerjaws, with the current flowing direction in

0ordertosynchronizethephasesofmeasuredcurrent

andoutputvoltage.

(3)Ensurethatthetipsoftransformerjawsarefirmly

closed.

5/10/20/50A50AMODEL8128

6-2SettingforMODEL6300Powermeter

Referto the tablebelowwhenusing these clampsensors

with MODEL6300, It shows the settings for clamp sensor

andavailablecurrentrangesonMODEL6300.

Forfurtherdetailsonthesettings,seetheinstruction

manualforMODEL6300.

MODEL

SettingforMODEL6300

Typeof

Clampsensor Currentrange

www. .com information@itm.com1.800.561.8187