Model Year 2019 page 2

Maverick Boat group, Inc. • 3207 Industrial 29th St. • Fort Pierce, Florida 34946 • (772)-465-0631 or (888)-shallow • Fax: (772) 489-2168

TABLE OF CONTENTS

Specifications……………………………………..………………….2

Pre-Operation Checklist…………………………………………….3

Yamaha Engine Break-In Periods................................................4

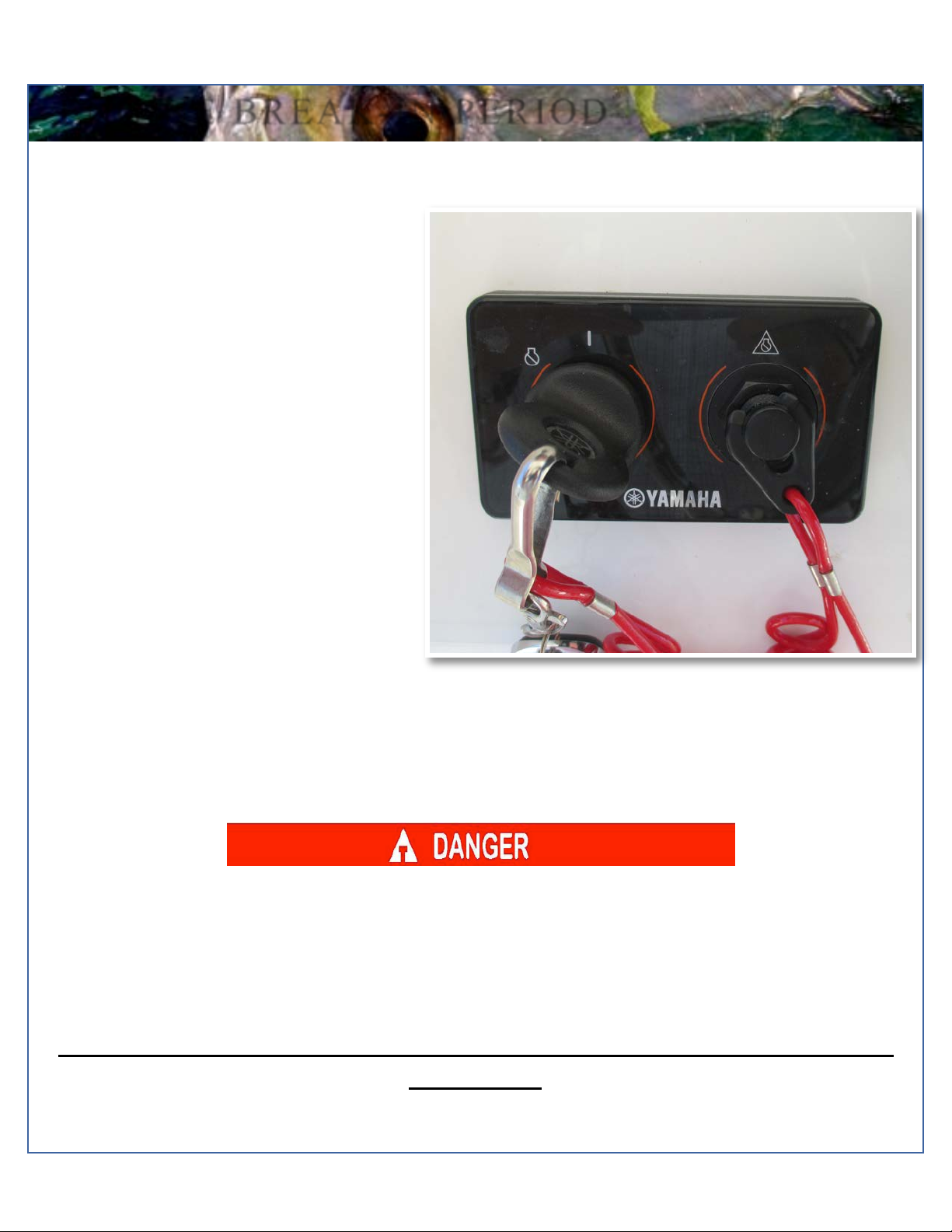

Engine Stop Switch......................................................................4

Switch Panels...............................................................................5

Instrument Panel with Yamaha Multi-Function Gauges…….……5

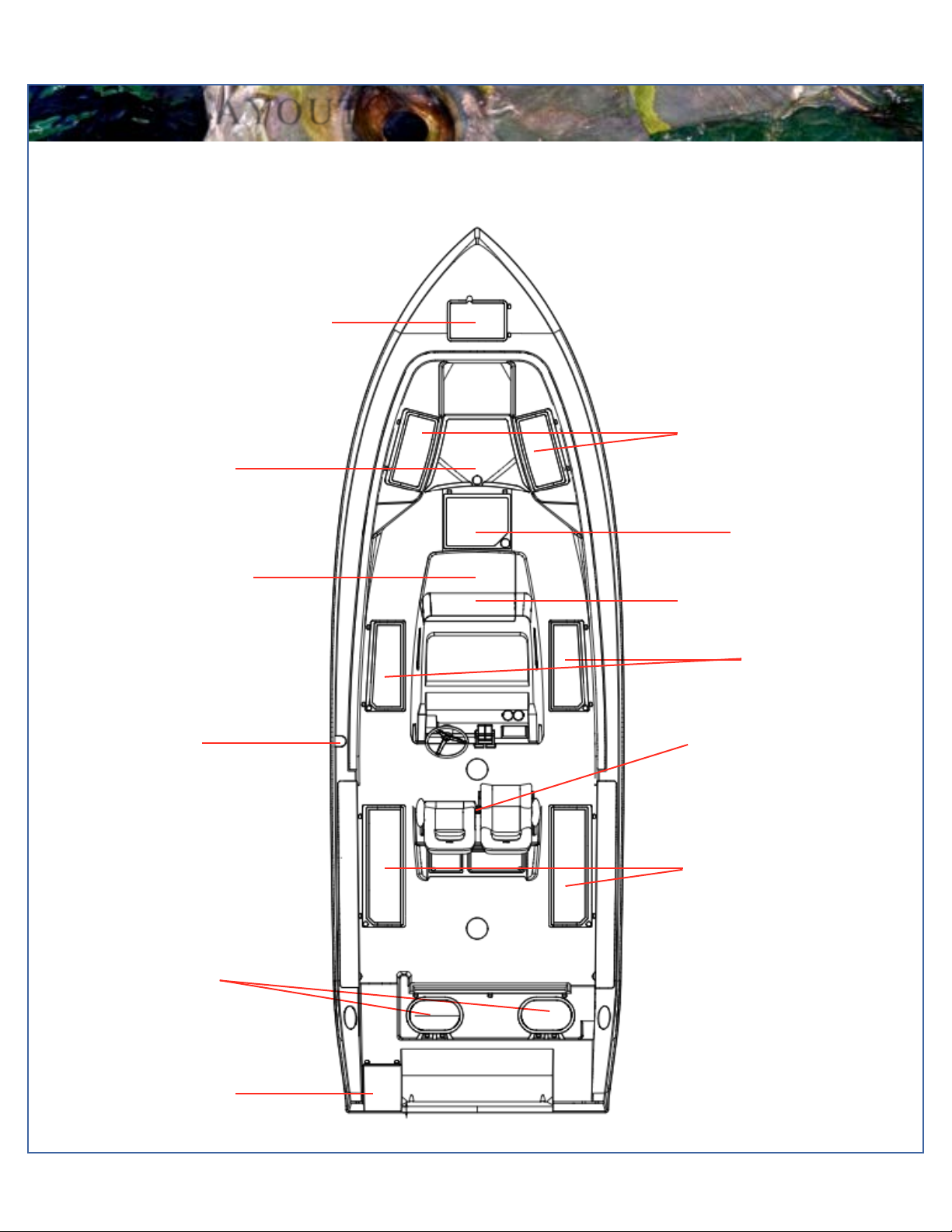

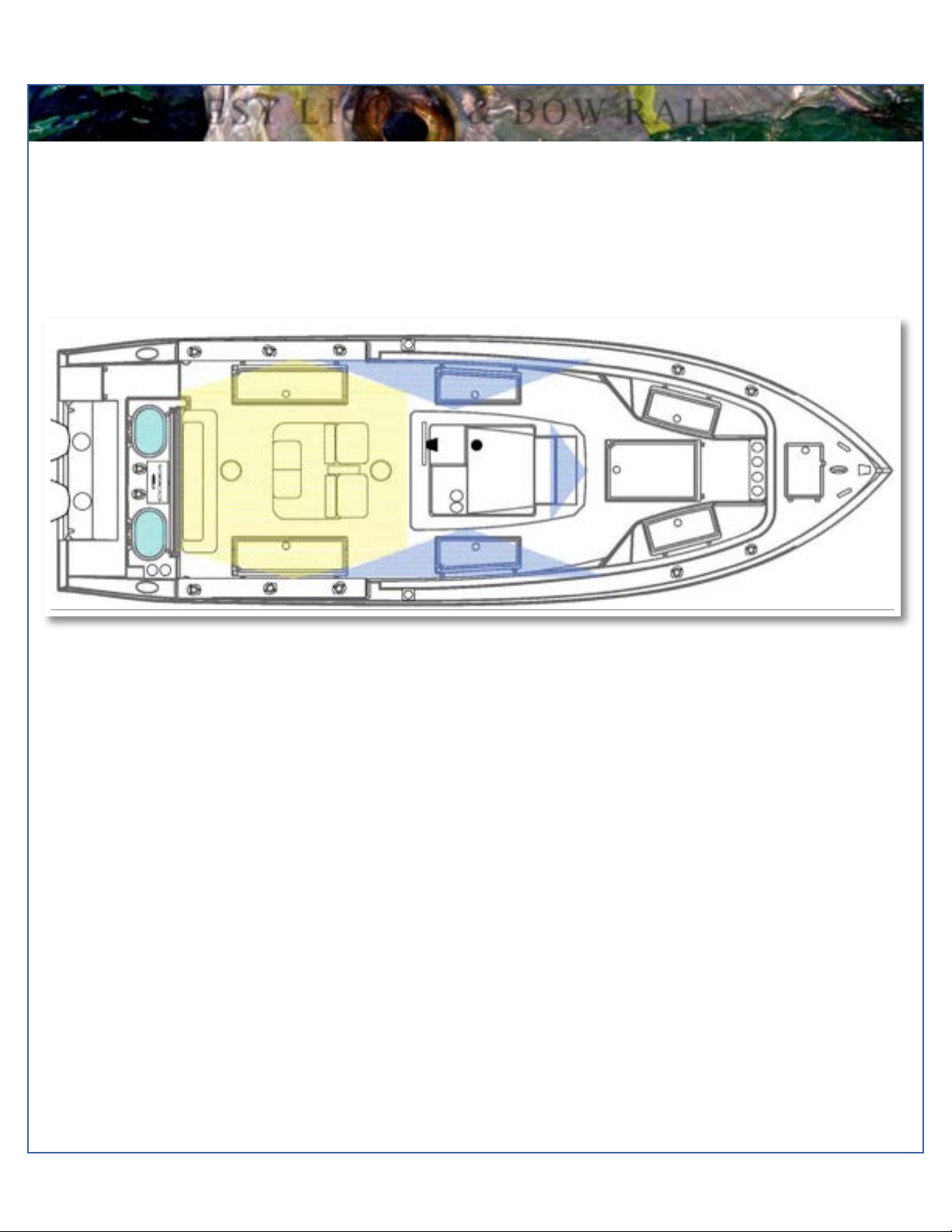

301 Boat Layout………………………………………………….…..6

Cobia Duffel Bag..........................................................................7

Fuel/Water Separators.................................................................8

Garboard Drain Plug....................................................................8

Bilge Access.................................................................................9

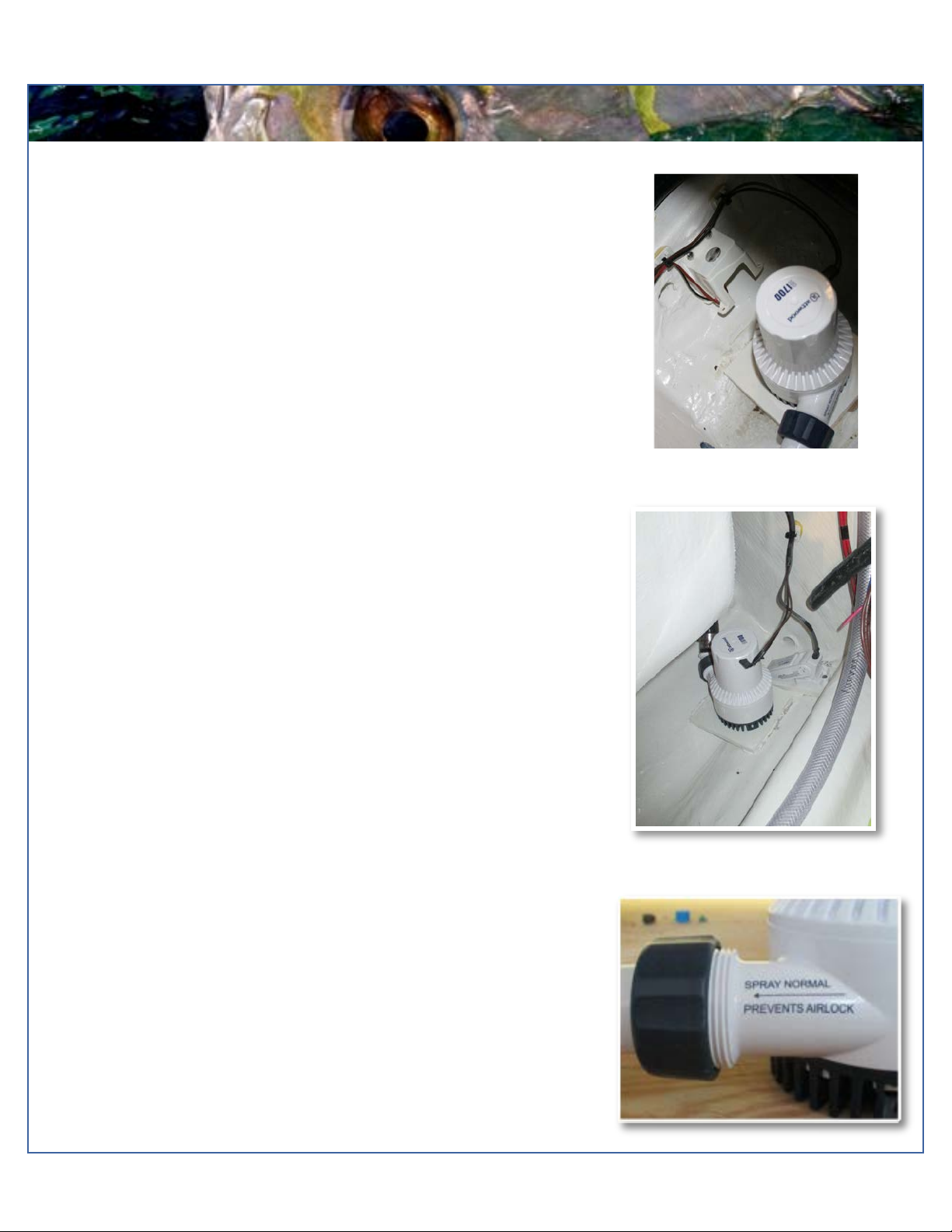

Bilge System…………………………………………………..….…10

Ball Valves, Thru Hull Fittings & Scuppers………….……………11

Cockpit Courtesy Lights & Bow Rail……..……………………….12

Head Systems…………………………………………………..13-15

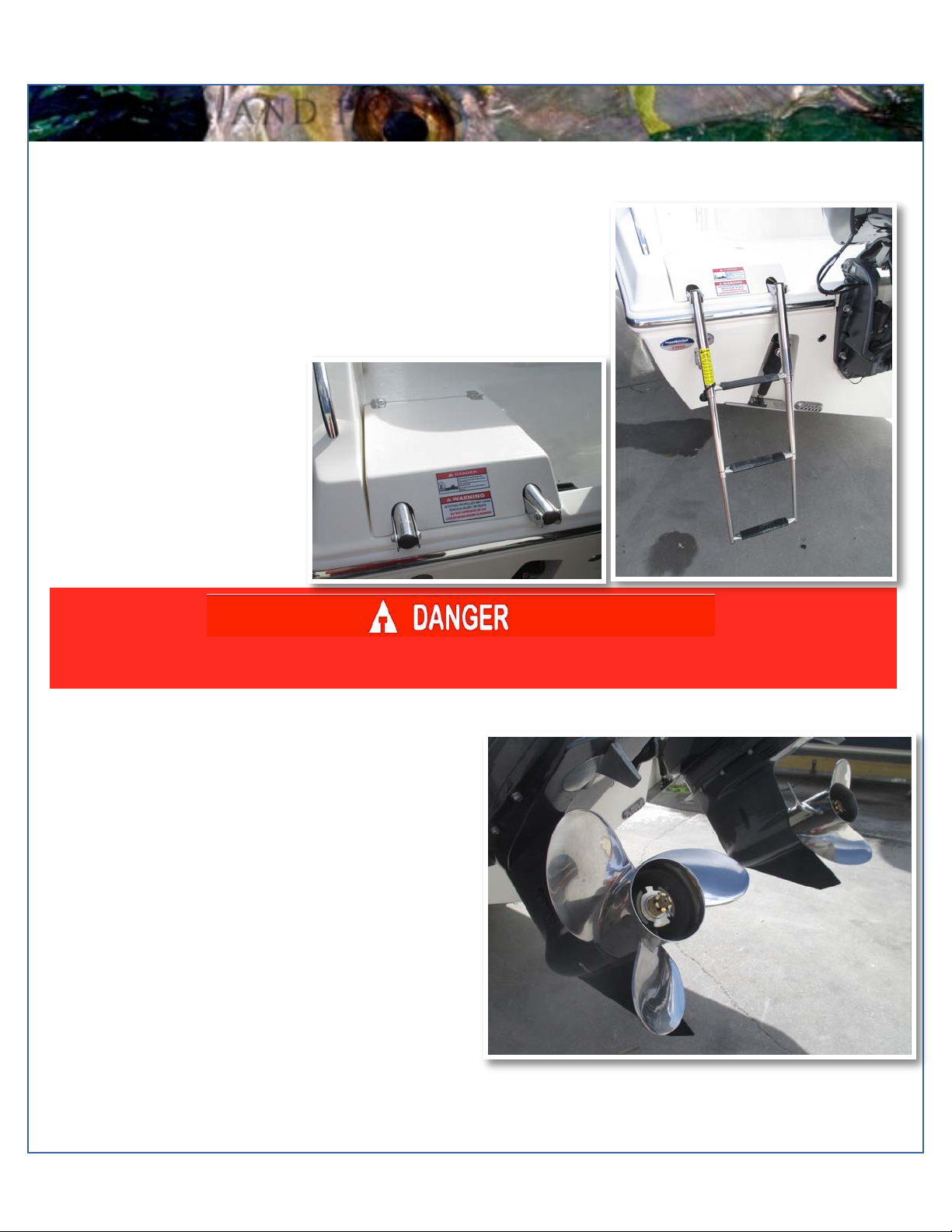

Stainless Boarding Ladder.........................................................16

Props..........................................................................................16

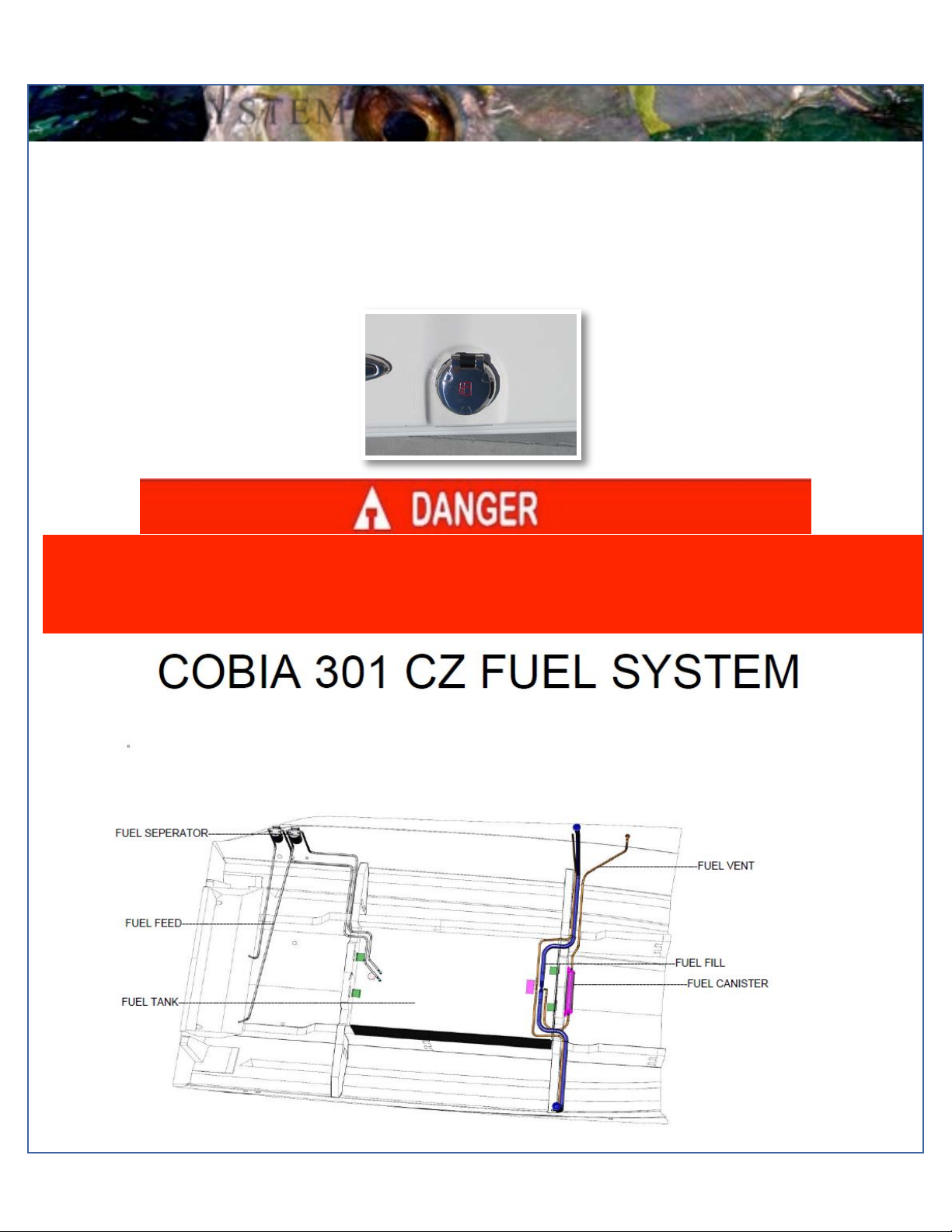

Fuel System...............................................................................17

Steering......................................................................................18

Self Bailing Cockpit....................................................................19

Livewell System.........................................................................20

Fish Lockers...............................................................................20

Anchor Locker / Rode Storage…………………………………….21

Table Lift…….……………………………………………………….21

Trim Tabs………………….……………………………………..….22

Macerators………………………………………………………..…23

Console Access & Saltwater Washdown…………………….…..24

Freshwater System................................................................25

Battery Switch & Distribution Panel.……………………….26-27

Battery Charger………………………………………………….28

12 Volt Accessory Plug…………………………………………28

Leaning Post & Battery Access..………………………………29

Aft Seating……………………………………………………..…30

Optional Bow Cushion Set.....................................................30

Cockpit Bolsters.....................................................................31

Pop-up Bow Light & Cleats……………………………………..31

T-Top Options........................................................................32

Kite/Rod Holders....................................................................33

Optional Stereo System.........................................................34

Optional Windlass System………………………………….34-35

Wiring System Diagrams……………………………………36-38

Warranty………………………………………………………… 39

L.O.A............................................................29’ 07”

BEAM...........................................................10’ 00”

DRAFT...............................................................21”

WEIGHT W/O ENGINE..........................5915 LBS.

FUEL CAPACITY.....................................230 GAL.

DEADRISE @ TRANSOM......................21.5 DEG

MAXIMUM H.P............................................600 HP

TRANSOM HEIGHT…….......................25”TWINS