Innity™ Usage 4

8

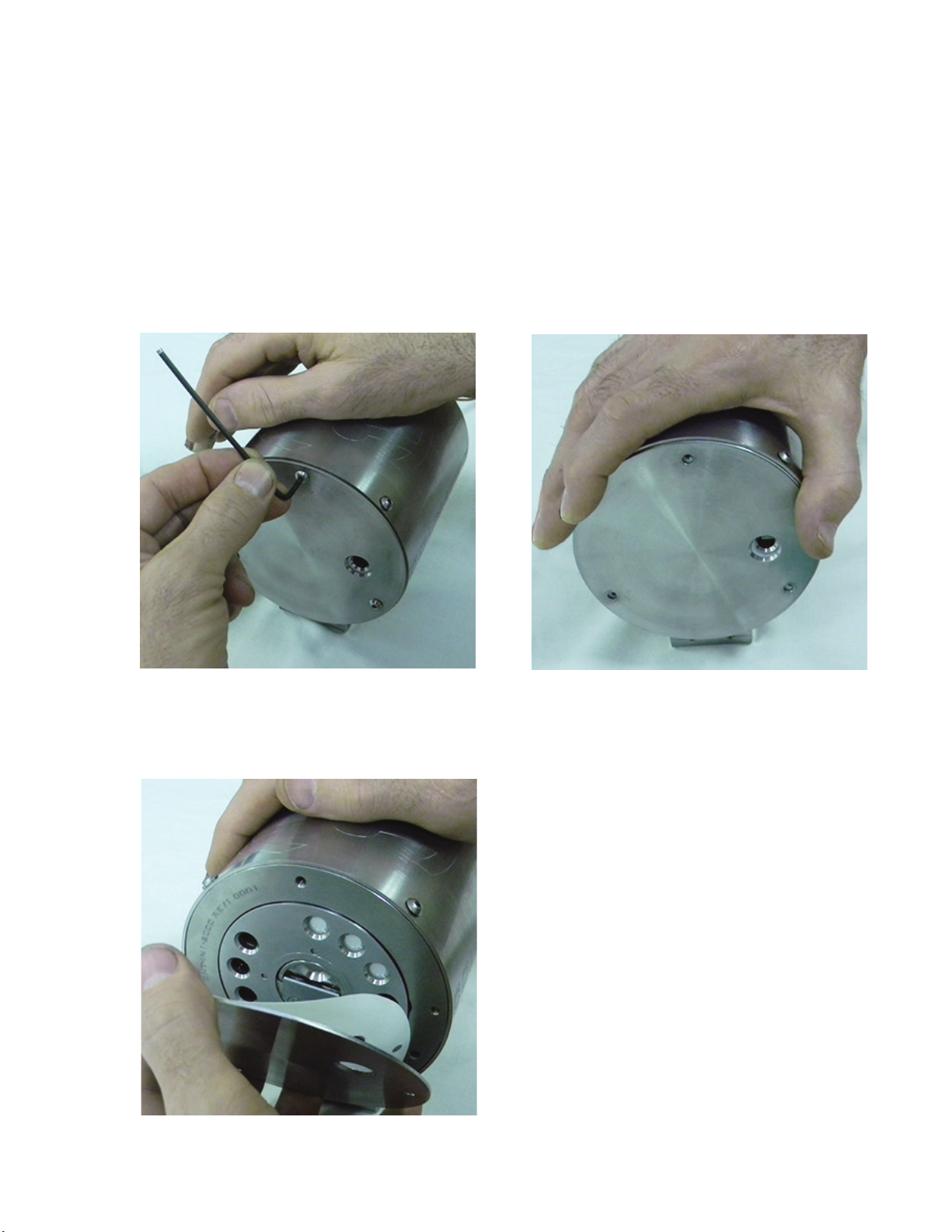

• Turn on the controller (power switch on the back panel). The red LED will light

up. The controller is programmed so that the step button does not function until

the Innity™ crystal carousel has been homed.

• Press the Home button (green) to start the homing function. When the crystal

carousel has nished homing, the green light on the control box will glow.

• Press the Step button (red) once to move from one crystal location to the next.

When the nal crystal location has been reached the step function must be

reset. Press Home button to reset the step function.

Controlling Innity™ from an external source operates on the same principles as

the Innity™ control box. When external control is used, the external control system

remotely operates the home and the step functions.