CMR Electrical DPC200 User manual

home

DPC200 PRESSURE - VOLUME CONTROL

DPC200 Page 1

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

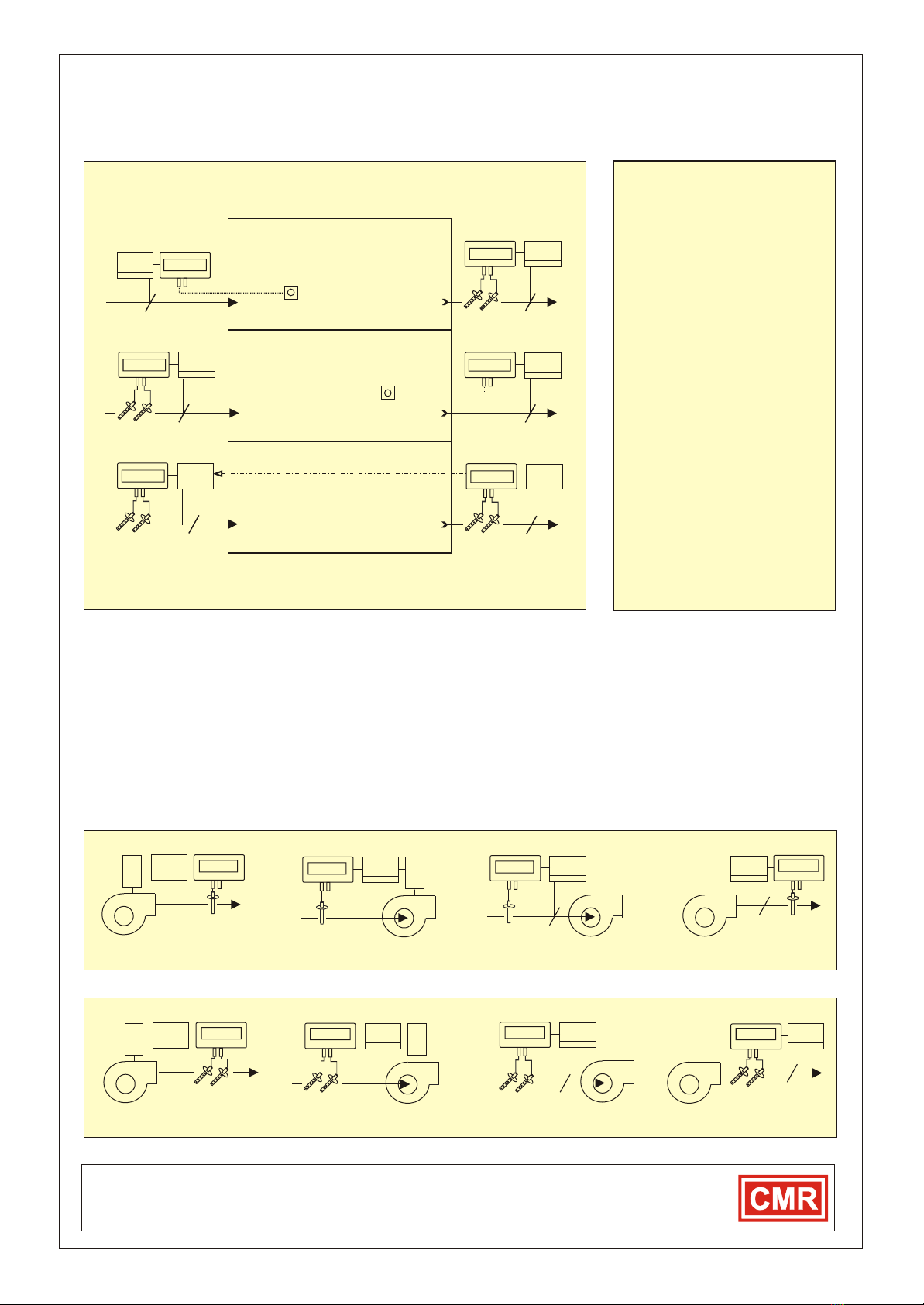

DPC200 Controller with Type 'J' display, hand-auto and Alarms

DPM50/55 Sensor

V- F- VT- Sensors

CMR Extract Valve

Invertor 0-100Hz

P-Sensor

REMOTE CMR SENSORS

The DPC200 was designed to function with

all CMR measurement sensors for which

data sheets are available separately. The

most popular sensors are the DPM50

Pressure and the DPM55 air velocity or

volume instruments. The units are normally

built into a central control panel together with

the DPC200 s.

OTHER REMOTE CMR SENSORS

The sensors can also be mounted in the field

at any distance and the CMR P-Sensors

either in ABS or Aluminium Enclosures are

ideal for pressure control. The V-Sensors, F-

Sensors and VT-Sensors are used for air

volume control either for constant or variable

air volume applications.

CMR DAMPERS AND ACTUATORS

CMR provides a large range of dampers

either circular or rectangular with a variety of

actuators from 4 up 150 seconds rotation

speed for 0...90°. The DPC200 can control

all these actuators accurately and without

hunting. It is recommended to use CMR

dampers and actuators as the mechanical

strength and torque of the actuator is critical

when operating at very high speeds.

FAN SPEED INVERTOR CONTROL

The DPC200 is ideal to control any Fan

Speed Invertor from small to large

applications either on static pressures or fan

volumes using the CMR fan inlet ring

measuring probes. It is of great advantage

where an independent control loop is

required to provide fail safe operation. The

DPC200 can run the fan in auto or manual

mode and provides override capability for

the BMS.

The DPMs have the advantage to provide

additional alarm contacts and a separate

4...20mA signal to independent pressure

monitoring systems. Another feature is the

large LED display which indicates the

pressures or velocities on the front panel for

the operator convenience. Calibration is

also made easy as all the controls are under

the front lense of the DPM.

GENERAL

The DPC200 was designed to provide accurate air volume and

room pressure control especially in clean room environments but

over the years it has found a multitude of uses in all kinds of control

systems. The principle of the control is simple and easily adopted

by any controls engineer. It consists of one control loop with a

number of options such as auto or manual control and remote BMS

interface. The DPC200 can be connected to any CMR external

sensor, damper motor or fan speed invertor. It provides constant air

volume control in ventilation systems or accurate room pressure

control especially in pharmaceutical production and research

areas. It has an option for local and remote alarm outputs and has

BMS and Scada monitoring systems connectivity. Full calibration

certificates traceable to National Standards can be supplied to

make the CMR control system conform to validation procedures.

REMOTE MEASUREMENT SENSORS

The Controller can read in a 0...10V signal from any CMR sensor.

The sensor actual value is displayed on an LCD Display on the front

operators panel of the DPC200. The LCD Display is normally scaled

0...100% of the 0...10V but can be scaled to different engineering

units i.e. Pa, mBar, m/s etc.

AUTO CONTROL SET POINT

A set point adjustment dial is provided for the user to select an

operating set point. The dial is available either as 0...100% or

-100%...0...+100% depending on type ordered.

CONTROL OUTPUT OPEN- OFF- CLOSE OR 0...10V/4...20mA

The DPC can drive all fast acting CMR motors which have a 24VAC

synchronous motor to drive open or close. Because of the high

speeds, the controller has all built in facilities to control in all

applications without hunting.

The DPC is also available with 0...10V output normally used for fast

acting Invertor Fan Speed Controls or specialist damper actuators.

MANUAL HAND CONTROL

A Hand-Auto switch is provided. When selecting the Hand option,

the manual set point dial is made active and the user can select a

manual operating set point to drive the invertor or damper into any

position. This is ideal for commissioning or emergency actions. The

dial is scaled to 0...100% as standard.

The actual speed of the Fan Invertor i.e. 0...100% of the Hz output or

the position of the actuator i.e. 0...100% of the damper angle is

continuously monitored. This value is available as 0...10V signal to

the BMS and the LCD display.

POWER SUPPLY

The DPC200 can be supplied for various power supplies such as

24V AC, 110V AC and 230V AC.

• Ultra fine pressure or volume control

• Controls fan speed invertors and actuators

• Hand - Auto and BMS change over control

• Local or external BMS actual sensor display

• Local or external BMS position sensor display

• Internal or remote BMS set point adjustment

• Door switch control freeze with timer

• Low and High alarm thresholds and alarms

• Volt free alarm contact for remote BMS.

• Excellent repeatability

• After Sales Service is provided by CMR

• 24 month warranty

• 20 Years field application experience

For External Pressure or Volume Sensors

DPC200 CLEAN ROOM CONTROLLER

DPC200 Page 2

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

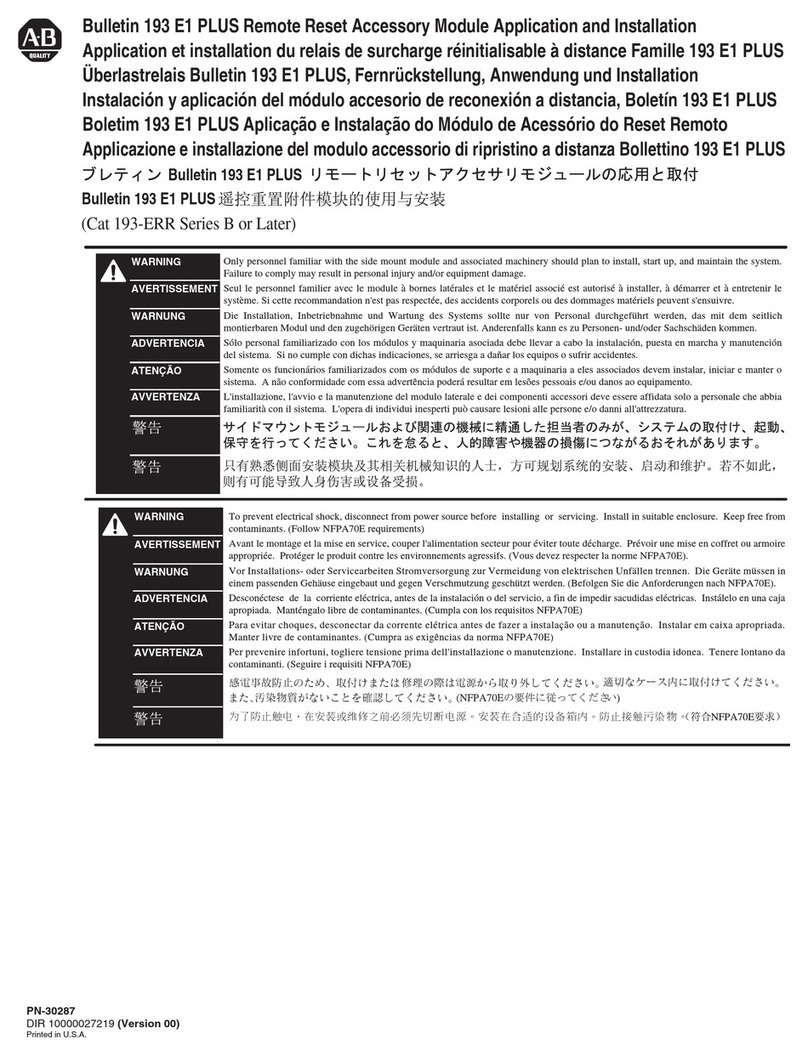

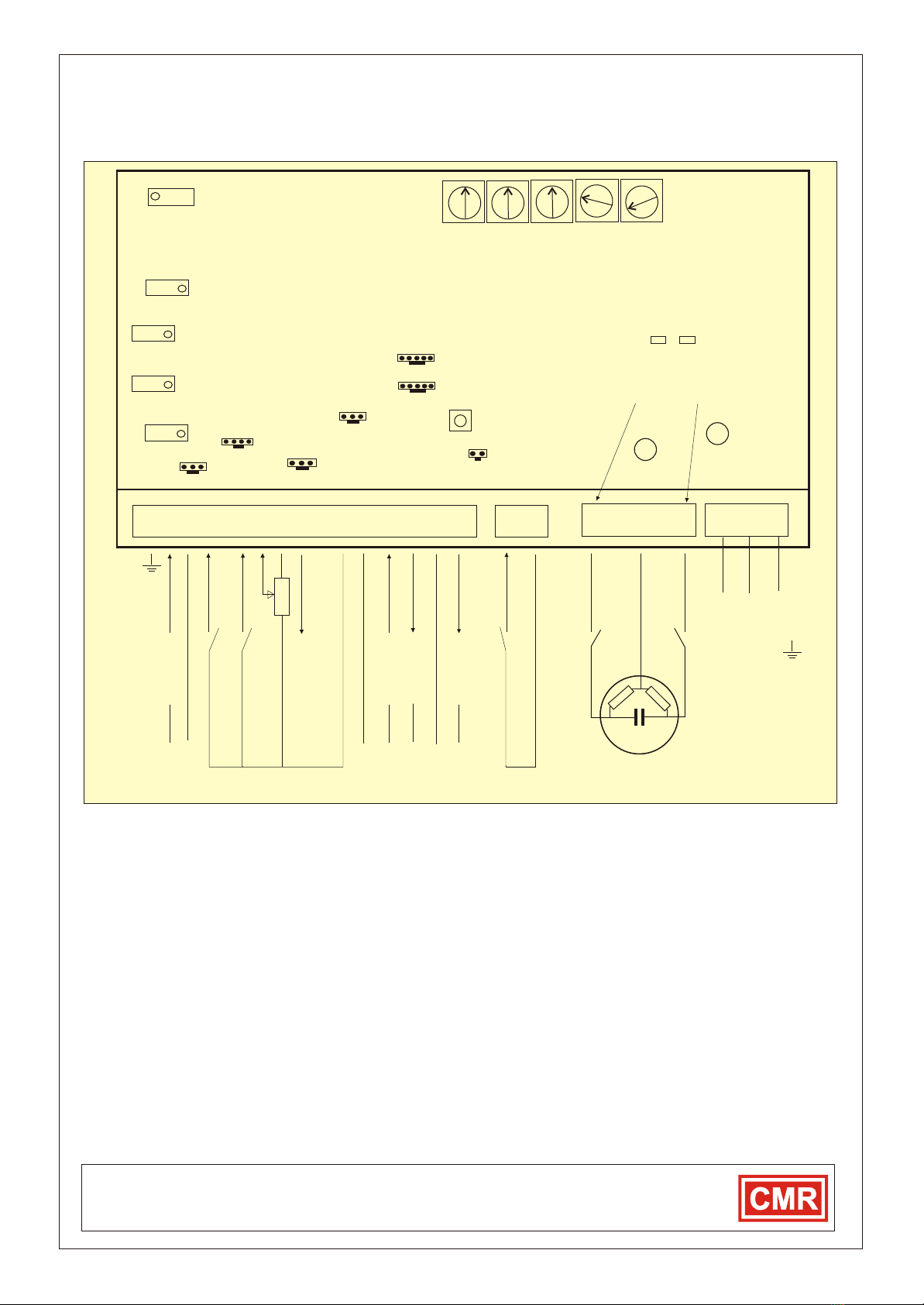

The above CMR Control Panel has three DPM55 air volume sensors

fitted into the front door. The air volume is measured at the venturi

mounted into the CMR Valve providing an accurate air volume

measurement. The DPC200 reads the air volume and controls the

constant volume supply (CVS) valves to provide constant air-change

rate into the rooms. Three DPM50 room pressure sensors are also

fitted into the front door.

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

White White

White

DPC200 CONTROL PANEL

Reference Datum

Air Probe Air ProbeAir Probe

Blue PVC Tube

30.00.15 45.0

Pa Pa Pa

ROOM 1 ROOM 2 ROOM 3

Up to 200m Distance

Up to 200m Distance

45.0

CMR remote alarm

display/mute plate

5 Core Cable 5 Core Cable

CMR remote alarm

display/mute plate

30.0

0.93

0.45 0.50

m3/s m3/s m3/s

Red-Blue

Red-Blue

Red-Blue

CVSCVS CVS

VVE VVE VVE

CONSTANT SUPPLY (CVS) AND VARIABLE VOLUME EXTRACT (VVE) CONTROL

door open

control freeze

door open

control freeze

door open

control freeze

door open

control freeze

door open

control freeze

door open

control freeze

CMR Control Panel with DPM50 and

DPM55 instruments built into the

front door for remote measurement.

Internal view of the CMR Panel. An isolator, fuses, power

supply, computer interface terminals and six DPC200

Controllers are fitted on the back plate All factory tested.

CMR panel door showing the rear of

the DPMs. Designed for easy access

during calibration in future.

TYPICAL ROOM PRESSURE AND VOLUME CONTROL PANEL FITTED WITH DPM50/55s AND DPC200s

Top of the CMR panel with all tube

nipple connections, cable glands

and identification engraving.

Each room pressure is measured against a reference datum i.e. plant

room and is controlled by driving the CMR motorised Variable Volume

Extract Valves (VVE) to the pressure set point at an adjustable speed

to provide stabile room pressure at any time. Remote display and

alarm plates are provided for the operator's safety. Door open

interlock switches can be connected to freeze the controls. When the

door is closed again a timer is provided to re-activate the controls.

TYPICAL ROOM PRESSURE CONTROL AND VOLUME TRACKING

DPC200 AIR CONTROL APPLICATIONS

DPC200 Page 3

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

In most cases, the DPM instruments and DPCs are built into a central

panel located in the plant room. PVC tubing is installed up to 200m in

length to the constant volume valves and the room pressure air probe

plates. The advantage of a central panel is easy commissioning, final

calibration and validation.

The DPC200 is a standard controller which can be configured to

provide constant supply, constant extract, variable volume supply or

variable volume extract. It has the necessary interfaces to be set up as

a tracking controller which means the extract DPM gives a signal to

the supply DPC to follow and provide the same volume as the extract.

An offset can be adjusted to either have more or less extract to suit the

application.

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

TYPICAL STATIC PRESSURE AND CONSTANT VOLUME FAN SPEED AND DAMPER CONTROL APPLICATIONS

STATIC PRESSURE CONTROL

Supply Fan Speed Control Extract Fan Speed Control Extract Damper Control Supply Damper Control

1360 Pa

+-

DPC200 DPC200

-360 Pa

+-

DPC200

+-

DPC200

CONSTANT VOLUME CONTROL

Supply Volume Fan Control ExtractVolume Fan Control Extract Volume Damper Control Supply Volume Damper Control

DPC200 DPC200

+-+-

DPC200

DPC200

+-

0.45 m3/s

CLEAN ROOM AIR CONTROLS

ROOM A

The extract is set up as constant volume

extract (CVE) to maintain 0.45m3/s.

The supply air is set up to be variable

volume supply (VVS). The room

pressure is measured via the air probe

and the supply air is controlled to

maintain -45Pa in the room.

ROOM B

The supply air is set up to be a constant

volume supply (CVS) to maintain

0.62m3/s.

The extract is set up as variable volume

extract (VVE). The room pressure is

measured via the air probe and the

extract air is controlled to maintain

+15Pa in the room.

ROOM C

The supply is set up as constant volume

supply (CVS) and the extract is set up as

constant volume extract (CVE). The

volume can be offset by external means

i.e. BMS and both CVE or CVS can track

each other. The DPC is adjustable to

achieve either over or under pressure in

the controlled space. The schematic

shows the extract volume sets the

supply volume.

DPC200

+-

0.45 m3/s

- 45 Pa

+-

DPC200

DPC200

+-

+ 15 Pa

DPC200

+-

0.62 m3/s

DPC200

+-

0.45 m3/s

DPC200

+-

0.40 m3/s

ROOM A

ROOM B

ROOM C

AIR PROBE

AIR PROBE

VVS CVE

CVS VVE

CVECVS

-45Pa

+15Pa

It can also be set up to measure the supply air and let the extract

follow. It is recommended to use the CMR dampers and valves with

CMR actuators, as the mechanical connections and the gearboxes

have been designed for continuous high speed action all year round.

All DPCs and DPMs can be connected to remote MPCs, BMS or

Scada computers systems to read in the pressures, volumes and set

points. The DPC can also receive remote set points and be controlled

to be in automatic or manual mode. In case of computer failure, the

DPC reverts back to its default set points, a vital advantage in critical

manufacturing processes. Any CMR Sensors can be connected and

supplied with traceable calibration certificates to National Standards

and site certification can be carried out on request.

0.45 m3/s 1.12 m3/s

1360Pa

-360 Pa

+-

+-

1.21 m3/s

DPC200 DAMPER CONTROL METHODS

Damper Actuators can either be the OPEN-OFF-CLOSE or the 0-10V Type

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

DPC200 Page 4

The room must be controlled at 15Pa positive pressure using

variable volume supply and manual constant extract. On start up,

the supply damper must be open and starts closing if the room

pressure is greater than 15Pa. The damper motor stops when a

door is opened and re-starts after a time out when closed again.

The room must be controlled at -45Pa negative pressure using

variable volume supply and manual constant extract. On start up,

the supply damper must be closed and starts opening if the room

pressure is more negative than -45Pa. The damper motor stops

when a door is opened and re-starts after a time out when closed

The room must be controlled at 1.0m3/s constant supply volume.

On start up, the supply t damper must be open and if the volume is

more than the set point the damper starts closing to achieve the

required constant volume. The controller has an adjustable set

point to vary the supply volume if required. The DPC can be linked

to an extract DPC controller if fitted to provide supply to extract

tracking.

+15 Pa

DPC

200

Constant

Volume

Extract

CVE

VVS

Variable

Volume

Supply

Positive Room Pressure

+15 Pa

-45 Pa

Constant

Volume

Extract

CVE

VVS

Variable

Volume

Supply

Negative Room Pressure

-45 Pa

1.0m3/s

Controlled

Constant

Volume

Supply

Constant Supply Volume

1.0m3/s

Constant

Volume

Extract

CVE

CVS

Mode 'A'

Mode 'C'

Mode 'E'

door switch

air Probe

door switch

air Probe

DPC

200

DPC

200

The room must be controlled at 15Pa positive pressure using

variable volume extract and manual constant supply. On start up,

the extract damper must be closed and starts opening up if the

room pressure is greater than 15Pa.The damper motor stops when

a door is opened and re-starts after a time out when closed again.

The room must be controlled at -45Pa negative pressure using

variable volume extract and manual constant supply. On start up,

the extract damper must be open and starts closing if the room

pressure is more negative than -45Pa. The damper motor stops

when a door is opened and re-starts after a time out when closed

The room must be controlled at 1.2m3/s constant extract volume.

On start up, the extract damper must be open and if the volume is

more than the set point the damper starts closing to achieve the

required constant volume. The controller has an adjustable set

point to vary the extract volume at any time. The DPC can be linked

to a supply DPC controller if fitted to provide extract to supply

tracking.

+15 Pa

Constant

Volume

Extract

CVS V VE

Variable

Volume

Extract

Positive Room Pressure

+15 Pa

- 45 Pa

Constant

Volume

Extract

CVS V VE

Variable

Volume

Extract

Negative Room Pressure

- 45 Pa

1.2m3/s

Controlled

Constant

Volume

Extract

Constant Extract Volume

CVE

1.2m3/s

Constant

Volume

Supply

CVS

Mode 'B'

Mode 'D'

Mode 'F'

TYPICAL AIR PRESSURE OR AIR VOLUME DAMPER CONTROLS USING DPC200 CONTROLLERS.

door switch

door switch

air Probe

air Probe

DPC

200

DPC

200

DPC

200

DPC200 FAN SPEED CONTROL METHODS

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

DPC200 Page 5

The room must be controlled at 15Pa positive pressure using

variable volume supply and manual constant extract. On start up,

the supply fan must speed up and starts reducing speed if the room

pressure is greater than 15Pa. The fan speed locks when a door is

opened and re-starts after a time out when closed again.

The room must be controlled at -45Pa negative pressure using

variable volume supply and manual constant extract. On start up,

the supply fan must reduce speed and starts speeding up if the

room pressure is more negative than -45Pa. The fan speed locks

when a door is opened and re-starts after a time out when closed

The room must be controlled at 1.0m3/s constant volume supply.

On start up, the supply fan must speed up and if the volume is more

than the set point the fan speed starts reducing to achieve the

required constant volume. The controller has an adjustable set

point to vary the supply volume if required. The DPC can be linked

to the extract fan to provide supply to extract tracking.

+15 Pa

Manual

Constant

Volume

Extract

CVE

VVS

Controlled

Variable

Volume

Supply

Positive Room Pressure

+15 Pa

-45 Pa

Manual

Constant

Volume

Extract

CVE

VVS

Controlled

Variable

Volume

Supply

Negative Room Pressure

-45 Pa

1.2m3/s

Controlled

Constant

Volume

Supply

Constant Supply Volume

1.0m3/s

CVS

Mode 'G'

Mode 'J'

Mode 'L'

door switch

door switch

air Probe

air Probe

DPC

200

DPC

200

DPC

200

The room must be controlled at 15Pa positive pressure using

variable volume extract and manual constant supply. On start up,

the extract fan must reduce and starts speeding up if the room

pressure is greater than 15Pa. The fan speed locks when a door is

opened and re-starts after a time out when closed again.

The room must be controlled at -45Pa negative pressure using

variable volume extract and manual constant supply. On start up,

the extract fan must speed up and starts reducing speed if the room

pressure is more negative than -45Pa. The fan speed locks when a

door is opened and re-starts after a time out when closed again.

The room must be controlled at 1.2m3/s constant volume extract.

On start up, the extract fan must speed up and if the volume is more

than the set point the fan speed starts reducing to achieve the

required constant volume. The controller has an adjustable set

point to vary the extract if required. The DPC can be linked to the

supply fan to provide extract to supply tracking.

+15 Pa

Manual

Constant

Volume

Extract

CVS

VVE

Controlled

Variable

Volume

Extract

Positive Room Pressure

+15 Pa

- 45 Pa

Manual

Constant

Volume

Extract

CVS

VVE

Negative Room Pressure

- 45 Pa

1.2m3/s

Constant Volume Extract

CVE

1.2m3/s

Mode 'H'

Mode 'K'

Mode 'M'

TYPICAL AIR PRESSURE OR AIR VOLUME FAN SPEED CONTROL USING DPC200 CONTROLLERS.

Controlled

Variable

Volume

Extract

Controlled

Constant

Volume

Extract

CVE

door switch

door switch

air Probe

air Probe

DPC

200

DPC

200

DPC

200

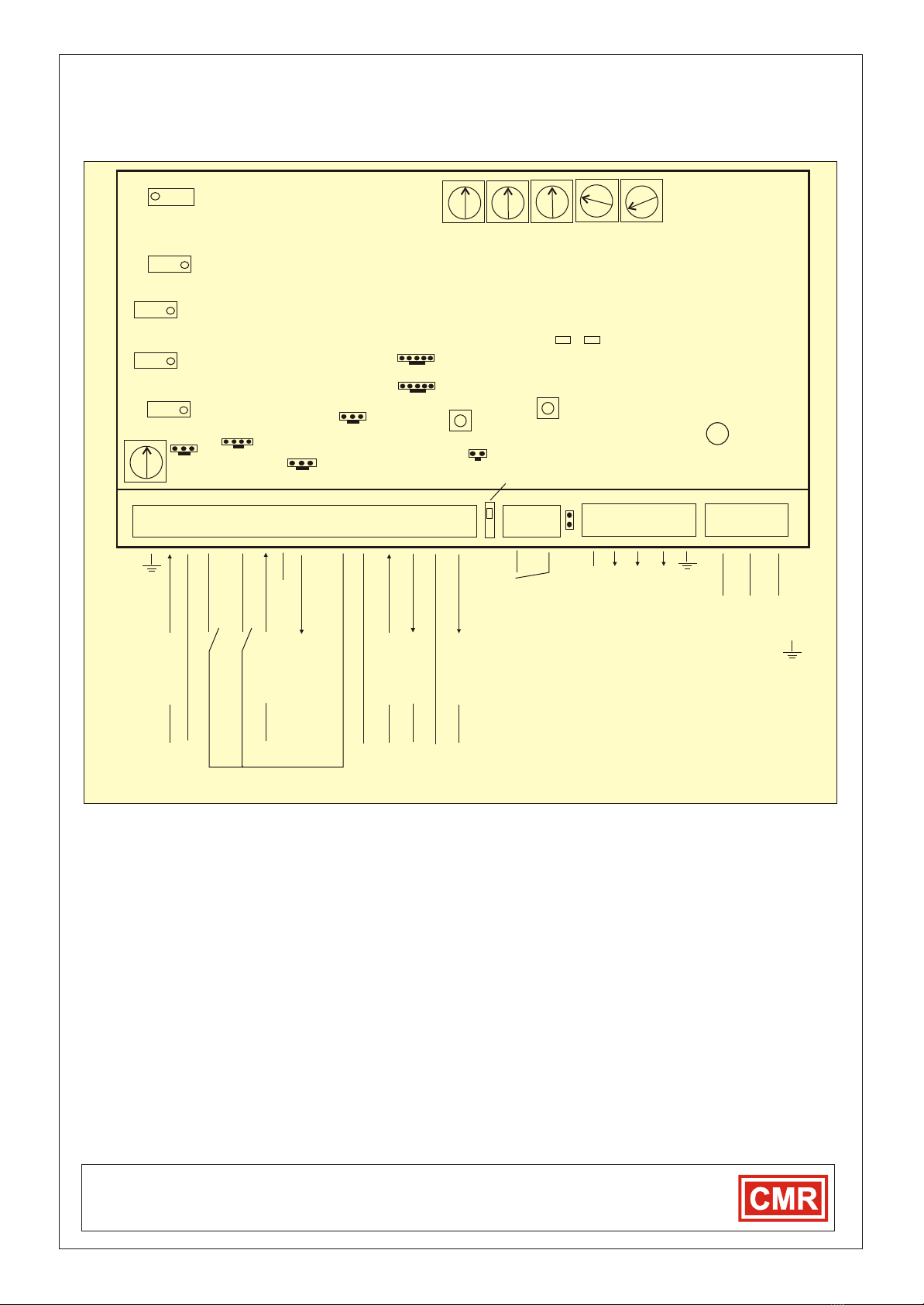

DPC200 AST-VMS/L MOTOR CONTROL

DPC200 CONTROL BOARD WITH TRIAC OUTPUT TO DRIVE SYNCHRONOUS MOTORS

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

DPC200 Page 6

25 27 29

PE

Earth

24/ 110/ 230 VAC

0 VAC

20 22 24

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19

J8

Power Supply

Must be ordered

to suit the voltage

Prop-

band

Timing

Sensi-

tivity

sensor

signal

Balance

DO NOT

ADJUST

unless

used as

off-set.

Scaler 2

Positioner

P16

ZERO

P15

SPAN

P10 is factory adjusted but if it was

tampered with turn P10 fully clockwise and

then 10 turns anti clockwise

Try for best results 8 - 11 turns.

To stop hunting

adjust P10 and

finger pots

Try Sensitivity

Prop Band

Timing and

look at LED's

for best results

P10

J9

J1

J2

J7

P18

P4

ZERO

P5

SPAN

Scaler 1

Remote sensor

Hand/Auto switch

Internal Sensor

Actual Set Point

Manual Set Point

Door switch

control freeze

Door delay timer

Red

LED

Green

LED

If 'on' 20 is

energised

If 'on' 24 is

energised

External Set Point

(-)(+)

0...10V DC

External Set Point

Hand/Auto Change

Potentiometer in Actuator

0...10V DC

10V DC Reference

(-) (+)

0...10V DC

(+) (-) (+)

0...10V DC

5...24V DC 150mA

External Sensor Input

Scaled Sensor Actiual Output

Power Supply for External Sensor

24VAC

0 VAC

0 VAC

Synchronous

Motor Actuator

Normally 24V AC

DPS201T

Coarse Fine

Factory setting as shown

End

switch

End

switch

LCD1

LCD2

Sensor

Position

To change direction of actuator change over the wiring motor from 20 to 24 and 24 to 20

and the feed back potentiometer from 8 to 11 and 11 to 8 and adjust Scaler 2..

COMMISSIONING DAMPER ACTUATOR MOTION

he green LED must be on and

With no pressure or volume applied to the sensor and the setpoint

set to +50% the green LED must be on and the damper must drive

to closed position on 20. If not, change over motor wires from 20 to

24 and 24 to 20 to change direction of motor. Adjust the end limit

switches in the motor to give fully closed position.

Apply pressure to (+) port of the sensor so that the signal is higher

than the set point, the red LED must be on and the damper should

drive to open position 24. Adjust the open limit switch to fully open

position. Repeat this process a few times until correct.

Control method: Damper must be open on start up.

With no pressure or volume applied to the sensor and the setpoint

set to +50% t the damper must drive to

open position on 20. If not, change over motor wires from 20 to 24

and 24 to 20 to change direction of motor. Adjust the end limit switch

in the motor to give maximum opening position.

Apply pressure to (+) port of the sensor so that the signal is higher

than the set point and the damper should drive to closed position.

The red LED and 24 should be on. Adjust the closed limit switch to

fully closed position. Repeat this process a few times until correct.

Control method : Damper must be closed on start up.

COMMISSIONING DAMPER ACTUATOR POSITION

Control method: Damper must be open on start up.

The scaler 2 is the actuator position potentiometer scaling.

The potentiometer is connected to 11 (10V) and 8 (GND) the output

wiper is connected to 7. When the damper is fully open adjust span

(P15) to 10V measured on 9. Close the damper as described on the

left. Adjust the zero (P16) to be 0V on 9.

If the damper works incorrectly change over 8 to 11 and 11 to 8 to

inverse the potentiometer function and repeat above process until

correct.

Control method: Damper must be closed on start up.

The scaler 2 is the actuator position potentiometer scaling.

The potentiometer is connected to 11 (10V) and 8 (GND) the output

wiper is connected to 7. When the damper is fully closed adjust span

(P15) to 10V measured on 9. Open the damper as described on the

left. Adjust the the zero (P16) to be 0V on 9.

If the damper works incorrectly change over 8 to 11 and 11 to 8 to

inverse the potentiometer function and repeat above process until

correct.

Scaled Position Output 0...10V

Not normally connected

see page 9

F1

F2

Main Fuse

Motor Fuse

When door is open switch is made and

the output to the motor frezes.

When door is closed switch is open.

The output starts after delay time out.

DPC200 CONTROLLER 0-10V OR 4-20mA

DPC200 CONTROL WITH 0...10V/4...20mA OUTPUT TO DRIVE FAN SPEEDS OR DAMPER MOTORS

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

DPC200 Page 7

COMMISSIONING A

On start up the fan must speed up or the damper opens

With no pressure or volume applied to the sensor and the set point

set to +50% the green LED must be on and 0...10V drives the fan up

or damper open. If not, change over the invertor switch to normal

position to change direction of the output signal. Adjust any top end

limits on the external equipment if required. Apply a pressure or flow

to (+) port of the sensor so that the signal is higher than the set point

and the Fan should reduce speed or the damper closes. The red

LED must be on and 0V drives the fan down. Adjust any end limits on

the external equipment if required. Repeat this process a few times

until correct.

The scaler 2 is the feed back positioner scaling circuit..

The feed back voltage from the Invertor or damper motor should

preferably be 0...10V. The signal is fed into 7. If the fan is in low

speed position adjust zero (P16) to read 0V on 9. If the fan is in full

speed position adjust span (P15) to read 10V on 9. Try the controller

on manual control by changing the set point. Repeat this process a

few times until correct.

COMMISSIONING B

On start up the fan must reduce speed or the damper closes.

With no pressure or volume applied to the sensor and the set point

set to +50% the green LED must be on and 10 ... 0V drives the fan

down or closes the damper. If not, change over the invertor switch to

inverted output position to change direction of the output signal.

Adjust any top end limits on the external equipment if required.

Apply a flow to (+) port of the sensor so that the signal is higher than

the set point and the Fan should speed up. The red LED must be on

and 10V drives the fan up or the damper opens. Adjust any end limits

on the external equipment if required. Repeat this process a few

times until correct.

It is essential that the external equipment can invert the feed back

signal otherwise the DPC270 cannot function. Consult CMR in case

of difficulties.

The scaler 2 is the feed back positioner scaling circuit..

The feed back voltage from the Invertor or damper motor should

preferably be 10...0V. The signal is fed into 7. If the fan is in low

speed position adjust span (P15) to read10V on 9. If the fan is in full

speed position adjust zero (P16) to read 0V on 9. Try the controller

on manual control by changing the set point. Repeat this process a

few times until correct.

Inverted Output 10-0V

Switch down for normal and up for inverted control

Front Plate Set Points

P19

When door is open switch is made and

the control output freezes.

JP9

25 27 29

PE

Earth

24/ 110/ 230 VAC

0 VAC

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Power Supply

Must be ordered

to suit the voltage

Prop-

band

Timing

Sensi-

tivity

sensor

signal

Balance

DO NOT

ADJUST

unless

used as

off-set.

P10 is factory adjusted but if it was

tampered with turn P10 fully clockwise and

then 10 turns anti clockwise

Try for best results 8 - 11 turns.

To stop hunting

adjust P10 and

finger pots

Try Sensitivity

Prop Band

Timing and

look at LED's

for best results

P10

J9

J1

J2

J7

P18

Hand/Auto switch

Internal Sensor

Door switch

control freeze

Door delay timer

External Set Point

(-)(+)

0...10V DC

External Set Point

Hand/Auto Change

10V DC Reference

(-) (+)

0...10V DC

(+) (-) (+)

0...10V DC

5...24V DC 150mA

External Sensor Input

Scaled Sensor Actiual Output

Power Supply for External Sensor

Coarse Fine

Factory setting as shown

LCD1

LCD2

Sensor

Position

Scaled Position Output 0...10V

Not normally connected

see page 9

F1 Main Fuse

DPS201V

Red

LED

Decrease

Green

LED

Increase

P20 Output Ramp Speed

J8

Scaler 2

Positioner

P16

ZERO

P15

SPAN

P4

ZERO

P5

SPAN

Scaler 1

Remote sensor

2nd Set Point

20 21 22 23 24

17 19

20...4mA

If jumper is fitted than T22 is connected to T7

Control Output

suitable for

Invertors or

Damper Motors

When door is closed switch is open.

The output starts after delay time out.

GND (-)

10...0V DC

24 VAC 50Hz 150mA

from internal

(+)

0...10V DC

(-)

External Position Feed Back

4...20mA

0...10V DC

DPC200 CONTROL BOARD FUNCTION

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

DPC200 Page 8

THE LINK SETTINGS ARE FACTORY SET AND TESTED TO WORK WITH A DPC200 AS ORDERED

POTENTIOMETERS

P1 Sets the external sensor power

supply voltage on14 from 5 to 24VDC.

P2 Set P3 fully clockwise to have

maximum output on 11 then adjust P2

to have 10V on 11.

P3 follow P2

P4 If the Jumper on JP7 scaler1 has

been set to up position then P4 is the

span adjustment for the external

sensor coming in on 13 and out on 16.

P5 see P4. P5 is the zero adjustment

for scaler1.

P15 if Jumper on JP7 scaler2 has

been set to up position then P15 is the

span adjustment for the feed back of

the position sensor coming in on 7 and

out on 9.

P16 see P15. P16 is the adjustment for

the zero for scaler2.

LINK SETTINGS

Sensor input on 13

JP7 1- 3 2- 4 scaler 1 connected

JP7 3- 5 4- 6 scaler 1 not connected

Square Root Option

Position Sensor on 7

JP7 7- 9 8-10 scaler 2 connected

JP7 9-11 10-12 scaler 2 not connected

External Set Point on 2

Standard factory setting

JP8 3- 5 9- 11 scaler 2 not connected

Square Root and scaler2 option

If the set point must be square rooted

in case of tracking two volumes with

pressure sensors then link as follows:

If input on 13 must be square rooted

then link as follows:

JP7 1- 3 2- 4 scaler 2 connected

JP8 2- 4 square root connected

JP8 8- 9 square root connected

JP7 9-11 10-12 scaler2 not on7

JP8 1- 3 7- 9 scaler 2 connected to 2

Internal Set Point P3 connection

If a plain plate has been ordered and

no potentiometer can be connected to

the board then P3 is the internal set

point. In order to make it function link:

JP6 1-3 P3 is now internal set point

To commission P3 turn P3 fully

clockwise, measure on 10 and adjust

P2 until 10.00 V is achieved. Then turn

P3 from 0-100% = 0...10V internal set

point.

Note: if P3 is used as set point 11

cannot be used as reference 10V.Use

14 instead and adjust P1 to 10V on 14.

20 21 22 23 24

17 191 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

P10

P9

P2

P3

P5

Scaler 1

Scaler 2

Zero

P16 Zero

P4 Span

P15 Span

JP11

JP12

LCD1

LCD2

P1

J2 J1

J6 J5 J4 J3

Zero

coarse

Hand - Auto

14

Internal

set point

Prop

band

TimingSensi-

tivity

Balance

Do not

adjust

unless

used as

off set

1N4148 1N4148

J8

Manual

set point

IsolationTransformer

24VAC

or

110VAC

or

230VAC

50/60 Hz

J9

Internal

sensor

JP6

JP8

JP14

JP7

JP15

JP16

Sensor Value

Manual Value

1

1

1

1

1

1

1

1

5

5

3

3

1 3

R1 R2

Linear1

Linear2

SQR1

SQR2

scaler1

scaler2

10V scalers for 11

turn P2 fully clock

wise Adjust 10V

with P3 on 11

25 26 27 28 29

5..24V

GND

Sensor

Manual

Sensor always

5..24V

GND

Sensor

Manual

Manual always

DPC200 LINK - FRONT PLATE CONNECTORS AND POTENTIOMETER SETTINGS

2

11 12

12

2

11

F1

F2

Correct Power

Supply must be

selected at the

time of order

Main

Motor

24VAC POWER SUPPLY

The standard power supply is 24VAC on J3 with

fuse F1 (1A). With the 24VAC version the

damper motor is connected directly to the

external power supply linked under the board

toJ3 via a separate fuse F2 (1A). Any 24VAC

motor can be connected to J4 provided the

external power supply is large enough to drive

one 24VAC synchronous motor up to 1A.

110V-230VAC POWER SUPPLY

The optional power supply is 110V or 230VAC

on J3 with fuse F1 (315mA). With this version

the 24VAC is produced by the on-board

isolation transformer and a maximum of

350mA can be connected to J4. In this case the

board must be configured to internal 24VAC

supply to J4. Do not exceed the maximum

power available from the board. Consult CMR.

OPTIONAL FC201 ALARM BOARD CONNECTIONS AND SETTINGS

JP7

If the alarm board is fitted as retrofit in the field, make sure that the link JP7 is unsoldered.

Use SW1 switch settings to achieve different alarm modes and times.

30 31 32 33 34 35 36 37 38 39 40 41

High

J2

Low

Off

1 2 3 4 5 6 7 8

Alarm Setpoint

Test Points

Earth

Mute

Mute

Ground

makes R3

24VDC

NC

Common

Common

Common

Buzzer

Lo-Hi Alarm

Re-peater

Front Panel

Mute switch

Alarm connected

to Front Plate

SW1

Front Panel

Alarm Lamp

SW1

R1 R2 R3

1 3

3

1

6 On=Latching Alarm

7 On=Re-Alarm Timer set

8 On=High Alarm on Re-peater

Off=Sash Alarm Output

4 off - 5 off 0s Alarm Delay

4 off 5 on 10s Alarm Delay

4 on 5 off 30s Alarm Delay

4 on 5 on 60s Alarm Delay

1 n/a

2 n/a

3 n/a

4 Timer

5 Timer

DPC200 OPERATOR FRONT PANEL

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 2 2001

DPC200 Page 9

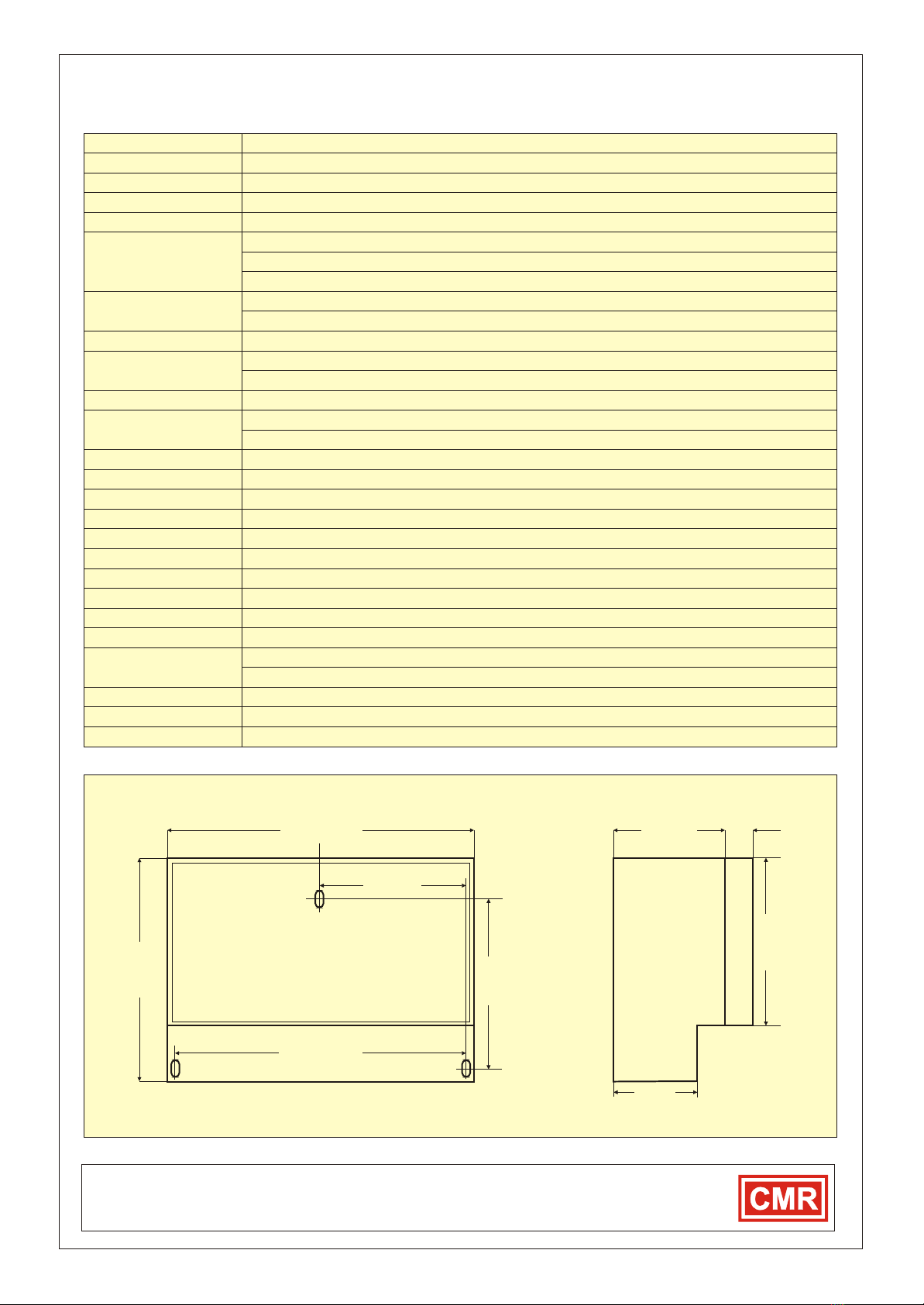

FRONT PANEL EXPLANATION CHOICE OF FRONT PANELS WITH OR WITHOUT ALARM

0..100%

CONTROL

SET POINT

0..100%

MANUAL

SET POINT

CONTROL

VALUE

50.0 %

CAL

OFF

ON

8

2

7

9

MANUAL

POSITION

50.0 %

AUTO

HAND

1

10

1. LCD displays the actual sensor value in %

2. Control set point in 0...100% or -100..100 %.

3. Low Alarm set point 0...100% or -100 ..100 %.

4. High Alarm set point 0...100% or -100..100 %.

5. Alarm light switches on after time out of alarm.

6. If the Mute button is switched to off position, then

the buzzer shall switch on after the time out of

any alarm. In on position, the buzzer is always

muted.

7. In auto the controller follows the sensor set point.

In hand operation the controller follows the

manual set point.

8. LCD displays manual position of the actuator or

the feed back of the invertor in %.

9. Control set point for the Manual positioner.

10. When switching the CAL to on, the control

output freezes and the sensor can be calibrated

CHOICE OF FRONT PANELS

TYPE 'A' Fully populated with alarms, hand - auto

and LCDs for actual sensor and position

feed back. The sensor range is 0...100%

suitable for positive range only.

TYPE 'B' Same as Type 'A' but sensor range is

-100%-0-+100% suitable for positive

and negative range.

TYPE 'C' Same asType 'A' but without alarm.

TYPE 'D' Same as Type 'B' but without alarm.

TYPE 'E ' Same asType 'C' but without manual

LCD and without manual set point.

TYPE 'F' Same as Type 'D' but without manual

LCD and without manual set point.

TYPE 'G' Same as Type 'A' but with digital set

point adjusters instead of dial.

TYPE 'H' Same as Type 'G' but without manual

LCD and without manual set point.

TYPE 'I' Same as Type 'H' but without alarms.

TYPE 'J' Same as Type 'G' but without alarms.

TYPE 'K' Plain plate without any controls.

Note: The layout may change . Consult CMR.

FRONT PLATE TYPE 'J' 0...100%DIGITAL TYPE 'I'

SENSOR

SET POINT

0..100%

CONTROL

VALUE

50.0 %

CAL

OFF

ON

2

7

AUTO

HAND

1

10

0...100% FRONT PLATE TYPE 'A'

-100%-0-100% FRONT PLATE TYPE 'B'

%%

100 100

0 0 100

%

CONTROL

SET POINT

100

0 %

MANUAL

SET POINT

LOW HIGH

ALARM

CONTROL

VALUE

50.0 %

CAL

OFF

ON

MUTE

OFF

8

23 4

56

7

9

0

-100%-0-100% FRONT PLATE TYPE 'D'

0...100% FRONT PLATE TYPE 'C'

-100%-0-100% FRONT PLATE TYPE 'F'

0...100% FRONT PLATE TYPE 'E'

0...100% PLATE DIGITAL TYPE 'G' 0...100% PLATE DIGITAL TYPE 'H'

MANUAL

POSITION

50.0 %

ON

AUTO

HAND

1

%%

100 100

-100 -100 100

%

CONTROL

SET POINT

100

-100 %

MANUAL

SET POINT

LOW HIGH

ALARM

CONTROL

VALUE

50.0 %

CAL

OFF

ON

MUTE

OFF

8

23 4

56

7

9

0

MANUAL

POSITION

50.0 %

ON

AUTO

HAND

1

100

%

CONTROL

SET POINT

1000 %

MANUAL

SET POINT

CONTROL

VALUE

50.0 %

CAL

OFF

ON

8

2

7

9

0

MANUAL

POSITION

50.0 %

AUTO

HAND

1

100

%

CONTROL

SET POINT

100-100 %

MANUAL

SET POINT

CONTROL

VALUE

50.0 %

CAL

OFF

ON

8

2

7

9

0

MANUAL

POSITION

50.0 %

AUTO

HAND

1

SET POINT

100-100 %

CONTROL

VALUE

50.0 %

CAL

OFF

ON

2

7

9

AUTO

HAND

1

SET POINT

1000 %

CONTROL

VALUE

50.0 %

CAL

OFF

ON

2

7

AUTO

HAND

1

%%

100 100

0 0

0..100%

CONTROL

SET POINT

0..100%

MANUAL

SET POINT

LOW HIGH

ALARM

CONTROL

VALUE

50.0 %

CAL

OFF

ON

MUTE

OFF

8

2

34

56

7

9

MANUAL

POSITION

50.0 %

ON

AUTO

HAND

1

%%

100 100

0 0

CONTROL

SET POINT

0..100%

LOW HIGH

ALARM

CONTROL

VALUE

50.0 %

CAL

OFF

ON

MUTE

OFF

2

34

56

7

ON

AUTO

HAND

1

10

10

10 10

10

10

10 10

DPC200 PRESSURE - VOLUME CONTROLLER TO BE USED WITH EXTERNAL SENSOR

DPC200 ORDER DESCRIPTION

DPC200 Page 10

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

GENERAL

CMR manufactures a large range of DPC200 wall or panel mount

pressure or volume controllers to suit many applications. Because of

the variety of control outputs and power supplies it has been

necessary to design an easy to use selection table for anybody to

make up a DPC200 controller specification to satisfy a requirement.

You will find all specifications available with the associated ordering

Code on the DPC200 Controller Selection Table (Page 11) . In order

to select the correct part we have made up a sample selection

below:

DPC200 PART NUMBER

The DPC200 Part Number starts with the selection of the controller

type of enclosure without Lid, with Lid or with Lid and key lock.

DPC200 enclosure without Lid has the Code ’ 66A ’.

DPC200 enclosure with Lid has the Code '66B'

DPC200 enclosure with Lid and key lock has the Code '66C'

As an example, we have chosen the Code 'A'.

The Part Number starts therefore with '66A'

NEGATIVE PRESSURE RANGE

The DPC200 is always supplied without internal sensor and acts as

controller only. If a sensor is required, refer to the CMR P-Sensor,

DPM, V-Sensor, VT-Sensor and F-Sensor specification sheets.

As there is no sensor fitted the Code is always '000'.

The Part Number extends to ‘66A 000’.

POSITIVE RANGE

The DPC200 is always supplied without internal sensor and acts as

controller only. If a sensor is required, refer to the CMR P-Sensor,

DPM, V-Sensor, VT-Sensor and F-Sensor specification sheets.

As there is no sensor fitted the Code is always '000'.

The Part Number extends to ‘66A 000 000’.

OPERATOR FRONT PANEL

The operator panel is an anodized aluminium panel which has

various options as shown on page 9. The choice of plate is

expressed as Plate Type as follows:

Type 'A' has all functions and the sensor control set point is a dial

0...100%. The order Code is 'A'

Type 'B' is similar to Type 'A' except the sensor set point dial is

-100..0..+100% . This type is used , when using a sensor which has

a measurement range i.e. -100Pa - 0 - +100Pa, which means the

sensor can measure from 0Pa to(-)100Pa and from 0Pa to (+)100Pa

and the set point can be adjusted from 0 to (-)100% and 0 to

(+)100%. The Code is 'B'.

Other Types are available such as 'C' up to 'J'. see DPC200

Operator Front Panel on page 9.

In the example we have chosen Type 'A'

The Part Number extends to ’66A 000 000 A’.

POWER SUPPLY

The DPC200 can be ordered for 24VAC with Code '3', 110VAC with

Code '4' and 230VAC with Code '5'.

We have chosen 24VAC which has the Code '3'.

The Part Number extends to ’66A 000 000 A 3’.

CONTROL MODE

Page 4 and Page 5 shows various control modes. The mode

selection is important to set up the controller's output. Look at the

sketches and select the desired mode or ask CMR for assistance.

We have chosen Mode 'B' on page 4.

The Part Number extends to ’66A 000 000 A 3 B’.

CONTROL OUTPUT

The Industry Standard for Output Signals is 0...10V which has the

order Code 'A'. The Control output signal can also be inversed to

provide 10...0V. This is normally required, when a fan must be at

high speed at no pressure feed back. The Code is 'B'.See Page 5

Speed Control Methods.

The Control output for CMR damper motors as described on Page 4

Damper Control Methods is a triac output to drive synchronous

motors open-off-close. The output is generated by the isolation

transformer built into the DPC, which means the output is named

24VAC I (internal) and has the code 'C'. This means no matter what

the power supply is i.e. 24VAC, 110VAC or 230VAC by choosing

code 'C' the control output is always 24VAC (internal) but it is limited

to 350mA.

If AC X (external) Code 'D' is ordered, then the control output is the

same as the power supply i.e. 24VAC, 110VAC or 230VAC non

isolated.

It is advisable to mention what type of equipment shall be driven by

the DPC200 controller during order stage in order to make sure the

control output is capable to drive the used actuator.

We have chosen 24V ACX as control output which has the Code 'D'.

The Part Number extends to ‘66A 000 000 A 3 B D'.

SCALED UNITS

The range is printed on the product label fixed to the lid of the

controller. Normally, the range is printed in % but other ranges can

be selected under this order code. If and LCD or LED is required

then the set point dials are always in %.The set point dials and

manual LCD are always in % and cannot be scaled unless a special

factory order is made. The 3 1/2 digit sensor LCD is factory scaled

to suit the front operator plate ordered. If the front plate is Type 'A'

than the sensor LCD is calibrated as 0-100.0%. If the front plate

Type 'B' is selected than the sensor LCD is scaled to -100% to

+100% over the range. The order code for % scaling is '1'.

The sensor LCD can be ordered calibrated in other engineering

units and full details of range must be specified during order stage.

Pa (Pascals) has the Code '2' , mBar has the Code '3'.

m/s has the Code '4', m3/s has the Code '5'

In the example we have chosen the Code '1' .

The Part Number extends to ‘66A 000 000 A 3 B D 1'

DECIMAL PLACES

If no LCD is fitted then this is N/A (not applicable).

The 3 1/2 digit LCD can only display 1999 or 199.9 or 19.99 or

1.999 all depending on the decimal place setting.

No decimal place can be set to Code 'A' which displays 000

Code 'B' displays 00.0, Code 'C' displays 0.00

Code 'D' displays .000

We have chosen the standard setting 00.0 with Code 'B'.

The Part Number extends to ‘66A 000 000 A 3 B D 1 B'

ALARM FUNCTION

The DPC200 can be supplied with an alarm threshold output board

as described on page 8. The board has a low/high alarm relay and a

buzzer relay. A low and high threshold set point adjuster is on the

front of the control panel. If the sensor signal is below or above the

threshold, a timer can be programmed to switch on the alarm and

buzzer relay. The buzzer can be muted. A repeater relay is available

for remote BMS input. If the alarm board is not required the Code

shall be '0' for 'NO'. If the alarm board is required, the order Code is

'1' for 'AL'

In the example we have chosen Code '0'.

The Part Number extends to ‘66A 000 000 A 3 B D 1 B 0'

FINAL PART NUMBER to order is ' 66A000000A3BD1B0'.

Make up your own DPC200 Pressure Volume Controller selection below using the empty cells

HOW TO ORDER

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

DPC200 Page 11

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

DPC200 ORDER SELECTION TABLE

EXAMPLE PART NUMBER SELECTION ( The code after the ( = ) sign is used i.e. No Lid = 66A )

EXAMPLE

A wall mount pressure controller is required of the type DPC200

The DPC200 shall have a Lid with a key lock

The DPC200 will be used with an external sensor type DPM50

The negative pressure range must be -100Pa

The positive pressure range must be +100Pa

The front plate must have two dial set points for hand/auto with two LCDs and Alarms

The power supply must be 24V AC

The control output must be 0...10V to drive a fan speed invertor on the Supply

The scaled units must be in %

The indication must be 100.0% with one decimal place

An Alarm contact must be provided

The part Number for this DPC200 is 66C 000 000 B 3 G A 1 B 1

The control mode should be VVS to control positive pressure with a fan ( Mode 'G')

Call CMR for assistance at any time

66A

DPC200

Part No.

000

Negative

Range

000

Positive

Range

A

Front

Plate

No Lid = 66A

With Lid = 66B

With Key =66C

N/A = 000 T = A

T = B

T = C

T = D

T = E

T = F

T = G

T = H

T = I

T = J

T = K

3

Power

Supply

24 VAC = 3

110 VAC = 4

230 VAC = 5

B

Decimal

Places

0

Alarm

fitted

N/A = N

000 = A

00.0 = B

0.00 = C

.000 = D

NO =0

YES =1

D

Control

output

0...10V = A

10...0V = B

24VAC I = C

AC X = D

1

Scaled

Units

% = 1

Pa = 2

mBar = 3

m/s = 4

m3/s = 5

N/A = 000

B

Control

Mode

N/A = 0

Mode = A

Mode = B

Mode = C

Mode = D

Mode = E

Mode = F

Mode = G

Mode = H

Mode = I

Mode = J

Mode = K

Mode = L

Mode = M

The selection Table has been prepared to make ordering easy. Each

Column contains a number of different options which are available

and a Part Number can be established by yourself depending on

your specific requirements.

The Example Part Number 66A 000 000 A 3 B D 1 B 0 which is

printed above the Selection Table can be identified as being a

DPC200 Pressure - Volume Controller.

The controller has no Lid and is suitable for an external CMR

sensor. The Negative and Positive Range is not applicable. The

front plate is fully populated Type 'A' with 0...100% sensor set point

dial. The power supply is 24VAC, the control mode is Type B driving

an extract damper motor in positive pressure. The control output is

24V ACX . The LCD is scaled to 0...100.0% with one decimal place.

No alarm is required.

THE SELECTION TABLE IS FOR A DPC200 CONTROLLER WITH EXTERNAL SENSOR

DPC200 TECHNICAL SPECIFICATION

CMR CONTROLS

Division of C.M.RICHTER EUROPE LTD

22 Repton Court Repton Close

Basildon Essex SS13 1LN GB

Website : http://www.cmr.co.uk

Tel +44 (0) 1268 287222

Fax +44 (0) 1268 287099

e-mail: sales@cmr.co.uk

DPC200 Page 12

Copyright © 2000 CMR® C.M.RICHTER EUROPE LTD All rights reserved The information is subject to change without notice Issue GB 2 - 1 2001

ENCLOSURE DIMENSIONS

Measurement Range

Control Range Sensor

Control Range Feed Back

Set Point Range

Scaler1 and 2 Range

AC Power Supplies

AC Control Output

Volt Output Signal

Set point Signal

Feed BackSignal

Sensor Signal

Proportional Band

Timing

Sensitivity

Operating-Storage Temp.

Alarm Relay Low/High

Low/high Alarm Threshold

Buzzer Relay

Repeater Relay

Alarm Timers

Relay Latching

Weight

Electrical Connections

Enclosure

Cable Glands

Conformity

Calibration Certificate

See Order Selection Table of the external CMR sensor to be used

The control range is 0...10V or 0-100% of the CMR sensor range. Input is on Terminal 13.

Any range +/- 0...10V input = +/-0...10V output. Scaler1 input T13 - out T16. Scaler 2 input T7 - out T9

24 VAC 50/60Hz Fuse 1.0 A Wickmann

110VAC 50/60Hz Fuse 315 mA Wickmann

230VAC 50/60Hz Fuse 315 mA Wickmann

24 VAC I (internal power from isolation transformer) max 350mA (Fused 1A Wickmann)

24VAC (1A), 110VAC (200mA), 230VAC (100mA) output bridged directly to Input Terminals. Fused

0-10V (0...100%) or 10...0V (100%...0%) switchable (

0...10V (0...100% of range)

0...10V (0...100% of range)

0...10V (0...100% of range)

0...30% of range

0...4 seconds adjustable

0... 10% of sensor range

Operating Temperature 10...70 °C - Storage Temperature -20 to 85

24VDC ( 1A) non inductive - single pole change over.

Adjustable 0...10V (0...100% of range)

24VDC (1A) non inductive - single pole on-off. Works on same threshold as high/low alarm.

24VDC (1A) non inductive - single pole on-off.

Switch selectable 0s - 10s - 30s - 60s.

Switch selectable - Latching or auto-reset.

1.5 kg

5 way power, 5 way control output, 2 and 3 way control board. All Plugs with Screw Connections.

ABS Plastic without perspex Lid IP44

ABS Plastic with perspex Lid with or without key lock Protection Class IP65

4 x PG13 and 1 x PG11 entries.

EN61326-1 EMC EN61010-1 SAFETY

Can be supplied with Certificate traceable to National Standards depending on external sensor used.

The control range is 0...10V or 0-100% of the position of the CMR actuator or the speed input on T7.

The set point range is 0...10V or 0-100% of the position of set point potentiometer or external input on T2

RL = 5kOhm min.) 4...20mA or 20...4mA

°C

240mm

198mm

145mm

185mm

125mm

95mm 25mm

70mm

99mm

Three point Wall Mount

Table of contents