COBIA 301CC User manual

1

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

301 CC Owner’s Manual

Revised September 2020

2

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Dear New Cobia Owner,

On behalf of Cobia Boats, I would like to

congratulate you on your purchase. We at Cobia

strive to build the best products possible and wish

you years of trouble-free enjoyment. There are

many things to know about the operation, care,

and maintenance of our products and the systems

we install in them. Please review all the applicable

information for your new boat. The more you

know, the more you will enjoy your new Cobia.

Again, a heartfelt thank you from myself and the

whole Cobia Family.

Scott Deal

President and CEO

3

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Table of Contents

Cobia 301 CC Specifications ...............................................................................................................4

Pre-Operation Checklist.........................................................................................................................6

Maintenance & Cleaning .....................................................................................................................7

Engine Break-In Period ...........................................................................................................................8

Helm & Command Link Gauges .........................................................................................................9

Fuel-Water Separator & Drain ............................................................................................................10

Bilge ...........................................................................................................................................................11

Systems......................................................................................................................................................13

Ladder & Props.......................................................................................................................................18

Fuel System ..............................................................................................................................................19

Self-Bailing Cockpit & Livewell ...........................................................................................................20

Rod Storage & Fish Lockers .................................................................................................................21

Macerator Access & Operation........................................................................................................22

Anchor Locker ........................................................................................................................................23

Table Lift....................................................................................................................................................23

Trim Tabs ...................................................................................................................................................24

Water System ..........................................................................................................................................24

Battery Switch and Main Distribution Panel ...................................................................................25

Seating......................................................................................................................................................27

Standard Features .................................................................................................................................28

Cockpit Courtesy Lights .......................................................................................................................29

Optional Features ..................................................................................................................................30

Cobia 301 CC Sanitation System ......................................................................................................38

Cobia 301 CC Fuel System..................................................................................................................39

Cobia 301 CC Deck Wire Harness ....................................................................................................40

Cobia 301 CC Hull Wire Harness........................................................................................................41

Cobia 301 CC Hardtop Wire Harness...............................................................................................42

Cobia 301 CC Water Drain System...................................................................................................43

Cobia 301 CC Fresh Water System...................................................................................................44

4

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Cobia 301 CC Bunk Placement.........................................................................................................45

Cobia 301 CC Bunk Placement.........................................................................................................46

Upholstery Care & Cleaning Guide ......................................................................................47

Warranty...................................................................................................................................................48

Cobia 301 CC Specifications

L.O.A.......................................................................................................................29’07”

BEAM......................................................................………………….…..................10’ 00”

DRAFT...........................................................................................................................21”

WEIGHT W/O ENGINE......................................................................................5,915 LBS.

FUEL CAPACITY.................................................................................................267 GAL.

DEADRISE @ TRANSOM...................................................................................21.5 DEG.

MAXIMUM H.P............................................................................................................600

TRANSOM HEIGHT…………………………………..…...…….………………….. 25” TWINS

COCKPIT SQUARE FOOTAGE……………………………………….……………..82 SQ. FT.

5

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

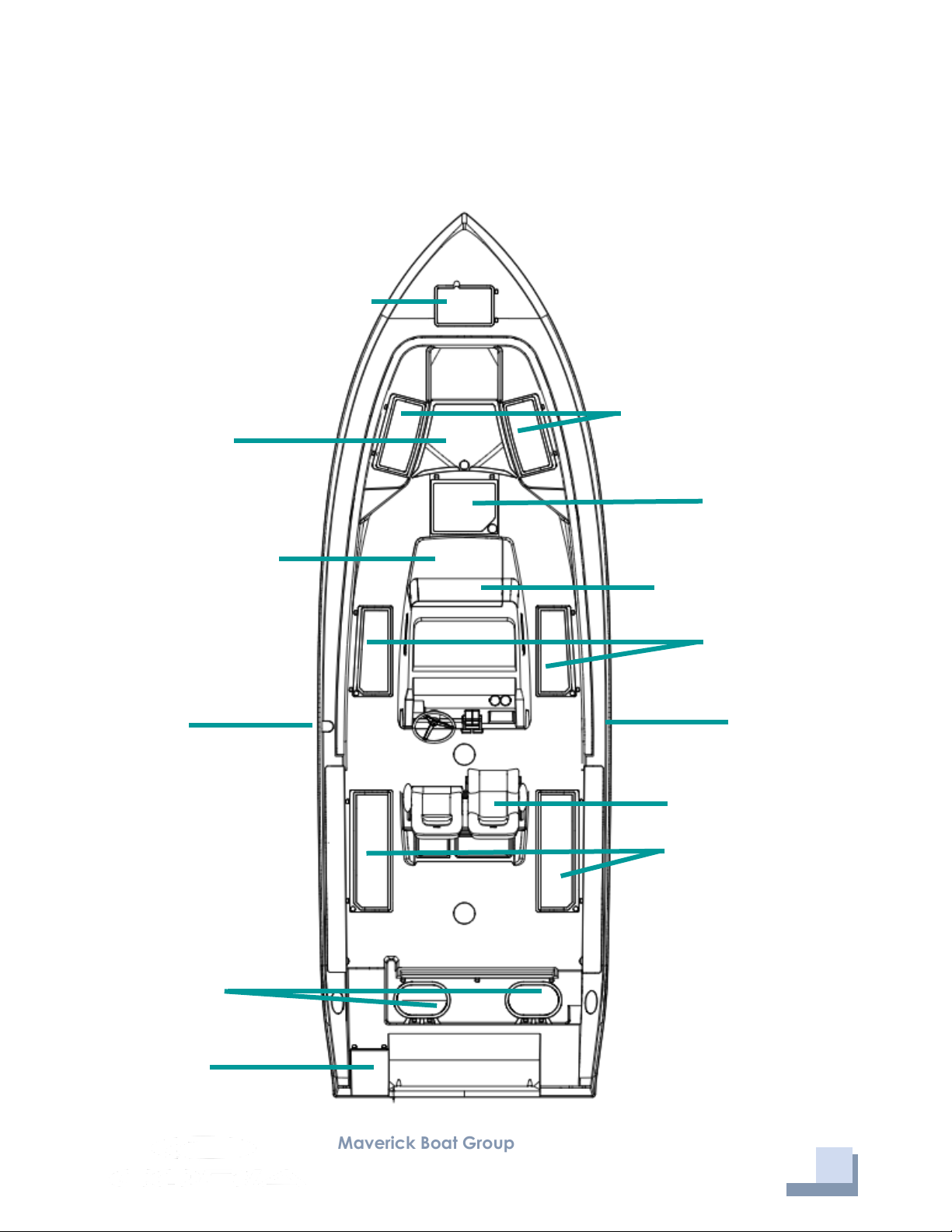

301 CC Deck Layout

Anchor Locker

Table Lift

Cooler Box

Fuel Fill

28 Gal. Livewells

Boarding Ladder

Storage Hatches

Forward Dry Storage

Forward Console/Head Entry

Mid Dry Storage

Leaning Post/Tackle Station

40 Gal. Fish Lockers

Fuel Fill

6

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Pre-Operation Checklist

We recommend you print this document and store it at the helm station.

7

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Maintenance & Cleaning

Maintenance

Cobia advises owners that maintenance and repairs should be performed at an

authorized Cobia Dealer. The following information is general in nature and should not

be considered a repair manual or guidelines set forth by Maverick Boat Group.

Cleaning

Each Cobia boat is constructed using the finest materials and components available.

However, no material is immune to the ravages of the saltwater environment. After each

use, your boat should be thoroughly washed using fresh water. To avoid water spots, dry

your vessel using a soft cloth. A fiberglass wax may be used to preserve the luster of the

hull.

Thorough and routine cleanings of your stainless fittings are required to maintain their

appearance. After each use of your boat, clean stainless fittings using fresh water and a

mild soap. Dry fittings completely. A wax or polish may be applied after cleaning. Any

rust must be removed as soon as possible to prevent irreversible damage to your vessel

and/or its components. A light coat of lubricant on metal railing, screws and electrical

connections will help prevent electrolysis. The same holds true for your trailer. Refer to

page 47 for upholstery care and cleaning instructions.

8

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Engine Break-In Period

Engine Break-In Period

New engines require a period of break-in to allow the surfaces of the moving parts to

mate evenly. Different engines require different break-in periods and methods. For

instructions on break-in methods, refer to your Yamaha Engine Owner’s Manual for the

correct break-in procedures and times for your model engines.

Engine Stop Switch

If activated, the spring-loaded engine stop switch

will automatically shut down the engine during

emergency situations to prevent uncontrolled or

unattended operation. Certain emergency conditions

(e.g., turbulent water, wakes, unanticipated

movement) may impair a person’s ability to operate

the craft safely. The switch, located on the helm,

must have the safety lanyard attached at its base.

This activates the protective shutdown circuitry.

Securely attach the other end of the lanyard to the operator of the boat. If the operator

moves, falls or is at an unsafe distance from the steering wheel, tension on the lanyard

will pull it from the switch. When the lanyard is removed, the engine stop switch is

released and automatic engine shutdown occurs.

Engine Stop Switch

DANGER:

An engine stop switch system that is not used or does not function

properly can cause death or serious injury. DO NOT operate the boat if

the engine stop switch system does not function properly. Go to a

Cobia Dealer to have this resolved immediately.

The lanyard should be securely attached to the boat operator at all times that

the engine is on.

9

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Helm & Command Link Gauges

Switch Panel & Helm

At the helm of your Cobia, you have a

main switch panel, which is located above

the steering wheel. This panel controls

your lights, horn, accessories, livewell,

and your bilge. When a switch is in the

“on” position, its tip is illuminated. This alerts you that the associated accessory should

be functioning and also reminds you to turn it off during boat shutdown. When the

“NAV” light switch is in the “on” position, the labels for the switches will be illuminated.

To the right of the steering wheel you have your two trim tab switches. The boat also

comes standard with a compass mounted on top of the console.

When the indicators above the bilge switches are illuminated in red that means the bilge

pump is running from its float switch being activated. It is not uncommon for the float

switches to be activated for a few seconds for a couple periods over the course of a full

day on the water. However, if the bilge indicators stay on for a prolonged period or come

on numerous times, this is likely evidence of a leak and the bilge should be checked

immediately for water intrusion. Any leaking should be addressed right away. For more

information on the bilges, bilge pumps and bilge switches, refer to page 11.

Command Link Gauges

Yamaha’s new 6YC Command Link gauge

comes standard on your new Cobia. This

gauge allows access to more information and

is user-selectable so you can choose the

functions displayed. Speed data can be

displayed from a pitot tube, Triducer, or

NMEA protocol GPS unit. To learn the gauge’s

full functionality, refer to your Yamaha engine

owner’s manual located in the Cobia Duffel

Bag.

Switch Panel

Yamaha Command Link Gauge

10

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Cobia Duffel Bag

Along with your boat, you received a Duffel Bag with your new Cobia. Inside the Duffel

Bag are the following items:

oLarge Livewell Standpipe

oShort Livewell Standpipe

o1.5” Livewell Pacifier Plug

o2 ignition Keys and Emergency Kill Cord /Engine Stop Lanyard

oEngine Start Cord

oVarious Accessories Manuals

Fuel-Water Separator & Drain

Fuel-Water Separator

Two Yamaha Fuel-Water Separators are installed on the portside of the transom pass

through. The new, improved 10-micron filter provides superior filtration ahead of the

engine's on-board filters and injectors. Large filtering and water capture areas maximize

filtration while maintaining adequate flow rate for larger engines. The micron filter and

head are mounted inside an access panel located aft of the port transom gate. The fuel

system primer bulb is located next to the filter. The fuel separators can be checked by

removing them from the mounting bracket and dumping it into an approved waste

collection device. If there appears to be an excessive amount of water, the filter

component should be replaced. See your authorized Cobia Dealer for replacement parts.

Maintenance Note: Yamaha recommends replacing the 10-

micron fuel filter on new boats after the first 10 hours or 1 month of

operation and every 50 hours or every 6 months thereafter. In

areas of high humidity where water in fuel supplies is a problem or

extensive engine operation occurs, more frequent replacement

may be necessary.

11

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Garboard Drain Plug

The garboard drain plug is the small metal plug located at the

lowest point on the hull, at the bottom of the transom right above

the keel. The drain has been designed so that it can be loosened

by hand while the hull is out of the water for draining. This

allows the plug to stay in contact with the surrounding frame so

you’ll never misplace or lose it. You can completely remove the

insert by pulling back and continue turning in a counter-

clockwise motion. It is manufactured with a rubber seal in place

to ensure your bilge is watertight. Always make sure before putting the boat in the water

that this plug is hand tightened firmly. Excess water in the bilge may be an indication of

a problem with this plug or the automatic bilge pump. (Refer to Water Drain System

diagram, page 43.)

Bilge

Bilge Access

Accessing the bilge on your new 301 is made easy. First, locate the controls on the

electronic lift assist, labeled “Hatch”, mounted on the starboard side of the tackle station

directly across from the gunwale. Next, press and hold the top button on the controls.

This will cause the rear access to lift revealing the bilge access. To lower the hatch

simply press and hold the bottom button on the control panel until the aft section is

fully closed. Remember that the electronic lift assist operates using the house battery

system.

In the event that the boat does not have power to electronically lift the hatch, the

electronic lift can be disengaged by lowering the bench seat and using the access

opening shown below to remove the pin from the electronic ram. Keep in mind that at

this point the hatch will no longer be supported in the up position and will require being

held up to maintain access to the bilge. Once the work in the bilge is finished and power

is restored to the hatch lift, it is important to attach the ram to the hatch with the pin

once again to secure the door in the closed position. To access the forward bilge pump,

disassemble the drawers underneath the bathroom sink.

Drain Plug

12

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Bilge

The bilge of your Cobia should always be checked before and after a launch. While

checking the bilge, note that a small amount of water in the bilge is normal. However, a

large amount of water or any signs of fuel or oil requires immediate attention. If such a

situation exists, the boat should be taken to a certified marine technician

immediately. Never pump fuel or oil overboard while your boat is in the

water.

Large quantities of water in the bilge may be an indication of a leak or that the bilge

pump and/or automatic float switch is not functioning properly due to a jam, clog or

electrical issue. The automatic float switch is wired to the 24-hour side of the battery

switch through the “BILGE” breaker on the battery switch panel. When functioning

properly, the float switch activates the bilge pump to pump water overboard once water

in the bilge reaches a level that submerges the switch.

If the bilge pump does not come on when the float switch is submerged, attempt to

manually turn it on through your switch panel. If the bilge pump comes on and

evacuates the water, it is clear that the float switch is not functioning properly. If the

bilge pump does not come on via the switch panel, check the breaker on the battery

switch panel to see if a breaker has been tripped. If the breaker has been tripped, reset it

and turn the switch on again, listening for the bilge pump to turn on.

If the bilge pump fails to turn on, turn the battery switch to the OFF position, then

unhook the bilge pump from its cradle by pressing the locking tab and twist motor

housing counter-clockwise. You will feel the pump release from the cradle. The entire

bilge pump and wiring should release from the cradle. After removing the pump, check

Electric Ram and Hatch Pin

Bilge Access

Hatch Control

13

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

the underside and impeller areas for miscellaneous items that might clog the pump. If

any obstructions are present remove the debris and set the pump back into the cradle.

Once set back in the cradle, press the pump down on the base then twist until the lock

button snaps it into place. Once this is completed you can try to turn the pump on again.

If the bilge pump still does not turn on, it likely needs to be replaced. It is not

recommended to use your boat if the bilge pump and/or float switch are not functioning

properly.

Systems

Ball Valves

Ball valves can be used to serve several purposes. They allow

seawater to enter the boat, in the case of livewells, and they also

act as a safeguard to stop water from entering. To tell

which position a ball valve is in, open or closed, look at the

valve and determine the direction of flow. When the ball

valve handle is in the same position as the direction of

flow, the valve is in the “OPEN” position. When the ball

valve handle appears to cross the direction of flow, the

valve is in the “CLOSED” position. The ball valves can be

accessed in the bilge compartment behind the aft seating.

301 Deckdrain System

The deckdrain system is equipped with 1 1/2” thru hull fittings through the aft port and

starboard hull sides. These fittings have to be installed lower than the drains in the

cockpit floor so that gravity will allow the cockpit to drain free of water. This puts these

fittings very close to the water line of the hull. These drains are rigged with ball valves

that can be opened and closed to control the flow of water. In the open position, these

ball valves will allow water to flow freely from the cockpit, thus making the boat “self-

bailing”. When closed, no water will be allowed to travel to or from the cockpit.

14

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

301 Livewell Pump Assembly

The livewell pump assembly is composed of a scoop strainer

mounted to the bottom of the hull, a thru hull fitting, ball valve

assembly, and the pump. As you can see, the ball valve assembly is

in the “OPEN” position. This is the correct position for the

operation of the livewell.

Console/Head Access

Located at the top on the inside of the console/head access door is a locking gas shock

that aides in opening the door and keeping the door open once the shock is fully

extended. With the door fully opened, it can only be closed by releasing the pressure of

the metal sleeve on the door side against the shock

that is mounted to the console. To do this, open the

door to its fullest open position, thereby allowing

the door slide sleeve to be moved so that it will slide

overtop of the gas shock as the door closes. Failure

to release this locking mechanism while attempting

to close the door will lead to the gas shock failing, or

damage to the mounting brackets.

DC Main Breaker Panel

The DC main breaker panel is located to the left of the mirror and contains

the breakers for the accessories on the helm switch panel. If an accessory is

not working it may because its breaker has been popped. Simply find the

rubber button on the breaker panel for the associated accessory and press it

in. You should feel an internal button move in and then catch. This will reset

the breaker and close the circuit. If the accessory still is not working or the

breaker pops again, another issue is present.

The backside of the switch panel and the electronics can be reached inside

the door with the mirror. The fuse box on the back of the door contains the

fuses for the helm electronics such as the GPS units and VHF.

Gas Shock

Main Breaker Panel

Livewell Pump Assembly in

“OPEN” Position

15

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Electric Head Operation

To operate the head, first, make sure that the intake/fill valve located on the inside of

the bottom of the hull accessed through the hatch to the left side of the toilet (see

Sanitation System diagram, page 38). The valve is open when its handle is pointing

straight up. This will allow water to enter the head upon flushing.

Once you’ve finished using the head, press the flush button labeled “Elec Head” on the

switch panel. This will push the contents of the head into the holding tank. Note that the

toilet contents will always go into the holding tank first, no matter if planning on

pumping out or using the macerator.

To evacuate the holding tank via a

marina pump out, make sure that

the handle for the Y-valve (located

in the access hatch to the right of

the toilet) is in the correct position.

This will allow the tank contents to

be sucked out of the tank via the

waste deck fitting on the deck. The

discharge for the deck fitting will

always be the topmost outlet on the

Y-valve. The handle is in the

correct position if the arrow for the

top outlet IS NOT covered by the

wide end of the handle.

Note: The visible arrows on the Y-valve always show the direction of

the flow. In other words, the wide end of the handle always covers the

arrow for the outlet where the flow is NOT going to go. If the flow is

pointing downwards, the waste is being directed through the bottom

of the hull and overboard. If the flow is pointing up, the waste is being

directed upward to the deck and the pump out fitting.

Intake/Fill Valve in the “OPEN” Position

16

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

This is the position the handle should be kept in at all times to prevent the possibility of

mistakenly discharging waste overboard in waters illegally. (Within 3 miles of shore and

where otherwise designated.) If desired, the handle can be locked in this position by

inserting a padlock through the hole on the handle and through the housing on the Y-

valve.

To evacuate the tank overboard using the macerator, open the valve on the waste

discharge thru hull located next to the head intake valve/thru hull. The Y-valve handle

should then be turned so that the wide portion of the handle covers the silver arrow for

the pump-out outlet (the top outlet.) The visible arrows should now be showing the flow

to be going downward. Next, press down the macerator switch on the panel. This will

push the contents in the holding tank out the bottom of the boat through the waste

discharge thru hull. Once the process is complete it is advisable to close the discharge

valve and put the Y-valve handle back into the pump-out position. (The wide portion of

the handle covering the down arrow.)

The Jabsco Y-Valve is designed to provide flexibility of onboard waste management by

diverting waste either to the dockside pump-out fitting or directly overboard where legal

to do so. Check local and federal regulations to determine where direct overboard

discharge of untreated waste is permitted.

17

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Note that the wide portion

of the handle is covering

the down arrow. The

exposed arrows show the

direction of the flow up.

FLOW UP = DECK

PUMPOUT

Note that the wide portion of the

handle is covering the up arrow. The

exposed arrows show the direction of

the flow down.

FLOW DOWN = BOTTOM

DISCHARGE

18

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Ladder & Props

Stainless Boarding Ladder

This Cobia model comes standard with a telescoping stainless-steel boarding ladder

integrated into the starboard aft platform area. This provides a stepping area while the

ladder is in the up position. Once the ladder is down and in the extended position, close

the lid cover for safe and secure entry and exit via the ladder. When washing off your

boat at the end of the day make sure to extend the ladder and wash it off as well, making

sure to dry it completely before stowing. Leaving saltwater in the telescoping tubes may

lead to corrosion and affect the useful life of your ladder.

Props

Prop selection on your Cobia is determined by your

local Cobia Dealer, but all props are based on

recommendations from Cobia Boat Company and

Yamaha Marine in order to give your boat maximum

overall performance. The needs of your prop will

determine the prop design and size that best fits your

performance requirements. Always inspect the

engine and prop prior to launching your boat with

DANGER:

No passenger should attempt to enter or exit the boat by

the ladder or by any other means while the engine is on.

Engine Prop

19

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

the engine off. Key prop issues include tangled fishing line or other types of debris,

cracked blades or fluid leaking out of the seal. Look for fishing line tangled around the

prop or lower unit seal. Consult your Yamaha Owner’s Manual to address these

issues.

Fuel System

Fuel System

This Cobia comes equipped with a 267-gallon fuel cell stationed below the leaning post

between the stringer system. There are two fuel fill receptacles, one on the port gunwale

and one on the starboard gunwale. The primer bulbs are located by the transom gate

inside an access hatch. Every fuel tank is pressure tested at the factory before and after

installation. Should you experience any fuel related problems or suspect problems with

the fuel system, immediately take your boat to a Cobia Dealer. See Fuel System Diagram

on page 39.

DANGER:

Do not smoke while filling the tank. Be sure to turn off the engines

and all electrical equipment when fueling the boat to prevent

accidental discharges of static electricity. Use only the

recommended gasoline (see Yamaha Owner’s Manual). Do not

use fuels with alcohol or alcohol related derivatives that can

cause marine fuel system hoses to deteriorate.

20

Maverick Boat Group

3207 Industrial 29th St. • Fort Pierce, Florida 34946

(772)-465-0631 •cobiaboats.com

Self-Bailing Cockpit & Livewell

Self-Bailing Cockpit

The cockpit is designed to be self-bailing, meaning that all the water that comes into the

cockpit will be directly drained overboard. This keeps the boat from acquiring standing

water and allows the boat to drain at all times, including while the boat is docked.

Water drains out of the cockpit through two aft cockpit drains located at the far aft

cockpit floor on both the port and starboard sides. Each side drains overboard through

the side of the hull independently. None of this water is drained into the bilge. The ball

vales are located inside the hull sides and can be accessed through the bilge hatch. Refer

to page 13 for operation of the ball valve associated with this system.

The bilge is designed to drain any water entering the inside of the hull. All hoses are

sealed and double clamped during construction. Continuous or periodic running of the

automatic bilge pump may be an indication of a hose leak or break in a seal and should

be investigated by a Cobia Dealer immediately. Refer to page 11 for further information

regarding bilge pump operation and maintenance. A diagram of the Water Drain system

can be found on page 43.

Livewell System

The livewell system is designed to keep your

baitfish alive and strong for as long as possible.

This livewell provides a cool, clean, and

oxygenated environment that allows you to keep

your baitfish alive for long periods of time. To

efficiently operate your livewell, the following

steps should be taken:

1. Open livewell hatch.

2. Install stand-up pipe snugly.

3. Ensure livewell pump ball valve is in open position.

4. Turn on livewell switch.

Livewell

Other manuals for 301CC

1

Table of contents

Other COBIA Boat manuals

COBIA

COBIA 240 CC User manual

COBIA

COBIA 237 CC 2014 User manual

COBIA

COBIA 350 CC User manual

COBIA

COBIA 280 CC User manual

COBIA

COBIA 2012 Cobia 237 User manual

COBIA

COBIA 280 DC 2019 User manual

COBIA

COBIA 330 DC User manual

COBIA

COBIA 344 CC User manual

COBIA

COBIA 240 DC User manual

COBIA

COBIA 2012 296 CC User manual

Popular Boat manuals by other brands

Jeanneau

Jeanneau SUN ODYSSEY 41 DS owner's manual

Meridian

Meridian 490 Pilothouse owner's manual

Advanced Elements

Advanced Elements AdvancedFrame Expedition AE1009 owner's manual

Robo Marine Indonesia

Robo Marine Indonesia GEOMAR user manual

Swallow Boats

Swallow Boats BayRaider owner's manual

X SHORE

X SHORE EELEX 8000 owner's manual