Infranor XtrapulsCD1-pm User manual

1

XtrapulsCD1-pm

User manual

PROFIBUS

POSITIONER

2

XtrapulsCD1-pm - User manual

Windows®is a registered trade-mark of MICROSOFT®CORPORATION.

STEP7®is a registered trade-mark of SIEMENS®.

3

XtrapulsCD1-pm - User manual

WARNING !

This is a general manual describing a series of servo amplifiers having output capability suitable for driving AC

brushless sinusoidal servo motors.

Instructions for storage, use after storage, commissioning as well as all technical details require the

MANDATORY reading of the manual before getting the amplifiers operational.

Please see XtrapulsCD1-pm Installation Guide for the hardware installation of the amplifier (dimensions, wiring,

...).

For the PROFIBUS communication, see manual XtrapulsCD1-pm –PROFIBUS Communication Profile.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the amplifier manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

!

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the amplifiers (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (ElectroStatic Discharge)

INFRANOR amplifiers are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the amplifiers are not properly

stored and handled.

STORAGE

- The amplifiers must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the amplifier connectors and material with electrostatic potential

(plastic film, polyester, carpet…).

HANDLING

- If no protection equipment is available (dissipating shoes or bracelets), the amplifiers must

be handled via their metal housing.

- Never get in contact with the connectors.

ELIMINATION

In order to comply with the 2002/96/EC directive of the European Parliament and of the Council of

27 January 2003 on waste electrical and electronic equipment (WEEE), all INFRANOR devices

have got a sticker symbolizing a crossed-out wheel dustbin as shown in Appendix IV of

the 2002/96/EC Directive.

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with standard waste.

4

XtrapulsCD1-pm - User manual

All electrical industrial automatisms which lifetime is coming to its end are Waste Electronic and Electrical

Equipment (WEEE) according to article R543-172 of the French Environmental Code.

WEEE classification of the INFRANORproducts

Categorie 9: Monitoring and control instruments

In accordance with the Decree nr. 2012-617 of May 2nd, 2012 which specifies the provisions related to

the professional EEE manufacturers' obligations, INFRANOR France is a member of RECYLUM : eco-

organization ecosystem certified for the collection, treatment and recycling of WEEE.

In France, RECYLUM allows all professionals benefiting from a free collection and recycling solution, in

observance of the regulation, the environment and health.

Information and sorting instructions regarding INFRANORproducts

Type of waste

Waste category

Waste management

Packaging

Cardboard

Recyclable waste

Waste disposal centre / collection

point of recyclable waste

Documents

Paper

Recyclable waste

Waste disposal centre / collection

point of recyclable waste

Mechanics

Metal

Recyclable waste

Waste disposal centre / metal

collection point

Heatsinks

Metal

Recyclable waste

Waste disposal centre / metal

collection point

Electronical

boards and

components

WEEE (Waste Electronic and

Electrical Equipment)

Dangerous industrial

waste

France:

http://www.ecosystem.eco/fr/sous-

rubrique/solutions

Abroad:

Country-specific regulation

Sorting instructions may vary according to regions / countries.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

© INFRANOR, September 2020. All rights reserved.

Issue: 4.2

Chapter 1 - General description

5

XtrapulsCD1-pm - User manual

Contents

PAGE

CONTENTS..............................................................................................................................................5

CHAPTER 1 - GENERAL DESCRIPTION ..............................................................................................7

1-INTRODUCTION..............................................................................................................................7

1.1 –PROFIBUS MODE WITH SOFTWARE ADDRESSING...........................................................7

1.2 –PROFIBUS MODE WITH HARDWARE ADDRESSING ..........................................................7

1.3 –STAND-ALONE MODE ............................................................................................................7

2-ARCHITECTURE OF APOSITIONER.............................................................................................8

3-OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING .................................................8

CHAPTER 2 - COMMISSIONING............................................................................................................9

1–COMMISSIONING OVERVIEW ......................................................................................................9

2–INSTALLATION OF THE PC SOFTWARE................................................................................... 10

3-CHECKING THE POSITIONER HARDWARE CONFIGURATION............................................... 10

4-SELECTION OF THE OPERATION MODE .................................................................................. 10

5-COMMISSIONING ........................................................................................................................ 10

6-STARTING THE "VDSETUP" SOFTWARE .................................................................................. 11

7-MOTOR ADJUSTMENT................................................................................................................ 11

7.1 - CONFIGURATION OF THE SENSOR TYPE ........................................................................ 11

7.2 - SELECTION OF THE MOTOR TYPE.................................................................................... 12

7.3 - ENCODER COUNTING PROTECTION................................................................................. 12

7.4 - PARAMETER ADJUSTMENT FOR A LINEAR MOTOR ....................................................... 13

7.5 - MAXIMUM APPLICATION SPEED........................................................................................ 13

7.6 - CONFIGURATION OF THE THERMAL SENSOR................................................................. 13

7.7 - I2t PROTECTION.................................................................................................................... 14

8-SERVO LOOP ADJUSTMENT...................................................................................................... 15

8.1 - REGULATOR PARAMETERS ............................................................................................... 15

8.2 - LOOP ADJUSTMENT WITH A VERTICAL LOAD ................................................................. 16

9-ROTATION /COUNTING DIRECTION ......................................................................................... 16

10 -PARAMETER SAVING................................................................................................................ 16

11 -MOTOR PHASING AT POWER ON............................................................................................ 17

12 -INCREMENTAL ENCODER OUTPUTS...................................................................................... 17

13 –POSITION LOOP SETUP........................................................................................................... 18

14 –APPLICATIONS WITH THE SECOND SENSOR INPUT........................................................... 18

14.1 –SECOND POSITION SENSOR FEEDBACK ...................................................................... 19

14.2 - ELECTRONIC GEARING APPLICATION............................................................................ 20

15 -COGGING TORQUE COMPENSATION..................................................................................... 21

CHAPTER 3 –FUNCTIONALITIES...................................................................................................... 23

1-DESCRIPTION OF THE LOGIC I/OS............................................................................................ 23

1.1 -LOGIC INPUTS ..................................................................................................................... 23

1.2 -LOGIC OUTPUTS ................................................................................................................. 23

2-LIMIT SWITCHES ADJUSTMENT ................................................................................................ 24

3-BRAKE CONTROL........................................................................................................................ 25

4-PROFIBUS ADDRESS.................................................................................................................. 25

4.1 - PROFIBUS SOFTWARE ADDRESSING............................................................................... 25

4.2 - PROFIBUS HARDWARE ADDRESSING .............................................................................. 25

CHAPTER 4 - PROGRAMMING........................................................................................................... 26

1–GENERAL DESCRIPTION........................................................................................................... 26

2–POSITIONER CONFIGURATION ................................................................................................ 26

2.1 –POSITION SCALING............................................................................................................. 26

2.2 –POSITION LIMIT AND SAFETY............................................................................................ 27

2.3 –MANUAL MOVEMENTS........................................................................................................ 28

Chapter 1 –General description

6

XtrapulsCD1-pm - User manual

2.4 –BRAKE CONTROL AND AMPLIFIER DISABLING ...............................................................28

2.5 –POSITIONING PROFILE.......................................................................................................29

2.6 –POSITION MODULO.............................................................................................................29

2.7 –POSITIONER I/Os .................................................................................................................29

2.8 –SECOND SENSOR................................................................................................................30

2.9 –PROFIBUS COMMUNICATION ............................................................................................30

3–EDITION OF ASEQUENCE .........................................................................................................30

3.1 -HOMING SEQUENCE...........................................................................................................32

3.2 -POSITIONING SEQUENCE..................................................................................................33

3.3 - SPEED SEQUENCE...............................................................................................................34

3.4 - TORQUE SEQUENCE ...........................................................................................................34

3.5 - GEARING SEQUENCE..........................................................................................................35

3.6 - SEQUENCES CHAINING.......................................................................................................35

3.7 - PROGRAMMABLE OUTPUTS...............................................................................................37

3.8 - PROGRAMMABLE INPUTS...................................................................................................37

4-PROGRAMME EXECUTION.........................................................................................................37

5-SPEED LIMITATION .....................................................................................................................38

CHAPTER 5 –PROFIBUS COMMUNICATION...................................................................................39

CHAPTER 6 –TROUBLESHOOTING................................................................................................. 40

1-DIAGNOSTICS..............................................................................................................................40

1.1 - XtrapulsCD1-pm FAULT LEDs...............................................................................................40

1.2 –FAULT RESET.......................................................................................................................40

2–FAULT FINDING...........................................................................................................................40

2.1 –SYSTEM FAULT....................................................................................................................40

2.2 –NON STORED FAULTS ........................................................................................................40

2.3 –STORED FAULTS .................................................................................................................40

3–OPERATING PROBLEMS............................................................................................................45

3.1 –MOTOR DOES NOT MOVE ..................................................................................................45

3.2 –MOTOR SUPPLIED BUT NO TORQUE................................................................................45

3.3 –SHAFT LOCKED, ERATIC OSCILLATIONS OR ROTATION AT MAXIMUM SPEED .........45

3.4 –DISCONTINUOUS MOTOR ROTATION WITH ZERO TORQUE POSITIONS ....................45

3.5 –LOUD CRACKLING NOISE IN THE MOTOR AT STANDSTILL...........................................45

3.6 –LOUD NOISE IN THE MOTOR AT STANDSTILL AND WHEN RUNNING ..........................46

3.7 –SEQUENCE NOT EXECUTED..............................................................................................46

4-SERVICE AND MAINTENANCE ...................................................................................................46

APPENDIX ............................................................................................................................................ 47

1-SERVO CONTROLLER STRUCTURE .........................................................................................47

2–USE OF THE SERIAL LINK..........................................................................................................48

2.1 –OVERVIEW............................................................................................................................48

2.2 - INSTRUCTIONS LIST ............................................................................................................49

3-USE OF THE VT 100 TERMINAL..................................................................................................52

3.1 - CONFIGURATION..................................................................................................................52

3.2 –USE OF THE TERMINAL ......................................................................................................53

3.3 –FAULT DISPLAY....................................................................................................................55

Chapter 1 - General description

7

XtrapulsCD1-pm - User manual

Chapter 1 - General description

1 - INTRODUCTION

Series XtrapulsCD1-pm Profibus positioners are PWM servo amplifiers for the control of AC sinusoidal motors

(brushless) equipped with a position sensor.

The XtrapulsCD1-pm servo drive is available as a stand-alone single-axis block that includes all supplies and

mains filter. It is available in both mains operated versions 230 VAC and 400/480 VAC.

The XtrapulsCD1-pm positioner generates itself the positioning trajectory and is suited for axis positioning

applications. Up to 128 control sequences including axis homing, absolute or relative displacement, speed profile

running, electronic gearing and torque regulation can be programmed and combined in order to solve various

applications. The sequence chaining capability allows defining macro-sequences for complex applications:

several control sequences can be linked together in order to be automatically executed one after the other. The

control sequences are pre-programmed. So, the application programming simply consists in initializing the

sequences parameters with the desired values. A control sequence can then be selected by using the

programmable logic inputs and its execution is started by using the START logic input. The XtrapulsCD1-pm

positioner can operate in stand-alone mode or in connection with a host controller (PROFIBUS mode).

The selection of the various operation modes is made by means of micro-switches accessible by the operator.

1.1 –PROFIBUS MODE WITH SOFTWARE ADDRESSING

This mode is activated by the 00 micro-switches selection.

This operation mode is fully compliant with the CD1-p positioner.

The positioner Profibus address is saved into a non volatile memory (EEPROM). This EEPROM can be modified

via Profibus (message Set_Slave_Add) by a Profibus master of class 2. The new address will be automatically

saved.

1.2 –PROFIBUS MODE WITH HARDWARE ADDRESSING

This mode is activated by the 01 to 7D micro-switches selections (Profibus address valid for one slave: 3 to 125).

In this mode, the drive address is defined by the micro-switches status and not by the serial link or by Profibus.

The address modification via Profibus is still possible but the address taken into account at the next power up is

always the one defined by the selection micro-switches.

1.3 –STAND-ALONE MODE

This mode is activated for the 7E and 7F combinations of the selection micro-switches:

▪The 7E combination corresponds to the stand-alone mode with VT100.

▪The 7F combination corresponds to the stand-alone mode without VT100.

In this mode, the Profibus is not used. The positioner operation is managed by the inputs START, STOP, IN1 to

IN6 as well as by the outputs SEQ, POS, SPEED, OUT1 to OUT4.

The ENABLE input enables/disables the positioner. The positioner cannot be enabled/disabled via the serial link

RS-232 or by the Profibus. Consequently, the positioner adjustment phase (autophasing, autotuning,

cogging torque acquisition ...) must not be made in stand-alone mode.In stand-alone mode, the brake delay

time with regard to the enabling/disabling is not possible either.

Chapter 1 –General description

8

XtrapulsCD1-pm - User manual

2 - ARCHITECTURE OF A POSITIONER

Electric motor

Electric device that transforms electrical energy into a mechanical movement.

This transformation is often made by means of a current commutation.

Generally, the movement is a rotation but there are also linear motors.

Motor

Electric motor which current commutation is made by mechanical brushes.

Brushless or synchronous

motor

Electric brushless motor. The current commutation is electronically made and

requires a position sensor (resolver, encoder, Hall sensor...).

Resolver

Absolute position sensor over one revolution. The resolver is often used

together with brushless motors because of its robustness.

Encoder

Incremental or absolute position sensor. The encoder is used together with

brushless motors for its accuracy.

Amplifier

Servo drive

Electric device for the control of electric motors. It also includes a current

regulator, a speed servo control and, a position servo control.

Current loop

Current regulator

Used for the motor current control. The motor torque is generally proportional

to the current amplitude.

Speed loop

Speed regulator

Allows the motor speed control with a speed input command.

Position loop

Position regulator

Allows the motor position control.

Positioner

Positioner with position loop and trajectory generator that allows positioning.

Trajectory generator

Generates a speed profile (acceleration, step speed, deceleration) that

allows positioning (start position -> arrival position).

Fieldbus

Digital link that allows real time data exchange between various electric

devices. The characteristic of field busses is their high protection and fault

correction level as well as a predictable communication time.

Profibus

Fieldbus initially defined by Siemens®. This bus is widely used in automation.

Enabled/disabled

(Servo On/Off)

When a motor is enabled, it is controlled by the positioner and the servo

loops are operating. When disabled, its rotation is free and there is no current

in the motor.

3 - OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING

" XtrapulsCD1-pm Profibus positioner Installation Manual".

" XtrapulsCD1-pm Profibus Communication Profile".

Sequence

selection

Trajectory

generator

Position

loop

Speed

loop

Current loop

Current

feedback

Motor

Speed

feedback

Position

feedback

Position

sensor

Logic I/0s

Profibus-DP

interface

Chapter 2 - Commissioning

9

XtrapulsCD1-pm - User manual

Chapter 2 - Commissioning

WARNING

During the machine adjustments, some drive connection or parameterization errors may involve

dangerous axis movements. It is the user's responsibility to take all necessary steps in order to

reduce the risk due to uncontrolled axis movements during the operator's presence in the

concerned area.

1 –COMMISSIONING OVERVIEW

The various stages of a first positioner commissioning are described below:

Both operation stages are:

The positioner parameters are accessible via:

- the serial link and the PC parameterization software,

- or by the PKW of the PROFIBUS DP.

CAUTION !

Do not make the drive parameterization by means of both PC software and Profibus at the same time.

SERVO CONTROL ADJUSTMENT

(chapter 2 section 8)

MOTOR ADJUSTMENT

(chapter 2 section 7)

CONFIGURATION

(chapter 4 section 2)

PROFIBUS COMMUNICATION

(PROFIBUS communication profile

manual)

- Current regulator adjustment.

- Definition of the current limitations and of the I2t protection.

- Adjustment of the motor control parameters.

- Speed limitation definition.

- Rotation direction.

- Adjustment of the servo control parameters according to the

load.

- Definition of the resolution.

- Limit switches.

- Following error.

PROFIBUS operation mode :

- Communication start between PLC and positioner.

PROGRAMMATION

(chapter 4 section 3)

PROFIBUS OPERATION

(PROFIBUS communication profile

manual)

- Sequences programmation.

PROFIBUS operation mode :

- "Operational" phase: sequences execution by Profibus.

!

Chapter 2 - Commissioning

10

XtrapulsCD1-pm - User manual

2 –INSTALLATION OF THE PC SOFTWARE

The Visual Drive Setup software is PC compliant under Windows®

1

and allows an easy parameterization of the

XtrapulsCD1-pm amplifiers.

Please see our website www.infranor.com for downloading the "Visual Drive Setup" software.

3 - CHECKING THE POSITIONER HARDWARE CONFIGURATION

The standard amplifier configuration is adjusted to MAVILOR motors (resolver sensor with transformation ratio =

0.5). For the adjustment to other motor types, please see "XtrapulsCD1-pm - Installation Guide".

4 - SELECTION OF THE OPERATION MODE

A DIP micro-switch, accessible by the operator, allows the selection of the various operation modes.

7 6 5 4 3 2 1

(Switch 7 = MSB

Switch 1 = LSB)

Operation mode

Note

X0000000 (00)

Profibus software addressing

This mode is compliant with the CD1-p drive

Drive address is stored into the EEPROM

X0000001 (01) to X1111101 (7D)

Profibus hardware addressing

Profibus mode with hardware addressing via

"DIP" switch

X1111111(7F)

Stand-alone Mode without VT100

Drive used in Positioner mode via inputs

START, STOP, IN1 to IN6

X1111110(7E)

Stand-alone Mode with VT100

Drive used in Positioner mode via inputs

START, STOP, IN1 to IN6

Possible use of a VT100 terminal

X: Cursor unused.

Remark: The positioner automatic procedure for the commissioning phase (autophasing, autotuning, cogging

torque acquisition ...) cannot be started in the stand-alone operation mode .

5 - COMMISSIONING

Please see manual "XtrapulsCD1-pm - Installation Guide" before switching on the amplifier for the first time.

For switching on the amplifier, please proceed as follows:

•Switch on the +24V auxiliary supply:

The red front panel LED "ERROR" must be unlit and the red front panel LED "AP" must be lit ("Undervolt." error

displayed).

The AOK relay contact (pins 1 and 2 of X4) is closed. It is then possible to control the power ON relay.

•Switch on the power supply:

The red front panel LED "AP" must be unlit : the amplifier is ready for enabling.

1

Windows®is a registered trade mark of MICROSOFT®CORPORATION

CAUTION !

The 24 V auxiliary supply must always be switched on before the power supply.

It is mandatory to wait for at least 30 seconds between switching off and on again the amplifier.

Chapter 2 - Commissioning

11

XtrapulsCD1-pm - User manual

6 - STARTING THE "VDSETUP" SOFTWARE

•Connect the serial link RS232 between PC and amplifier.

•Switch on the amplifier and start the Visual Drive Setup software on the PC, under WINDOWS®.

If the message No serial communication found is displayed on the screen, click on OK and check the following

points:

oThe amplifier must be on,

oThe correct RS232 connection between amplifier and PC,

oThe correct software configuration (Com.port, ...).

For the parameterization of the amplifier via the Visual Drive Setup software, set all DIP micro-switches at

position OFF (address 00).

7 - MOTOR ADJUSTMENT

7.1 - CONFIGURATION OF THE SENSOR TYPE

The configuration of the sensor type is software selectable and saved in the amplifier EEPROM.

The amplifier is configured as standard for a resolver sensor. For motors equipped with an encoder, please

proceed as follows:

Select the appropriate encoder type in the Resolver & Encoder input configuration menu.

Select Encoder feedback and confirm this selection.

Then enter the Motor encoder Resolution value in the Servo Motor module.

If the motor is equipped with Hall effect sensors, check that the ENABLE input is not activated and the amplifier is

on, before moving manually the motor over one revolution or one pole pitch on linear motors. If the HES error is

displayed, switch off the amplifier and check the following points before switching it on again:

The Hall effect sensors (HES) must be correctly connected on the amplifier X3 connector (if 60° Hall sensor

types are used, check the various wiring combination of the HES signals for finding the right wiring order).

Check for the correct supply voltage of the Hall sensors.

Check for the correct value of the Motor encoder Resolution parameter.

If the motor Hall sensors do not work correctly, select the appropriate incremental encoder type (Incremental

Encoder without HES) in the Feedback configuration menu and start the amplifier commissioning with this

configuration.

If the motor used is equipped with an absolute Sin/Cos encoder over one revolution (Heidenhain ERN 1085 or

compliant), check that the ENABLE input is not activated and the amplifier on. Then move manually the motor

over one revolution. If the HES error is displayed, switch off the amplifier and check the following points before

switching it on again:

The commutation channels of the Sin/Cos encoder must be correctly wired on the amplifier X3 connector.

Check for the correct supply voltage of the Sin/Cos encoder.

Check for the correct value of the Motor encoder resolution parameter.

Perform the Save parameters to EEPROM procedure before switching off the amplifier in order to save the

sensor configuration.

Chapter 2 - Commissioning

12

XtrapulsCD1-pm - User manual

7.2 - SELECTION OF THE MOTOR TYPE

THE MOTOR USED IN THE APPLICATION IS CONTAINED IN THE MOTOR LIST OF THE

PARAMETERIZATION SOFTWARE.

Select, in the motor list, the motor used in the application.

The motor selection will start the automatic calculation of the current loop parameters.

Check that the values of the parameters Max. current and Rated current are compliant with motor and amplifier.

If necessary, modify them according to the motor and amplifier specifications.

The parameter Max current defines the maximum output current value of the amplifier. It may vary between 20 %

and 100 % of the amplifier current rating.

The parameter Rated current defines the limitation threshold of the amplifier output RMS current (I2t).

It can vary between 20 % and 50 % of the amplifier current rating.

If the Incremental encoder without HES sensor configuration is selected, start a motor phasing (Phasing)

procedure.

The motor phasing can be launched either in the control window of the VISUAL DRIVE SETUP software, via the

PROFIBUS fieldbus, or via the Enable input in stand-alone mode.

THE MOTOR USED IN THE APPLICATION IS NOT CONTAINED IN THE MOTOR LIST OF THE

PARAMETERIZATION SOFTWARE.

Select the New Motor function and follow the instructions.

7.3 - ENCODER COUNTING PROTECTION

When servo motors are equipped with an encoder, any error in the encoder pulse counting generates an error in

the position measurement of the rotor and may involve uncontrolled motor movements that can be dangerous for

both operator and machine. The encoder counting protection of the XtrapulsCD1-pm amplifier range allows the

detection of pulse counting errors and immediately disables the amplifier for reasons of security.

The encoder counting protection checks that the number of encoder pulses between to successive Z marker

pulses (or R reference signals) is equal to the value of the Motor encoder resolution parameter multiplied by the

one of the Zero mark pitch parameter. The encoder counting protection also checks that the encoder pulse

frequency is lower than 1,5 times the maximum encoder frequency. The maximum encoder frequency is

calculated in the amplifier according to the value of the Motor encoder resolution and Maximum speed

parameters.

The value of the Motor encoder resolution parameter defines the number of encoder pulses (or encoder signal

periods) per motor revolution (for a rotary motor) or per motor pole pairs (for a linear motor).

The value of the Zero mark pitch parameter defines the number of motor revolutions (for a rotary motor) or of

motor pole pairs (for a linear motor) between two successive Z marker pulses (or R reference signals).

With a rotary motor, the Zero mark pitch parameter is generally equal to 1 because the encoder has got one Z

marker pulse (or one R reference signal) per motor revolution.

On a linear motor with only one marker pulse over the whole motor travel, the Zero mark pitch parameter must

be defined at 15. In this case, the encoder counting protection checks that the measured encoder position has still

got the same value when the marker pulse is activated (no drift in the position measurement).

Note: In the Incremental encoder without HES configuration, the motor phasing procedure (Phasing)must be

renewed after the release of a Counting error because the current rotor position reference for the motor

commutation is not correct.

Chapter 2 - Commissioning

13

XtrapulsCD1-pm - User manual

7.4 - PARAMETER ADJUSTMENT FOR A LINEAR MOTOR

The Motor encoder resolution parameter is calculated as follows:

The value of the motor Maximum speed parameter in rpm is calculated as follows:

The linear speed value in m/s is calculated as follows:

7.5 - MAXIMUM APPLICATION SPEED

The parameter Max. speed defines the maximum speed at which the amplifier can control the motor.

This parameter can be:

•lower than or equal to the maximum motor speed,

•slightly higher than the maximum motor speed in the application (20%). This margin allows a speed

overshoot that avoids the position loop saturation (position following). This margin can be as small as

possible when using a high bandwidth or at low acceleration.

The speed set point value for the sequences and for the manual movements (positioning and jog) are saved in %

with regard to the Max. speed parameter value. So, when the Max. speed parameter value is changed, all

speed set point values are scaled accordingly.

7.6 - CONFIGURATION OF THE THERMAL SENSOR

According to the selected position feedback sensor of the motor, the thermal sensor is entering either the X1

connector (resolver) or the X3 connector (encoder).

7.6.1 –SELECTION OF THE SENSOR TYPE

The motor can be equipped either with a CTN sensor (ohmic resistance = decreasing temperature function) or

with a CTP sensor (ohmic resistance = increasing temperature function).

Check that the selected thermal sensor type actually corresponds to the sensor type mounted on the application

motor.

7.6.2 –TRIGGERING THRESHOLD ADJUSTMENT

Enter the sensor ohmic value (kOhm) corresponding to the required temperature value for the release of the

Motor overtemperature protection, according to the manufacturer's specifications.

Pole pitch

N

S

N

S

N

S

Motor magnets

1 encoder signal pitch = 4 counting increments

!

Motor pole pitch (mm)

Encoder signal pitch (µm)

Motor encoder resolution = 1000 x

Max. speed (rpm) = 60 x

x max. motor speed (m/s)

1000

Motor pole pitch (mm)

Motor speed (rpm)

60

x

Motor pole pitch (mm)

1000

Linear speed (m/s) =

Chapter 2 - Commissioning

14

XtrapulsCD1-pm - User manual

7.6.3 –WARNING THRESHOLD ADJUSTMENT

Enter the sensor ohmic value (kOhm) corresponding to a warning temperature value.

When the warning temperature is reached, the red front panel LED "ERROR" is blinking.

Note: When using a CTN sensor, the warning ohmic value will be higher than or equal to the triggering ohmic

value.

When using a CTP sensor, the warning ohmic value will be lower than or equal to the triggering ohmic value.

7.7 - I2t PROTECTION

2 selection modes are available: Fusing or Limiting.

It is advisable to use the Fusing mode during commissioning phases.

In Fusing mode, the amplifier is disabled when the current limitation threshold is reached.

In Limiting mode, the motor current is only limited at the value defined by the Rated current parameter when the

limitation threshold is reached.

7.7.1 - OPERATION OF THE CURRENT LIMITATION IN "Fusing" mode

When the amplifier output RMS current (I2t) reaches 85 % of the rated current, the red ERROR LED is blinking on

the amplifier front panel (t1 in the diagram). If the RMS current (I2t) has not dropped below 85 % of the rated

current within 1 second, the I2t error is released and the amplifier disabled, otherwise, the blinking is inhibited (t3

in the diagram).

When the amplifier output RMS current (I2t) reaches the rated current value, the I2t limits the amplifier output

current at this value (t2 in the diagram).

Diagram of the amplifier output current limitation in an extreme case (motor overload or shaft locked):

The maximum current duration before release of the blinking display is depending on the value of the parameters

Rated current and Max. current. This value is calculated as follows:

T dyn (second) = t1-t0= 3,3 x Rated current (A) / Max. current (A)2

The maximum current duration before limitation at the rated current is also depending on the value of the Rated

current and Maximum current parameters. This value is calculated as follows:

T max (second) = t2-t0= 4 x Rated current (A) / Max. current (A)2

NOTE 1

When the "Max. current / Rated current" ratio is equal to 1, the I²t error is never released. But these formulas

remain very precise as long as the "Max. current / Rated current" ratio is higher than 3/2.

Max. current

t0

t3

Rated current

t1

t2

Amplifier output current

1 second

t1 = Blinking

t2 = Current limitation

t3 = I2t error

time

Chapter 2 - Commissioning

15

XtrapulsCD1-pm - User manual

NOTE 2

The amplifier I2t signal can be displayed on the digital oscilloscope by selecting the I2t signal in the

Channel menu. The threshold values of the I2t signal, for the protection mode described above, are calculated as

follows:

Current limitation threshold (%) = Rated current (%)2 / 50

Rated current (%) = 100 x Rated current (A) / amplifier current rating (A)

The corresponding RMS current value of the amplifier can be calculated as follows:

Amplifier RMS current (A) = I2t signal value (%) x 501/2 xamplifier current rating (A) / 100

7.7.2 - CURRENT LIMITATION IN "Limiting" MODE

When the amplifier output RMS current (I2t) reaches 85 % of the rated current, the red ERROR LED on the

amplifier front panel is blinking (t1 in the diagram). When the RMS current (I2t) drops below 85 % of the rated

current, the blinking is inhibited.

When the amplifier output RMS current (I2t) reaches the rated current value, the I2t protection limits the amplifier

output current at this value (t2 in the diagram).

Diagram of the amplifier output current limitation in an extreme case (motor overload or shaft locked):

The maximum current duration before release of the blinking display (t1 - t0) and before limitation at the rated

current (t2 - t0) is calculated the same way as in the "Fusing" mode.

8 - SERVO LOOP ADJUSTMENT

8.1 - REGULATOR PARAMETERS

The Autotuning procedure identifies the motor and load specifications and calculates the speed/position loop

parameters.

In Pand PI speed mode, only the speed loop gains are calculated.

In PI2 speed mode, the proportional gain of the position loop is also calculated. But the Feedforward gains of the

position regulator are all initialized at 0.

In Position mode, all gains of both speed and position regulators are calculated.

Note: The position loop stability can be tested in PI² speed mode because the Feedback gains are identical to the

Position mode.

The operator can select a bandwidth (Low, Medium or High) as well as the filter type (standard,

antiresonance or max. stiffness).

The Autotuning procedure can be executed with the motor disabled or enabled. In the case of an axis with a

vertical load, see section 8.2 of this chapter.

Before executing the Autotuning procedure, check that the motor shaft is free and that its rotation over one

revolution is not dangerous for operator and machine. Check that the brake is released (the Autotuning

command does not control the brake).

Amplifier output current

Max. current

Rated current

time

t0

t1 = Blinking

t2 = Current limitation

t2

t1

Chapter 2 - Commissioning

16

XtrapulsCD1-pm - User manual

For a complete adjustment, the Autotuning procedure must always be executed in Position mode (at power on,

the amplifier is automatically in Position mode).

But the amplifier position loop stability can also be tested in Speed mode. In this case, after the execution of the

Autotuning procedure in PI² mode:

•check that the motor is correctly running in both directions,

•check the response at a small displacement without Idc saturation (oscilloscope function).

In case of loud noise in the motor at standstill or when running, check the rigidity of the mechanical transmission

between motor and load (backlashes and elasticities in motor and couplings).

If required, start a new Autotuning procedure by selecting a lower bandwidth.

If the instability remains, start a new Autotuning procedure by activating the Antiresonance filter. If necessary,

adjust more accurately the loop response stability by adjusting the stability gain.

If the Autotuning procedure was executed in PI² mode, when the Position mode was selected, the Feedforward

gains of the position regulator must be adjusted manually. Set the Feedforward speed 1 gain value at 1, in order

to avoid a high following error value.

8.2 - LOOP ADJUSTMENT WITH A VERTICAL LOAD

In the case of an axis with vertical load, proceed as follows:

Select the Limiting current limitation mode.

Initialize the speed loop gains corresponding to the unloaded motor (execute therefore the Autotuning

procedure with the motor uncoupled from its mechanical load).

Couple the motor with its load. If possible, make a control in speed mode; otherwise, close the position loop with a

stable gain.

Select the PI² speed mode and move the axis by means of the speed input command until a stall position where

one motor revolution is not dangerous for operator and machine (far enough from the mechanical stops).

Execute then the Autotuning procedure with the motor at standstill. If the axis is moving, the Autotunig

procedure is not accepted by the amplifier.

Select the Position mode and set the Feedforward speed 1 gain value at 1, in order to avoid a high following

error value.

9 - ROTATION / COUNTING DIRECTION

The counting direction can be reversed by selecting the Reverse movement in the Visual Drive Setup

parameterization software.

10 - PARAMETER SAVING

When all adjustments have been made, the parameters may have to be stored in a non volatile EEPROM (the

amplifier must be disabled).

Chapter 2 - Commissioning

17

XtrapulsCD1-pm - User manual

11 - MOTOR PHASING AT POWER ON

In the Incremental encoder configuration without HES, the motor Phasing procedure is executed according to the

following diagram at each amplifier power up (standalone mode) :

In the Profibus mode, the phasing procedure must be started by the master controller (PNU 896). In the Software

control mode via the serial link, the phasing procedure must be started by the Motor phasing command in the

VDSetup window.

Remark: In the Incremental encoder configuration without HES, the motor Phasing procedure must be carried out

again after a Feedback fault release or a Counting fault release. The motor Phasing procedure must also be

carried out again after the modification of the motor or the encoder parameter value.

- The analog output on the X2 connector can be configured in the Setup menu of the VISUAL DRIVE SETUP

software in order to get the Phasing OK output signal (output voltage from 0 V to 10 V when the motor phasing is

OK) .

- In the Profibus mode, the Phasing OK can be checked by the master controller (PNU 897).

- In the Software control mode via the serial link, the state of the Phasing OK output is displayed in the main

VDSetup window.

12 - INCREMENTAL ENCODER OUTPUTS

The incremental encoder outputs are two pulse channels A and B in quadrature and one Z marker pulse per

revolution.

AOK

Power On

ENABLE

PHASING OK

Start up

Power on

Phasing

Ready for running

Start phasing

End start up

End phasing

In the case of an axis with unbalanced load (constant torque due to the gravity effect on a

vertical axis), the motor phasing procedure is not valid. The motor must be equipped with an

incremental encoder + HES or an absolute Sin/Cos encoder.

!

Chapter 2 - Commissioning

18

XtrapulsCD1-pm - User manual

The Output encoder resolution is selected according to the table below:

Maximum motor speed (rpm)

up to 1600

up to 3200

up to 6400

up to 12800

up to 25000

Encoder output resolution (ppr)

512 to 16384

512 to 8192

512 to 4096

512 to 2048

512 to 1024

The resolution value defined in the Output encoder resolution parameter can be divided by 2, 4 or 8 by

selecting the Resolution division ratio parameter.

The Output encoder deadband parameter introduces a deadband at standstill around the current resolver

position in order to avoid oscillations of +/- 1 encoder edge on channels A and B. The value of 4095 corresponds

to 1/16 revolution of the motor shaft.

The Zero pulse origin shift parameter allows the shifting of the marker pulse position on channel Z with regard

to the resolver zero position. The value 32767 corresponds to one revolution of the motor shaft. The marker pulse

width is equal to ¼ of the A and B channels period.

13 –POSITION LOOP SETUP

The servo motor position loop can be closed by the motor feedback sensor or with the second position sensor

mounted on the load. In the case of the second position sensor feedback, please see section 14.1 of this chapter.

Open the "Position scaling parameters" window accessible in the "Positioner Application Setup" menu.

Check that "Enable second sensor feedback" is not selected, in order to use the motor position sensor (resolver

or encoder) for feedback.

Set the “Position resolution” parameter according to the desired position scaling of the load in order to display

the position in the load units as described below:

Position resolution = number of desired load position increments for one motor revolution

Ex: one motor revolution = 3.302 mm on the load, if the load position must be displayed in mm with a resolution of

1μm. Choose Position resolution = 3302, Decimal number = 3 and Unit = mm.

The servo loop stability is not affected by the Position Resolution parameter value.

Set at 0 the value of the “Position deadband” parameter. This parameter is only useful in applications with high

transmission backlashes or applications with high axis frictions. In those cases, when the position error value at

standstill is lower than the value of the “Position deadband” parameter, the proportional gain of the position loop

is set at 0.

14 –APPLICATIONS WITH THE SECOND SENSOR INPUT

The XtrapulsCD1-pm amplifier has got 2 position sensor inputs : one for a resolver and another for an encoder.

The position sensor input which is not used for the motor position feedback (encoder or resolver) is called

Second Position Sensor input. The Second Position Sensor input can be used for closing the drive position

loop if a position sensor is mounted on the motor load . The Second Position Sensor input can also be used for

an electronic gearing application.

Chapter 2 - Commissioning

19

XtrapulsCD1-pm - User manual

14.1 –SECOND POSITION SENSOR FEEDBACK

Resolver sensor feedback for the motor, and TTL incremental encoder for the second sensor is the default

configuration.

Select the required position sensor configuration in the "Resolver & encoder Input configuration" window

accessible in the "Setup" menu.

Open the "Position scaling parameters" window accessible in the "Positioner Application Setup" menu.

Select "Enable second sensor feedback" to use the second position sensor (encoder or resolver) for closing the

drive position loop. When this command is not selected, the drive position loop is using the motor position sensor

(resolver or encoder) for feedback.

Set the “Position resolution” parameter according to the desired position scaling of the load in order to display

the position in the load units as described below:

Position resolution = number of desired load position increments for one motor shaft revolution.

Enter the desired "Decimal" number and the "Unit" for the position display.

Ex: one motor revolution = 3.302 mm on the load, if the load position must be displayed in mm with a resolution of

1m, choose Position resolution = 3302, Decimal number = 3 and Unit = mm.

Remark: In the second sensor feedback configuration, the servo loop stability is affected by a wrong Position

resolution parameter value.

Set at 0 the value of the “Position deadband” parameter. This parameter is only useful in applications with high

transmission backlashes or applications with high axis frictions. In those cases, when the position error value at

standstill is lower than the value of the “Position deadband” parameter, the proportional gain of the position loop

is set at 0.

Open the "Second Sensor" window accessible in the "Positioner Application Setup" menu.

Adjust the "Position scaling factor" (numerator / denominator) according to the desired load position scaling and

the current load sensor resolution as described below:

- For an encoder sensor type on the load:

Position scaling factor Numerator = "Position resolution" parameter value (see “Position scaling parameters”

window).

Position scaling factor Denominator = 4 x number of encoder pulses/channel for one motor shaft revolution.

Trajectory

generator

Position

loop

Speed

loop

Current loop

Motor

Motor

feedback

Load

position

Load

Scaling factor

Num / Den

Enable

2nd sensor

Chapter 2 - Commissioning

20

XtrapulsCD1-pm - User manual

- For a resolver sensor type on the load:

Position scaling factor Numerator = "Position resolution" parameter value (see “Position scaling parameters”

window).

Position scaling factor Denominator = 65536 x number of resolver shaft revolution for one motor shaft revolution.

Select "Reverse position" to reverse the counting direction of the second position sensor if required.

When the second position sensor is a SinCos encoder type, select "Pulse interpolation".

Enable the amplifier and check that the motor and load positions are stable. If the motor is moving (and then the

following error is released), the sign of the load position feedback is not correct. In this case, select the “Reverse

position” command in the “Second sensor” window.

14.2 - ELECTRONIC GEARING APPLICATION

Electronic gearing applications require the use of the second amplifier position sensor for measuring the

displacements of the master axis.

If the motor is equipped with a resolver, select the encoder type for the input of the second sensor in the

"Resolver & encoder Input configuration" window accessible in the "Setup" menu.

Open the "Position scaling parameters" window accessible in the "Positioner Application Setup" menu.

Check that "Enable second sensor feedback" is not selected.

Set the “Position resolution” parameter according to the desired position scaling of the load in order to display

the position in the load units as described below:

Position resolution = number of desired load position increments for one motor shaft revolution

Enter the desired "Decimal" number and the "Unit" for the position display.

Ex: one motor revolution = 3.302 mm on the load, if the load position must be displayed in mm with a resolution of

1m, choose Position resolution = 3302, Decimal number = 3 and Unit = mm.

Set at 0 the value of the “Position deadband” parameter. This parameter is only useful in applications with high

transmission backlashes or applications with high axis frictions. In those cases, when the position error value at

standstill is lower than the value of the “Position deadband” parameter, the proportional gain of the position loop

is set at 0.

Open the "Second Sensor" window accessible in the "Positioner Application Setup" menu.

Position

loop

Speed

loop

Current loop

Motor

Motor

feedback

Master

position

Scaling factor

Num / Den

REMARK:

If the calculated Numerator and Denominator values exceed the parameters max. value

(65535), they must be scaled in order to get the same ratio (Numerator / Denominator) or to be

as close as possible to the theoretical value: scaled Numerator / scaled Denominator =

calculated Numerator / calculated Denominator.

!

Other manuals for XtrapulsCD1-pm

1

Table of contents

Other Infranor Control Unit manuals

Popular Control Unit manuals by other brands

Toray

Toray TORAYFIL HFU-B2315AN instruction manual

Kohler

Kohler TOUCHLESS K-13686 installation guide

Strange

Strange Lightstorm Setup guide

Pittway

Pittway Fire-Lite Alarms MMF-300 installation instructions

SEW-Eurodrive

SEW-Eurodrive MOVITRAC LT Series operating instructions

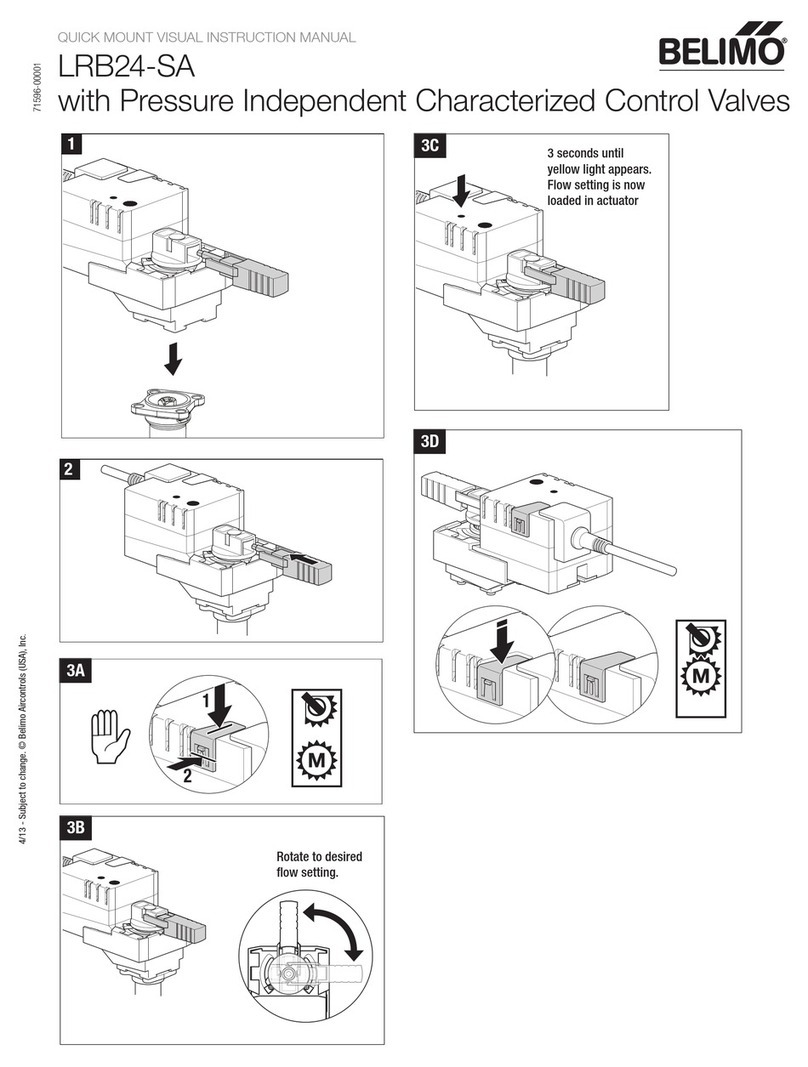

Belimo

Belimo LRB24-SA QUICK MOUNT VISUAL INSTRUCTION MANUAL

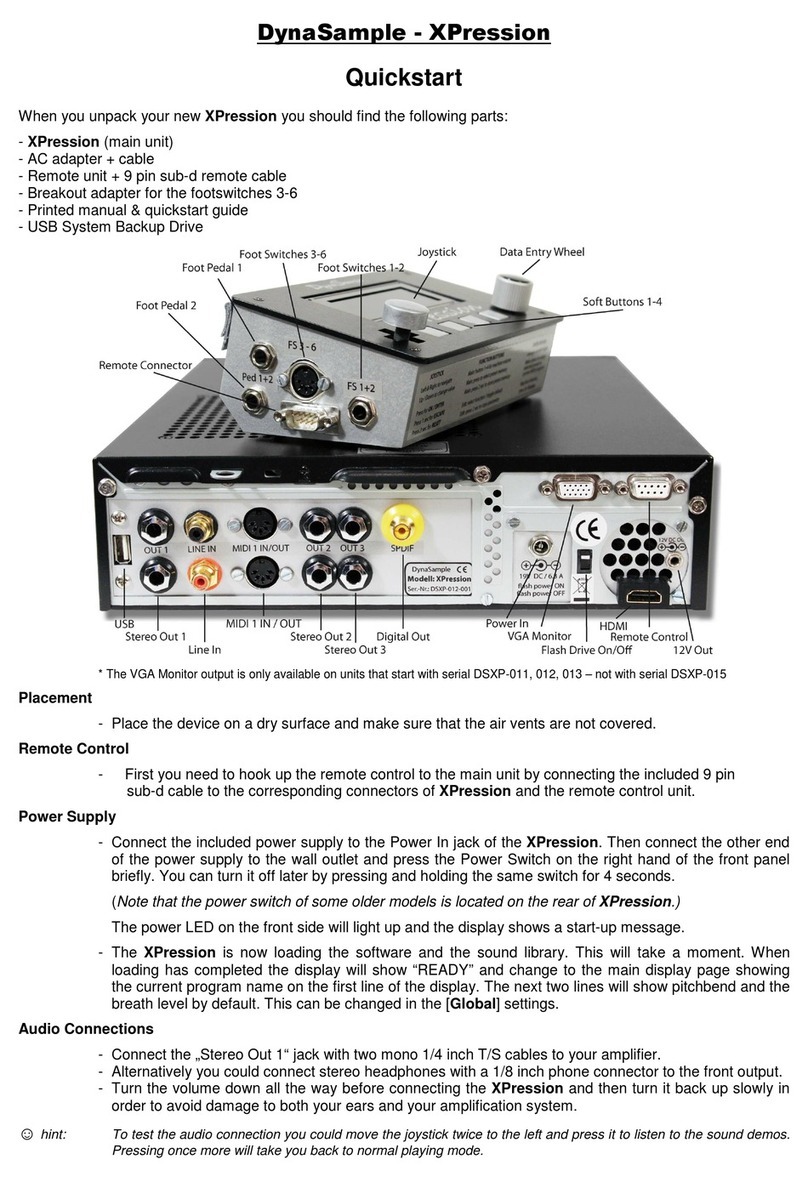

DynaSample

DynaSample XPression quick start guide

Mircom

Mircom QMP-5100AX installation instructions

Telit Wireless Solutions

Telit Wireless Solutions GE865 Hardware user's guide

Xpresskit

Xpresskit DBALL2 installation guide

Eaton

Eaton Vickers FCGT-02-A-11 Series Overhaul manual

Panasonic

Panasonic PAN4620 Integration guide