DANGER

Before starting the appliance, make

certain you do not detect the odor

of gas.

IF YOU SMELL GAS:

• Shut off the gas supply immediately.

• Do not attempt to light any appliance.

• Do not touch any electrical elements.

• Extinguish any open fl ame.

• Evacuate the area.

• Use a telephone outside the property

and immediately contact your gas

supplier.

• If unable to contact your gas supplier,

contact the fire department.

i

Delivery.......................................................................... 1

Unpacking ..................................................................... 1

Safety Procedures and Precautions.............................. 2

Installation

Installation Codes and Standards............................. 4

Ventilation Requirements ........................................... 4

Sound Pressure.......................................................... 4

Free Mechanical Start-Up.......................................... 4

Installation Duties and Responsibilities...................... 5

Pre-Installation Checklist ........................................... 7

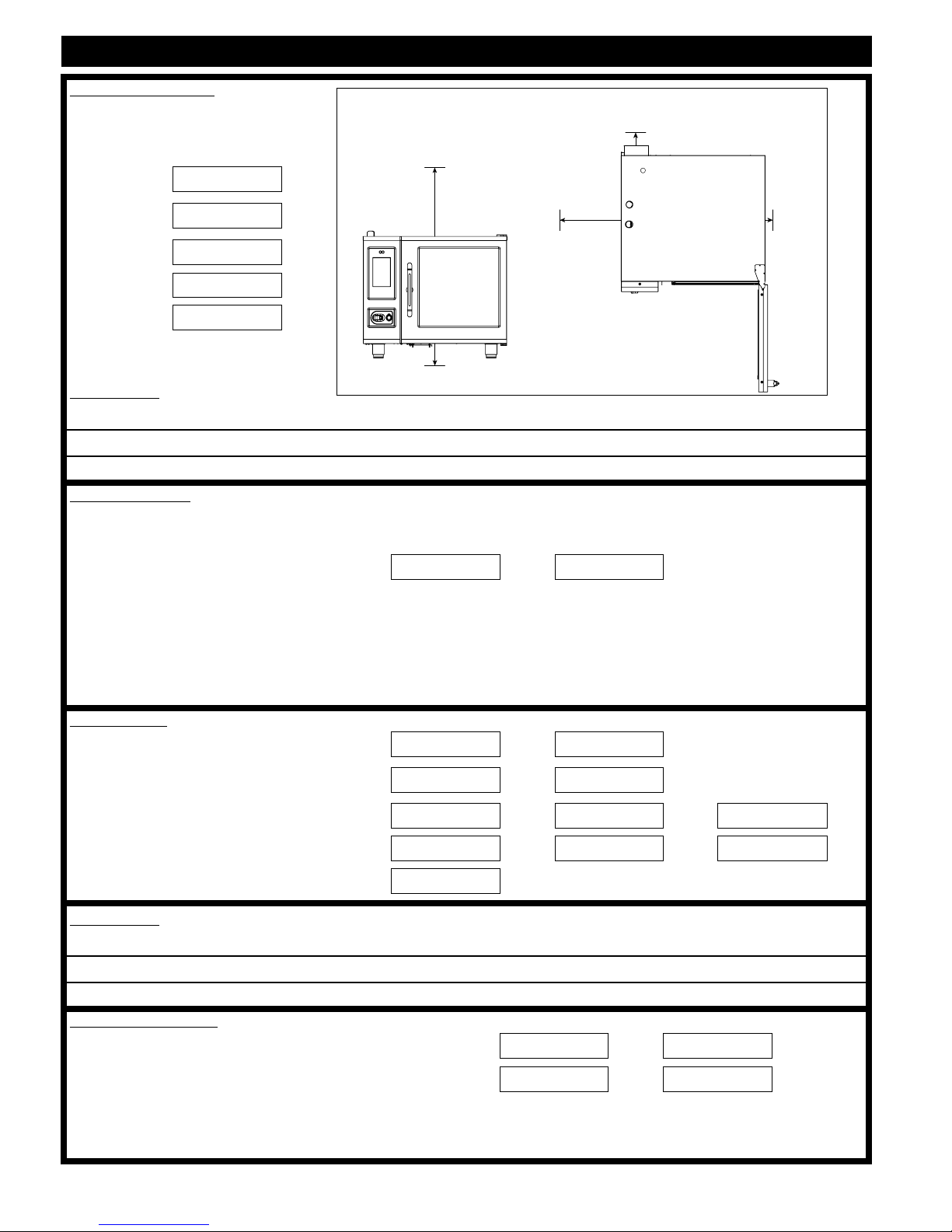

Specications, CTP6-10E........................................ 10

Specications, CTC6-10E........................................ 11

Specications, CTP6-10G........................................ 12

Specications, CTC6-10G....................................... 13

Specications, CTP10-10E...................................... 14

Specications, CTC10-10E...................................... 15

Specications, CTP10-10G...................................... 16

Specications, CTC10-10G..................................... 17

Specications, CTP7-20E........................................ 18

Specications, CTC7-20E........................................ 19

Specications, CTP7-20G........................................ 20

Specications, CTC7-20G....................................... 21

Specications, CTP10-20E...................................... 22

Specications, CTC10-20E...................................... 23

Specications, CTP10-20G...................................... 24

Specications, CTC10-20G..................................... 25

Specications, CTP20-10E...................................... 26

Specications, CTC20-10E...................................... 27

Specications, CTP20-10G...................................... 28

Specications, CTC20-10G..................................... 29

Specications, CTP20-20E...................................... 30

Specications, CTC20-20E...................................... 31

Specications, CTP20-20G...................................... 32

Specications, CTC20-20G..................................... 33

Lifting Instructions.................................................... 34

Clearance Requirements.......................................... 35

Positioning on Site, Countertop Models ................. 35

Stand Installation .................................................... 35

Positioning on Site, 20-10, 20-20 Models............... 36

Options and Accessories ........................................ 37

Electrical Safety Regulations ................................... 38

Electrical Connection for Gas Models ..................... 39

Electrical Connection for Electric Models ................ 40

Ventilation Requirements ......................................... 42

Gas Supply & Installation ......................................... 43

Gas Leak Testing...................................................... 47

Gas Exhaust............................................................. 47

Water Quality Requirements .................................... 48

Water Supply & Installation ...................................... 49

Water Drainage......................................................... 50

Mobile Equipment Restraint..................................... 52

Combihood PLUS™ Installation .............................. 53

Grease Collection Hook-up...................................... 55

Liquid Cleaning Hook-up ......................................... 56

CT PROformance Start-up Procedures ................... 57

CT PROformance Screen Calibration ...................... 57

CT Classic Start-up Procedures .............................. 59

Post-Installation Checklist ...................................... 60

Preventative Maintenance Checklist........................ 62

Error Codes ............................................................. 68

Service Parts ............................................................ 76

Warranty

Original Equipment Limited Warranty ...................... 77

Transportation Damage and Claims........................ 78

InstallatIon

table of contents

Please post the following instructions in a prominent

location in the event the user smells gas.