Table of Contents

Safety Warnings / Symbols................................................................................................................................. 3

Limitation of Liability ........................................................................................................................................... 3

Warranty ............................................................................................................................................................. 4

I. Product Information................................................................................................................................ 5

II. Unpacking Your Cabinet ........................................................................................................................ 5

2.1Step-By-Step Procedure................................................................................................................................ 5

2.2Packaging Contents...................................................................................................................................... 6

III. Installing Your Cabinet ......................................................................................................................... 7

3.1Choosing aSuitable Location........................................................................................................................ 7

3.2 Environmental /Electrical Conditions ........................................................................................................... 7

3.3 InstallingYour Cabinet .................................................................................................................................. 8

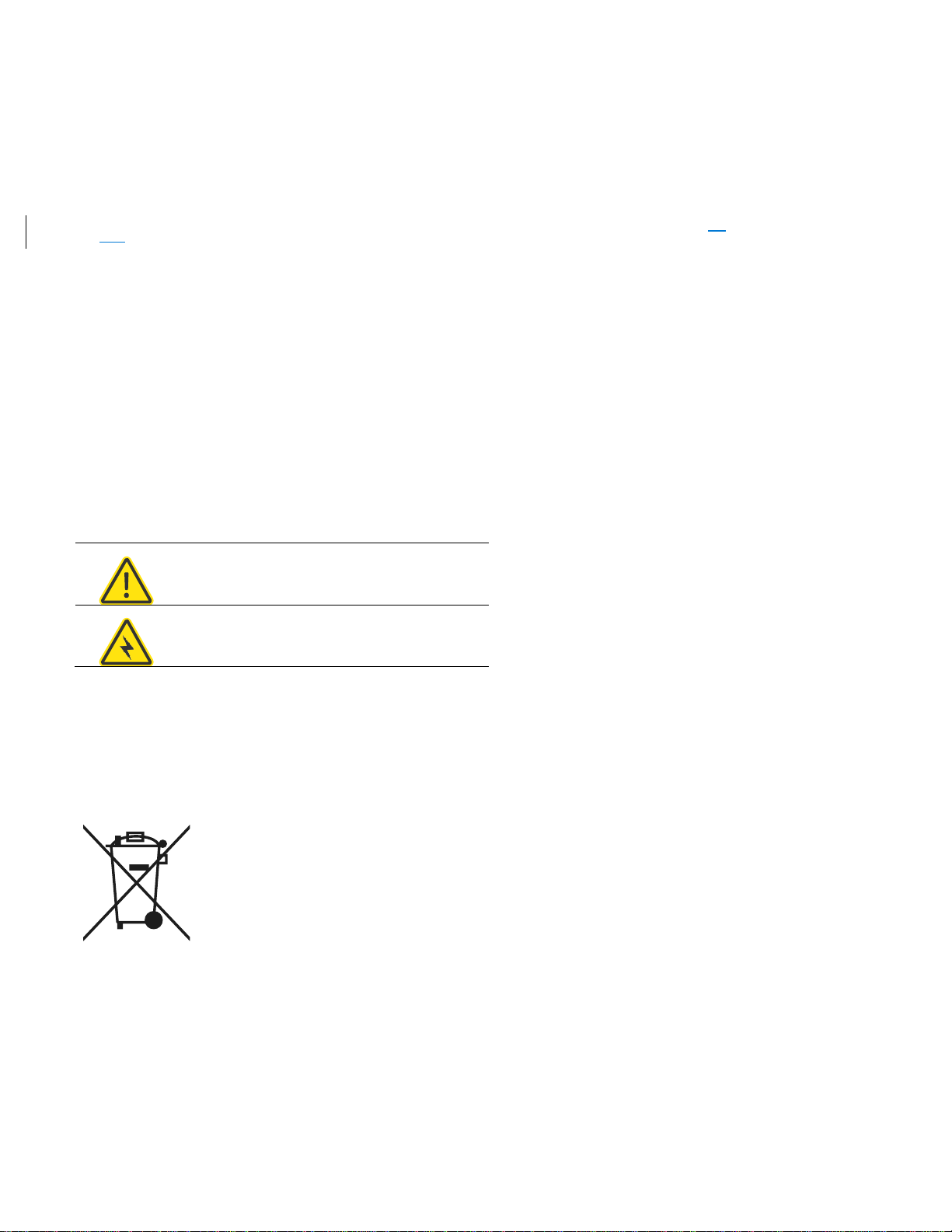

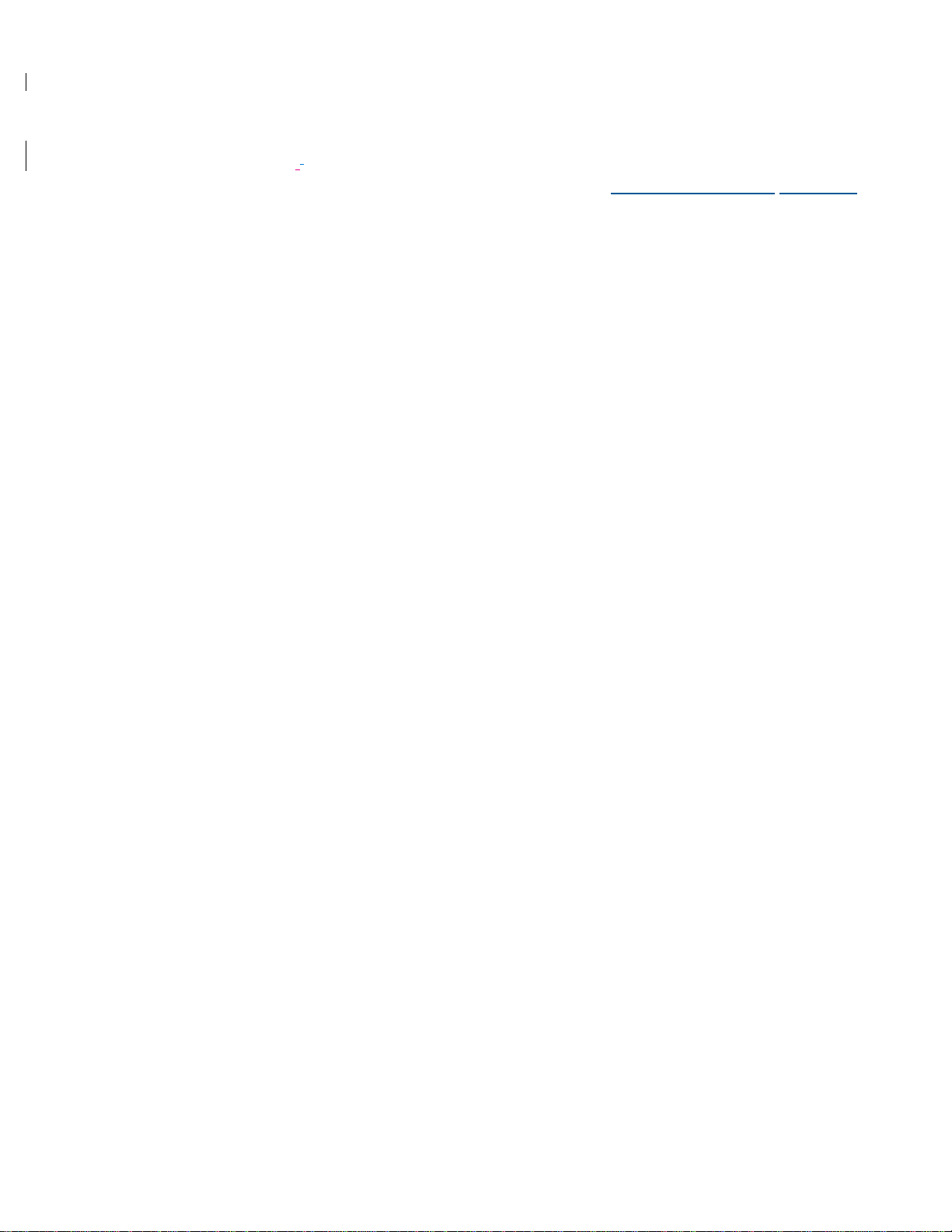

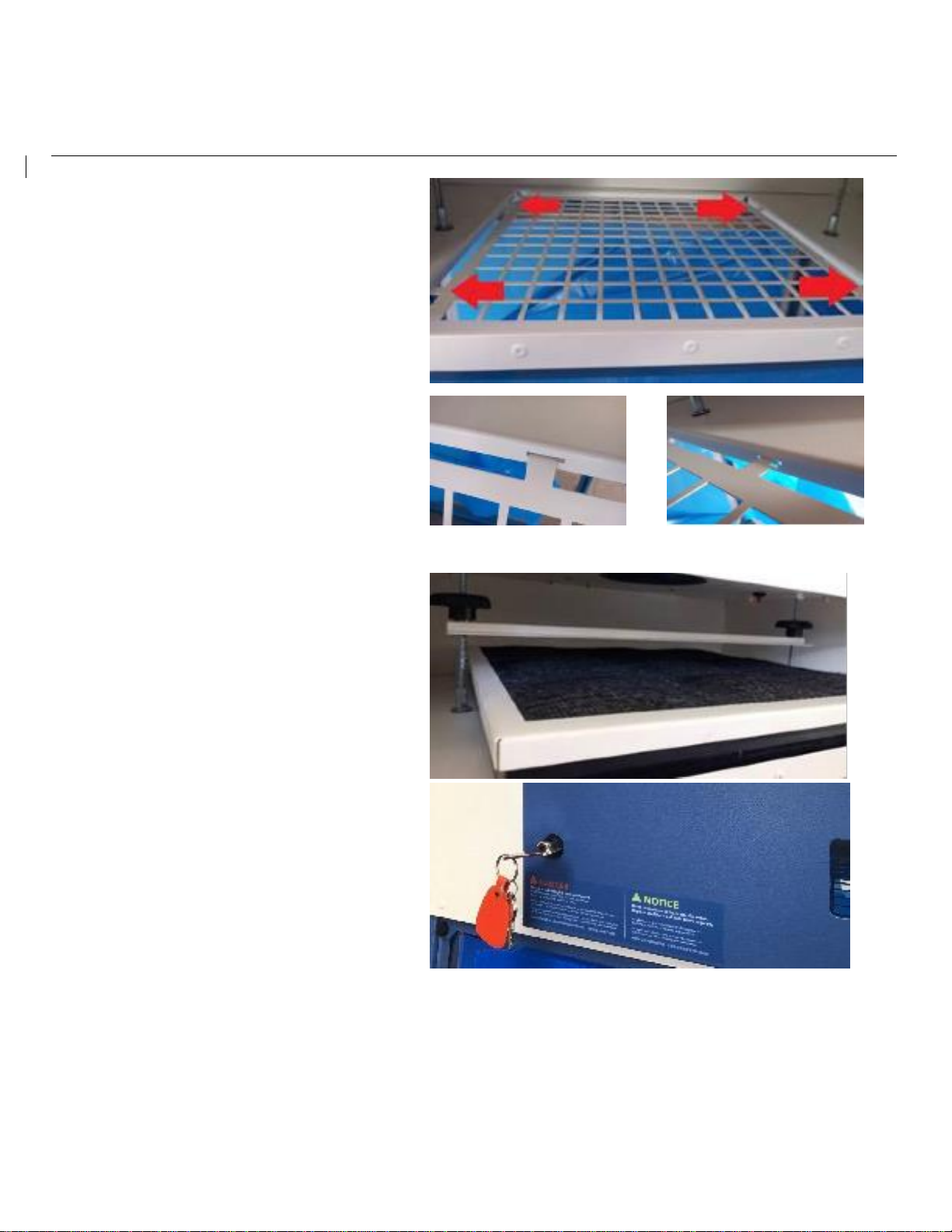

3.4Set Up ........................................................................................................................................................... 9

3.5 Performance Validation / Certification .........................................................................................................16

3.6 Importance of Performance Validation / Certification..................................................................................16

3.7 Disclaimer....................................................................................................................................................16

IV. Operating Your Cabinet .......................................................................................................................17

4.1Control System.............................................................................................................................................17

4.2 CabinetOperating Procedure ......................................................................................................................18

V. Monitoring....................................................................................................................................................19

5.1 General........................................................................................................................................................19

5.2Manual Monitoring........................................................................................................................................19

VI. Maintenance .............................................................................................................................................. 20

6.1 General....................................................................................................................................................... 20

6.2General Cleaning ........................................................................................................................................ 20

6.3 Pre-Filters ................................................................................................................................................... 20

6.4 Lights .......................................................................................................................................................... 20

6.5 Airflow......................................................................................................................................................... 20

6.6Calibration Instructions................................................................................................................................ 21

6.7 ChangingOut Filters ................................................................................................................................... 22

6.8 Airflow Adjustment ...................................................................................................................................... 22

6.9 Maintenance Schedule............................................................................................................................... 23

6.10 User MonthlyMaintenance Schedule ....................................................................................................... 23

6.11 Fault Finding............................................................................................................................................. 24

6.12 Component Changing............................................................................................................................... 25

VII. Filter Information ............................................................................................................................... 26

7.1 Filter Descriptions ....................................................................................................................................... 26

VIII. Product Specifications .......................................................................................................................... 27