Operating manual testing equipment

Page 4

Table of contents

Introduction .............................................................................................................2

1.1 Information about this operating manual ................................................2

1.2 Limitation of liability ................................................................................ 2

1.3 Symbols used in this manual ...................................................................3

1.4 Customer service ....................................................................................3

1. Test equipment for the humimeter BMC ...................... 6

1.1 Verication process .................................................................................6

2. Test equipment for the humimeter BMA-2 ................... 8

2.1 Verication process .................................................................................8

3. Checking the calibration of the humimeter FSG ........ 10

3.1 Checking the scale ................................................................................10

3.2 Checking the device .............................................................................. 10

4. Checking the calibration of the humimeter FS2 ......... 12

4.1 Checking the scale ................................................................................12

4.2 Checking the device .............................................................................. 12

5. Checking the calibration for the humimeter FS3 ....... 14

5.1 Checking the scale ................................................................................14

5.2 Checking the device .............................................................................. 14

6. Checking the calibration for the humimeter FS4 ....... 16

6.1 Checking the scale ................................................................................16

6.2 Checking the device .............................................................................. 16

7. Checking the calibration for the humimeter BP1 ....... 18

7.1 Checking the scale ................................................................................18

7.2 Checking the device .............................................................................. 18

8. Checking the calibration of the FSA ............................ 20

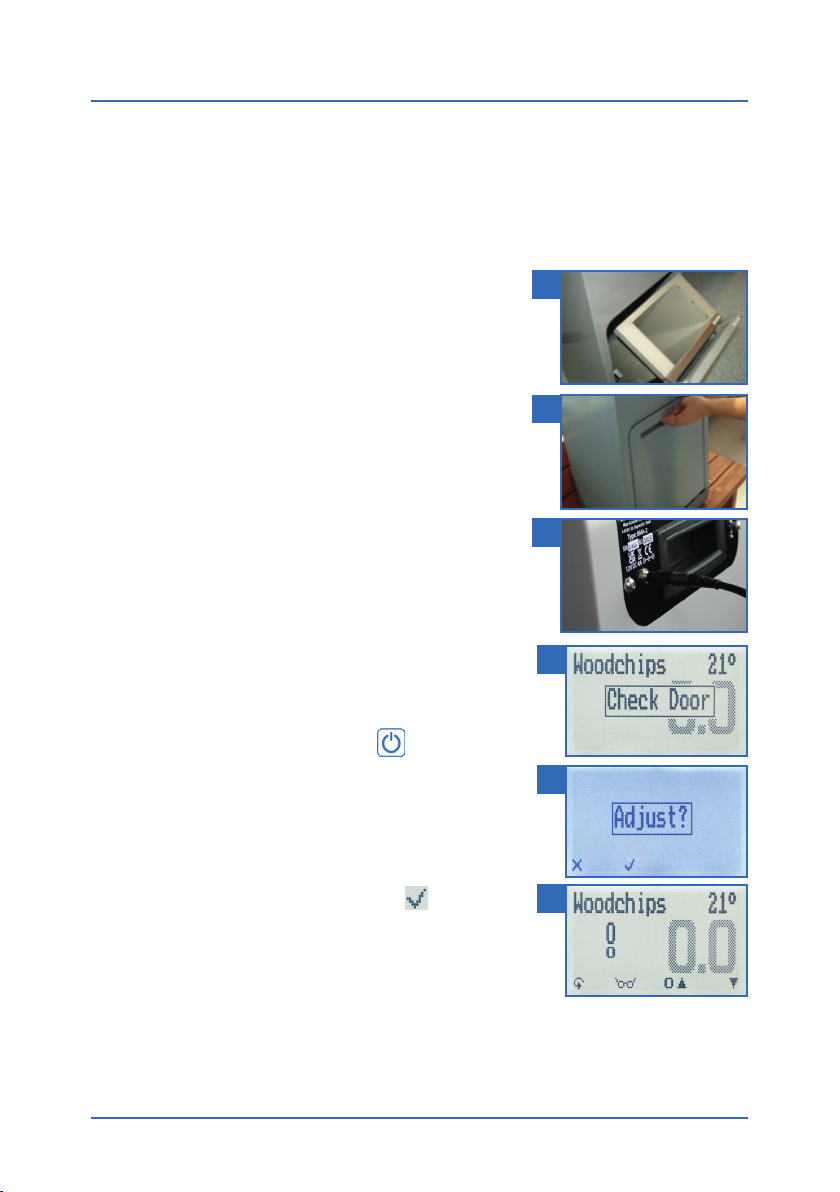

8.1 Sensor test ............................................................................................20