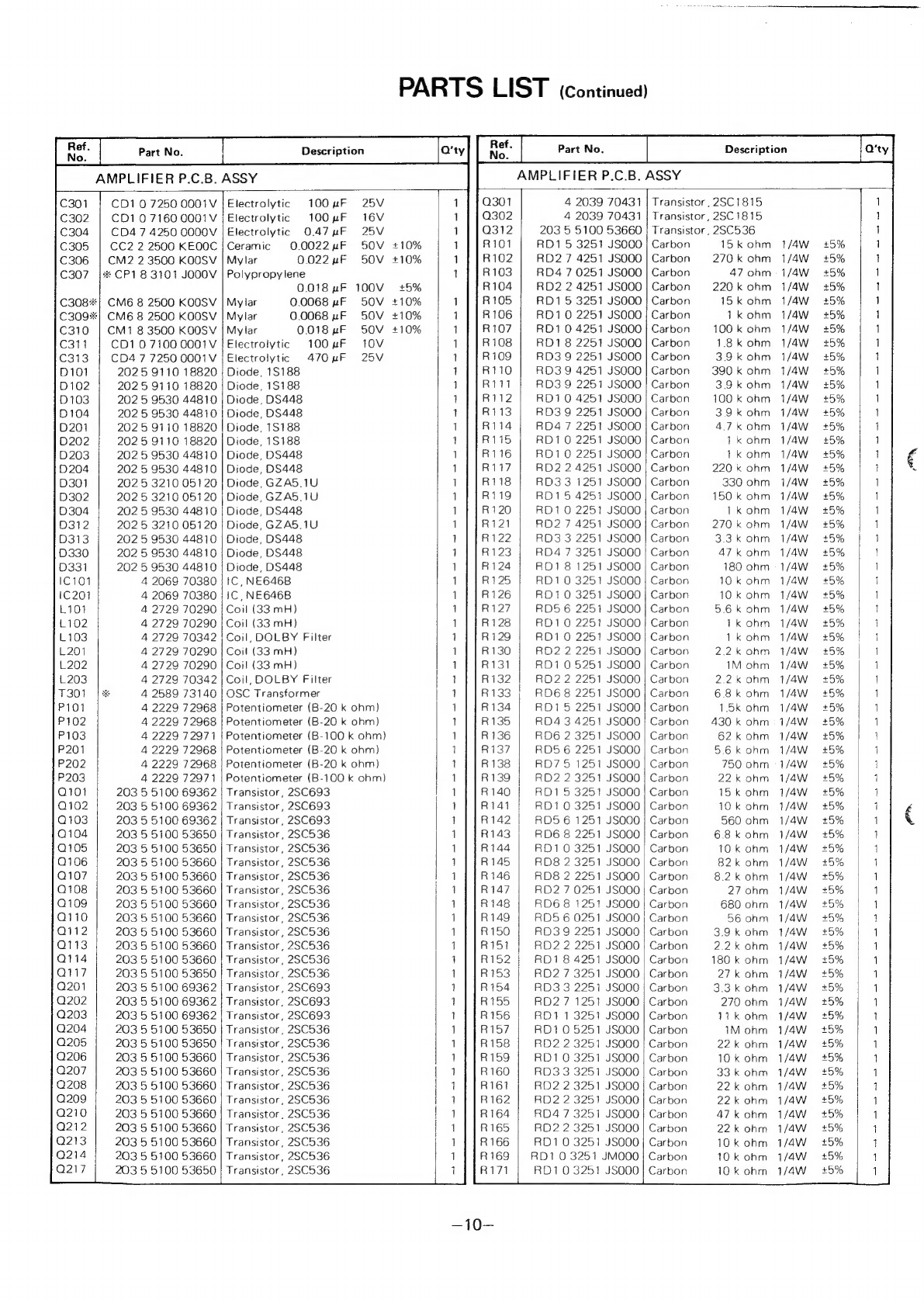

PARTS

LIST

(Continued)

Part

No.

Description

lany|

Rese

Part

No.

Description

AMPLIFIER

P.C.B.

ASSY

4

2039

70431

|

Transistor,

2SC1815

4

2039

70431

|

Transistor,

2SC

1815

203

5

5100

53660

|

Transistor,

2SC536

RD1

5

3251

JSOOO

;

Carbon

15k

ohm

1/4wW

RD2

7

4251

JSOOO

|

Carbon

270

k

ohm

1/4W

RD4

7

0251

JSOOO

|

Carbon

47

ohm

=

1/4W

RD2

2

4251

JSOOO

|

Carbon

220k

ohm

1/4W

RD1

5

3251

JSOOO

|

Carbon

15k

ohm

1/4W

RD1

0

2251

JSOOO

|

Carbon

1kohm

1/4W

RD1

0

4251

JSOOO

|

Carbon

100

k

ohm

=1/4W

D1

8

2251

JSOOO

|

Carbon

18k

ohm

1/4W

D3

9

2251

JSOOO

|

Carbon

39k

ohm

1/4w

D3

9

4251

JSOOO

|

Carbon

390

k

ohm

=

1/4W

D3

9

2251

JSOOO

|

Carbon

39k

ohm

1/4W

D1

0

4251

JSOOO

|

Carbon

100

k

ohm

1/4W

D3

9

2251

JSOOO

|

Carbon

39k

ohm

1/4W

D4

7

2251

JSOOO

|

Carbon

47k

ohm

1/4w

Di

GO

2251

JSOOO

|

Carbon

1k

ohm

1/4w

D1

0

2251

JSOOO

|

Carbon

1k

ohm

1/4w

D2

2

4251

JSOOO

|

Carbon

220

k

ohm

1/4W

D3

3

1251

JSOOO

|

Carbon

330

ohm

1/4W

D15

4251

JSOOO

}

Carbon

150k

ohm

1/4W

D1

0

2251

JSOOO

|

Carbon

1k

ohm

1/4W

D2

7

4251

JSOOO

|

Carbon

270

k

ohm

1/4W

D3

3

2251

JSOOO

|

Carbon

3.3k

ohm

1/4W

D4

7

3251

JSOOO

|

Carbon

47k

ohm

1/4W

01

8

1251

JSOOO

|

Carbon

180

ohm

=

1/4W

No.

AMPLIFIER

P.C.B.

ASSY

C301

CD107250

0001V

j

Electrolytic

100uF

25V

C302

CD10

7160

0001V

j

Electrolytic

100uF

16V

C304

CD47

4250

O000V

|

Electrolytic

O47

uF

25V

C305

|

CC22

2500

KEOOC|Ceramic

O0.0022uF

5OV

+10%

C306

|

CM2

2

3500

KOOSV

|

Mylar

O0.022uF

5O0V

+10%

C307

1%

CP18

3101

JOOOV

|

Polypropylene

0.018

uF

100V

+5%

C308%|

CM6

8

2500

KOOSV

|

Mylar

0.0068

pF

50V

+10%

C309%|

CM6

8

2500

KOOSV

|

Mylar

0.0068

uF

5OV

+10%

C310

|

CM1

83500

KOOSV

|

Mylar

0.018

uF

50V

+10%

C311

CD107100

0001V

|

Electrolytic

100uF

10V

C313

CD47

7250

0001V

|

Electrolytic

470uF

25V

D101

2025

9110

18820

|

Diode,

1$188

D102

2025

9110

18820

|

Diode,

18188

D103

202

5

9530

44810

|

Diode,

DS448

D104

202

5

9530

44810

|

Diode,

DS448

D201

202

5

9110

18820

|

Diode,

18188

D202

202

5

9110

18820

|

Diode,

18188

D203

202

5

9530

44810

|

Diode,

DS448

D204

202

5

9530

44810

|

Diode,

DS448

D301

202

5

3210

05120

|

Diode,

GZA5.1U

D302

202

5

3210

05120

|

Diode,

GZA5.1U

D304

202

5

9530

44810

|

Diode,

DS448

0312

202

5

3210

05120

}

Diode,

GZA5.1U

D313

202

5

9530

44810

|

Diode,

DS448

D330

202

5

9530

44810

|

Diode,

DS448

D331

202

5

9530

44810

|

Diode,

DS448

-=o

emo

oo

DOUDDDDIVIDVIVIUDDIAIIADANDIAIIAN

C101

4

2069

70380

|

IC,

NE646B

D1

0

3251

JSOOO

;

Carbon

10k

ohm

1/4W

1C201

4

2069

70380

;

IC,

NE646B

D1

0

3251

JSOOO

|

Carbon

10k

ohm

1/4W

L101

4

2729

70290

|

Coil

(33

mH)

D5

6

2251

JSOOO

|

Carbon

56k

ohm

1/4W

L102

4

2729

70290

|

Coil

(33

mH)

D1

0

2251

JSOOO

|

Carbon

Tk

ohm

1/4W

L103

4

2729

70342

|

Coil,

DOLBY

Filter

D1

0

2251

JSOOO

|

Carbon

Tk

ohm

1/4W

L201

4

2729

70290

|

Coil

(33

mH)

RD2

2

2251

JSOOO

|

Carbon

22k

ohm

1/4W

L202

4

2729

70290

|

Coil

(33

mH)

RD10

5251

JSOOO

|

Carbon

1M

ohm

1/4W

L203

4

2729

70342

|

Coil,

DOLBY

Filter

RO2

2

2251

JSOOO

|

Carbon

2.2k

ohm

1/4W

T301

1%

4

2589

73140

|

OSC

Transformer

RD6

8

2251

JSOOO

|

Carbon

68k

ohm

1/4W

P101

4

2229

72968

|

Potentiometer

(B-20

k

ohm)

RD1

5

2251

JSOOO

|

Carbon

1.5k

ohm

1/4W

P102

4

2229

72968

|

Potentiometer

(B-20

k

ohm)

D4

3

4251

JSOOO0

|

Carbon

430

k

ohm

=

1/4W

P103

4

2229

72971

|

Potentiometer

(B-100

k

ohm)

D6

2

3251

JSOOO

|

Carbon

62k

ohm

1/4W

P201

4

2229

72968

|

Potentiometer

(B-20

k

ohm)

D5

6

2251

JSOOO

|

Carbon

56k

ohm

1/4W

P202

4

2229

72968

|

Potentiometer

(B-20

k

ohm)

D7

5

1251

JSOOO

|

Carbon

750

ohm

=

1/4W

P203

4

2229

72971

|

Potentiometer

(B-100

k

ohm)

|

D2

2

3251

JSOO0

|

Carbon

22k

ohm

1/4W

D1

5

3251

JSOOO

|

Carbon

15k

ohm

1/4W

D1

0

3251

JSOO00

|

Carbon

10k

ohm

1/4W

D5

6

1251

JSOOO

|

Carbon

560

ohm

1/4W

D6

8

2251

JSOOO

|

Carbon

68k

ohm

1/4W

D1

0

3251

JSOOO

|

Carbon

10k

ohm

1/4W

D8

2

3251

JSOOO

|

Carbon

82k

ohm

1/4W

D8

2

2251

JSOOO

|

Carbon

8.2k

ohm

1/4W

D2

7

0251

JSOOO

|

Carbon

27

0hm

1/4W

D6

8

12571

JSOOO

|

Carbon

680

ohm

1/4W

D5

6

0251

JSOOO

|

Carbon

56

ohm

71/4W

D3

9

2251

JSOOO

|}

Carbon

3.9k

ohm

1/4W

D2

2

2251

JSOOO

}

Carbon

22kahm

1/4W

D1

8

4251

JSOO0O

|

Carbon

180k

ohm

1/4W

RD2

7

3251

JSOOO

|

Carbon

27k

ohm

1/4W

RD3

3

2251

JSOOO

|

Carbon

3.3k

ohm

1/4W

RD2

7

1251

JSOOO

|

Carbon

270

ohm

=

1/4W

RD1

1

3257

JSOOO

|

Carbon

11k

ohm

1/4W

RD?1

0

5251

JSOOO

|

Carbon

IM

ohm

1/4W

RD2

2

3251

JSOOO

|

Carbon

22k

ohm

1/4W

RD1

0

3251

JSOOO

|

Carbon

10k

ohm

1/4W

RD3

3

3251

JSOOO

|

Carbon

33k

ohm

1/4W

RD2

2

3251

JSOOO

|

Carbon

22k

ohm

1/4W

RD2

2

3251

JSOOO

|

Carbon

22k

ohm

1/4W

RD4

7

3251

JSOOO}

Carbon

47

k

ohm

1/4W

RD2

2

3251

JSOOO!

Carbon

22

k

ohm

RD1

0

3251

JSOOOj|

Carbon

10

k

ohm

RD1

0

32571

JMOOO/

Carbon

10k

ohm

1/4W

RD1

0

3251

JSOOO

|

Carbon

10

k

ohm

101

203

5

5100

69362

|

Transistor,

2SC693

Q102

203

5

5100

69362

|

Transistor,

2SC693

Q103

203

5

5100

69362

|

Transistor,

2SC693

Q104

203

5

5100

53650

|

Transistor,

2SC536

Q105

203

5

5100

53650

|

Transistor,

2SC536

Q106

203

5

5100

53660

|

Transistor,

2SC536

Q107

203

5

5100

53660

|

Transistor,

2SC536

|

Q108

203

5

5100

53660

|

Transistor,

2SC536

i

Q109

203

5

5100

53660

|

Transistor,

2SC536

Q110

203

5

5100

53660

|

Transistor,

2SC536

Q112

203

5

5100

53660

|

Transistor,

2SC536

Q113

203

5

5100

53660

|

Transistor,

2SC536

Q114

203

5

5100

53660

|

Transistor,

2SC536

Q117

203

5

5100

53650

|

Transistor,

2SC536

Q201

203

5

5100

69362

|

Transistor,

2SC693

Q202

203

5

5100

69362

|

Transistor,

2SC693

Q203

203

5

5100

69362

|

Transistor,

2SC693

Q204

203

5

5100

53650

|

Transistor,

2SC536

Q205

203

5

5100

53650

|

Transistor,

2SC536

Q206

203

5

5100

53660

|

Transistor,

2SC536

Q207

203

5

5100

53660

|

Transistor,

2SC536

{

Q208

203

5

5100

53660

|

Transistor,

2SC536

Q209

203

5

5100

53660

|

Transistor,

2SC536

|

i

i

if

DDDDDDVDDIDIVIAIIIIADIAND

Q210

203

5

5100

53660

|

Transistor,

2SC536

Q212

203

5

5100

53660

|

Transistor,

2SC536

Q213

203

5

5100

53660

|

Transistor,

2SC536

Q214

203

5

5100

53660

|

Transistor,

2SC536

Q217

203

5

5100

53650

|

Transistor,

2SC536

cb

es

pe

Nee

pk

as

ae

a

ey

le

Se

ea

ek,

a

a

eS,

a

ee

a

ee

ey

ee

ee

ea

a

702

ey