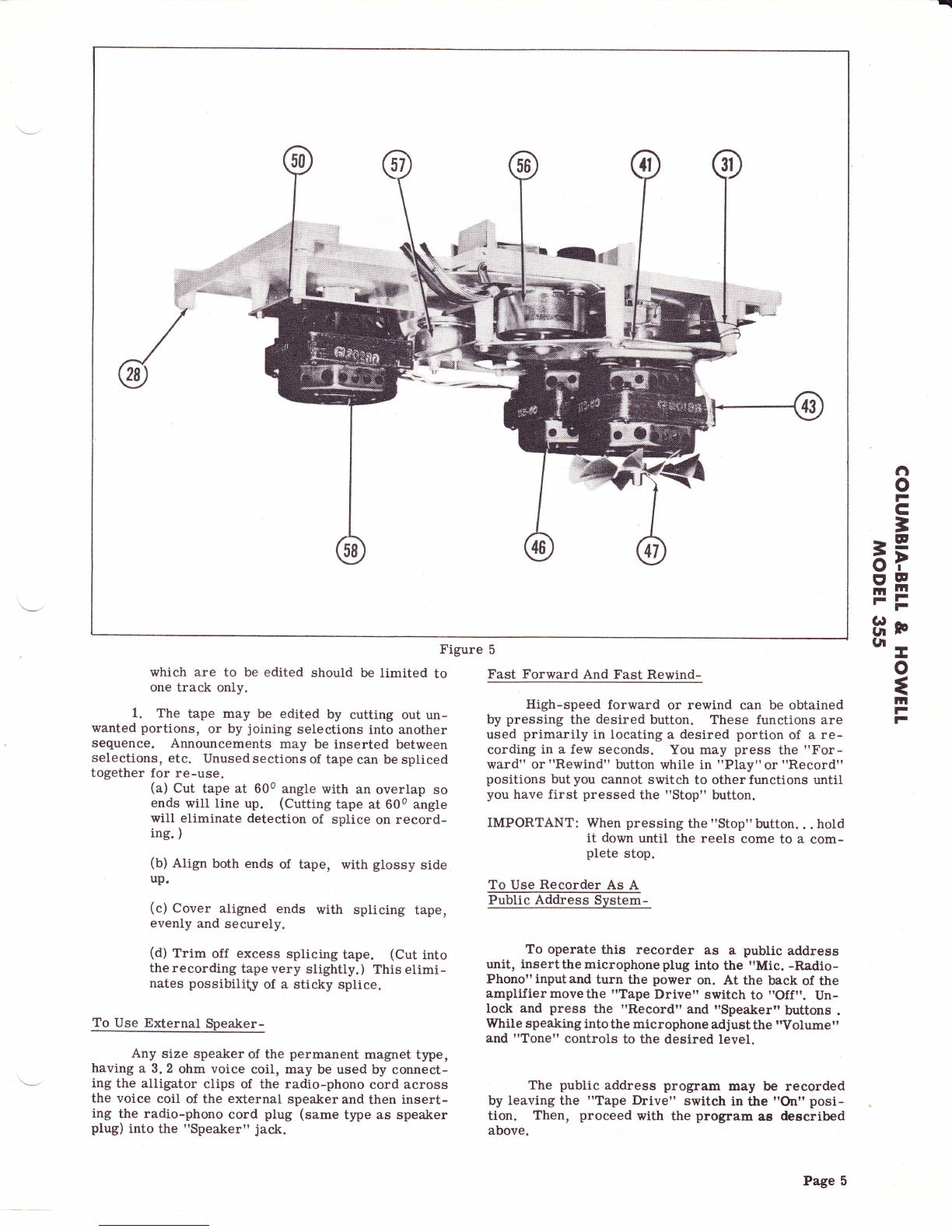

In Brakin

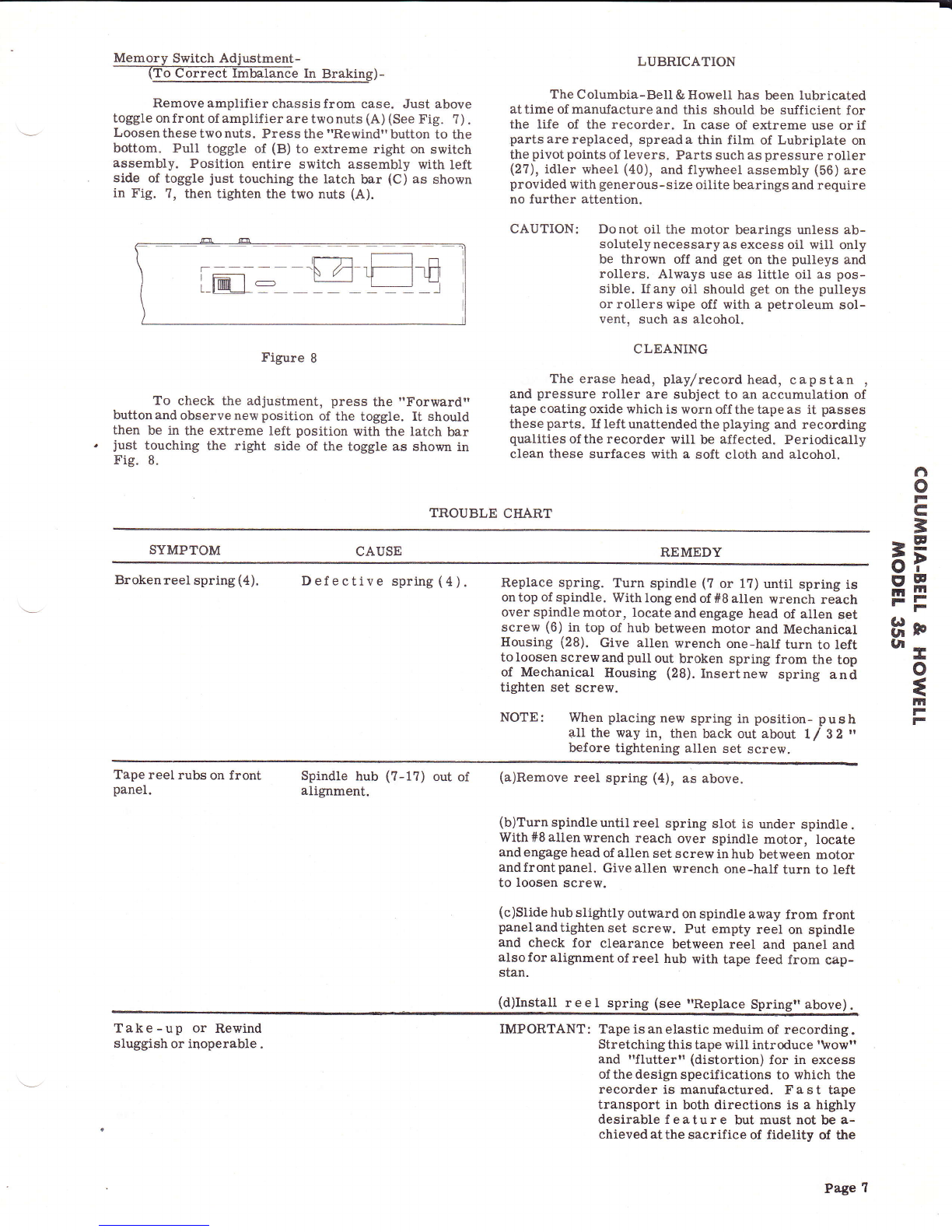

Remove amplifier chassis from case. Just above

toggle onfrontof amplifier are twonuts (A) (See Fig. ?).

Loosen these two nuts, Press the "Rewind" button to the

bottom. Pull toggle of (B) to extreme right on switch

assembly. Position entire switch assembly with left

side of toggle just touching the latch bar (C) as shown

in Fig. ?, then tighten the two nuts (A).

LUBRICATION

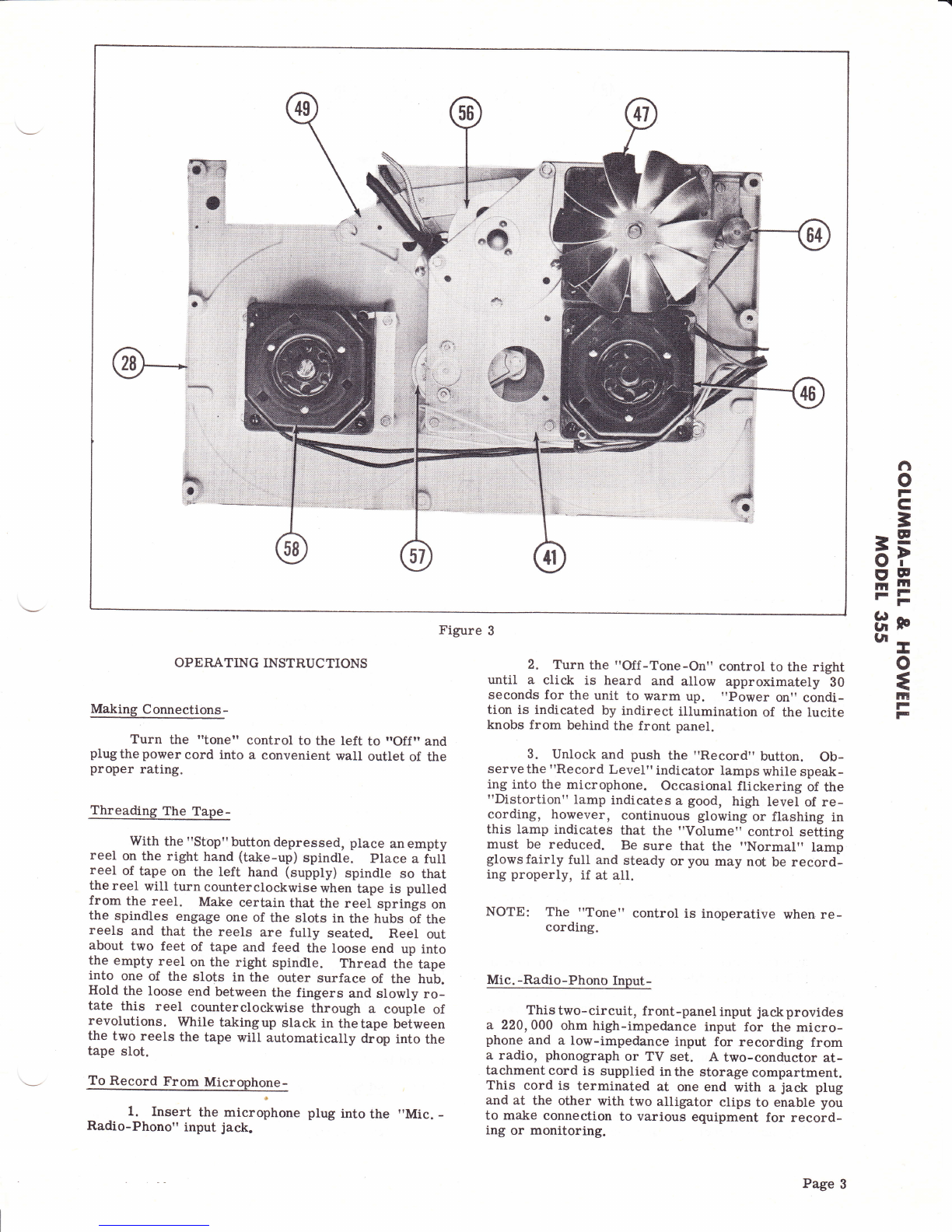

The C olumbia-Bell & Ilowell has been lubricated

attime of manufactureand this should be sufficient for

the life of the recorder. In case of extreme use orif

parts are replaced, spread a thin film of Lubriplate on

the pivotpoints of levers. Parts such as pressure roller

(2?), idler wheel (40), and flywheet assembly (56) are

provided with generous-size oilite bearings and require

no further attention.

CAUTION: Donot oil the motor bearings unless ab-

solutelynecessaryas excess oil will only

be thrown off and get on the pulleys and

rollers. Always use as little oil as pos-

sible. Ifany oil should get on the pulleys

or rollers wipe off with a petroleum sol-

vent, such as alcohol.

CLEANING

The erase head, play/record head, capstan ,

and pressure roller are subject to an accumulation of

tape coating oxide which is worn off the tape as it passes

these parts. If left unattended the playing and recording

qualities of the recorder will be affected. Periodically

clean these surfaces with a soft cloth and alcohol.

l-m= --M-E---'n

Figure g

To check the adjustment, press the "Forward"

buttonandobservenewposition of the toggle. It should

then be in tlre extreme left position with the latch bar

just touching the right side of the toggle as shown in

Fig. 8.

TROUBLE CHART

SYMPTOM CAUSE REMEDY

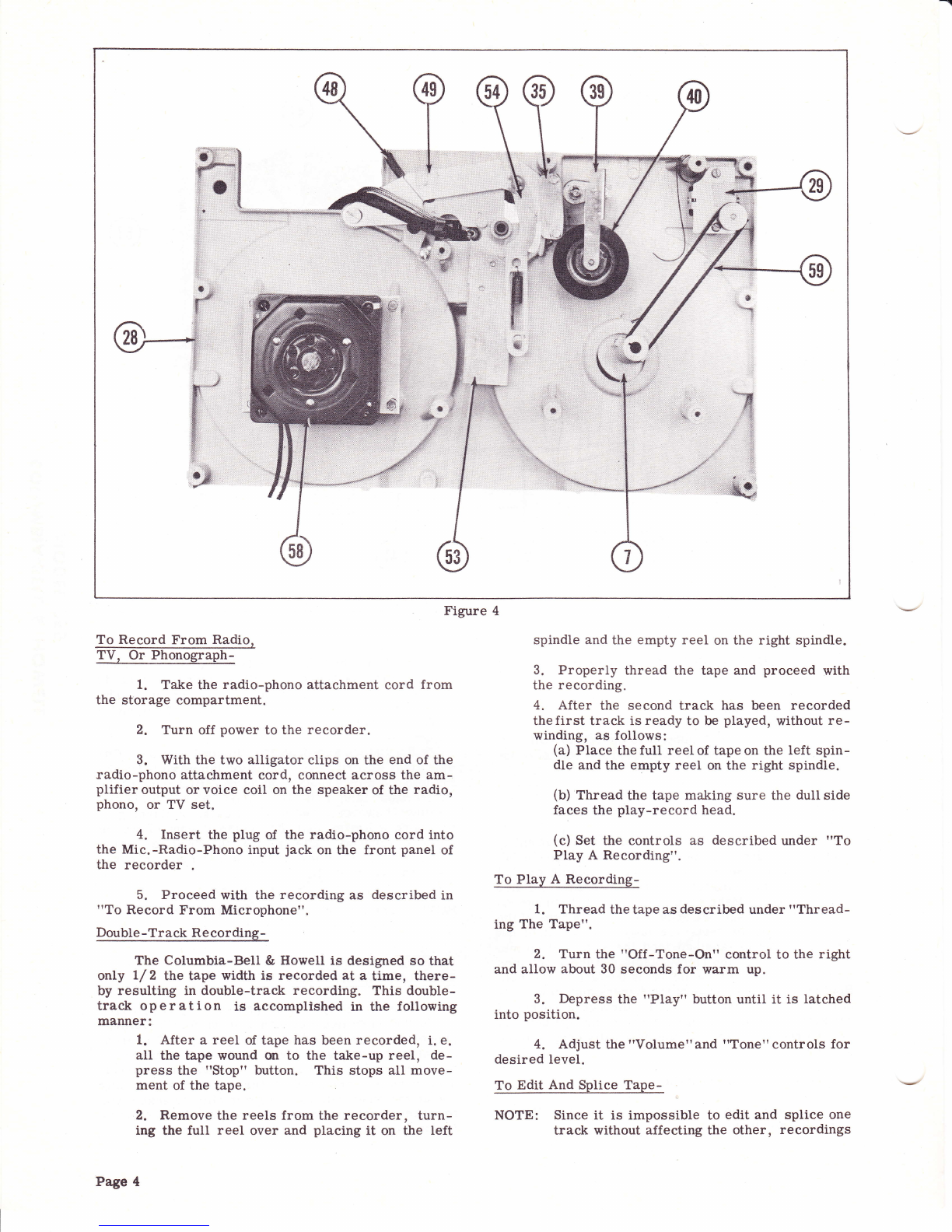

Brokenreel sprine (4). Defective spring (4). Replace spring. Turn spindle (7 or 17) until spring is

ontop of spindle. Withlongendof #8 allen wrench reach

over spindle motor, locate and engage head of allen set

screw (6) in top of hub between motor and Mechanical

Housing (28). Give allen wrench one-half turn to left

to loosen screw and pull out broken spring from the top

of Mechanical Housing (28). Insertnew spring and

tighten set screw.

NOTE: When placing new spring in position- push

all the way in, then back out about t / gZ "

before tightening allen set screw.

fl

o

F

c

=

EF

EE

8r

tEo

{

tn

F

F

Tape reel rubs on front Spindle hub (?-17) out of

panel. alignment. (a)Remove reel spring (4), as above.

(b)Turn spindle until reel spring slot is under spindle .

With#Sallenwrench reach over spindle motor, locate

and engage head of allen set screw in hub between motor

andfrontpanel, Giveatlen wrench one-half turn to Ieft

to loosen screw.

(c)Slide hub slightly outward on spindle away from front

panelandtightenset screw. Put empty reel on spindle

and check for clearance between reel and panel and

alsoforalignmentofreel hub with tape feed from cap-

stan.

(d)Install reel spring (see rReplace Springl above)

Take-up or Rewind

sluggish or inoperable .IMPORTANT : Tape is an elastic meduim of recording .

Stretching this tape will introduce '\vowrr

and "flutterr'(distortion) for in excess

of the design specifications to which the

recorder is manufactured. Fast tape

transport in both directions is a highly

desirable feature but must not be a-

chieved at the sacrifice of fidelity of t}e

Fage ?