Table of contents

Part 1: General ...........................................................................................................................................................4

1General................................................................................................................................................................4

1.1 Definition........................................................................................................................................................4

1.2 Production of COLASIT fans .........................................................................................................................4

1.3 Warranty ........................................................................................................................................................4

1.4 Safety review.................................................................................................................................................5

1.5 Personnel qualifications.................................................................................................................................5

1.6 Possible emergencies....................................................................................................................................5

1.7 Safety officer (SO).........................................................................................................................................5

1.8 General risk matrix.........................................................................................................................................6

1.9 EU and UK conformity of the COLASIT fan ..................................................................................................7

1.10 Restrictions when putting into operation........................................................................................................7

1.11 General operating conditions.........................................................................................................................7

2Explosion protection............................................................................................................................................7

2.1 Fan EX marking.............................................................................................................................................8

2.2 Correct installation of ATEX fan ....................................................................................................................9

3Shipping, unpacking, inspection, storage............................................................................................................9

4Installation, design...............................................................................................................................................9

5Commissioning, initial startup, test run..............................................................................................................10

5.1 Inspection of the installation and settings....................................................................................................10

5.2 Drive.............................................................................................................................................................10

5.3 Electrical installations ..................................................................................................................................11

6Operation...........................................................................................................................................................11

6.1 Safety instructions .......................................................................................................................................11

6.2 Decommissioning ........................................................................................................................................11

7Putting out of operation .....................................................................................................................................12

7.1 Preparation ..................................................................................................................................................12

7.2 Performance ................................................................................................................................................12

8Spare parts........................................................................................................................................................14

9Operating instructions .......................................................................................................................................14

10 Logbook........................................................................................................................................................14

11 Disposal........................................................................................................................................................14

12 Troubleshooting............................................................................................................................................15

13 Retrofittable original accessories..................................................................................................................16

14 Fan identification...........................................................................................................................................16

Part 2: Components..................................................................................................................................................16

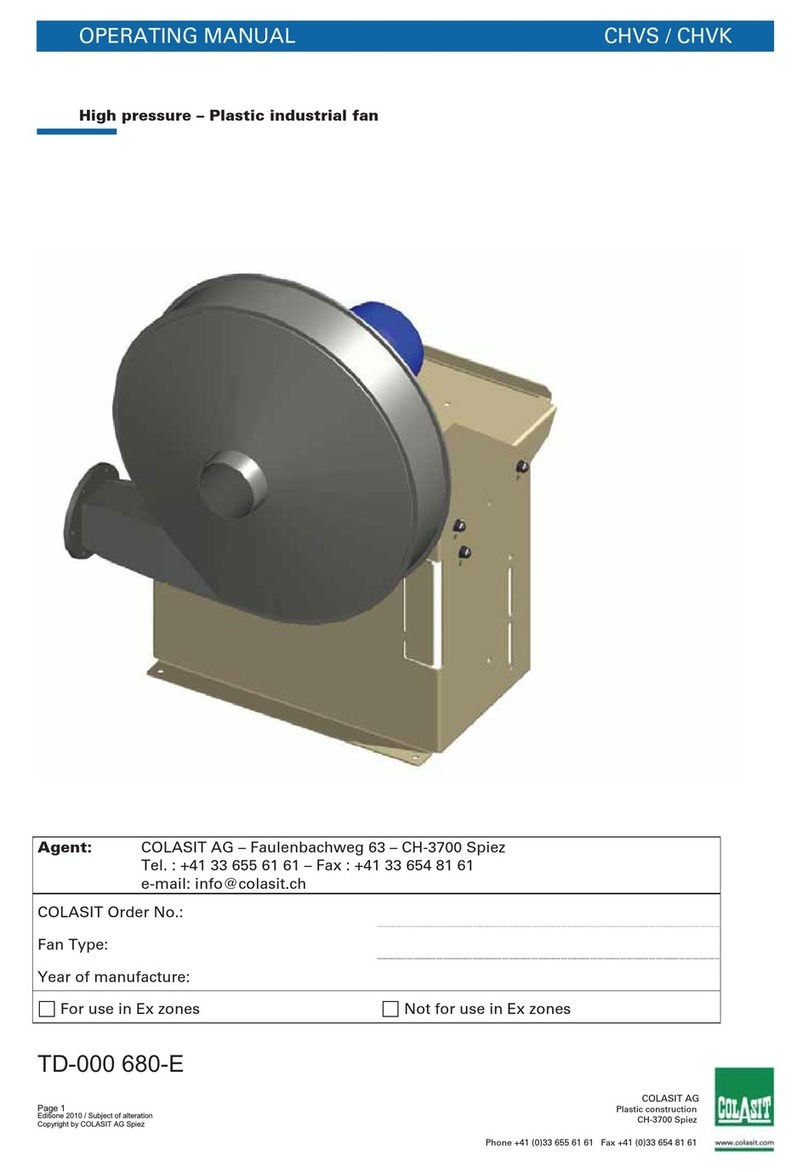

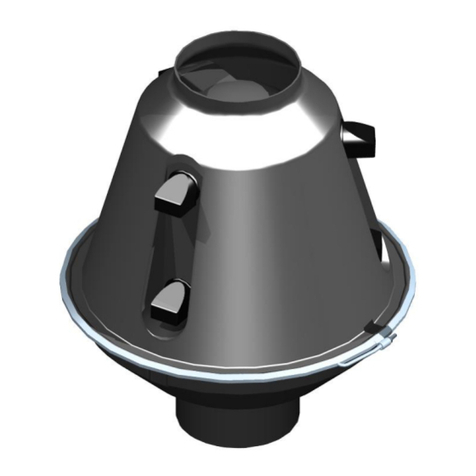

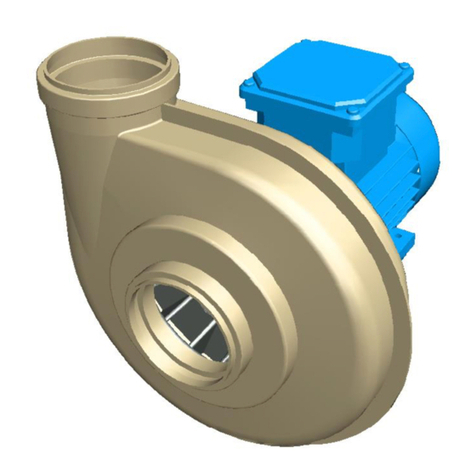

15 Design and function of the CHVN 315-710 ..................................................................................................16

16 Dimensional drawings...................................................................................................................................17

16.1 Dimensions of the CHVN 315-710 with direct drive....................................................................................17

16.2 Dimensions of the CHVN 315-710 with V-belt drive....................................................................................18

17 Assembly instructions...................................................................................................................................19

17.1 Assembly instructions CHVN 315-710 with direct drive..............................................................................19

17.2 Assembly instructions for CHVN 315-710 with V-belt drive ........................................................................20

18 Spare parts lists............................................................................................................................................22

18.1 Spare parts list for CHVN 315-710 with direct drive....................................................................................22

18.2 Spare parts list CHVN 315-710 with V-belt drive ........................................................................................23

Part 3: Certificates ....................................................................................................................................................24

19 Certificates....................................................................................................................................................24

19.1 UK Declaration of Conformity......................................................................................................................24

19.2 ATEX Declaration of Conformity..................................................................................................................25

19.3 Further certificates.......................................................................................................................................27

20 Form for the correct assembly of ATEX fans................................................................................................28