Chapter 07 – Tail assembly

Chapter 08 – Installation of the servos

Chapter 09 – Assembling the modules

Chapter 10 – Gear Ratios

Chapter 11 – Installation of the ESC and Bec

Chapter 12 – Motor Belt

Chapter 01 – Serial number/Specifications

Chapter 02 –

Important notes

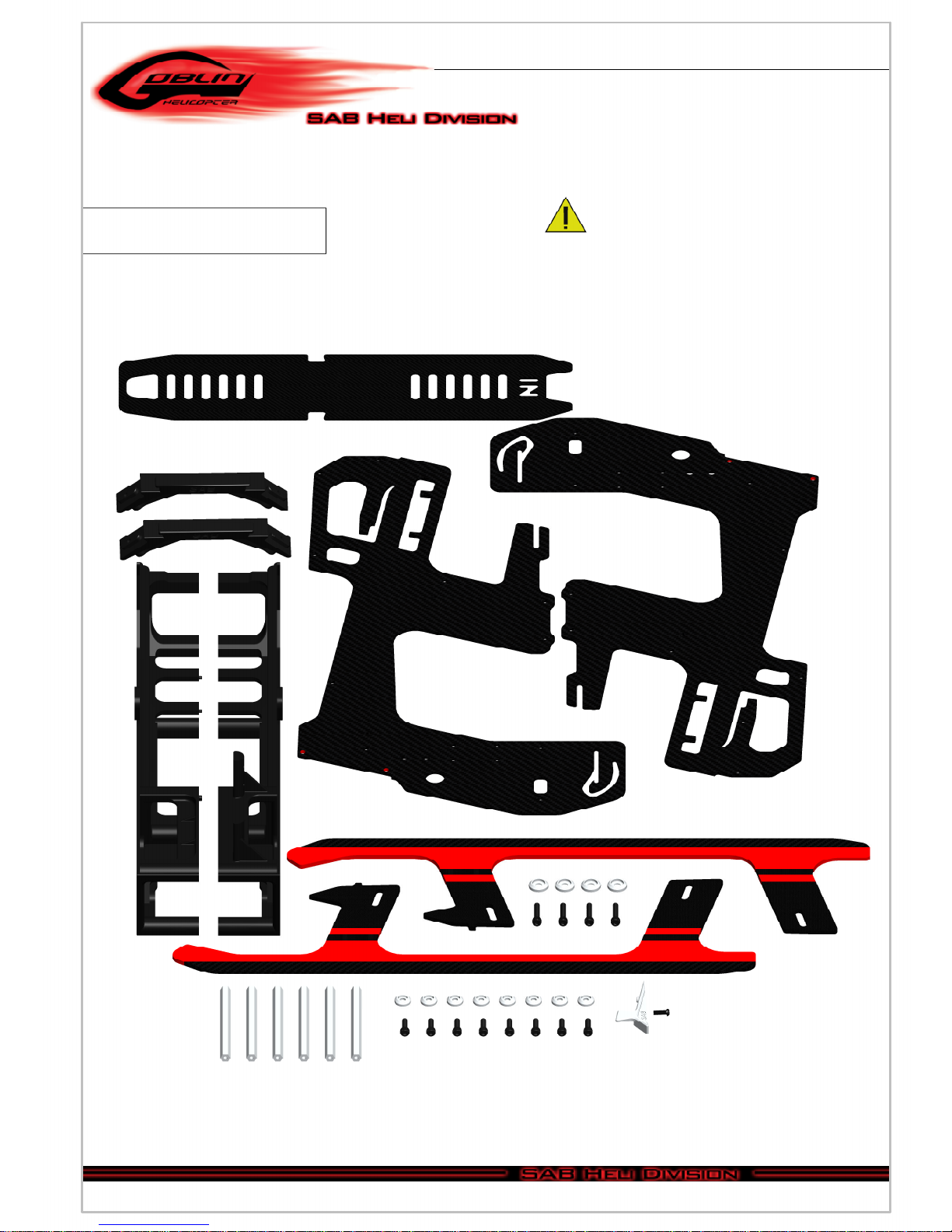

Chapter 03 – In the Box

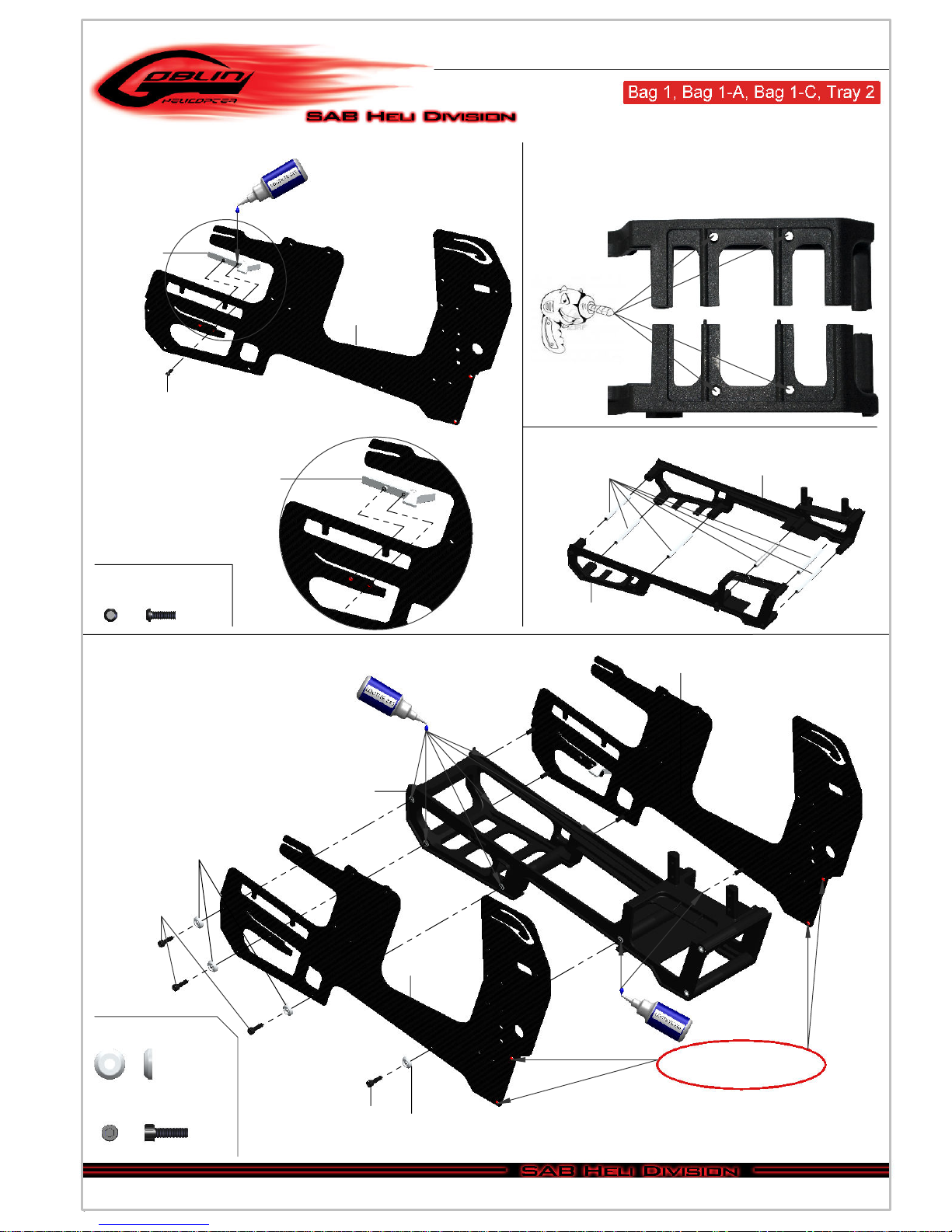

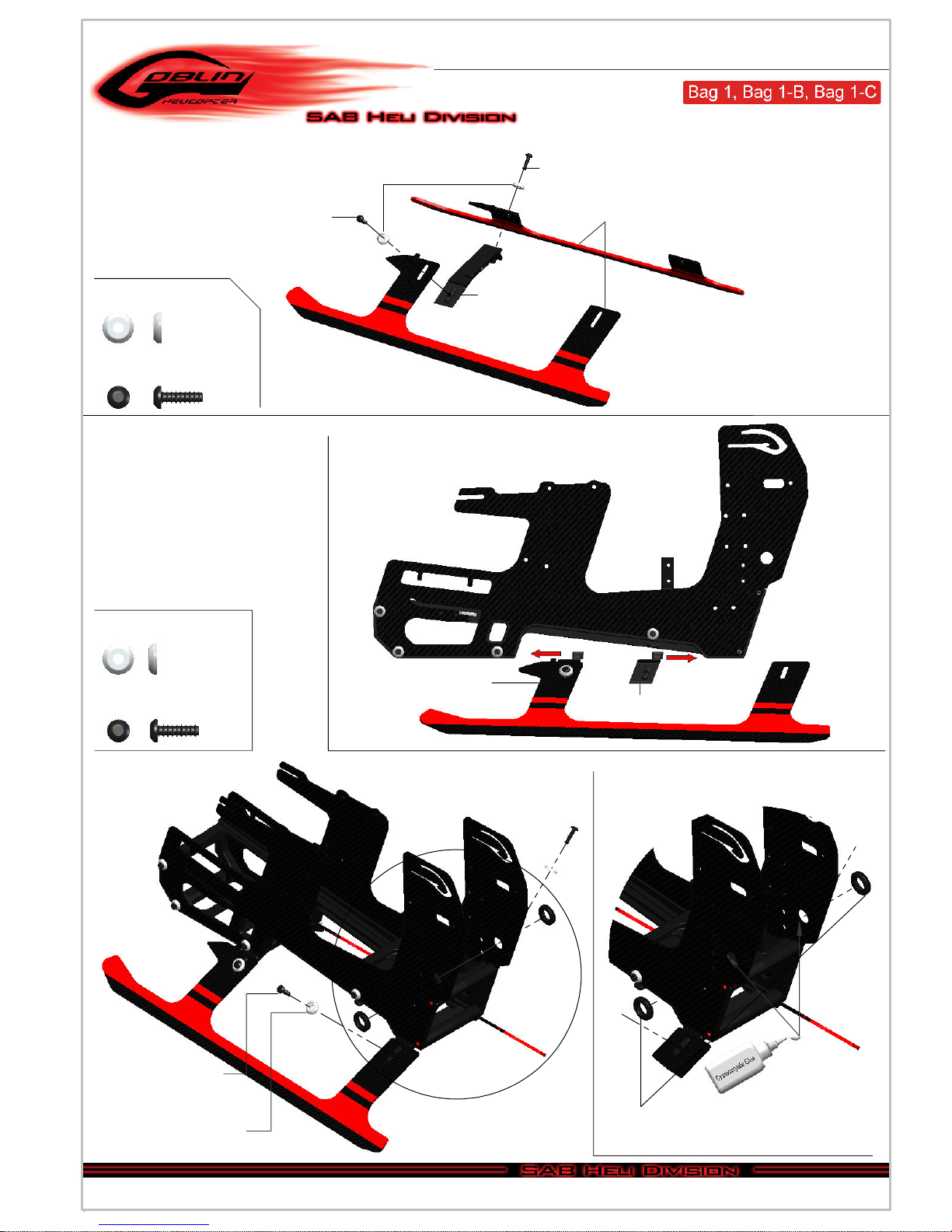

Chapter 04 – Carbon frame assembly

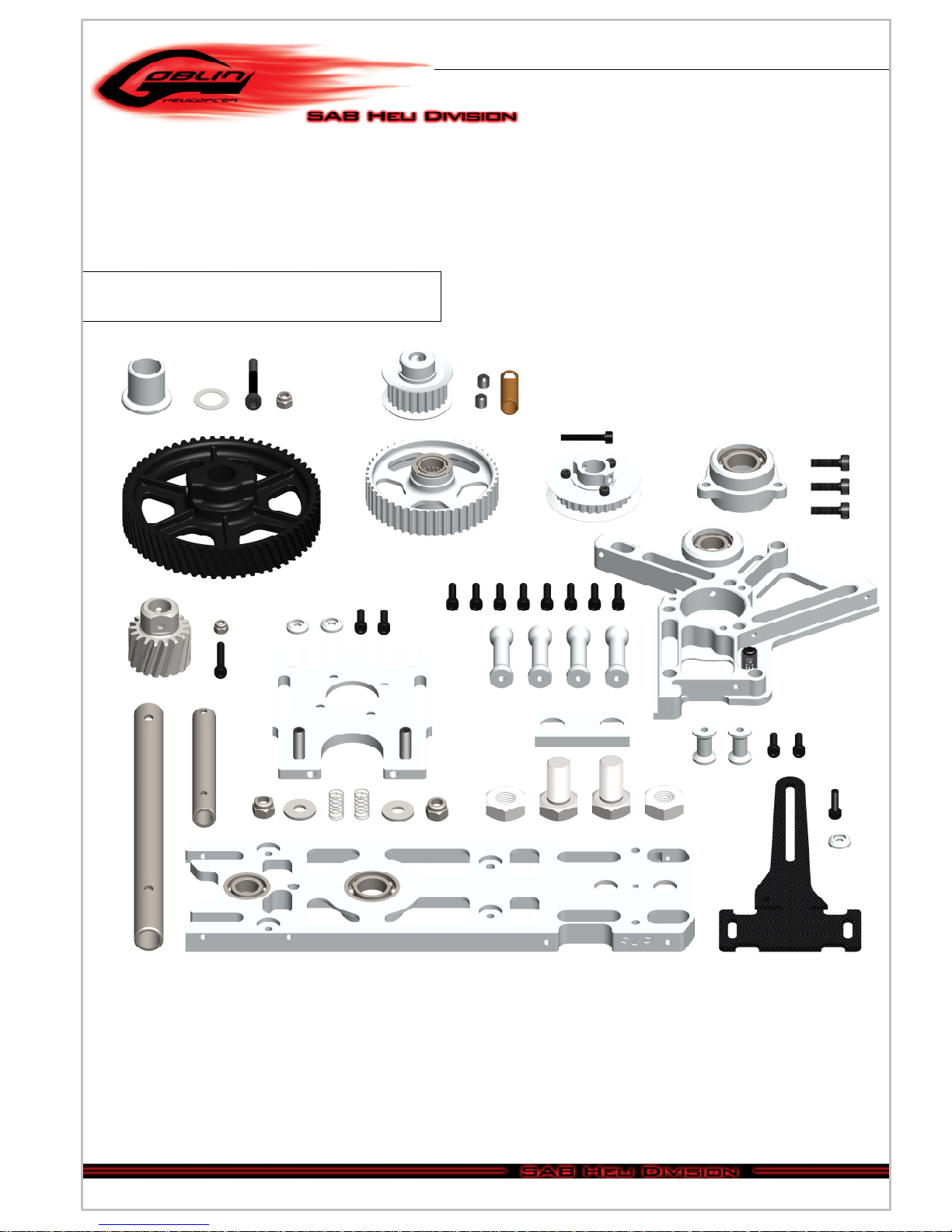

Chapter 05 – Trasmission assembly

Chapter 06 – Head assembly

INDEX

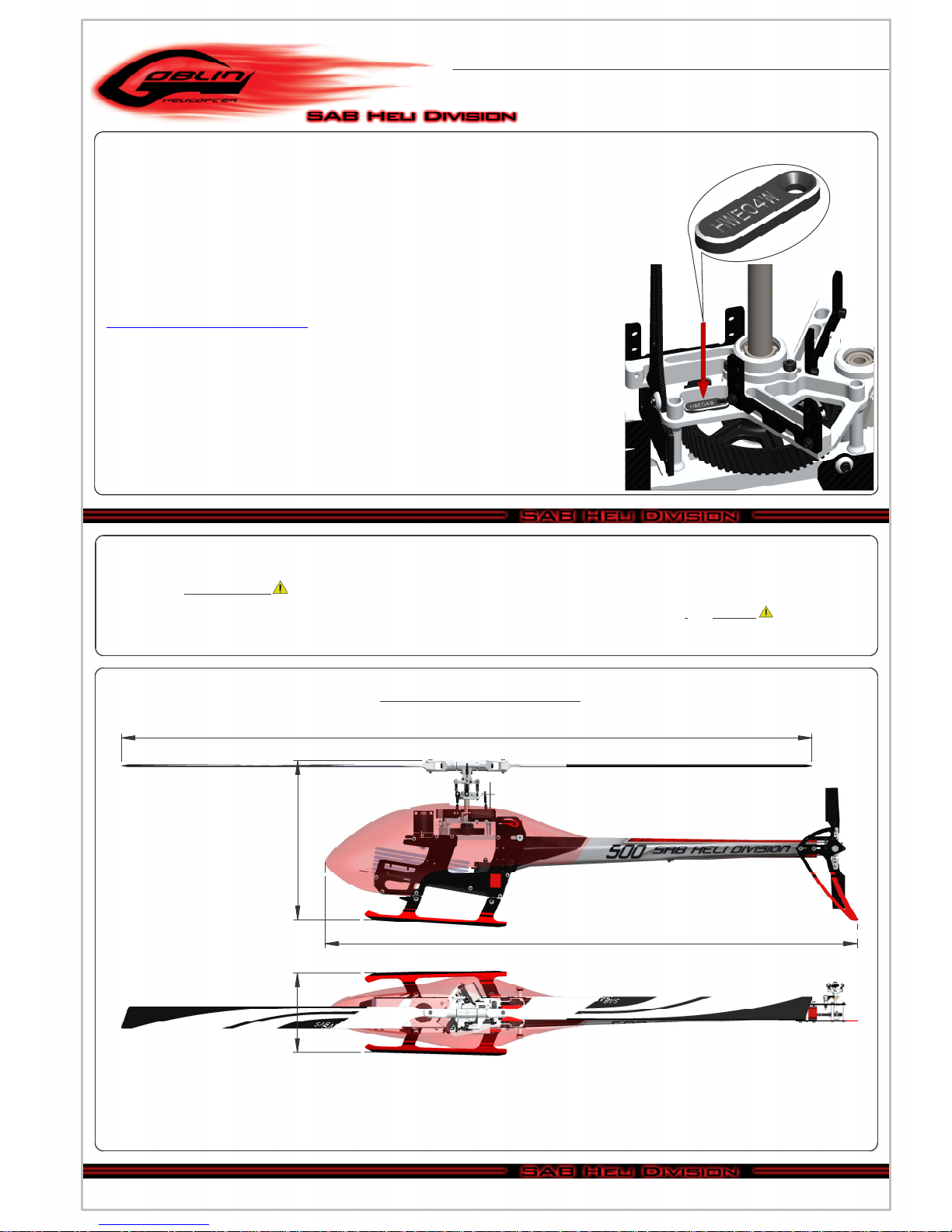

Very Impotant:

Inside Box 4, you will find Bag 9 with a red label. This bag contains your serial number

tag. Please take a moment to register your kit online via our web site at:

http://www.goblin-helicopter.com/

It is extremely important that you take a moment to register your helicopter with us.

This is the only way to ensure that you are properly informed about changes to your

kit, such as upgrades, retrofits and other important developments. SAB Heli Division

cannot be held responsible for issues arising with your model and will not provide

support unless you register your serial number.

To mount the serial number tag on your helicopter, please refer to page 26.

Thank you for your purchase, we hope you enjoy your new Goblin helicopter!

SAB Heli Division

Chapter 13 – Installation of the FBL System

Chapter 14 – Boom Assembly

Chapter 15 – Battery / Canopy

Chapter

16 –

In Flight

Chapter 17 – Maintenance

Chapter 18 – Exploded views

Chapter 19 – Spare parts

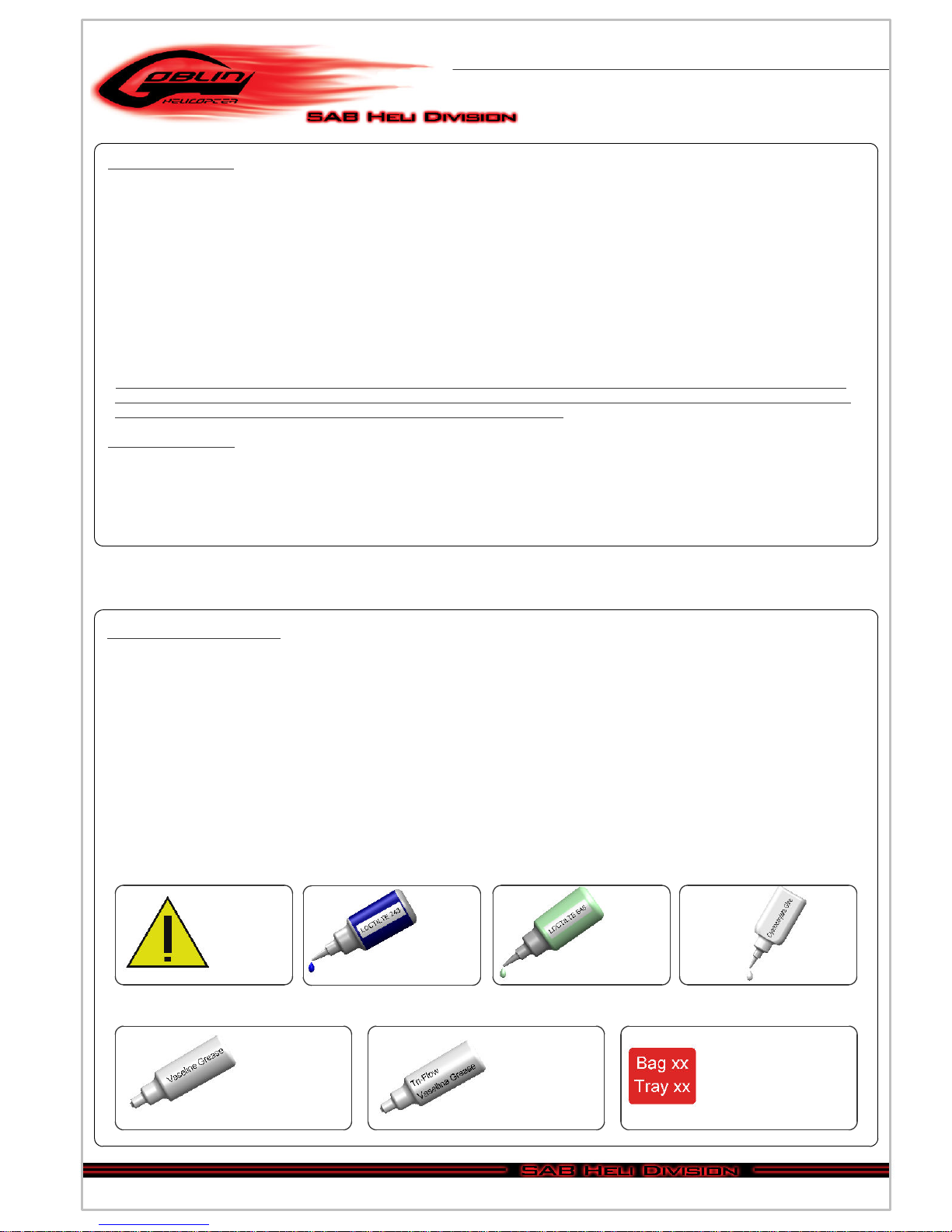

- Main rotor diameter: 1138mm (with 500mm blades)

- Main blade length: 500mm

- Tail rotor diameter: 226mm

- Tail blade length: 80mm

- Weight including standard electronics: 1900g (excluding batteries).

- Maximum motor size: diameter 52mm, height 53mm

- Battery compartment: 52x53x180mm.

SPECIFICATIONS

980mm

310mm

158mm

1138mm

The Goblin

is a high performance radio controlled helicopter.

The design is original, moving away from traditional schemes, searching rationality for simplicity.

Our goal was to create a simple, high performance helicopter, with a minimum of mechanical components,

and simple maintenance.

Please read this user manual carefully, it contains instructions for the correct assembly of the model.

Please refer to the web site www.goblin-helicopter.com for updates and other important information.

Copyright@2013 - SAB Heli Division - All rights reserved

Page 1

Chapter 1, Serial Number