Coastal Paragon NEO ANGLE w/Bi-fold User manual

( 1 )

FAX NO.

(904) 641-1697 Coastal Industries Inc.

P.O BOX 16091

JACKSONVILLE, FLORIDA 32246

TELEPHONE NO.

(904) 642-3970

Paragon

NEO ANGLE w/Bi-fold

PARA_NEO_BIFOLD_12/23/99

( 2 )

Parts List

KEY PART

LETTER NUMBER DESCRIPTION QUANTITY

A---- SILL

a1 900 Sill 1

a2 900 Sill Right Panel 1

a3 900 Sill Left Panel 1

B---- HEADER

b1 900 Header 1

b2 900 Header Right Panel 1

b3 900 Header Left Panel 1

C941 GUIDE TRACK (top & bottom) 2

D903 WALL JAMB 2

E909 45 DEGREE CORNER POST 2

F926 STRIKE JAMB 1

G---- DOOR ASSEMBLY

g1 920 Hinge Post 1

g2 922 Hinge Stile 3

g3 924 Strike Stile 1

g4 925 Rails 4

g5 940 Center Hinge Pull 1

g6 37 Slide Piece 2

g7 CP932 Hinge Pins (not shown) 6

g8 CP148TW Hinge Washer (not shown) 6

g9 C921B Hinge Sleeve (not shown) 3

g10 C940B Glazing Vinyl (not shown) --

g11 98-42 Magnetic Strip (not shown) 1

g12 6-8114FHP Door Panel Assembly Screws 8

HDRIP RAIL ASSEMBLY 2

h1 2340 Drip Rail 1

h2 C176G Vinyl Sweep 1

h3 4403 Drip Rail Tape (installed) 1

IMAGNET HOLDER ASSEMBLY

i1 942 Magnet Holder 1

i2 98-44 Magnet 1

JCP930 DOOR HANDLES (set) 1

K6114MSFHP DOOR HANDLE SCREWS 2

L83212SS SET SCREW 2

MSP189B BUSHING (3/4" x 3/8" O.D.) 2

N81MSFHP BUSHING SCREW 2

O8112P #8 x 1-1/2" INSTALLATION SCREWS 6

P1329 PLASTIC SCREW ANCHORS 6

QCP938 SETTING BLOCKS 4

R313.45C CORNER BRACKET, HEADER (45 degree) 4

S614 #6 x 1/4" SCREWS (45 degree brackets) 16

T638PHPT #6 x 3/8" ADJUSTMENT SCREWS 13

U---- GLASS 2

VC941G VERTICAL GLAZING --

WC942G HORIZONTAL GLAZING --

XSP116B DOOR STOP (1/2" x 5/16" O.D.) 1

Y634 DOOR STOP SCREW (#6 x 3/4") 1

Z98-44 MAGNET w/TAPE 1

( 3 )

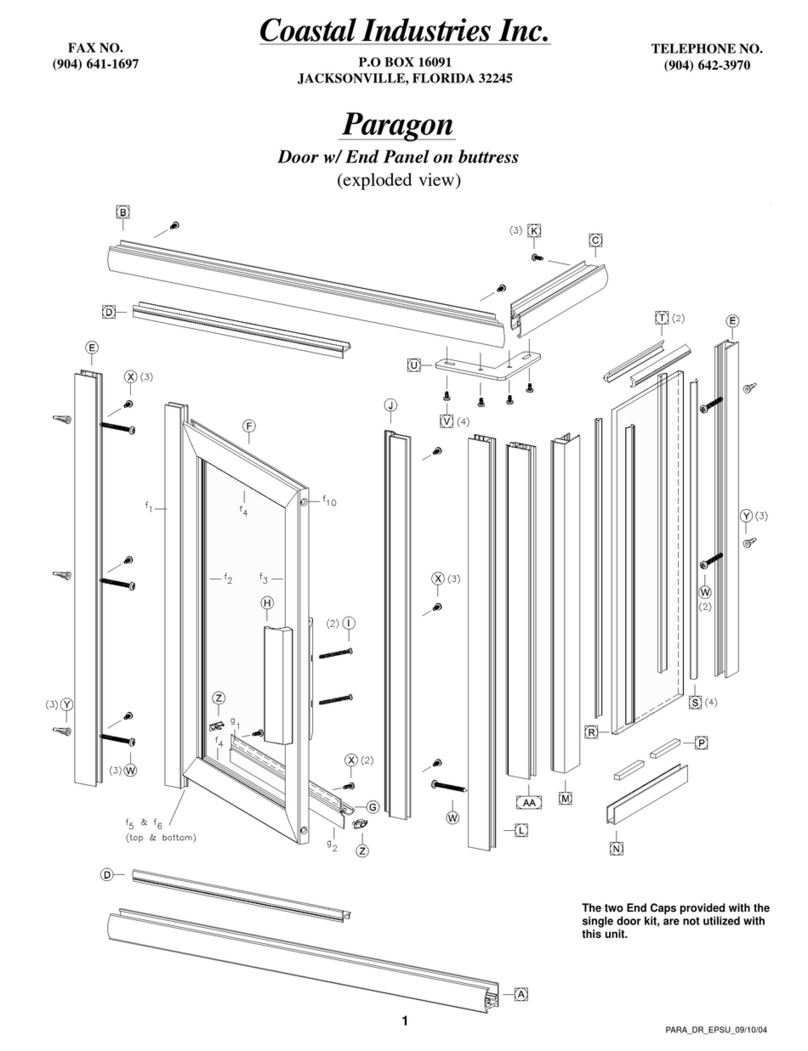

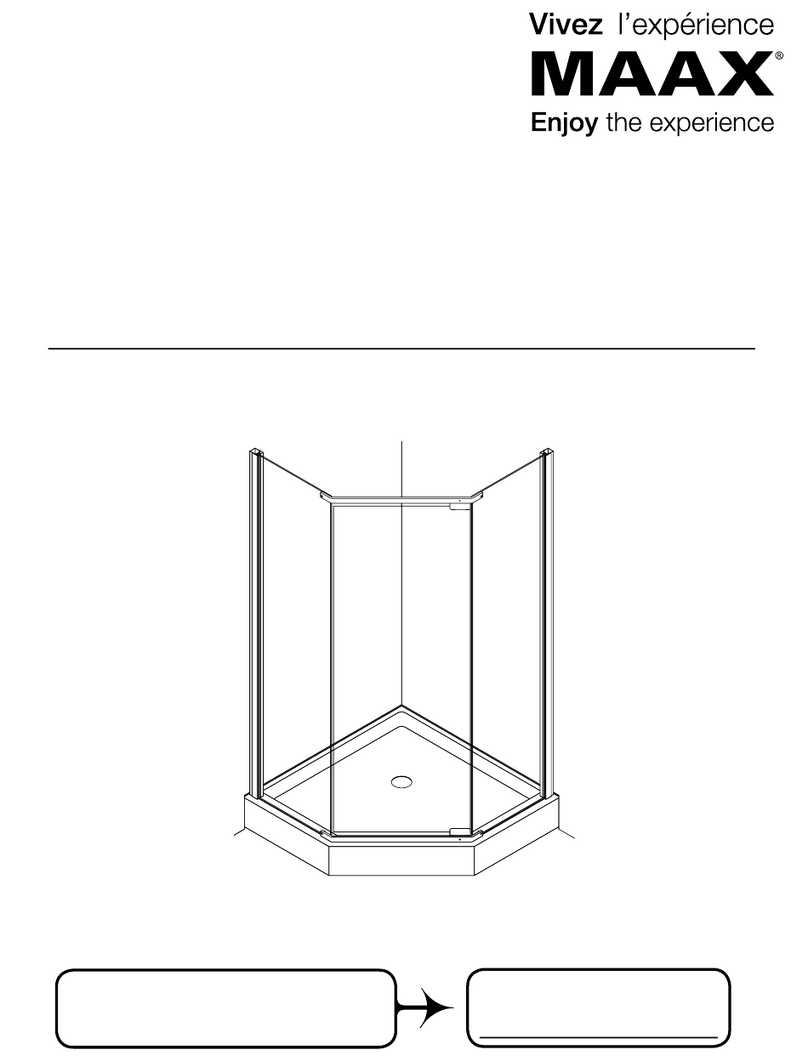

Paragon Neo-Angle

Bi - Fold

(exploded view)

PARA_NEO_BIFOLD_12/23/99

( 4 )4

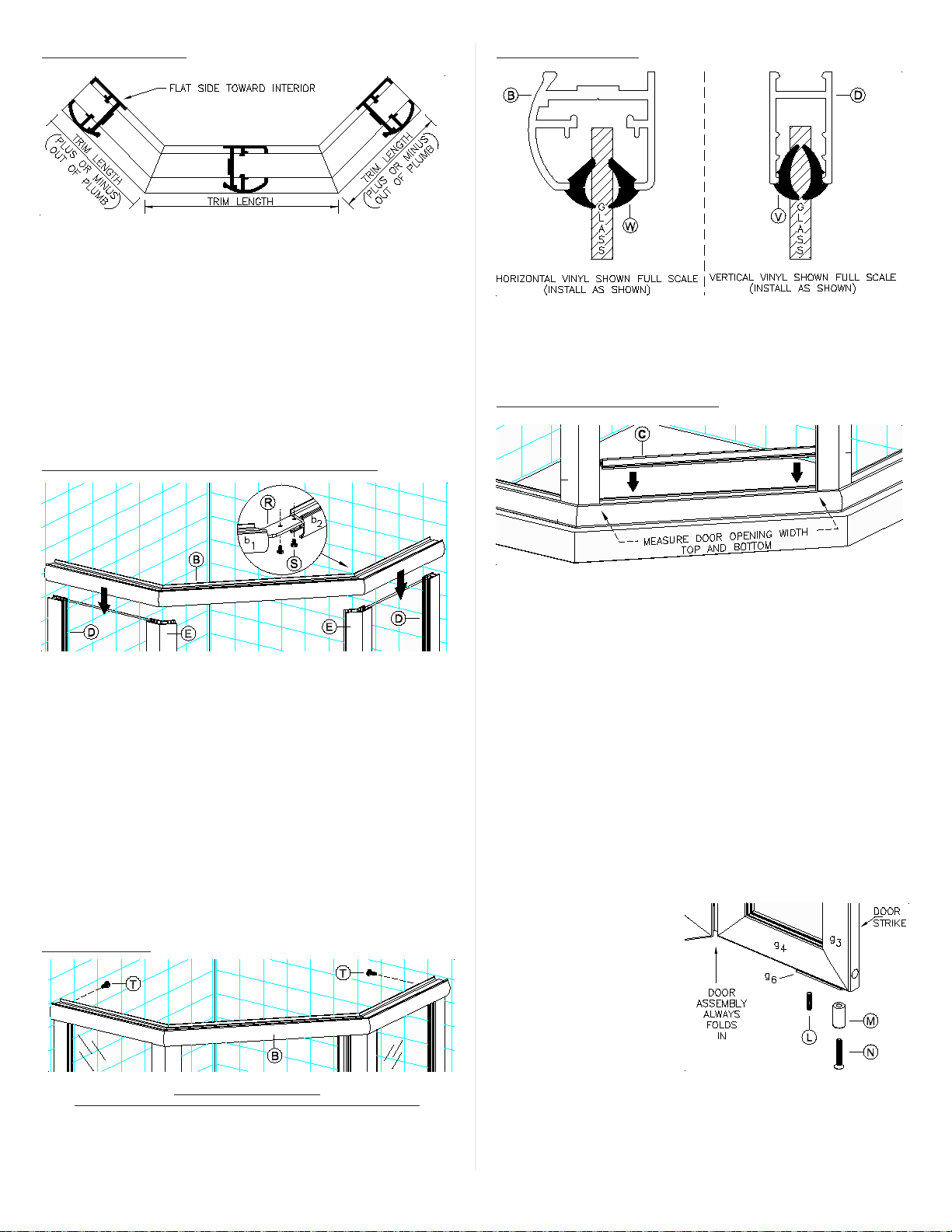

Mark Curb Centerline & Measure Segments

Pencil mark the curb centerline as shown. Measure the left, center

and right segment lengths and jot down their measurements in the

spaces provided below. These are critical dimensions, so make

sure to double-check your measurements.

left segment length _____+ 1” = left Sill trim length

right segment length _____+ 1” = right Sill trim length

center segment length ____+ 9/16” = center Sill trim length

Install Glass Panels

InsertglasssupportSettingBlocks(Q)intotheSillcavityasshown.

Set the Glass Panels (U) on the Setting Blocks and slide Glass

Panelsa1/2”intoitsrespectiveWallJamb(D). Holdpanelsinplace

byinsertingashortpieceofGlazingVinyl(V)betweenGlassPanels

and the Wall Jambs, both inside and out.

MEASURE

MEASURE TO

MEASURE

TO INTERSECTION

INTERSECTION

Trim Sill Pieces

Sill(A)andHeader(B)piecesareidenticalinappearanceexceptfor

the weep holes on the Sill pieces (Sill pieces have weep holes;

Header pieces do not). Trim the Sill pieces to the lengths specified

in step 1.

Assemble and Position Sill on Curb

Assemble Sill (A) by inserting Corner Brackets (R) into Sill pieces

and bringing the pieces together (see figure above and exploded

view - sheet 3).

Using the Corner Bracket holes as guides, mark and drill the Sill

pieces with a 1/8” drill bit. Secure the Corner Brackets to the Sill

pieces with eight(8) #6 x 1/4” machine screws (S). Now run a bead

of caulking on inside of crevice where Sill pieces join to insure no

leaks. PositionSillon curb. Temporarily tape Sill to curb to prevent

movement.

Position and Install Wall Jambs

PlaceWallJambs(D)intoendsofSill(A)andupagainsttheshower

wallsasshown. Plumbthe Jambs, then pencil mark the installation

hole locations on the shower walls (3 per Jamb). Remove Wall

jambs. Using a 3/16 masonry bit, drill 1-1/4” deep installation holes

in locations previously marked. Insert Plastic Screw Anchors (P)

into holes. Reposition Jambs as before and secure to wall using

six(6) 8112P Installation Screws (O)

Install 45 degree Corner Posts

GlassPanelsmusthavea1/2”insertionintotheirWallJambandthe

45 degree Corner Post in order for glazing vinyl to hold glass

properly.

Slide 45 degree Corner Posts (E) over the exposed edge of the

Glass Panels and set them into Sill cavity as shown. Double check

for 1/2” insertion before proceeding.

( 5 )5PARA_NEO_BIFOLD_12/23/99

Trim Header Pieces

Before trimming Header pieces (b2 & b3), remember to add or

subtract any out of plumb discrepancies that might exist on the

corresponding walls (as measured at top of Wall Jambs).

Trim Header (B) pieces to measurements specified in step 1 (plus

or minus any out of plumb discrepancies).

Assemble and Position Header atop Verticals

Assemble Header (B) by inserting Corner Brackets (R) into Header

pieces and bringing the pieces together (see figure above and

exploded view - sheet 3).

UsingtheCornerBracketholesasguides,markanddrilltheHeader

pieceswitha1/8”drillbit. SecuretheCornerBracketstotheHeader

pieces with eight(8) #6 x 1/4” machine screws (S). Position Header

atop verticals.

Secure Header

From interior, secure both ends of Header to Wall Jambs using one

638PHPTInstallationScrew (T)at each end.To prevent glass break-

age when drilling the Header, temporarily slide glass panel away

from Wall Jambs. When done, re-center glass panels as before.

TO PREVENT GLASS BREAKAGE

SLIDE GLASS PANELSAWAY FROM WALLJAMBS BEFORE DRILLING HEADER

Trim top & bottom Dam Strips

Measure the door opening width at Sill and Header levels. Trim top

andbottomGuideTracks(C)tomeasurementsobtained. Withhigh

lips toward exterior, position Guide Tracks on the Header and Sill

and snap them into place.

Insert Glazin Vinyls

Insert Vertical and Horizontal Glazing Vinyl (V & W) to secure the

Glass Panels (U) in place. Use a vinyl roller to speed up installation.

Install Strike Jamb

Determine which side you want your door to strike (left or right, your

choice). Once strike side has been determined, insert Strike Post

(F) into the appropriate Corner Jamb (E), magnet should be facing

toward exterior of enclosure, see exploded view - sheet 3.

Install Top and Bottom Bushings

Before proceeding with Door

Assembly installation, note

that the Door Assembly (G)

mustalwaysfoldintowardin-

terior of shower enclosure

(see exploded view - sheet

3).

Position Door Assembly on

floor the way it will be in-

stalledonenclosure(remem-

ber, unit must fold into enclosure).

InstallPivotBushings(M),PivotBushingScrews(N)andSlidePiece

Set Screws (L) onto top and bottom Slide Pieces (g6) as shown in

figure above and in exploded view - sheet 3.

( 6 )

Attach Door Handles

Attach the Door Handles (J) to the door using two(2) Door Handle

Screws (K) as shown in exploded view - sheet 3.

Install Magnet Holder

Install Magnet Holder Assembly (I) onto the bottom rail (g4) of the

“hinge side door” as shown in exploded view - sheet 3.

Note that Magnet Holder Assembly is installed as close to Center

Hinge Pull (g5) as possible. Magnet (i2) must face toward the out-

side of the shower enclosure as shown in figure.

Install Door Assembly

Pick the Door Assembly up. Now fold the Door Assembly making

sure that assembly folds in toward the shower enclosure as shown

in figure.

Insert the Door Assembly’s top and bottom Bushings (M) into cavi-

ties of the top and bottom Guide Tracks (C). Positioning the Door

Assembly diagonally to the door opening will help ease Bushing

insertion.

Once top and bottom Bushings are engaged with the top and bot-

tom Guide Tracks . . . insert the Door Assembly’s Hinge Post (g1)

into the Corner Post (E) from which it is to swing (see figure and

exploded view - sheet 3). Remember that regardless of whether the

door strikes on the left side or the on the right side . . . the Door

Assembly must always fold in toward interior of shower enclosure.

Temporarily leave as is.

Adjust Door Assembly

Step inside the shower enclosure and close the Door. Adjust Door

Assembly (G) and Strike Post (F) as needed for proper Door opera-

tion.

Note: DoorAssembly (G) bottom must always remain parallel to Sill

(A) in order for door to operate properly. Check to make sure that

bottom of DoorAssembly is parallel to the Sill. If it is not, make it so.

Whensatisfiedwithdooroperation, secureHingePost(g1)andStrike

Post(F)tothe verticalpostsusingsix(6)638PHPT Installation Screws

(T). See exploded view - sheet 3.

Install Drip Rails

Clean bottom rails of Door Assembly with alcohol to remove any oil.

Failure to clean door rails prior to installation of Drip Rails (H) may

cause tape to release.

Remove backing from tape and position Drip Rails flush with edges

of Hinge Stiles (g2) as shown in figure above and flush with bottom

of Door as shown in figure below.

( 7 )

Install Door Stop

The purpose of Door Stop (X) is to prevent the Door Panels from

hitting upon themselves.

Partiallyopenthe DoorAssembly. Measure and mark 2 inches from

hinge side as shown in figure below. Using a 1/8” drill bit, drill a pilot

hole thru center of Guide Track’s bottom (B). Using the pilot hole

you just drilled, secure Door Stop (X) to the GuideTrack with one(1)

Door Stop Screw (Y).

Install Sill Magnet

Clean the Sill face with alcohol where Magnet (Z) will make contact

with the Sill (see figure below).

Alignand bring together the magnet faces of pieces(Z&I)asshown

in figure. Remove backing from tape (z2) . . . step inside the shower

enclosure and close the DoorAssembly. Apply pressure on magnet

holdertoactivatetapeadhesiontoSill. Finishby running a 638PHPT

screw thru metals as shown in figure.

Leak Proof Your Installation

Run a bead of clear mildew resistant caulking down the full length of

each Wall Jamboutside where the Jambs meet the Walls. Now run

a bead outside where the Sill meets the curb. Follow caulking

manufacturer’sinstructionsbefore using shower (normally 24hours).

Installation is now complete. PARA_NEO_BIFOLD_12/23/99

Screws shown full scale for reference

( 8 )

Table of contents

Other Coastal Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

ClearGreen

ClearGreen BS1 quick start guide

Triton

Triton T60X Installation and operating instructions

Kohler

Kohler K-2440 Homeowner's guide

Sanipex

Sanipex BAGNODESIGN BDP-K9560-ESG3 Instruction guide

Homewerks Worldwide

Homewerks Worldwide H13L-421-CH quick start guide

Signature Hardware

Signature Hardware LEXIA SHWSCLE107L manual