Page 3

TD-000 713-E

Edition 10/2019, Subject of alteration

Copyright by COLASIT AG Spiez

Table of contents

Part 1: General ...........................................................................................................................................................4

1General................................................................................................................................................................4

1.1 Definition........................................................................................................................................................4

1.2 Manufacture of COLASIT fans ......................................................................................................................4

1.3 Warranty ........................................................................................................................................................4

1.4 Safety review.................................................................................................................................................5

1.5 Qualification of personnel..............................................................................................................................5

1.6 Possible emergencies....................................................................................................................................5

1.7 The safety inspector (So) ..............................................................................................................................5

1.8 General risk matrix.........................................................................................................................................6

1.9 EU conformity of the COLASIT fan................................................................................................................7

1.10 Restrictions when commissioning .................................................................................................................7

1.11 General operating conditions.........................................................................................................................7

2Explosion protection............................................................................................................................................8

2.1 Fan EX marking.............................................................................................................................................9

2.2 Correct installation of ATEX fan ....................................................................................................................9

3Shipping, unpacking, inspection..........................................................................................................................9

4Installation, configuration...................................................................................................................................10

5Commissioning, initial start-up, test run ............................................................................................................10

5.1 Inspection of the installation and settings....................................................................................................10

5.2 Drive.............................................................................................................................................................11

5.3 Electrical installations, EMERGENCY - STOP............................................................................................11

6Operation...........................................................................................................................................................11

6.1 Safety regulations........................................................................................................................................11

6.2 Decommissioning ........................................................................................................................................11

7Maintenance / repair / cleaning .........................................................................................................................12

7.1 Preparation ..................................................................................................................................................12

7.2 Performance ................................................................................................................................................12

8Spare parts........................................................................................................................................................13

9Operating instructions .......................................................................................................................................13

10 Log-book.......................................................................................................................................................14

11 Disposal........................................................................................................................................................14

12 Faults and fault clearance.............................................................................................................................14

13 Retrofitable original accessories...................................................................................................................15

14 Fan identification...........................................................................................................................................15

Part 2: Units..............................................................................................................................................................15

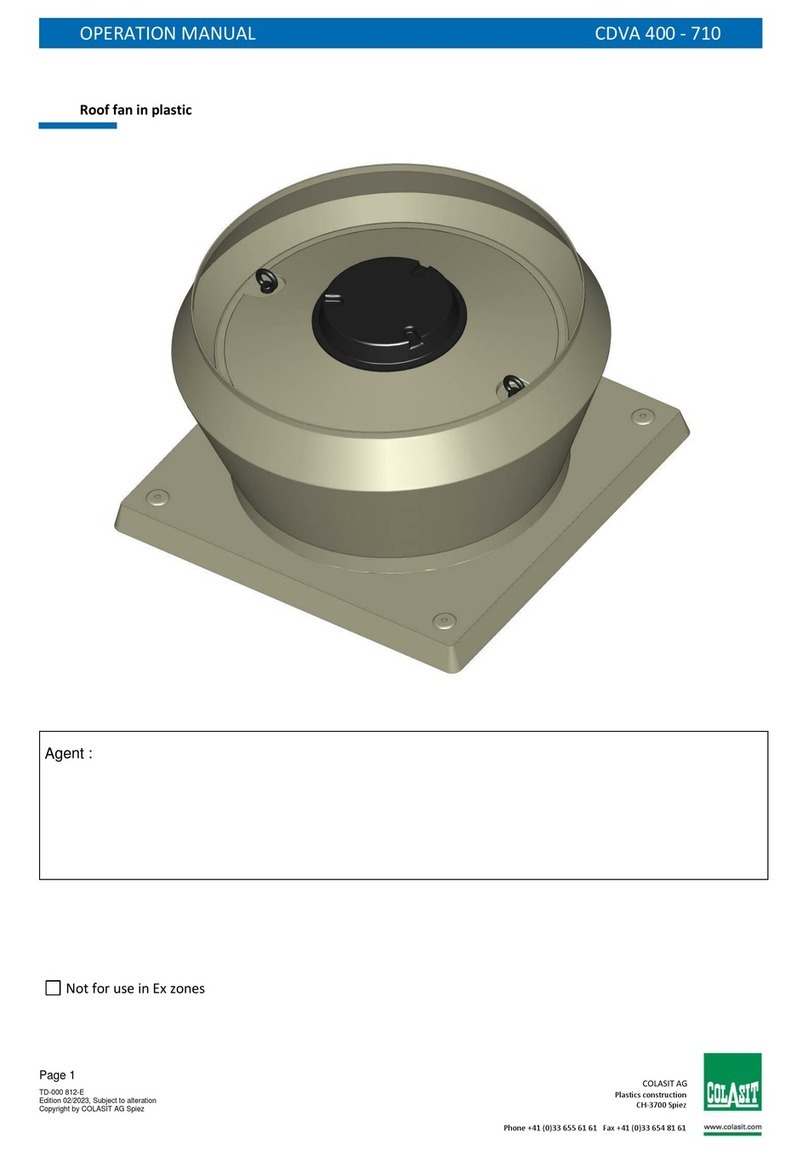

15 Design and function CCV 75 ........................................................................................................................15

16 Dimensions...................................................................................................................................................16

16.1 Dimensions of the CCV 75 ..........................................................................................................................16

17 Spare parts ...................................................................................................................................................17

17.1 Spare parts lists CCV 75 .............................................................................................................................17

Part 3: Certifications .................................................................................................................................................18

18 Certifications.................................................................................................................................................18

18.1 EU Declaration of Conformity......................................................................................................................18

18.2 ATEX-Declaration of Conformity .................................................................................................................19

18.3 Further certificates.......................................................................................................................................21

19 Form for the correct assembly ATEX-fans ...................................................................................................22