Table of contents

4 / 88 Operating instructions CMVpro 125-400 ATEX | Version 1-en

5.3.2 Sleeves ...................................................................................................... 29

5.3.3 Sleeves with flange .................................................................................... 29

5.3.4 Flange connections.................................................................................... 29

5.3.5 Condensate drain....................................................................................... 30

5.3.6 Isolation switch........................................................................................... 30

5.3.7 Frequency converter (FC).......................................................................... 30

5.3.8 Speed adjustment potentiometer ............................................................... 31

5.3.9 Wall bracket ............................................................................................... 31

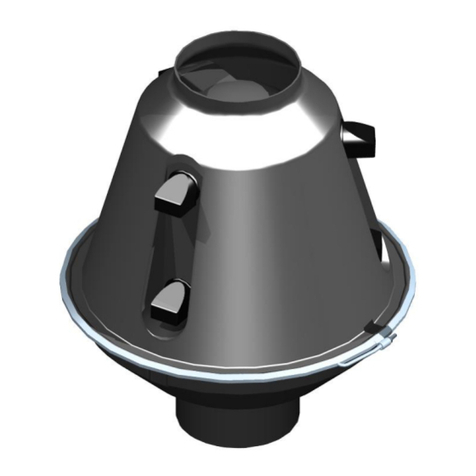

5.3.10 Motor cover ................................................................................................ 31

5.3.11 Protective grid ............................................................................................ 32

5.3.12 Hub seal..................................................................................................... 32

6 Transport............................................................................................................... 33

6.1 Safety instructions .................................................................................................. 33

6.2 Incoming goods inspection ..................................................................................... 33

6.3 Packing................................................................................................................... 34

6.4 Intermediate storage............................................................................................... 34

6.5 Transport to installation location............................................................................. 34

6.5.1 Transport by crane..................................................................................... 34

6.5.2 Transport by pallet stacker or forklift.......................................................... 35

7 Mechanical installation ........................................................................................ 36

7.1 Safety instructions .................................................................................................. 36

7.2 Installation location requirements ........................................................................... 36

7.3 Splinter protection - check proper mounting........................................................... 37

7.4 Vibration absorbers mounting................................................................................. 38

7.5 Foundation mounting.............................................................................................. 39

7.6 Wall mounting......................................................................................................... 39

7.7 Ceiling mounting..................................................................................................... 41

7.8 Connecting fan to ductwork .................................................................................... 41

7.9 Connecting condensate drain to siphon ................................................................. 42

7.9.1 Siphon calculations and execution............................................................. 43

7.10 Final inspection....................................................................................................... 44

8 Electrical installation............................................................................................ 45

8.1 Safety instructions .................................................................................................. 45

8.2 Electrical protective devices ................................................................................... 45

8.2.1 Isolation switch installation......................................................................... 45

8.2.2 Motor protection switch installation ............................................................ 46

8.2.3 PTC thermistor tripping device installation................................................. 46

8.2.4 Starting current limiter................................................................................ 47

8.3 Instructions for frequency converter (FC) use ........................................................ 47

8.3.1 Frequency converter (FC) installation options ........................................... 48