QCM486 Miniature Protector Connector (MPC)

- 2 –

comtestnetworks.com

2.4 The MPC is available stubless or equipped

with a 100-pair (top or bottom entry) stub.

Available stub lengths are 9.1, 15.2, or 30.5 mm

(30, 50 or 100 ft.) with 22 or 24-gauge

conductors. The dimensions and weights of the

MPC are shown in Table 1.

3. Precautions

3.1 The MPC is shipped in protective

packing with protector modules installed in the

detent position. Observe the following

precautions when storing, handling and

installing the unit:

•Store in a dry location. Do not leave on

loading docks or locations exposed to

weather or where temperatures are higher

than +45°C (+113°F).

•If the MPC has been exposed to

temperatures below -30°C ( - 22°F), allow

to warm to room temperature before

installing to avoid damage to cable stub.

•When unpacking, open the top of the

container marked THIS SURFACE UP AT

ALL TIMES.

•Do not remove protective packing material

around the MPC until the stub cable has

been placed through the cable vault

entrance, and the MPC is ready to be

mounted on the distributing frame.

•Do not bend the stub cable to a radius of

less than 150 mm (6 in.).

•To avoid damage to the MPC from rolling

ladders on the conventional MDF, the

ladder guard rail projection must be 650

mm (25.5 in.).

•Compact DSPF/PDF clearances for rolling

ladder and the MPC is approximately 51

mm (2 in.).

NOTE:

If this measurement is not met, contact

the Central Office Engineering Group for correction

prior to mounting MPC units.

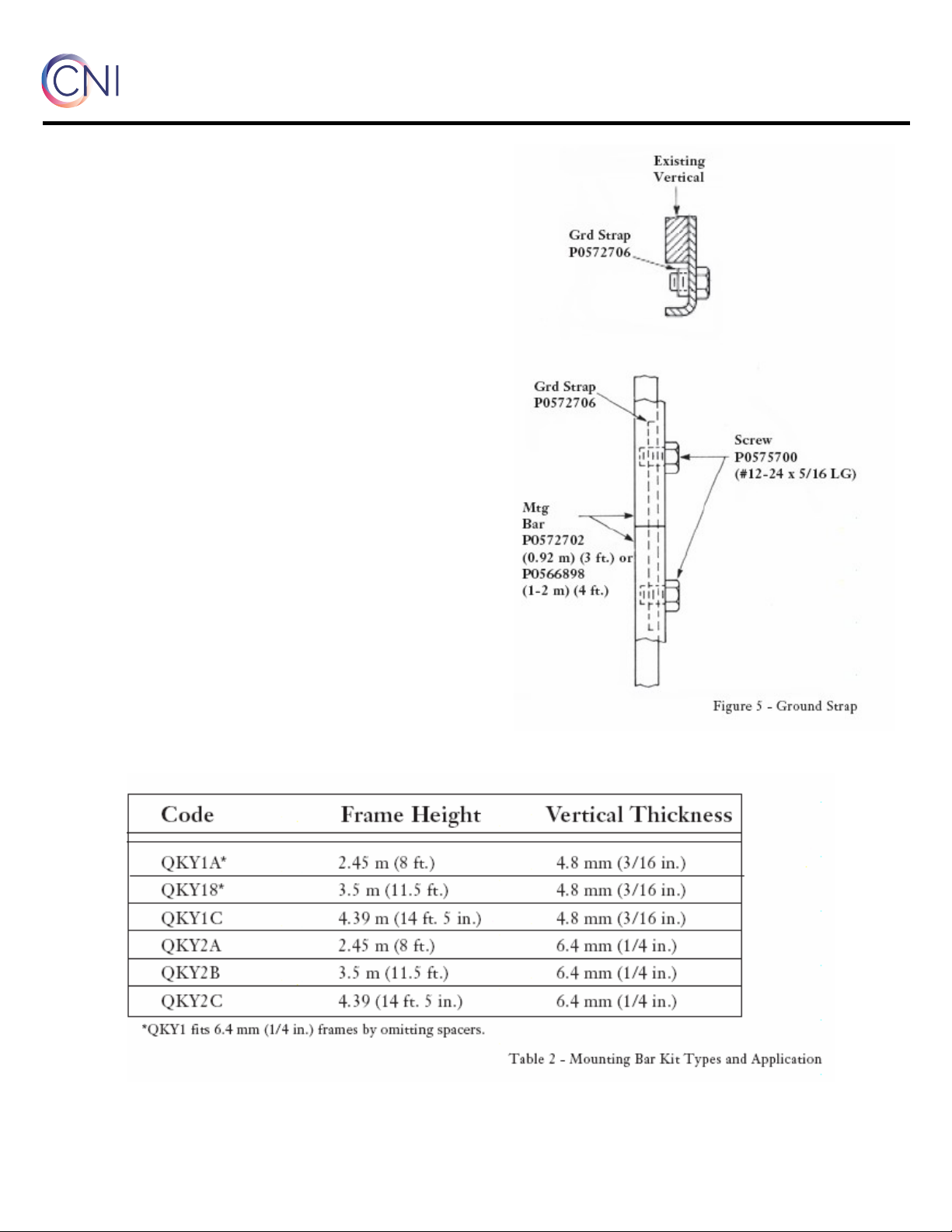

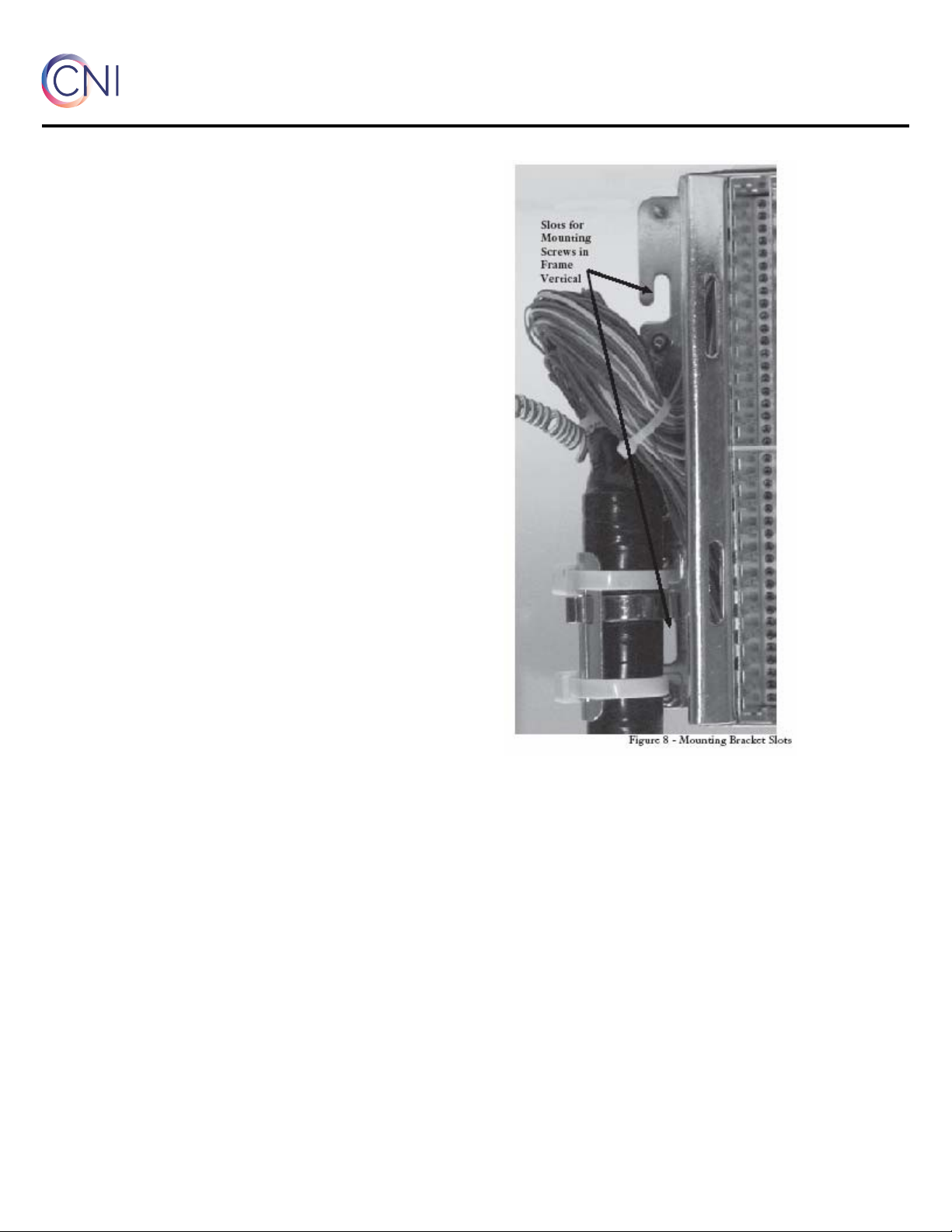

3.2 Where distributing frame verticals are not

drilled to fit MPC 140 mm (5.5 in.) mounting

centers, replace verticals, drill as required, or

install a mounting bar kit.

3.3 The following precautions are included

per requirement of the Underwriters

Laboratories Inc.®:

•National Electrical Code Requirements:

The installation of this product, including

any field-installed components, shall meet

all applicable federal, state, and local laws

and regulations and, if unrestricted, comply

with articles 800, 820 and all other

appropriate requirements of the National

Electrical Code, ANSI/NFPA 70.

•Only products marked “for indoor or

outdoor use” or “for outdoor use” are

suitable for outdoor use. Products without

this marking are not suitable for outdoor use

and are implied to be suitable for indoor use

only.

•The use of a fuse link for each and every

line is recommended when connecting any

equipment to the telephone circuit. For

typical applications, a one-foot or longer

length fuse link of at least two wire sizes

smaller than the typical wire gauge in use

within the circuit is recommended.

•It is recommended that any components

added to this product be both listed for the

purpose and compatible.

•Risk of electric shock — Protector is not to

be used without the arrester assembly

installed.